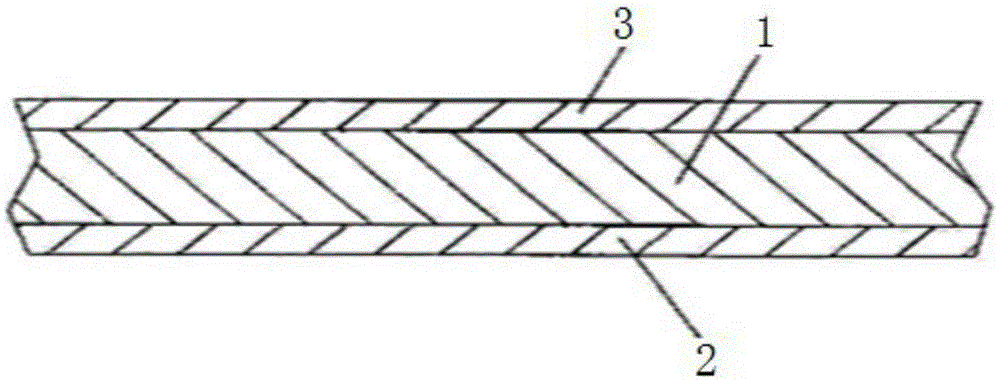

Double-sided corona cover light membrane

A cover light, double-sided technology, applied in the direction of flexible covering, packaging item type, application, etc., can solve the problems of complex production technology, high difficulty and difficulty in mastering the production process formula of double-sided corona cover light film, and achieve Stable stretching, smooth production process, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

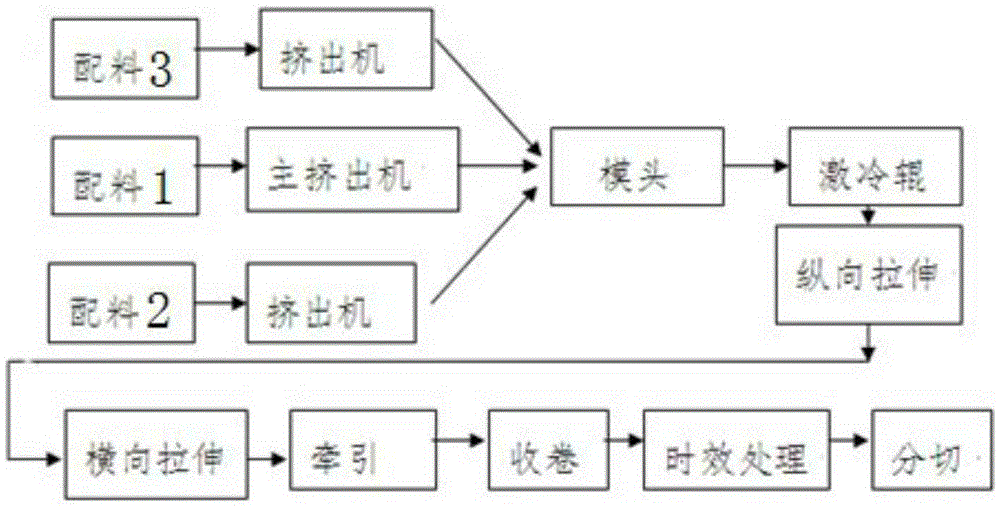

Method used

Image

Examples

Embodiment 1

[0044] Double-sided corona cover film: Polypropylene is a homopolymer or copolymer polypropylene with a melt index between 1-3g / 10min.

[0045] The antistatic agent is selected from one or more of erucamide, ethoxylated amine, and monoglyceride oleic acid amide.

[0046]The anti-blocking agent is selected from one or both of silicon dioxide and polymethyl methacrylate.

[0047] Preparation of covering agent: dilute 0.05-0.1 part of silane coupling agent or titanate coupling agent with solvent, and then evenly disperse in 7-10 parts of talc powder, volatilize the solvent through an oven, and then dry the dried The filler is crushed into fine powder with a high-speed pulverizer, and the fine powder is mechanically blended with 60 parts of polypropylene with a melt index MI of 0.3-0.5mg / 10min and 40-50 parts of high-density polyethylene on an open mill, and then extruded Machine plasticized granulation, extrusion temperature 180-200 ℃, made into spherical granule capping agent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com