Novel indoor decoration coating material and preparation method thereof

A technology for interior decoration and coatings, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of solvent-based fluorocarbon coating application limitations, achieve good storage stability, and improve anti-aging and chemical resistance, the effect of lowering the film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

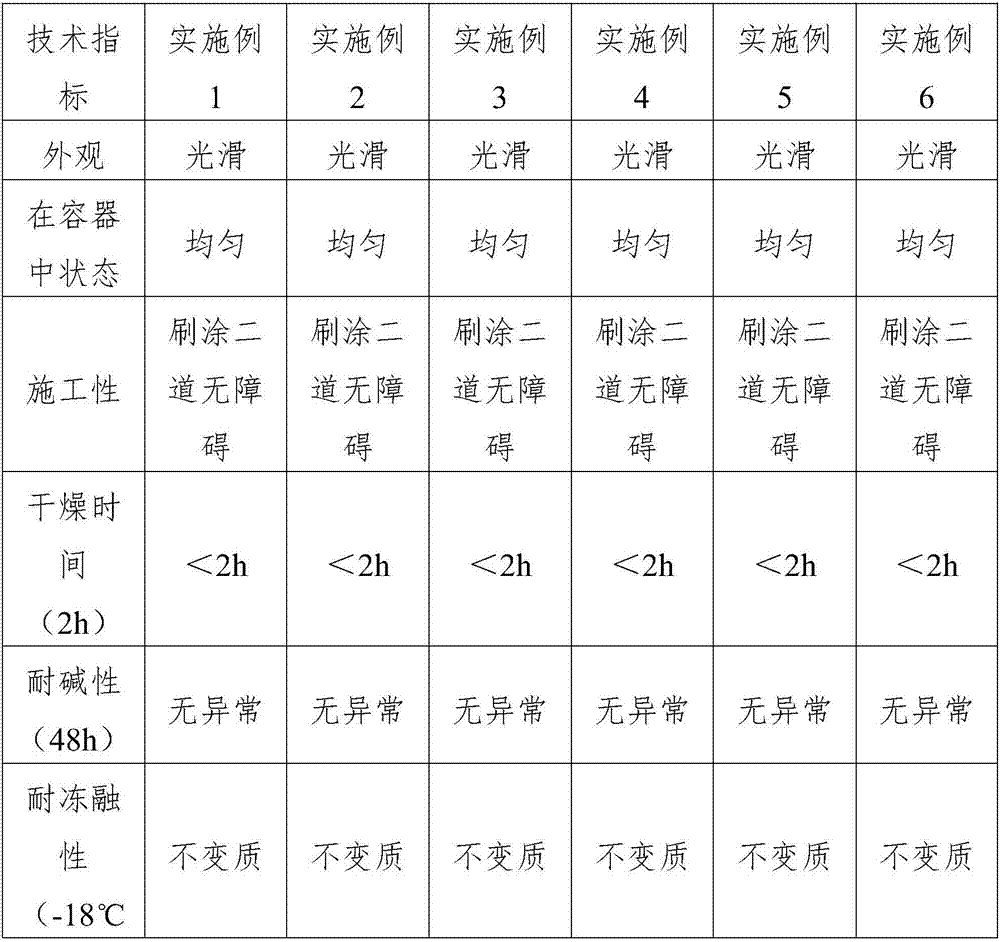

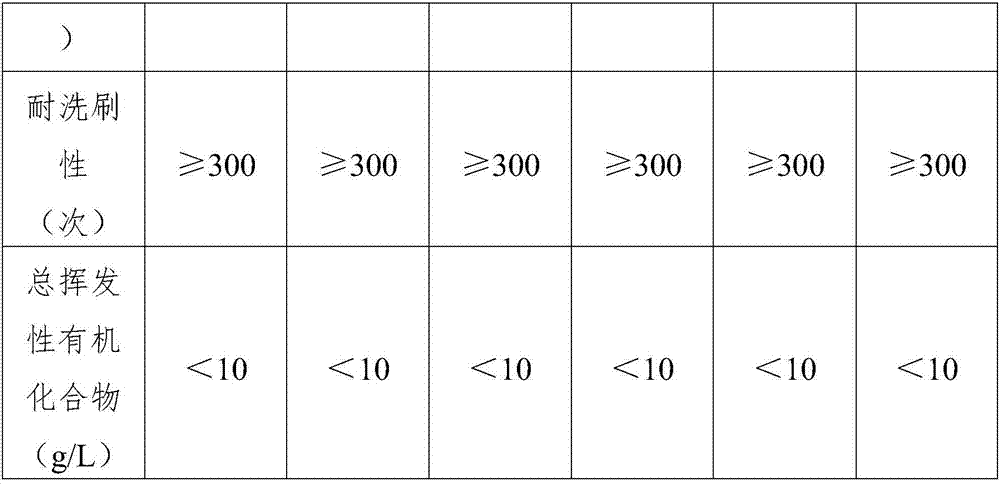

Examples

Embodiment 1

[0024] A new type of interior decoration paint, made of the following raw materials in parts by weight: 60 parts of water-based fluorocarbon emulsion, 7 parts of borax, 8 parts of water, 0.3 parts of organosiloxane, 1.5 parts of alcohol ester twelve, 0.5 parts of polyacrylamide 0.2 parts of nano-zinc oxide, 10 parts of nano-silica, 6 parts of water-based silicone oil, 7 parts of polyoxyethylene rosin acid, 3 parts of epoxy acrylate, 1.5 parts of polyether-modified polydimethylsiloxane copolymer parts, 0.6 parts of fluorocarbon modified polyacrylate.

[0025] The preparation method of above-mentioned novel interior decoration paint, comprises the following steps:

[0026] (1) First put the water-based fluorocarbon emulsion, borax and water into the sand mill according to the formula and stir at high speed for 10 minutes;

[0027] (2) Take the polyether-modified polydimethylsiloxane copolymer, organosiloxane and half of the formula amount of alcohol ester twelve by weighing aga...

Embodiment 2

[0032] A new type of interior decoration paint, made from the following raw materials in parts by weight: 70 parts of water-based fluorocarbon emulsion, 5 parts of borax, 8 parts of water, 0.4 part of organosiloxane, 1 part of alcohol ester twelve, and 1 part of polyacrylamide 0.5 parts of nano-zinc oxide, 11 parts of nano-silica, 4.5 parts of water-based silicone oil, 5 parts of polyoxyethylene rosin acid, 6.5 parts of epoxy acrylate, polyether modified polydimethylsiloxane copolymer 2 part, 0.5 part of polyether siloxane copolymer.

[0033] The preparation method of above-mentioned novel interior decoration paint, comprises the following steps:

[0034] (1) First put the water-based fluorocarbon emulsion, borax and water into the sand mill according to the formula and stir at high speed for 15 minutes;

[0035] (2) Add polyether-modified polydimethylsiloxane copolymer, organosiloxane, and half of the formula amount to a sand mill and grind for 3 hours;

[0036] (3) Stir at...

Embodiment 3

[0040] A new type of interior decoration paint, made of the following raw materials in parts by weight: 65 parts of water-based fluorocarbon emulsion, 4 parts of borax, 8 parts of water, 0.4 parts of organosiloxane, 2 parts of alcohol ester twelve, and 1 part of polyacrylamide 0.4 parts of nano-zinc oxide, 10 parts of nano-silica, 7.5 parts of water-based silicone oil, 5 parts of polyoxyethylene rosin acid, 6.5 parts of epoxy acrylate, polyether modified polydimethylsiloxane copolymer 2 parts, 0.7 parts of fluorocarbon modified polyacrylate.

[0041] The preparation method of above-mentioned novel interior decoration paint, comprises the following steps:

[0042] (1) First put the water-based fluorocarbon emulsion, borax and water into the sand mill according to the formula and stir at high speed for 20 minutes;

[0043] (2) Add polyether-modified polydimethylsiloxane copolymer, organosiloxane, and half of the formula amount to a sand mill and grind for 2 hours;

[0044] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com