High-intensity damage-free type flexible roughened surface geomembrane and producing method thereof

A non-destructive, geomembrane technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of breaking strength and elongation at break, affecting the quality of anti-seepage engineering, high cost of equipment and raw materials, etc. Achieve good stability, low equipment cost and raw material cost, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (single rough geomembrane):

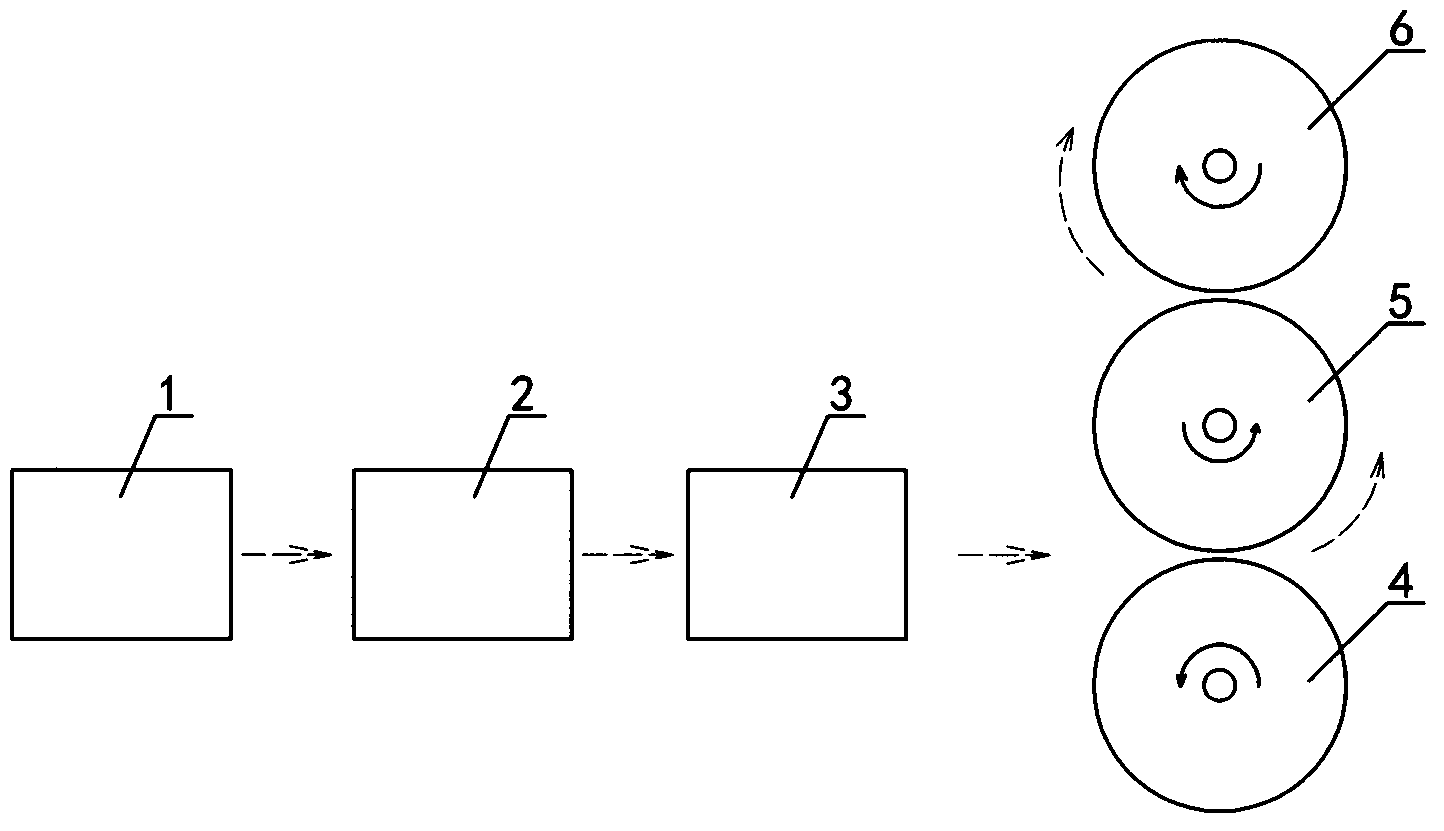

[0034] Production equipment: mixing machine 1, extruder 2, T-die 3 and calendering equipment.

[0035] The kneading machine 1, the extruder 2 and the T-shaped die 3 are equipment configurations for producing multi-layer composite geomembranes by calendering process, and can be used directly.

[0036] On the calendering equipment, a smooth calendering roller 4, a calendering roller with dimples 5 and a cooling roller 6 are sequentially arranged from bottom to top.

[0037] Raw material ratio:

[0038]

[0039] Production process (as attached image 3 shown):

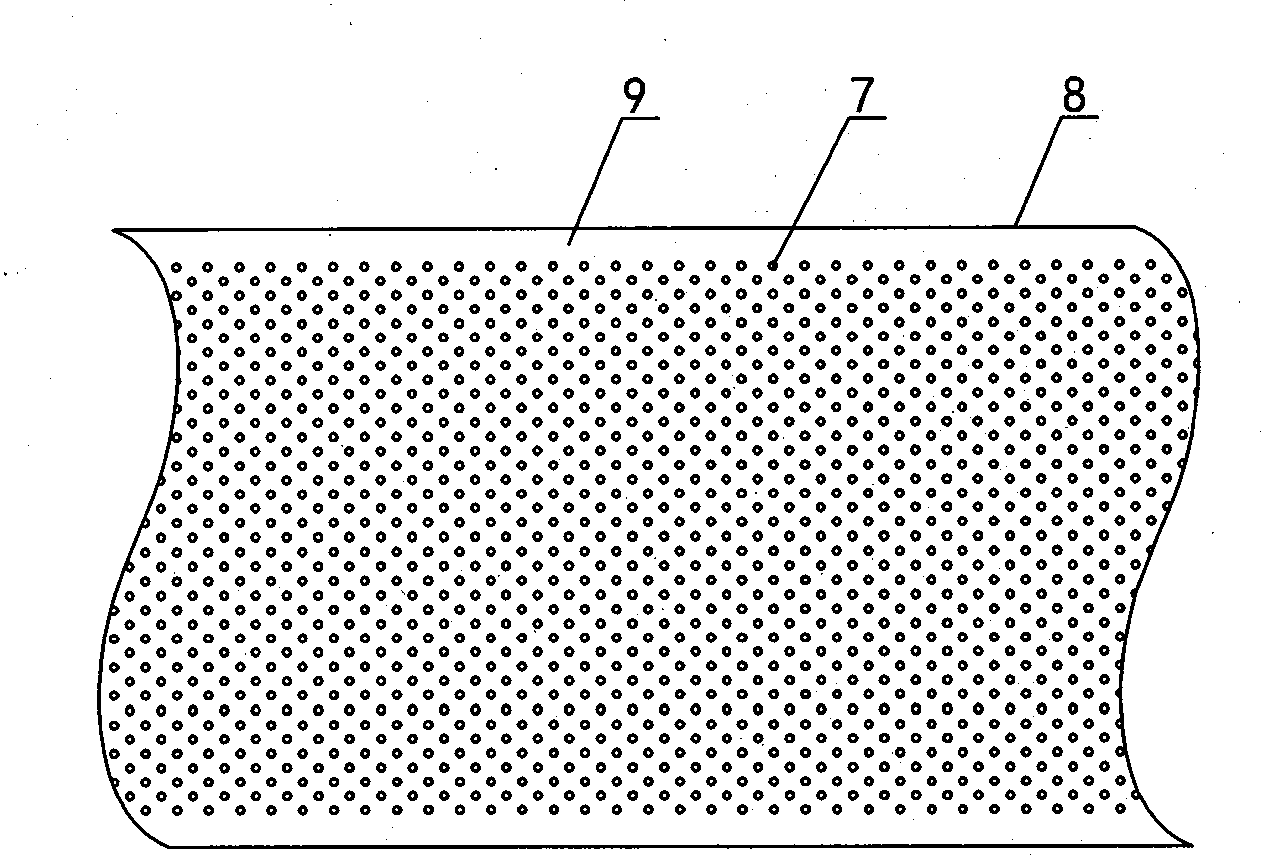

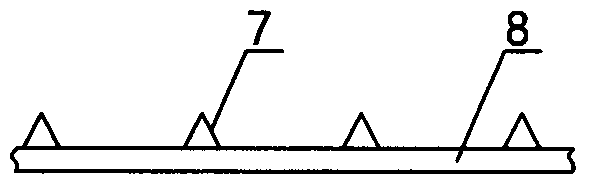

[0040] Feed the well-proportioned raw materials into the kneader 1 for full mixing, and carry out the preliminary molding of the width and thickness through the plasticizing extrusion of the extruder 2 and the shunt molding of the T-shaped die 3 to obtain the initial film of the geomembrane ; Before the initial film is cooled, it is directly introduced into the gap ...

Embodiment 2

[0042] Embodiment 2 (double rough geomembrane):

[0043] Raw material ratio:

[0044]

[0045]

[0046] The production equipment and production process are basically the same as those in Embodiment 1, except that the middle calender roll and the lower calender roll of the calendering equipment are both calender rolls with concave points.

Embodiment 3

[0047] Embodiment three (single-sided calender roll):

[0048] Raw material ratio:

[0049]

[0050] Production equipment and production technology are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com