Long-acting total-nutrient wheat special-purpose fertilizer suitable for straw turnover, and processing method thereof

A full-nutrition, special-purpose fertilizer technology, applied in the direction of urea compound fertilizer, application, nitrogen fertilizer, etc., can solve the problems of incomplete nutrition, low wheat yield, and defertilization, so as to improve fertilizer utilization rate, reduce environmental pollution, and reduce nitrogen loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

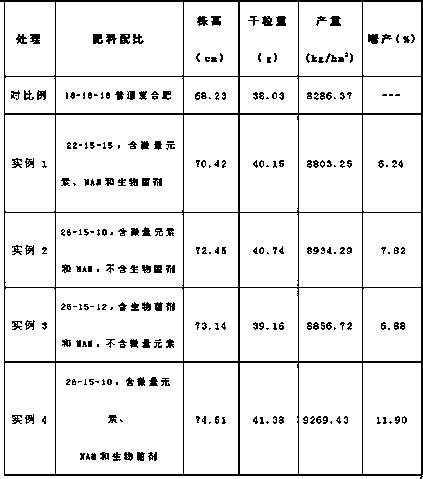

Examples

Embodiment 1

[0055] 420 parts of urea, 240 parts of potassium chloride, 300 parts of monoammonium phosphate, 8 parts of inhibitor NAM, 5 parts of boric acid, 7 parts of EDTA chelated zinc, 7 parts of EDTA chelated copper, 8 parts of EDTA chelated manganese, EDTA chelated iron 4.5 parts, 0.2 parts of ammonium heptamolybdate, and 0.3 parts of biological bacteria agent.

[0056] Above-mentioned raw material is all commercially available, and wherein:

[0057] Urea is small granular urea (N≥46.2%, particle size 0.85mm-2.80mm);

[0058] Monoammonium phosphate is ordinary powdered monoammonium phosphate (nutrient 60%);

[0059] Potassium chloride is white powder (potassium oxide content 62%);

[0060] Inhibitor NAM (developed by Shenyang Institute of Ecology, Chinese Academy of Sciences: composed of urease inhibitor, nitrification inhibitor and phosphorus activator);

[0061] Boric acid is white powder (industrial first-class product), boron content ≥ 17%;

[0062] EDTA chelated zinc: white ...

Embodiment 2

[0074] 500 parts of urea, 160.3 parts of potassium chloride, 300 parts of monoammonium phosphate, 8 parts of inhibitor NAM, 5 parts of boric acid, 7 parts of EDTA chelated zinc, 7 parts of EDTA chelated copper, 8 parts of EDTA chelated manganese, EDTA chelated iron 4.5 parts, 0.2 parts of ammonium heptamolybdate.

[0075] The specific implementation steps are the same as the implementation example 1.

[0076] The obtained product has a specification of 26-15-10, contains trace elements and NAM, and does not contain biological agents.

Embodiment 3

[0078] 500 parts of urea, 191.7 parts of potassium chloride, 300 parts of monoammonium phosphate, 8 parts of inhibitor NAM, and 0.3 parts of biological agent.

[0079] The specific implementation steps are the same as the implementation example 1.

[0080] The obtained product has a specification of 26-15-12, does not contain trace elements, and contains biological agents and NAM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com