Heat treatment technology for improving ageing impact toughness of austenitic heatproof steel for preparing boiler pipes

A technology of austenitic heat-resistant steel and impact toughness is applied in the field of heat treatment process for improving the aging impact toughness of austenitic heat-resistant steel for boiler tubes, which can solve the problem of reducing the life of the tube, reducing the microstructure stability, reducing the impact toughness of the alloy, etc. problems, to achieve the effect of improving impact toughness, simple heat treatment, and maintaining stable tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

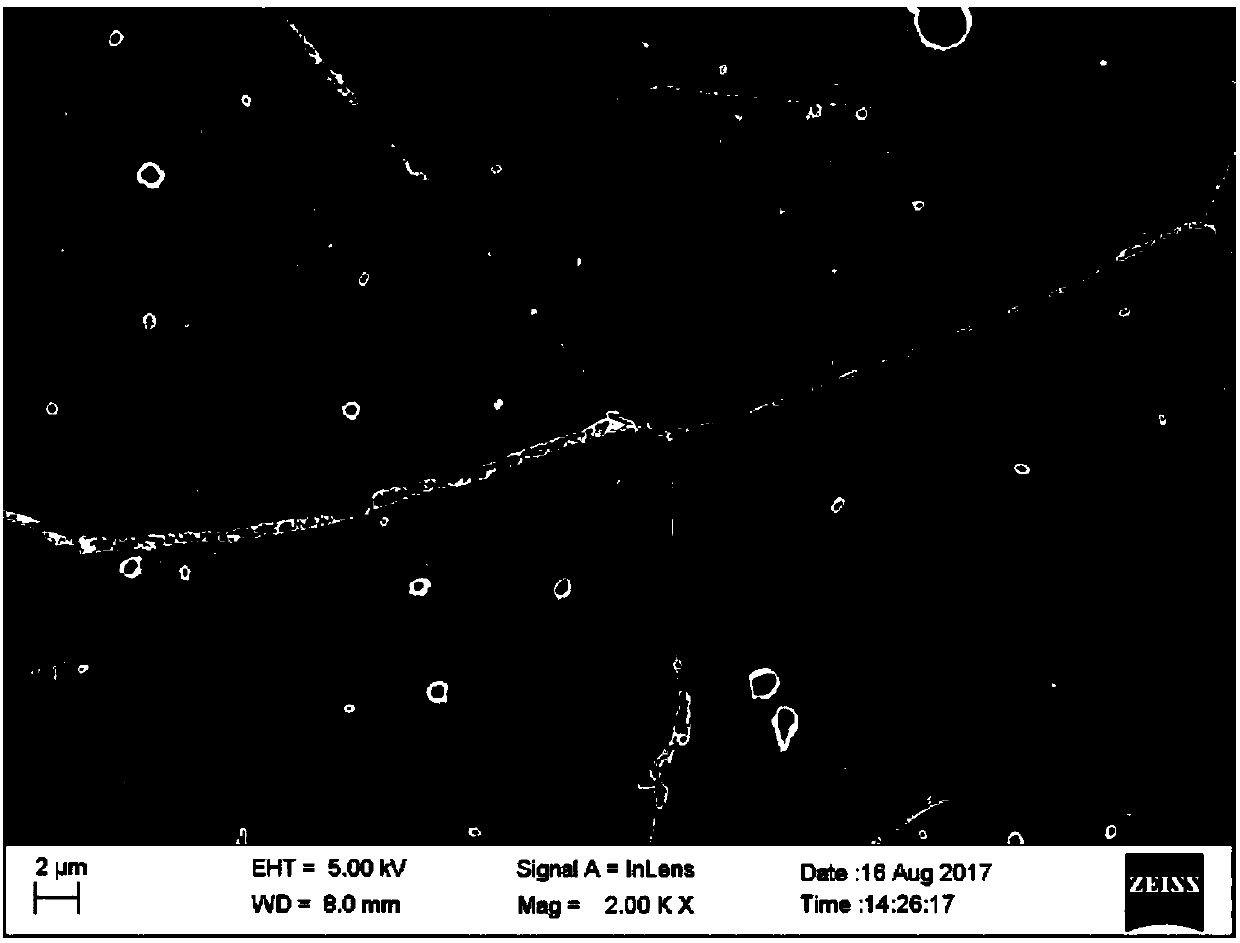

[0023] The supplied HR3C alloy was subjected to high-temperature solution treatment, the solution temperature was 900°C, and the holding time was 2 minutes; then it was slowly cooled from 900°C to 600°C at a rate of 2°C / min, and finally air-cooled to room temperature. After the above heat treatment, the microstructure of the alloy is as follows: figure 2 shown, from figure 2 It can be seen that more carbides are precipitated in the HR3C alloy after optimized heat treatment, and the carbides are uniformly and continuously distributed at the grain boundaries. The room temperature and high temperature tensile properties and impact toughness of the alloy were tested. The impact specimen was a V-notch Charpy impact specimen of 55mm×10mm×2.5mm. The test results are shown in Table 2. The yield strengths at room temperature and 650°C are 425MPa and 253MPa, respectively, which are equivalent to the tensile strength of the as-supplied state; the impact energy of the HR3C alloy after ...

Embodiment 2

[0032] The as-delivered HR3C alloy was kept at 880°C for 1 minute; then slowly cooled from 880°C to 700°C at a rate of 1°C / min, and finally air-cooled to room temperature.

Embodiment 3

[0034] The as-delivered HR3C alloy was kept at 950°C for 3 minutes; then slowly cooled from 950°C to 650°C at a rate of 5°C / min, and finally air-cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com