Method and system for converting livestock and poultry manure and waste straw materials into organic fertilizer

A technology of livestock and poultry manure and straw waste, which is applied in the field of converting livestock and poultry manure and straw waste into organic fertilizers. It can solve the problems of unsuitable long-term irrigation of farmland, unripe organic matter, pollution of rivers and surface waters, etc., and achieve automatic monitoring and real-time fault diagnosis, improving air permeability and water retention, and shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

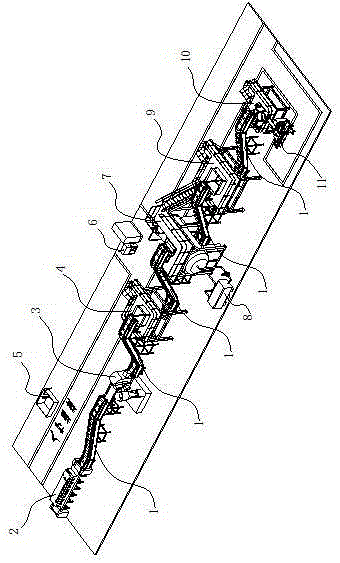

[0030] Such as figure 1 with figure 2 As shown, the system for converting livestock and poultry manure and straw waste into organic fertilizer in this embodiment includes a drying device 2, a straw crushing device 3, a powdered straw storage device 4, and an aerobic fermentation unit connected in turn by a conveyor belt 1. And drying granulation bagging unit. It also includes a fecal pump 5 and a console 6.

[0031] The console 6 is used to control the drying device 2, the straw crushing device 3, the powdered straw storage device 4, the aerobic fermentation unit, the manure pump 5, and the drying, granulating and bagging unit.

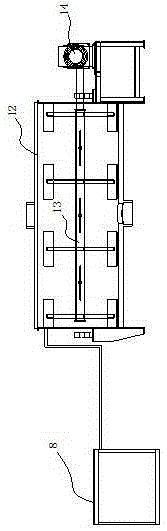

[0032] Among them, the aerobic fermentation unit is composed of an aerobic fermentation tank 7 and a heating device 8. The aerobic fermentation tank 7 is composed of a housing 12 with a stirring chamber inside, a stirring shaft 13 transversely arranged in the stirring chamber, and a stirring motor 14 for driving the stirring shaft 13. The fecal outlet ...

Embodiment 2

[0039] This embodiment is a method for converting livestock manure and straw waste into organic fertilizer, which includes the following steps:

[0040] a. Mix livestock and poultry manure with straw scraps to control the carbon to nitrogen ratio of the mixture at 20-28:1, and adjust the humidity of the mixture to 50-65%;

[0041] b. Add starter to the mixture;

[0042] c. Put the mixture into the fermentor and carry out aerobic fermentation for 8-9 hours at a temperature of 60-85 degrees and a stirring rate of 30-45 rpm. During aerobic fermentation, aerate the fermenter for aeration The ventilation volume per hour is 0.5-0.75 times the volume of the fermentation tank;

[0043] d. The fermented mixture is sterilized, dried, granulated and bagged.

[0044] It may be preferable that: before step a, it further includes a straw pretreatment step of microwave drying the straw shredded section recovered from the farmland and transporting it to a crusher for crushing treatment.

[0045] Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com