Disc-shaped suspension type composite insulator and manufacturing method thereof

A technology of composite insulators and manufacturing methods, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of glass core self-explosion, comprehensive price rise, and low production efficiency, and achieve high yield, light weight, and guaranteed The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

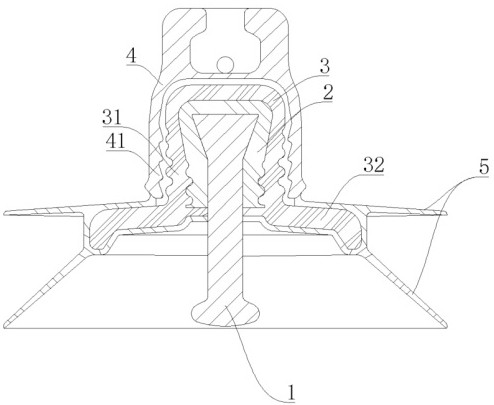

[0030] refer to figure 1 , a disk-shaped suspension composite insulator, including a steel foot 1, the outer side of the upper part of the steel foot 1 is provided with a cylindrical head 2, a core disk 3 and an iron cap 4 in sequence, the cylindrical head 2 and the core disk 3 are of an integrated structure, and the core The outer wall of the disk 3 is provided with a tooth-shaped connection part 1, and the position of the inner wall of the iron cap 4 relative to the tooth-shaped connection part 1 31 is provided with a tooth-shaped connection part 2 41 which meshes with each other. The lower end of the core disk 3 is provided with an extension part 32. The part 32 is wrapped with an umbrella skirt 5, the cylindrical head 2 and the core disk 3 are profiles made of composite materials, and the umbrella skirt 5 is a profile made of silicone rubber.

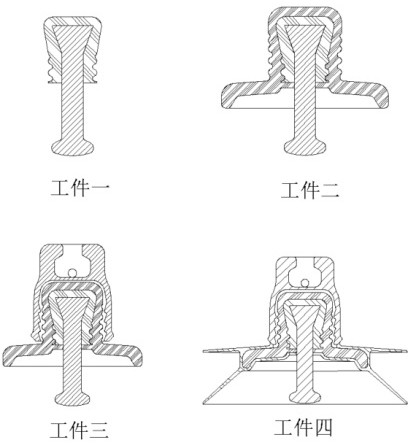

[0031] refer to image 3 , a method of manufacturing the above-mentioned disk-shaped suspension composite insulator, comprising t...

Embodiment 2

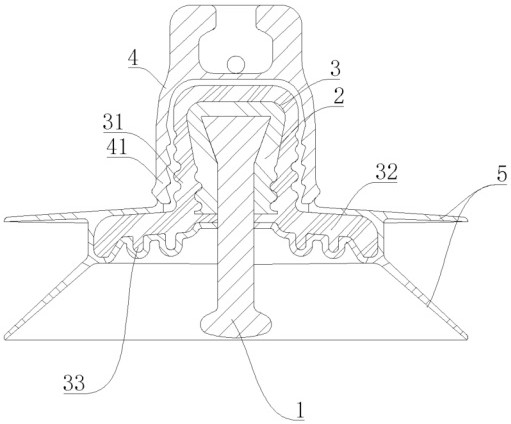

[0040] refer to figure 2 , a disk-shaped suspension composite insulator, including a steel foot 1, the outer side of the upper part of the steel foot 1 is provided with a cylindrical head 2, a core disk 3 and an iron cap 4 in sequence, the cylindrical head 2 and the core disk 3 are of an integrated structure, and the core The outer wall of the disk 3 is provided with a tooth-shaped connection part 1, and the position of the inner wall of the iron cap 4 relative to the tooth-shaped connection part 1 31 is provided with a tooth-shaped connection part 2 41 which meshes with each other. The lower end of the core disk 3 is provided with an extension part 32. The lower end of the part 32 is provided with four teeth 33, the extension part 32 is wrapped with an umbrella skirt 5, the cylindrical head 2 and the core plate 3 are profiles made of composite materials, and the umbrella skirt 5 is a profile made of silicone rubber.

[0041] A method for manufacturing the above-mentioned dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com