Super-high-molecular-weight polyolefin yarn, method for producing same, and drawing device

A technology of ultra-high molecular weight polyolefin yarn, which is applied in the fields of single-component polyolefin artificial filament, transportation and packaging, textiles and papermaking, and can solve problems such as uneven temperature distribution, single yarn breakage, and uneven temperature, and achieve Excellent uniformity, small total fineness, and small coefficient of variation of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

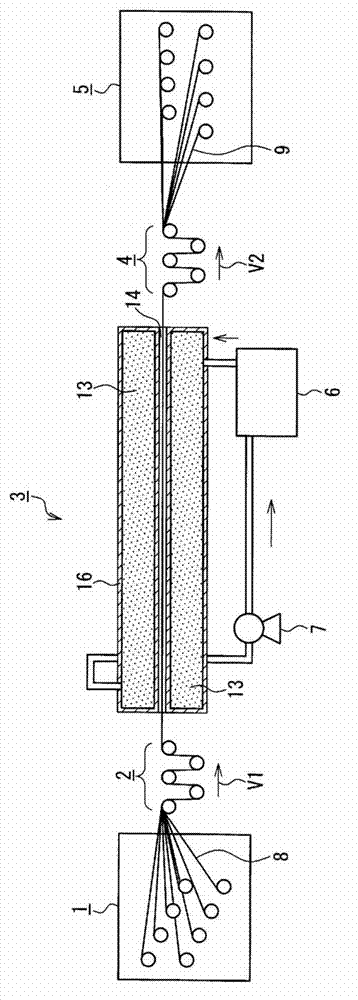

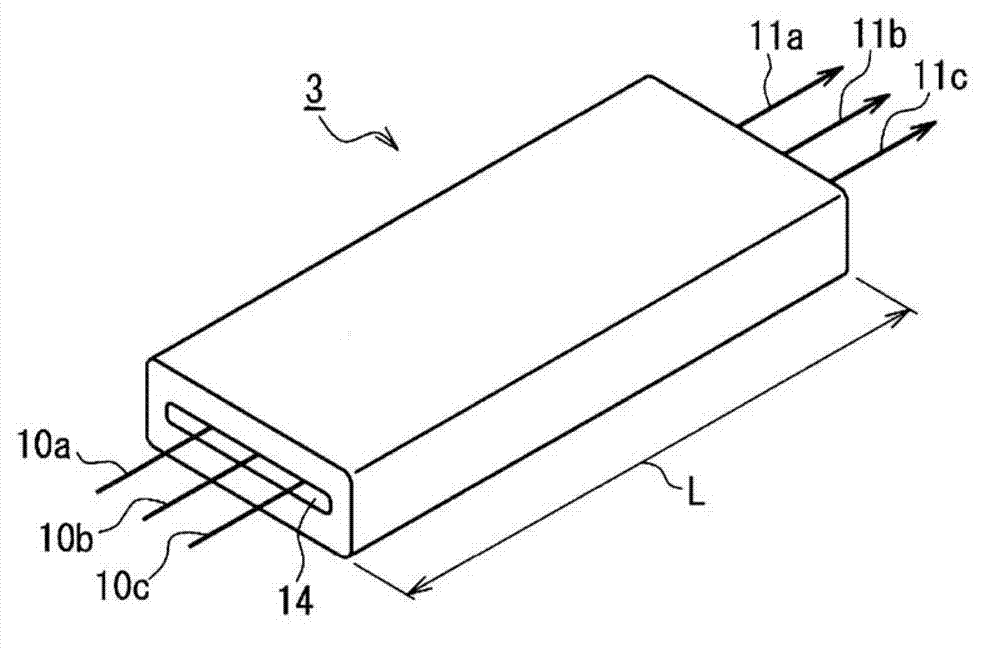

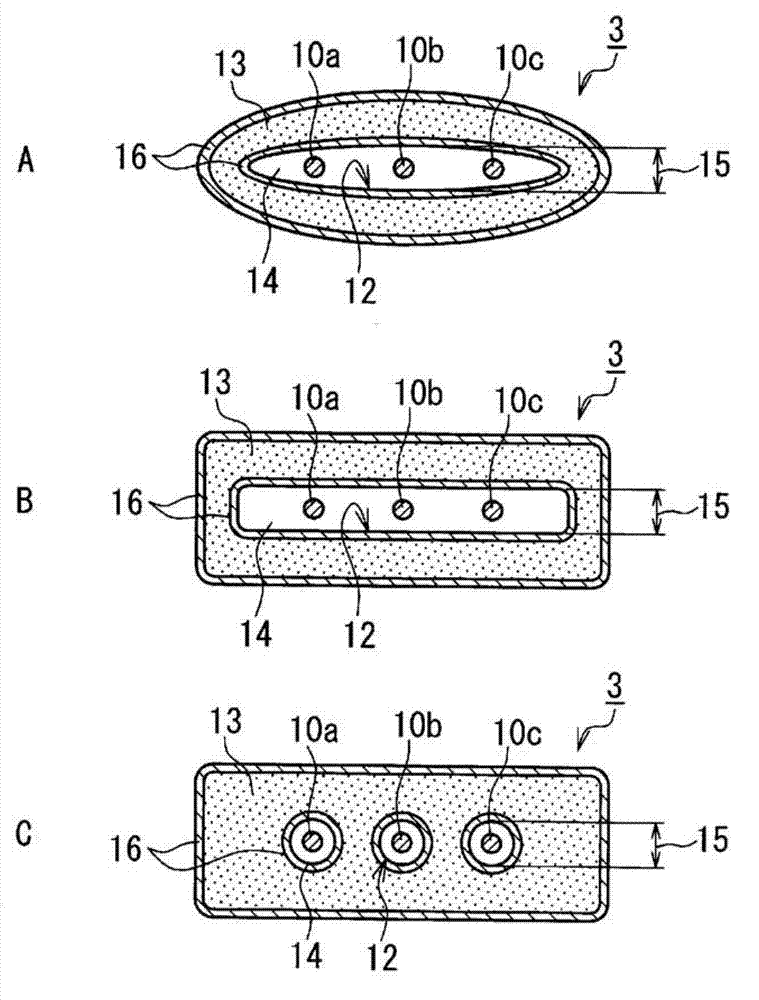

[0089] As the supply sliver, an ultra-high molecular weight high-strength polyethylene single-twisted raw yarn A [manufactured by Toyobo Co., Ltd., trade name "Dyneema", 110T-96F (total fineness: 110Tex, number of filaments) stretched by the conventional method was used. : 96 strands) of raw yarn with single twist (S) 90 times / m] Tensile test was carried out. The raw yarn used had a tensile strength of 31.8 CN / dtex, an elongation of 4.8%, a DSC melting point of 150.3°C, and a crystallinity of 75%. The DSC diagram of the sliver before stretching is shown in Figure 4 a. exist Figure 4 In A, the dotted line is an auxiliary line automatically added by the analyzer for calculating the peak area. This is also the same in the following DSC charts. The length of the stretching groove of the stretching device used is 3m, and the cross-sectional shape is as follows image 3 For the hollow rectangle shown in B, use figure 1 and figure 2 The 1-stage tensile apparatus shown was u...

Embodiment 2)

[0100] As the supply sliver, knitting yarn B made of raw yarn [manufactured by Toyobo Co., Ltd., trade name "Dyneema", 55T-48F (total fineness: 55Tex, number of filaments: 48)] was used as a set of 4 , a tensile test was carried out. The weaving yarn used had a tensile strength of 25.4 CN / dtex and an elongation of 4.9%. A tensile test was performed using a tensile tank of the same jacket heating system as in Example 1. As shown in Table 3 and Table 4, the highest draw ratio was 3.2 times, which was higher than that of the comparative example. The strength of the stretched yarn at this magnification was 27.0 CN / dtex, and the elongation was 2.9%.

Embodiment 3)

[0111] As the supply sliver, a relatively thick raw yarn [manufactured by Toyobo Co., Ltd., trade name "Dyneema", 165T-144F (total fineness: 165Tex, number of filaments: 144)] formed in groups of 8 is used. Weaving yarn C was subjected to a tensile test. The weaving yarn used had a tensile strength of 23.7 CN / dtex and an elongation of 5.9%. A tensile test was performed using a tensile tank of the same jacket heating system as in Example 1. As shown in Table 3, the maximum draw ratio was 2.4 times, which was improved compared with the comparative example. The strength of the stretched yarn at this ratio was 26.0 CN / dtex, and the elongation was 3.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com