Preparation method of heat-not-burn dry reconstituted tobacco

A heat-not-burn and reconstituted tobacco leaf technology, which is applied in the field of tobacco production, can solve problems such as low tensile strength, damaged paper web tensile strength, and low smoke-generating agent content, and meet processing requirements, improve physical properties, physical The effect of index stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

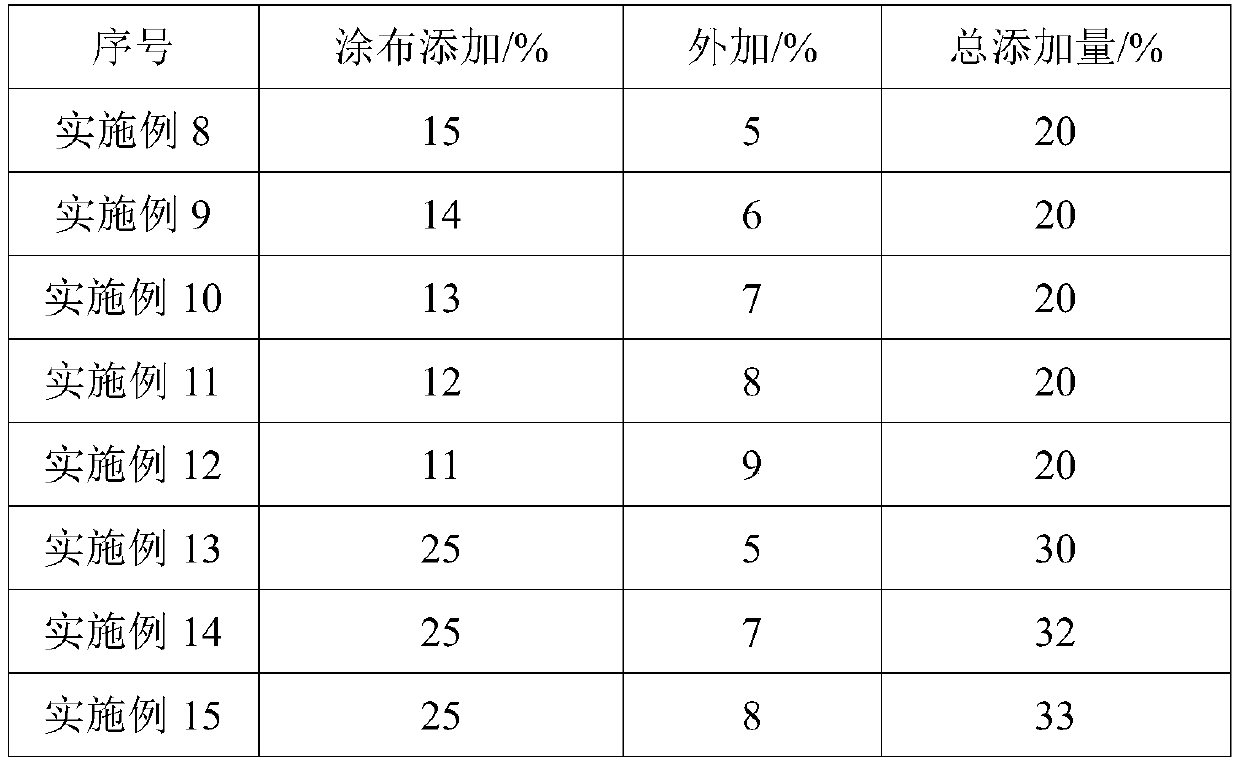

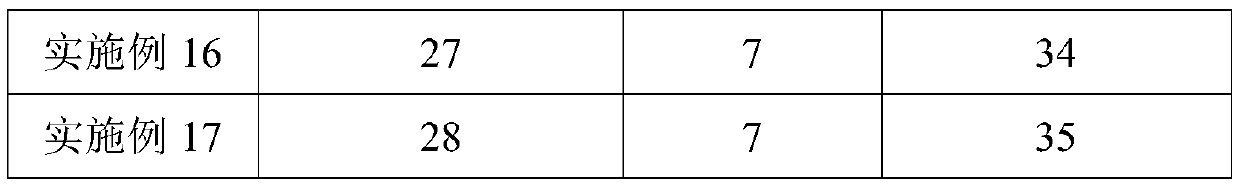

[0034] A method for preparing heat-not-burn reconstituted tobacco leaves by dry process, the method includes the preparation of tobacco powder, the preparation of coating solution, the coating and drying of a shaped substrate, wherein the coating solution is added with glycerin, a fuming agent, and the specific parameters are substrate Quantitative 20g / m 2 ;Product weight 80g / m 2 The amount of adhesive is 5%, and the amount of glycerin added is 20% of the mass of the substrate. The specific drying temperature parameters are shown in Table 1.

[0035] in:

[0036] (1) Substrate forming

[0037] The used added fiber pulp board enters the added fiber crushing and defibrating system through the quantitative feeding device to control the feeding speed of the pulp board. After coarse crushing and fine crushing, secondary crushing and defibration into dispersed fibers, and then cyclone separation and dust removal enter the storage tank, so far the defibration of the added fibers is ...

Embodiment 26~32

[0088] Examples 26-32 Effect of Calendering Temperature on Physical Properties of Dry Reconstituted Tobacco Leaf

[0089] A method for preparing heat-not-burn reconstituted tobacco leaves by dry method, including base sheet forming and setting-coating-drying, and calendering treatment after drying. The specific calendering treatment parameters are shown in Table 3.

[0090] table 3

[0091]

[0092]

[0093] Test results

[0094] Under the condition that the calendering pressure was determined to be 0.40 MPa, the samples were subjected to calendering treatment and then tested for physical indicators such as tensile strength, tensile elongation, and bulk. The results of the physical indicators are shown in Table 4 below.

[0095] Table 4

[0096]

[0097] It can be seen from the above table that under the condition of calendering pressure of 0.40MPa, as the calendering temperature increases, the tensile strength shows a trend of increasing first and then tending to b...

Embodiment 33~44

[0098] Examples 33-44 Effect of Calendering Pressure and Calendering Temperature Synergistically on Physical Properties of Dry Reconstituted Tobacco Leaf

[0099]A pretreatment method for forming heat-not-burn reconstituted tobacco leaves by a dry method, in which dry-process reconstituted tobacco leaves for heat-not-burn are subjected to calendering treatment before forming heat-not-burn cigarettes. The specific calendering treatment parameters are shown in Table 5.

[0100] table 5

[0101]

[0102]

[0103] Test results

[0104] The samples were processed according to the selected calendering pressure and temperature parameters, and the tensile strength and tensile elongation were tested respectively. The results obtained are shown in Table 6 below.

[0105] serial number

[0106] With the increase of pressure or temperature of the pre-pressing roller, the tensile strength of heat-not-burn reconstituted tobacco products showed a gradual increase trend, whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com