Method for testing surface energy of aggregate

A test method and aggregate technology, applied in the field of aggregate surface energy test, to achieve the effect of short test time, simple preparation process and good data reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

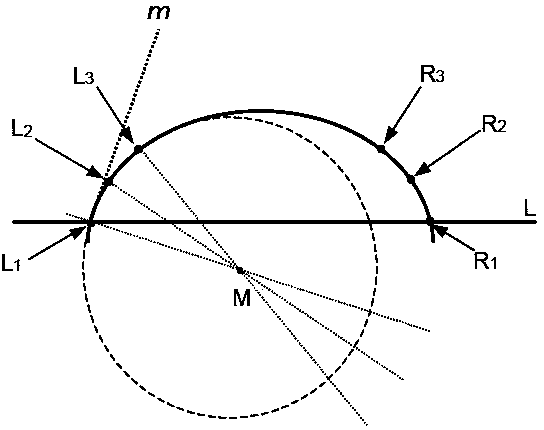

Method used

Image

Examples

Embodiment 1

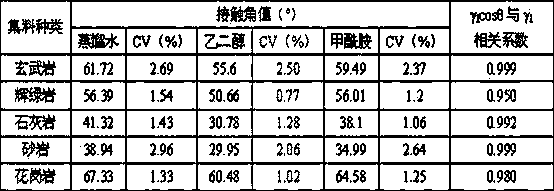

[0019] Example 1: Basalt, diabase, limestone, sandstone and granite were selected as aggregates. The density and water absorption of each aggregate are shown in Table 1. The test liquids were distilled water, ethylene glycol and formamide.

[0020] Specific steps are as follows:

[0021] 1. Obtain a sample of the required size. The aggregate obtained from the quarry is divided into 5cm×5cm×1cm samples by water sawing method;

[0022] 2. Polish the sample to obtain a smooth and flat surface. First use a polishing machine to polish the cut sample, then rinse the sample with clean water, dry it, and then use 240# water sandpaper to further polish the sample to obtain a uniform and flat aggregate surface;

[0023] 3. Clean the surface of the sample used in the test. Soak the sample in pre-prepared analytical pure alcohol (ethanol content ≥ 95%), then rinse with distilled water, and finally put it in a 100°C oven for 5 hours to dry, take it out and place it dry for later use;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com