Waterproof thermal insulation coating

A technology of thermal insulation coating and expanded perlite, which is used in antifouling/underwater coatings, anticorrosive coatings, fireproof coatings, etc. The effect needs to be improved to achieve the effect of low brush thickness requirement, good stain resistance and good core-shell coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of modified expanded perlite is:

[0030] Add expanded perlite to water containing 2wt% sodium lauryl sulfate, then add dropwise 150g / L indium trichloride solution and 100g / L tin tetrachloride solution, stir evenly, add 30% urea, and ultrasonically disperse Then gradually raise the temperature to 85°C for precipitation, wash with water after the precipitation, then raise the temperature to 500°C at 20°C / h, keep it for 50 minutes, then raise the temperature to 1000°C at 100°C / h, keep it for 3 hours, and you can get the modified Expanded perlite.

[0031] Acrylic emulsion, calculated in parts by weight, includes the following raw materials:

[0032] 170 parts of hydroxymethyl methacrylate, 90 parts of styrene, 15 parts of ammonium acrylate, 80 parts of alkaline silica sol, 46 parts of isooctyl acrylate, 105 parts of α-ethylhexyl acrylate, 20 parts of hydroxyethyl acrylate, 430 parts of water, 2 parts of potassium persulfate, 3.4 parts of pH regula...

Embodiment 2

[0040] The preparation method of modified expanded perlite is:

[0041] Add expanded perlite to water containing 1wt% sodium stearate, then add dropwise 100g / L indium trichloride solution and 150g / L tin tetrachloride solution, stir evenly, add 30% urea, and gradually Raise the temperature to 65°C for precipitation, wash with water after the precipitation, then raise the temperature to 700°C at 30°C / h, keep it for 30 minutes, then raise the temperature to 900°C at 80°C / h, keep it for 5 hours, and you can get the modified expanded pearl rock.

[0042] Acrylic emulsion, calculated in parts by weight, includes the following raw materials:

[0043] 180 parts of hydroxymethyl methacrylate, 100 parts of styrene, 13 parts of ammonium acrylate, 95 parts of non-ionic silica sol, 40 parts of isooctyl acrylate, 110 parts of α-ethylhexyl acrylate, 25 parts of hydroxyethyl acrylate , 460 parts of water, 2.5 parts of ammonium persulfate, 4 parts of pH regulator and 6 parts of sodium dodecy...

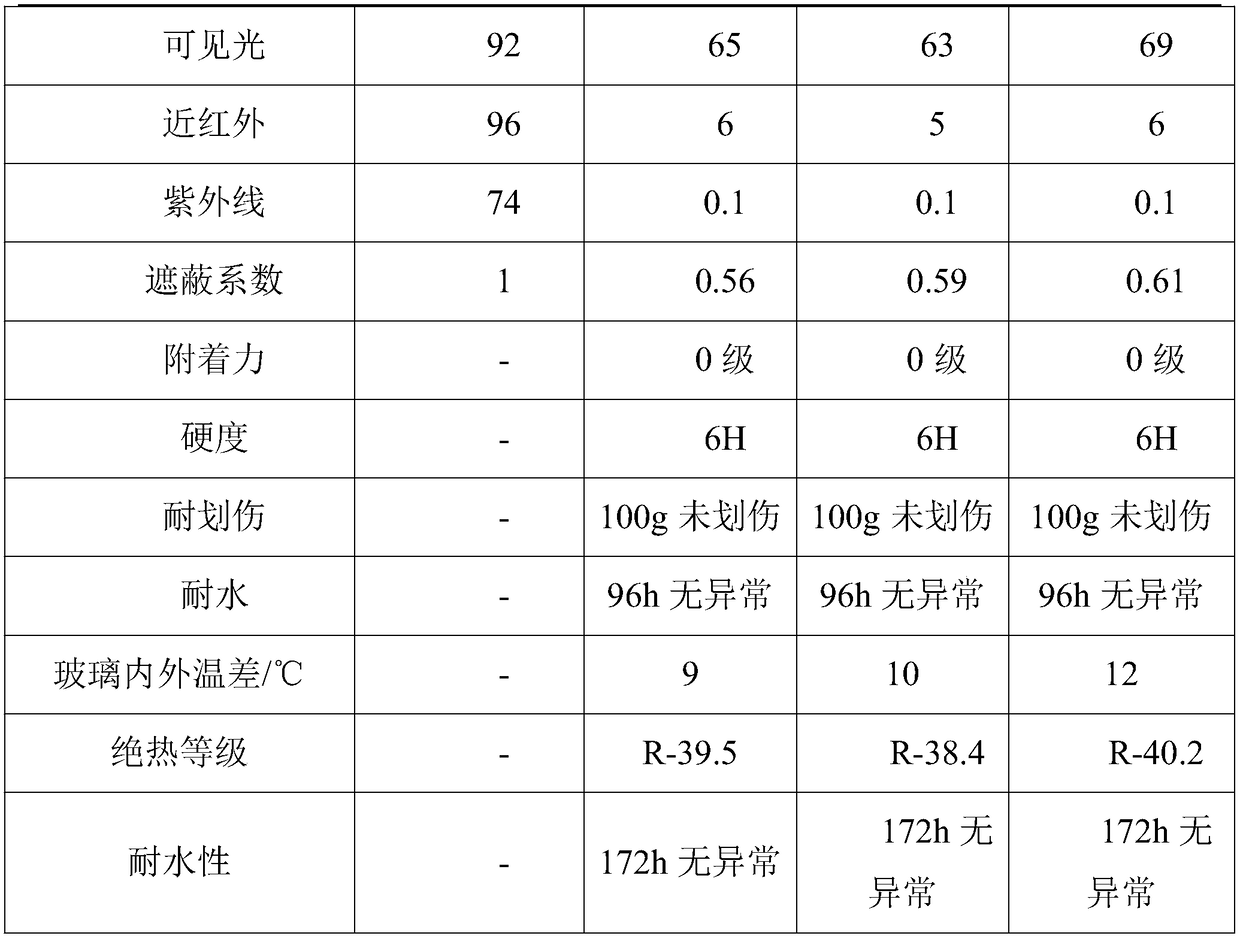

Embodiment 3

[0051] A waterproof and heat-insulating coating, calculated by weight percentage, comprising the following components:

[0052] 90 parts of alkyd resin, 50 parts of acrylic emulsion of Example 1, 26 parts of modified expanded perlite of Example 1, 10 parts of polyacrylic acid sodium salt, 6 parts of wetting agent, 12 parts of diethylenetriamine, thickener 6 parts and 20 parts of water. The thickener is a mixture of diatomaceous earth, sodium bentonite and microcrystalline cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com