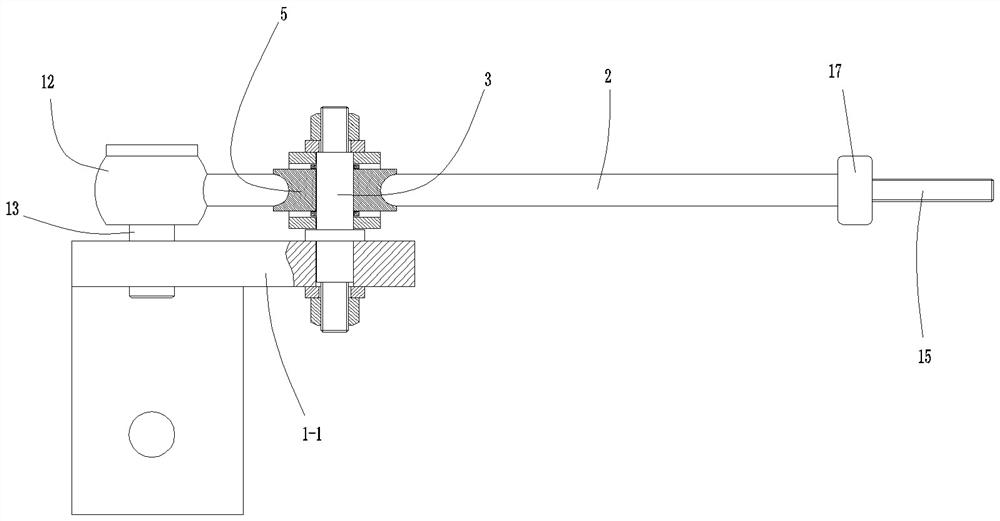

Bent pipe machining device of small-diameter thin-walled pipe for spraying and atomizing in deodorization equipment

A processing device, small diameter technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of round inner hole flattening, difficult quality control, cracking, etc., to achieve easy manual operation, smooth appearance, investment small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

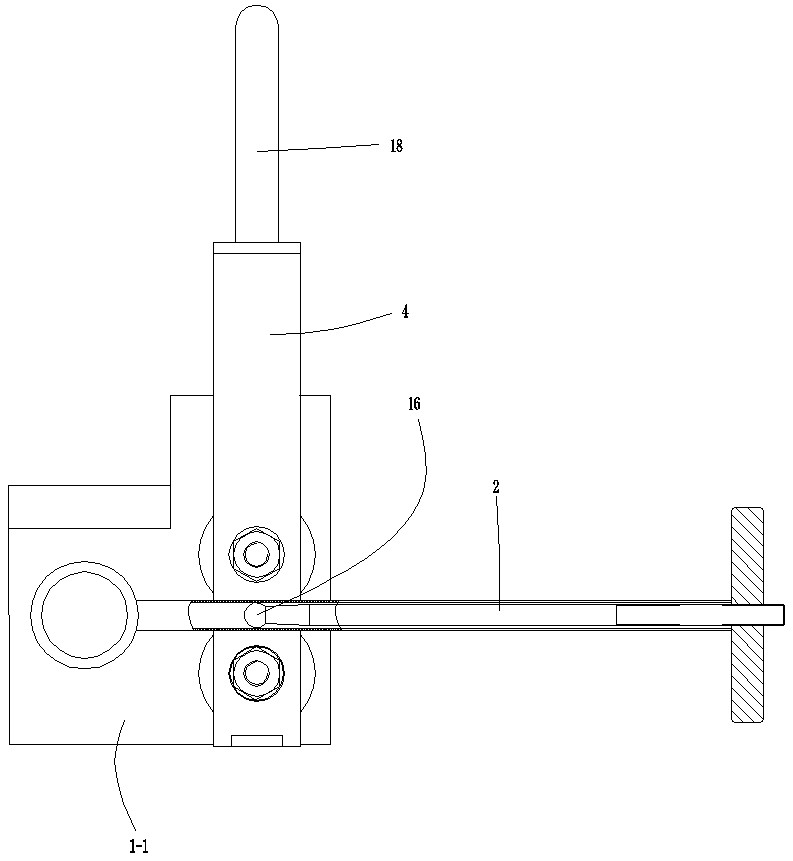

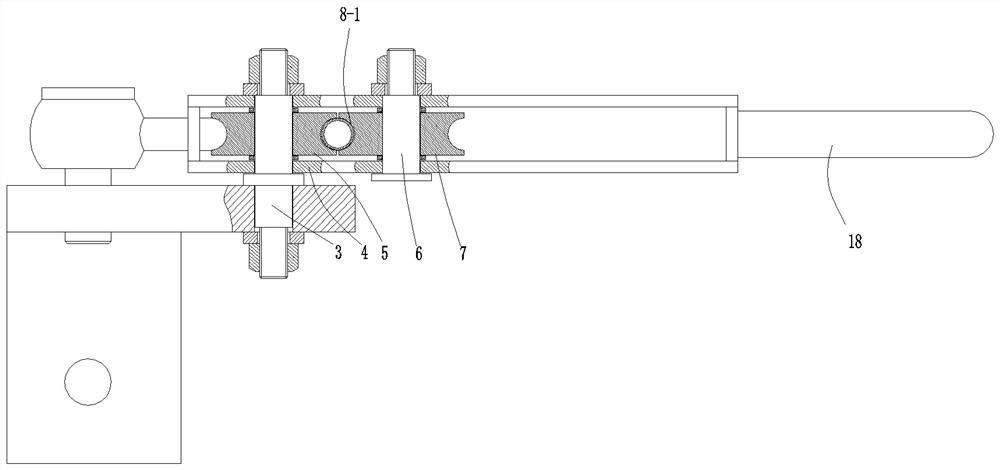

Method used

Image

Examples

specific example

[0043] Concrete example: the outer diameter is 14mm, the copper tube that wall thickness is 1mm, and bending radius is 20mm, and angle is the bend of 85 °, and the diameter of moving screw 15 can take 10mm, and the diameter of support ball 16 can take 11.8mm, and the movable pulley 7 outside The radius of the circle is 20mm, the arc groove radius is 14.1mm, and the size of the fixed pulley 5 is the same as that of the movable pulley 7. Appropriate tolerances are allowed for the above dimensions, eg ±0.01mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com