Fireproof hollow glass, manufacturing method and application

A fireproof glass and glass technology, applied in fire doors, parallel glass structures, window glass installations, etc., can solve the problems of melting loss, no fire protection requirements, glass falling off, etc. Mechanization, the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

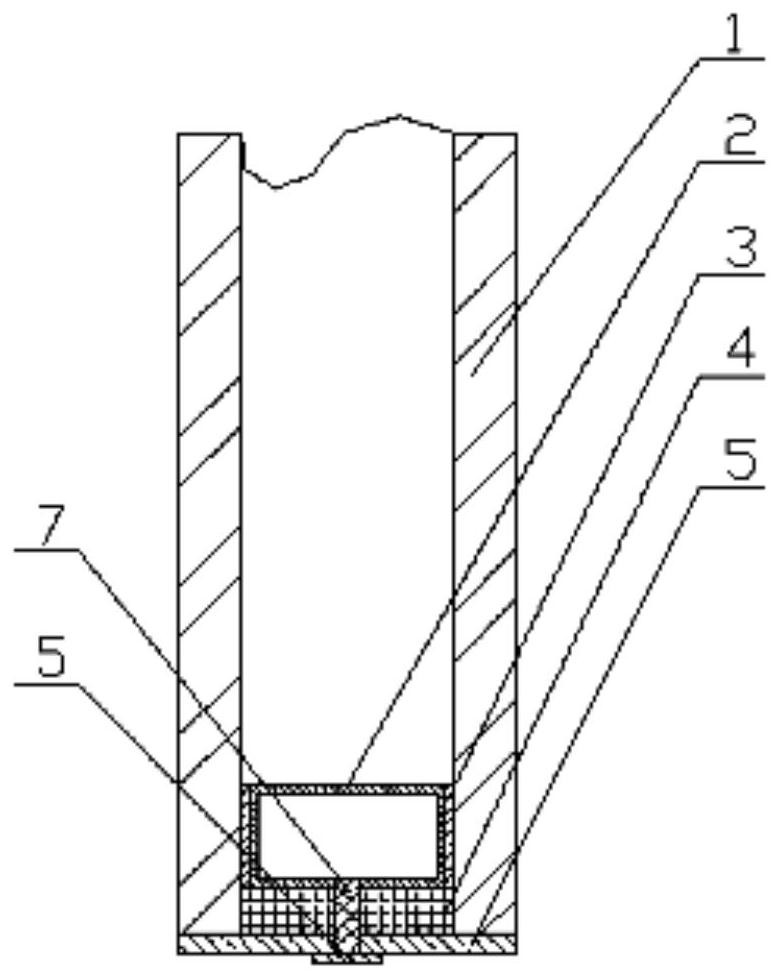

[0094] Such as figure 1 and Figure 10 , a kind of fireproof insulating glass, comprising glass 1, spacer bar 2, first seal 3, second seal 4, third seal 5, fourth seal 6 and pressure relief valve 7; cut two according to the size of the hollow glass made A piece of glass 1 of the same size is ground and cleaned; when tempered glass is needed, it is tempered in a tempering furnace; and one of the glass 1 is processed into a single piece by super-strong physical tempering process or spraying cesium potassium solution during tempering Fire-resistant glass, or other types of fire-resistant glass; spacer 2 adopts metal or composite metal spacer, preferably metal composite warm edge strip, according to the size and shape of glass 1 and the thickness of the structural glue used in the second seal 4 according to Figure 10 The length of each spacer 2 is determined by the placement method, the rectangular insulating glass uses 4 spacer 2, and the special-shaped insulating glass determi...

Embodiment 2

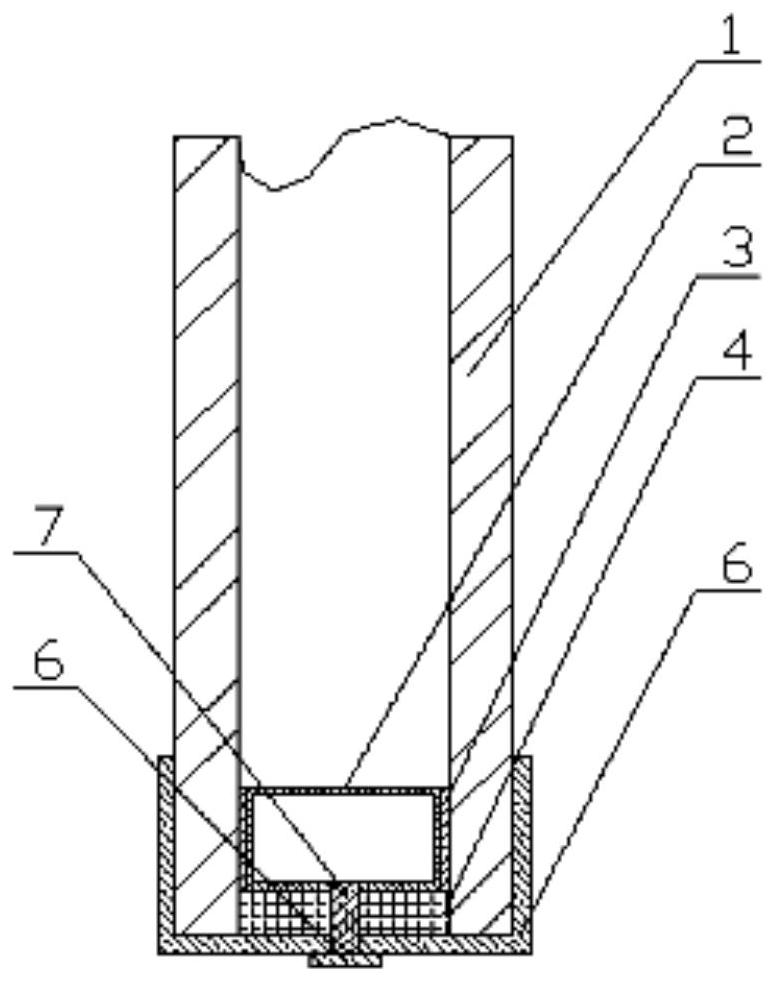

[0096] Such as figure 2 and Figure 11 , a fireproof insulating glass, including glass 1, spacer 2, first seal 3, second seal 4, fourth seal 6 and pressure relief valve 7, basically the same as embodiment 1, the difference is that the spacer 2 Placed as Figure 11As shown, the upper openings of the spacers 2 vertically placed on the left and right sides are exposed (the size of the exposure can be adjusted by the size of the cut corner), which facilitates the perfusion of molecular sieves and saves the process of punching holes on the spacers 2 , saving equipment investment and processing time; the difference is that the fourth seal 6 is used instead of the third seal 5, the fourth seal 6 is a sealing tape (aluminum foil composite tape, butyl rubber waterproof tape, etc.), the fourth seal 6 The periphery of the U-shaped sealed insulating glass, compared with Example 1, not only has a better sealing effect and a longer sealing time, but also has better clamping, fixing and p...

Embodiment 3

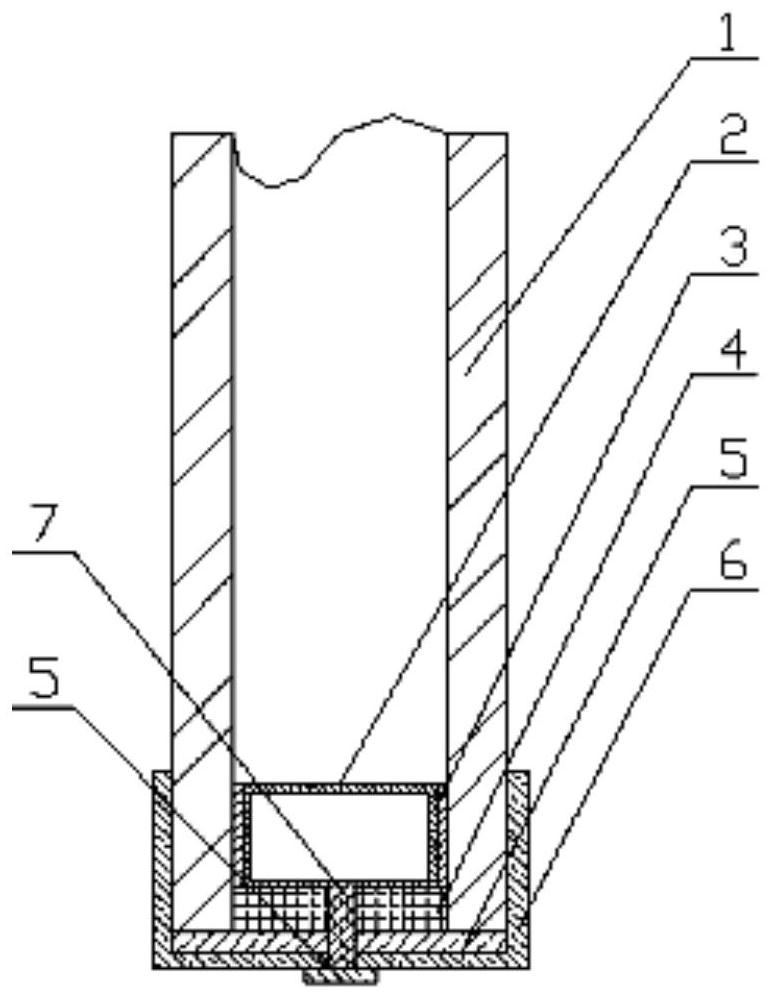

[0098] Such as image 3 and Figure 12 , a kind of fireproof insulating glass, comprising glass 1, spacer 2, seal 1 3, seal 2 4, seal 3 5, seal 4 6 and pressure relief valve 7, basically the same as embodiment 1, the difference is that spacer 2 placed like Figure 12 As shown, the spacer 2 is a flat incision, which can reduce the cutting amount by more than half compared with the oblique incision at an angle of 45 degrees, and produces no or less waste; in addition, the placement and positioning are also relatively simple, and the filling of molecular sieves It is more convenient; the difference is that it has four seals of seal 1 3, seal 2 4, seal 3 5 and seal 4 6 at the same time, so the sealing performance is better, and the fixing and protection effect on the glass is stronger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com