Potassium nitrate co-production tower-type melt micrograin water-soluble fertilizer and preparing method thereof

A technology of potassium nitrate and micro-grains, which is applied in nitrate fertilizers, potash fertilizers, and ammonium orthophosphate fertilizers, etc. It can solve the problems of fluctuations in nitrogen, phosphorus, and potassium nutrients in products, and achieve the effects of nutrient balance, hardening, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

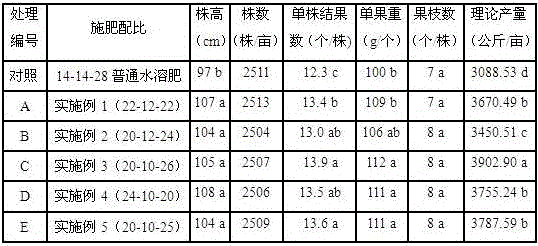

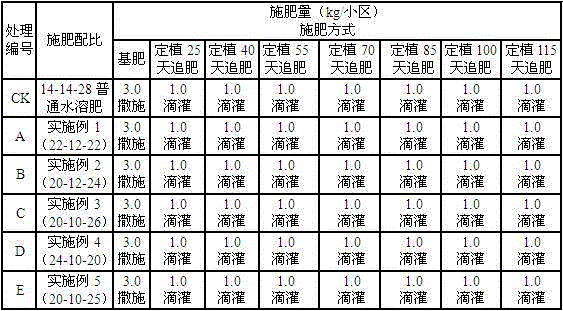

Examples

Embodiment 1

[0041] The microcrystalline water-soluble fertilizer produced by the present invention has the following raw material components, all in parts by weight: 200 parts of potassium nitrate concentrate, 350 parts of urea, 125 parts of industrial monoammonium phosphate, 100 parts of water-soluble ammonium polyphosphate, and 270 parts of potassium sulfate , 1.0 parts of EDTA-Fe, 7.0 parts of EDTA-Zn, 4.0 parts of EDTA-Mn, 3.0 parts of boric acid, and 0.2 parts of ammonium heptamolybdate.

[0042] The specific production process is as follows:

[0043] (1) The urea is melted at high temperature (130°C-140°C), enters the buffer tank, and then pressurized by the delivery pump, and then sent to the mixing tank at the top of the tower after metering.

[0044] (2) The potassium nitrate concentrate produced in the production of potassium nitrate by ion exchange is centrifuged and sent to the agitator through metering pipeline air.

[0045] (3) Pre-mix EDTA-Fe, EDTA-Zn, EDTA-Mn, boric acid,...

Embodiment 2

[0049]Take 300 parts of urea, 180 parts of potassium nitrate concentrate, 2.0 parts of EDTA-Fe, 4.0 parts of EDTA-Zn, 4.0 parts of EDTA-Mn, 5.0 parts of boric acid, 0 parts of ammonium heptamolybdate, 125 parts of industrial monoammonium phosphate, 105 parts Water-soluble ammonium polyphosphate, 325 parts potassium sulfate.

[0050] Concrete production technology is with embodiment 1.

[0051] The obtained product specification is 20-12-24, does not contain molybdenum, contains trace elements, and is water-soluble ammonium polyphosphate.

Embodiment 3

[0053] Take 300 parts of urea, 240 parts of potassium nitrate concentrate, 3.0 parts of EDTA-Fe, 8.0 parts of EDTA-Zn, 6.0 parts of EDTA-Mn, 7.0 parts of boric acid, 1.0 parts of ammonium heptamolybdate, 105 parts of industrial monoammonium phosphate, 90 parts Water-soluble ammonium polyphosphate, 310 parts of potassium sulfate.

[0054] Concrete production technology is with embodiment 1.

[0055] The obtained product has a specification of 20-10-26, contains trace elements, and is water-soluble ammonium polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com