Light dimming film and manufacturing method thereof

A technology of light-adjustable film and conductive film layer, which is applied in the field of light-adjustable film and its preparation, which can solve the problems of high energy consumption, non-energy saving, and potential safety hazards, and achieve the effects of reducing energy consumption, convenient use, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

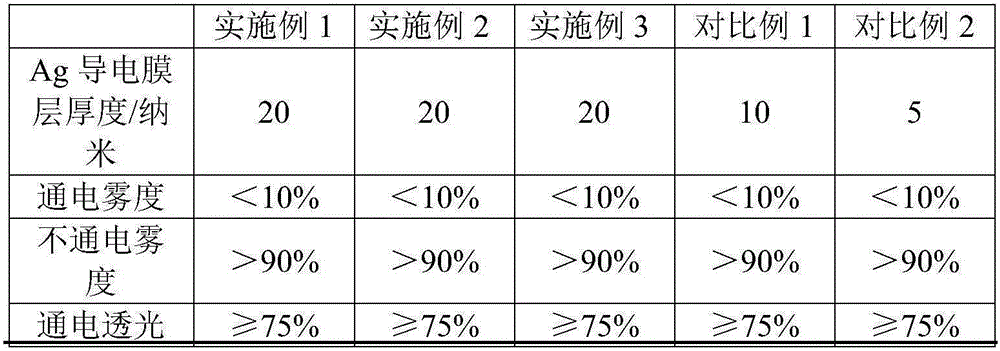

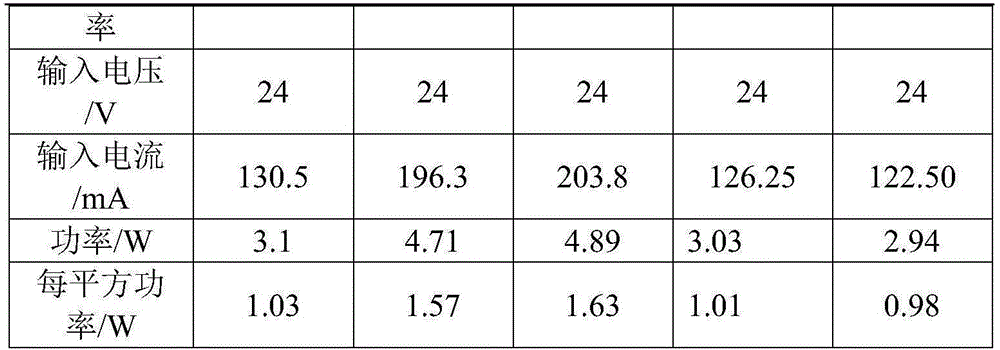

Embodiment 1

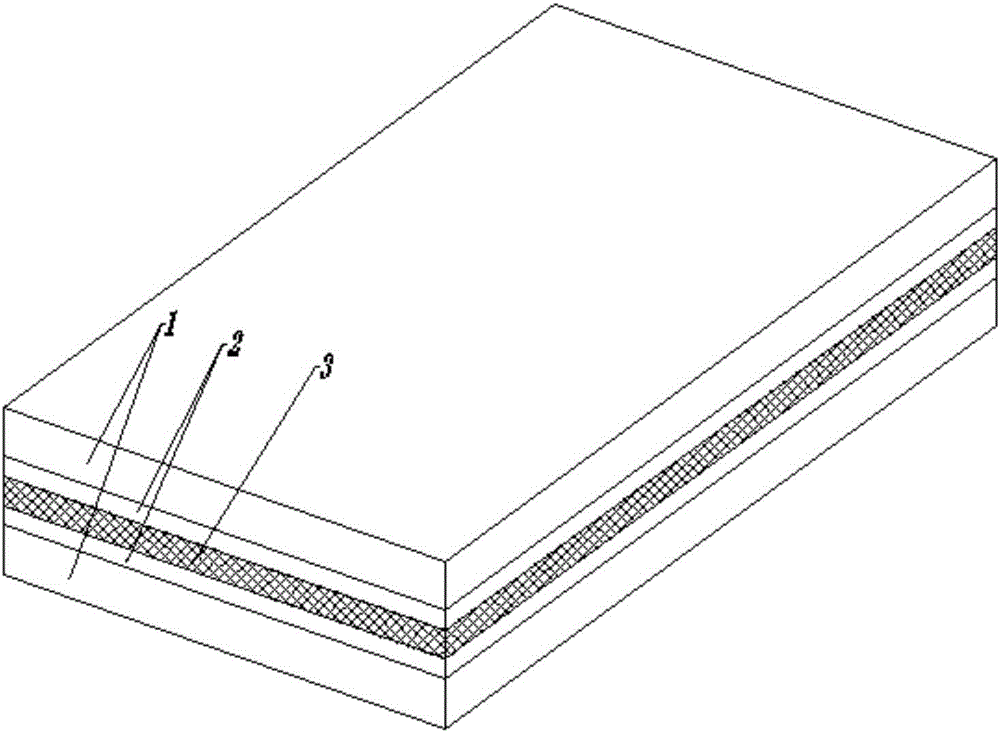

[0066] refer to figure 1 As shown, it is a schematic structural diagram of the light-adjusting film of the present invention. The dimming film of the present invention comprises a first PET layer, a second PET layer, a first Ag conductive layer, a second Ag conductive layer and a polymer dispersed liquid crystal layer. Wherein, the upper surface of the polymer dispersed liquid crystal layer is provided with a first Ag conductive layer, and the lower surface is provided with a second Ag conductive layer; the upper surface of the first Ag conductive layer is provided with a first PET layer, and the lower surface of the second Ag conductive layer is provided with a second PET layer. .

[0067] The thickness of the first Ag conductive layer and the second Ag conductive layer is 20 nanometers, is a transparent silver film, the thickness of the first PET layer and the second PET layer is 50 microns, and the polymer dispersed liquid crystal layer is 20 microns;

[0068] The prepara...

Embodiment 2

[0075] The thickness of the first Ag conductive layer and the second Ag conductive layer is 20 nanometers, is a transparent silver film, the thickness of the first PET layer and the second PET layer is 50 microns, and the polymer dispersed liquid crystal layer is 20 microns;

[0076] The preparation method of the above-mentioned dimming film:

[0077] The polymer dispersed liquid crystal layer formula is calculated by weight: polyurethane acrylic resin, 25 parts; 1,6-hexanediol diacrylate, 35 parts; fluorine-containing surfactant, 1 part; biphenylcyanide liquid crystal, 40 parts ; Photoinitiator 184, 0.5 parts.

[0078] 1) The first PET layer and the first Ag conductive layer are combined to form the first conductive film layer, and the second PET layer and the second Ag conductive layer are combined to form the second conductive film layer;

[0079] 2) Mix the polymer, liquid crystal, auxiliary agent and photoinitiator according to the above formula ratio, and stir evenly to...

Embodiment 3

[0083] The thickness of the first Ag conductive film layer and the second Ag conductive film layer is 20 nanometers, is a transparent silver film, the thickness of the first PET layer and the second PET layer is 50 microns, and the polymer dispersed liquid crystal layer is 20 microns;

[0084] The preparation method of the above-mentioned dimming film:

[0085] The polymer dispersed liquid crystal layer formula is calculated by weight: polyurethane acrylic resin, 35 parts; 1,6-hexanediol diacrylate, 25 parts; fluorine-containing surfactant, 1 part; biphenylcyanide liquid crystal, 50 parts ; Photoinitiator 184, 0.5 parts.

[0086] 1) The first PET layer and the first Ag conductive film are laminated together to form the first conductive film layer, and the second PET layer and the second Ag conductive film are laminated together to form the second conductive film layer;

[0087] 2) Mix the polymer, liquid crystal, auxiliary agent and photoinitiator according to the above formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com