Heat measuring type micro flow sensor

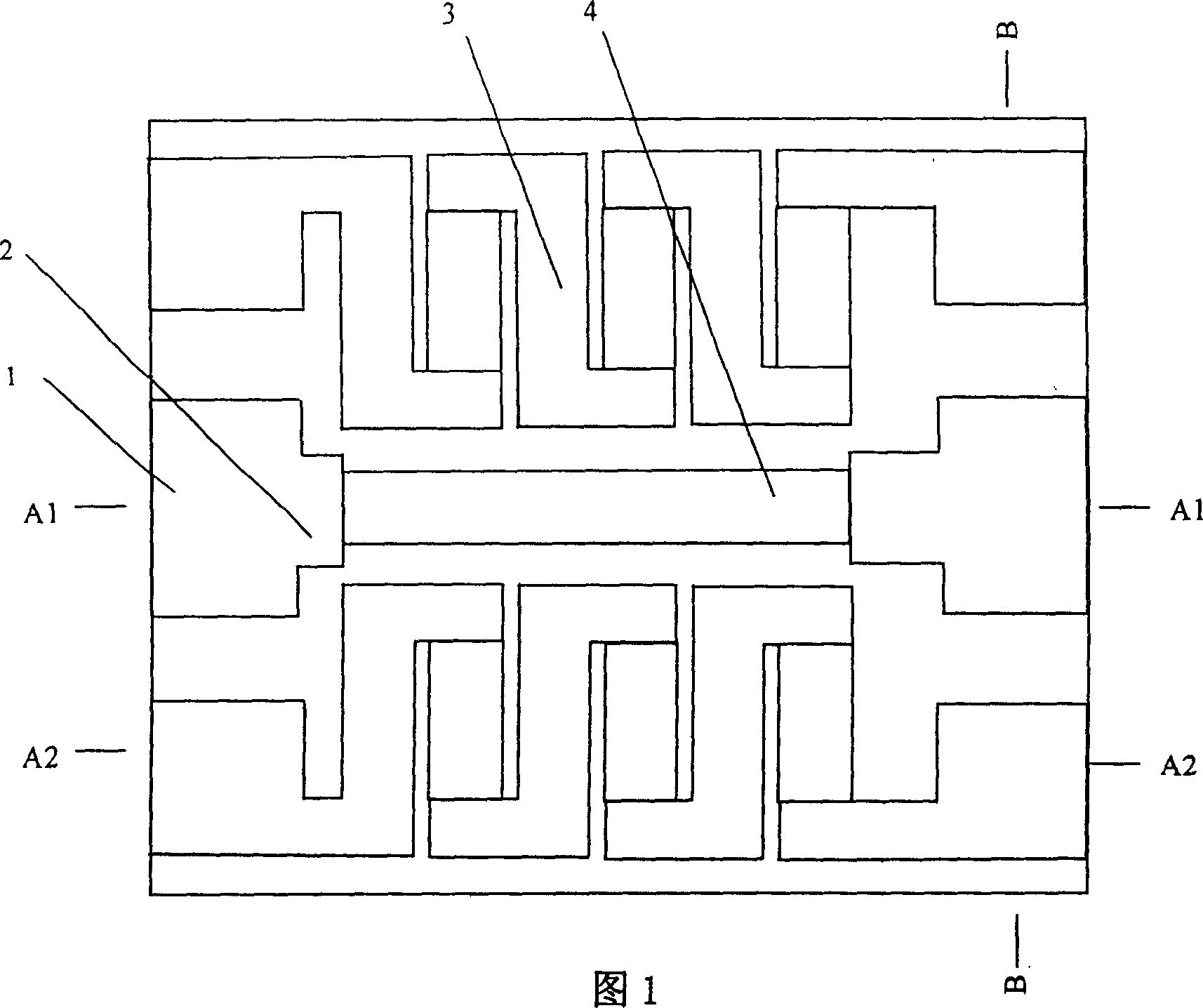

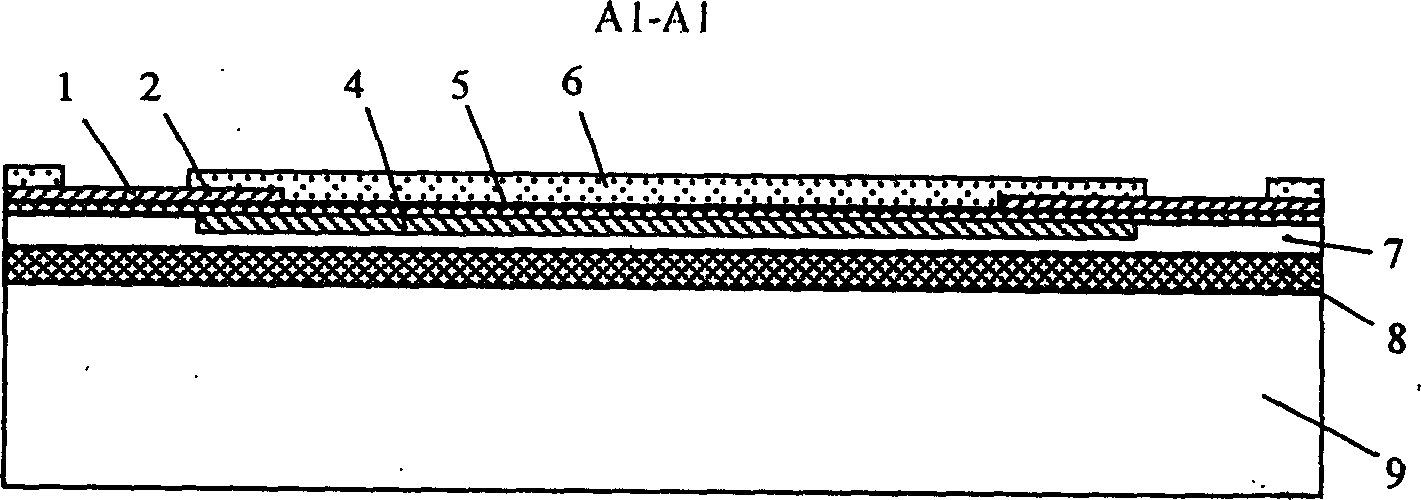

A flow sensor and miniature technology, used in the measurement of flow/mass flow, measurement device, liquid/fluid solid measurement, etc., can solve the problems of expanding the application range, reducing the strength of the sensor and the ability to resist pressure and impact, and achieve enhanced The effect of anti-corrosion and anti-wear ability, increasing the scope of use and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

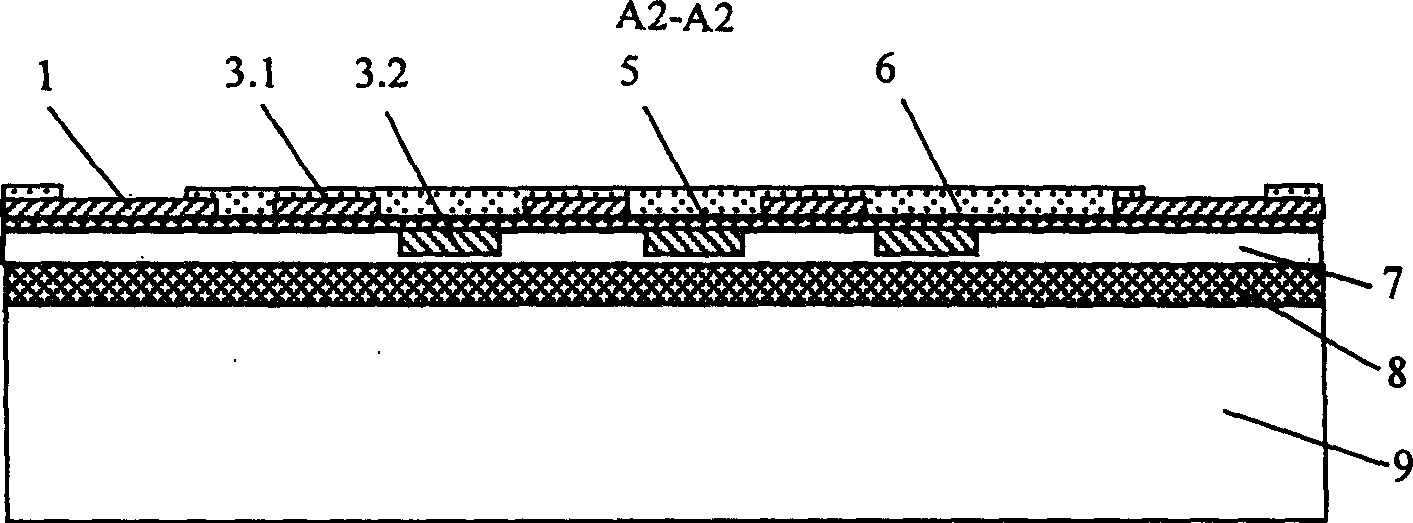

[0044] For Example 3, the substrate is replaced by the silicon dioxide heat insulating film 8 in Example 1 with a single crystal silicon substrate 9 containing silica gel filler 10 to achieve heat insulation effect. In this structure, the monocrystalline silicon substrate 9 forms a film structure above the silica gel filler 10, and this film structure belongs to the monocrystalline silicon substrate, but when the sensor is working, it plays a role similar to that of the monocrystalline silicon film in embodiment 1. Same insulation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com