Vacuum heat insulation heat fluid energy-saving running pipeline

A technology for vacuum heat insulation and transportation pipelines, which is applied in the direction of heat insulation protection pipelines, heat preservation, pipeline protection, etc. It can solve the problems of high heat loss rate, large amount of heat loss, low heat utilization rate, etc., and achieve the goal of reducing operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

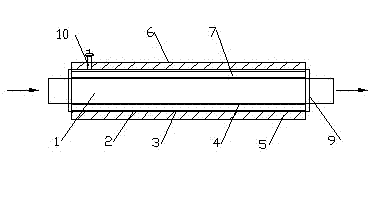

[0013] refer to figure 1 , an energy-saving conveying pipeline for vacuum heat-insulating thermal fluid, comprising an inner fluid pipe and an outer casing steel pipe, wherein the inner fluid pipe 1 is set in an outer outer steel pipe 2 . The specific package method is as follows: on the outer wall of the inner fluid pipe 1, a perforated circular plate with an inner diameter and an outer diameter respectively matched with the outer diameter of the inner fluid pipe 1 and the inner diameter of the outer jacket steel pipe 2 is installed, and at the same time, a certain length of the inner fluid pipe The heads of both ends of the outer jacket steel pipe 2 are to be welded and sealed, that is, the two ends of the outer jacket steel pipe 2 are welded and sealed by the head plate 9 so that a vacuum insulation layer 7 is formed between the two pipes, so that the outer jacket steel pipe 2 and the outer jacket steel pipe 2 are welded and sealed. The inner fluid pipe 1 is made as a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com