Method for manufacturing formula compound fertilizer

A manufacturing method and compound fertilizer technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of high geographical requirements, poor nutrient ratio adjustability, complicated process, etc., and achieve improved production efficiency, stable product quality, and good appearance smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

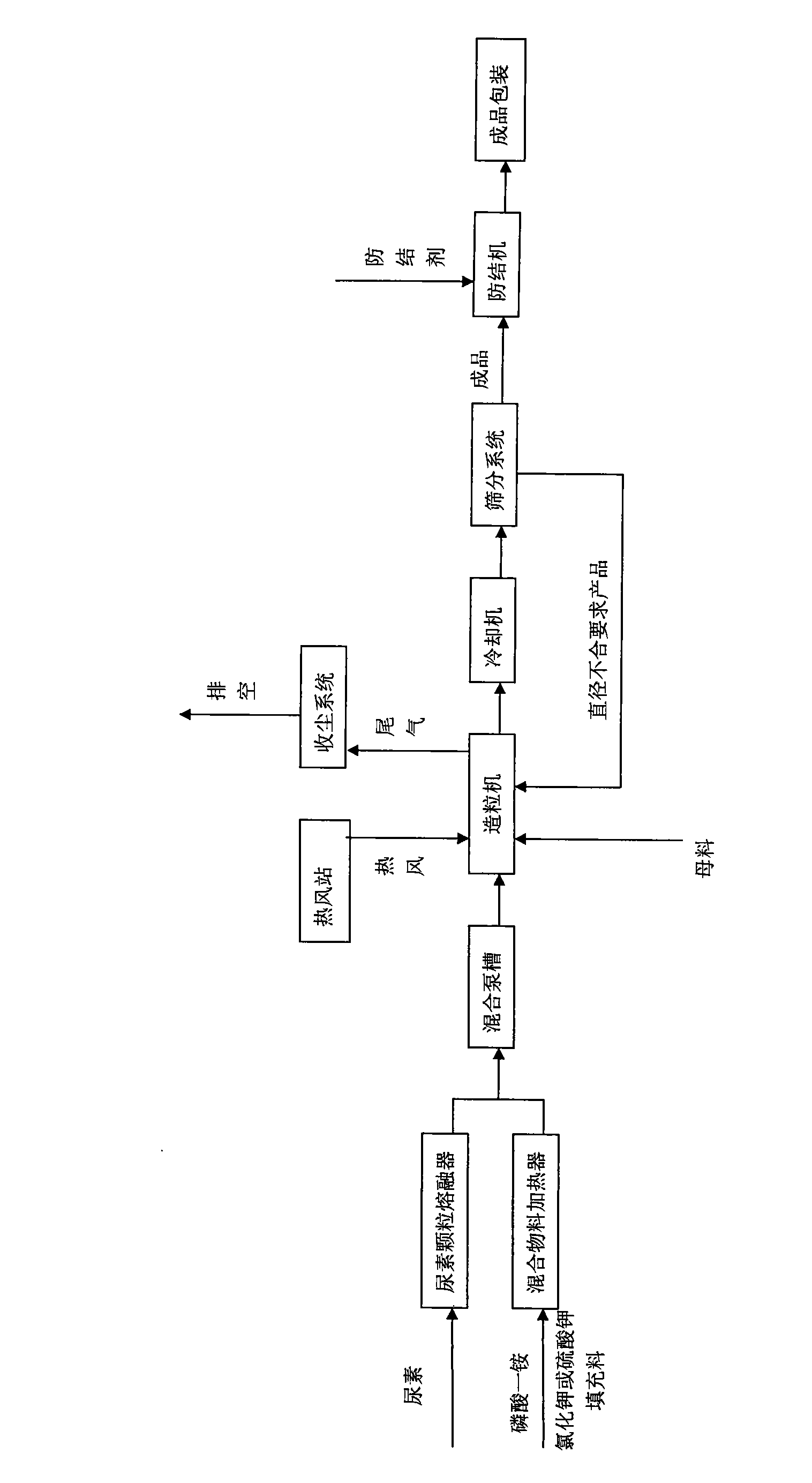

[0015] like figure 1 Shown, a kind of production method of formula compound fertilizer comprises the following steps:

[0016] (1) Send the masterbatch with a certain nutrient ratio to the horizontal granulator through the conveying system, supply hot air to the granulator to heat the masterbatch through the hot air station, and adjust the hot air station, tail gas dust collection system and the outlet of the granulator The baffle valve maintains a slight positive pressure inside the granulator;

[0017] (2) According to the nutrient ratio of the masterbatch, and then compare the nutrient ratio of the target product, a certain amount of single fertilizer ammonium phosphate, potassium chloride or potassium sulfate, fillers and other raw materials are evenly mixed and heated;

[0018] (3) According to the nutrient ratio of the masterbatch, then compare the nutrient ratio of the target product, and heat and melt a certain amount of urea in a urea melter;

[0019] (4) The above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com