Production method of hot-rolled plate coil used for high-strength corrosion-resistant pipe steel

A hot-rolled coil, corrosion-resistant technology, used in the field of iron and steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

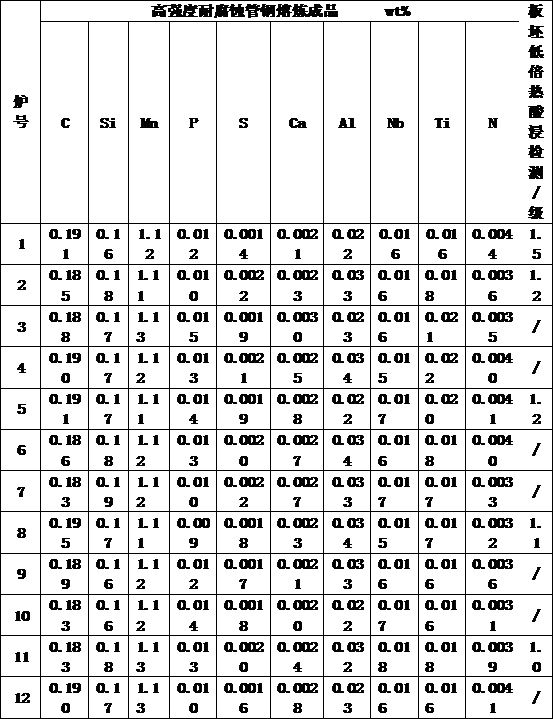

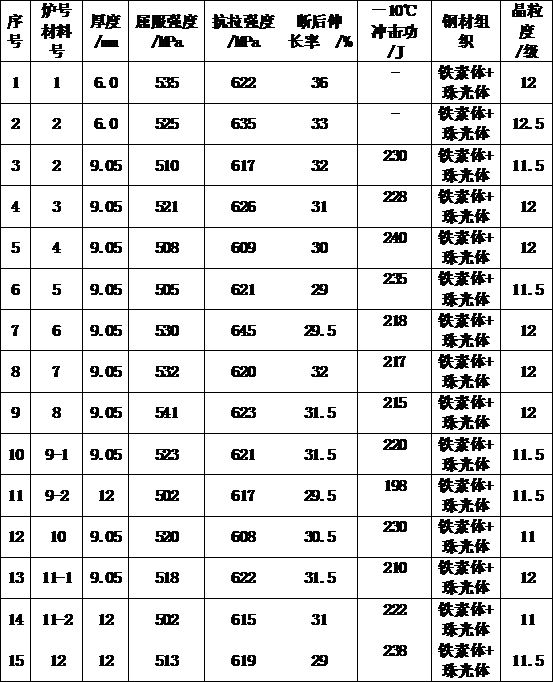

[0025] A preparation method of hot-rolled coils for high-strength corrosion-resistant pipe steel. In terms of composition design, the use of elements such as copper and nickel is meaningful for atmospheric corrosion resistance, but for casings serving underground, it is mainly resistant to H 2 S, CO 2、 , Cl - Etc. corrosion. Therefore, in terms of composition design, while satisfying various properties, it is necessary to consider the threading and tapping of the end connection of the steel pipe, and to ensure the machinability of the steel by appropriately increasing the carbon content. Therefore, the C content in the composition design is 0.185-0.205 wt%. Since the most influential factor on hydrogen sulfide corrosion is the banded structure of the steel caused by slab center segregation, the non-metallic inclusions enriched in the banded structure will become corroded The source of cracks, the main method to solve the corrosion resistance of steel is to improve the purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com