Tower-type melt granulation water-soluble fertilizer containing fulvic acid potassium macroelement and preparation method for fertilizer

A tower-type melt granulation and potassium fulvic acid technology, which is applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems that nutrients cannot be mixed evenly, fertilizers are easy to harden, and unfavorable storage, etc., so as to improve crop yield And quality, fast nutrient absorption, stable fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

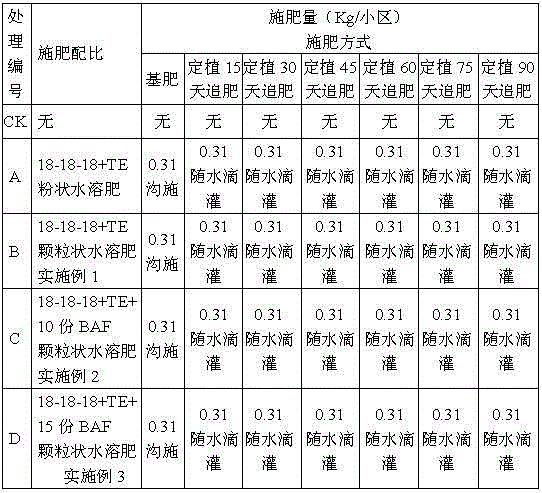

Embodiment 1

[0037] Raw material ratio: 510 parts of ammonium phosphorus nitrate, 170 parts of potassium nitrate, 299 parts of potassium dihydrogen phosphate, 6 parts of boric acid, 7.7 parts of EDTA chelated iron, 3.3 parts of EDTA chelated zinc, 4 parts of EDTA chelated manganese.

[0038] Preparation steps:

[0039] 1. Melt 510 parts of ammonium nitrate at high temperature (150°C~165°C), enter the buffer tank, pressurize it through the delivery pump, and send it to the mixing tank at the top of the tower after metering.

[0040] 2. Premix 6 parts of boric acid, 3.3 parts of EDTA chelated zinc, 7.7 parts of EDTA chelated iron, and 4 parts of EDTA chelated manganese in a certain proportion, and then mix the mixture with 299 parts of potassium dihydrogen phosphate and 170 parts of nitric acid After the potassium is measured separately, it is sent into the mixer and mixed thoroughly. The mixed raw materials are sent to the mixing heater after being crushed and screened, heated to 70°C-90°C...

Embodiment 2

[0044] Raw material ratio: 495 parts of ammonium phosphorus nitrate, 170 parts of potassium nitrate, 304 parts of potassium dihydrogen phosphate, 6 parts of boric acid, 7.7 parts of EDTA chelated iron, 3.3 parts of EDTA chelated zinc, 4 parts of EDTA chelated manganese, fulvic acid Potassium 10 parts.

[0045] The specific implementation steps are the same as the implementation example 1.

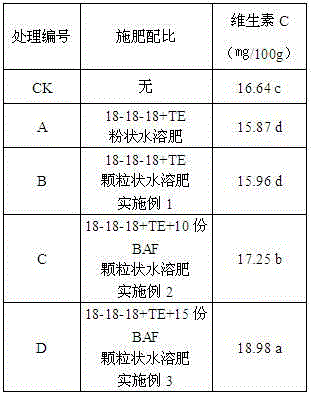

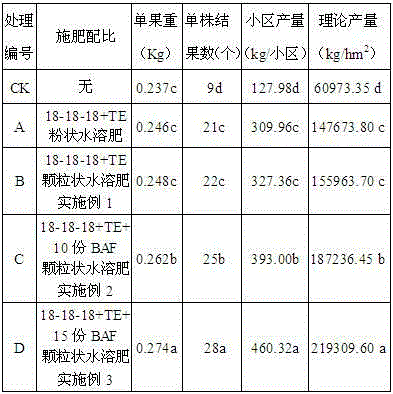

[0046]The obtained product specification is 18-18-18, containing 0.1% boron, 0.1% chelated iron, 0.05% chelated zinc, 0.05% chelated manganese, and 1% potassium fulvic acid.

Embodiment 3

[0048] Phosphorous ammonium nitrate 490 parts, potassium nitrate 170 parts, potassium dihydrogen phosphate 304 parts, boric acid 6 parts, EDTA chelated iron 7.7 parts, EDTA chelated zinc 3.3 parts, EDTA chelated manganese 4 parts, potassium fulvic acid 15 parts.

[0049] The specific implementation steps are the same as the implementation example 1.

[0050] The obtained product specification is 18-18-18, containing 0.1% boron, 0.1% chelated iron, 0.05% chelated zinc, 0.05% chelated manganese, and 1.5% potassium fulvic acid

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com