Special film for automatic laminating machine adopting double-sided corona and preparation method of special film

A technology of laminating machine and special film, which is applied in the field of special film for double-sided corona automatic laminating machine and its preparation, can solve the problems of large static electricity, inseparable products, and the film is not slippery enough, and achieves the effect of reducing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0026] The full matt transfer film includes a corona printing surface layer, a core layer and a composite layer. The core layer is arranged between the corona printing surface layer and the composite layer. The corona printing surface layer is made of polypropylene and slip agent, and the core layer is Jiujiang Petrochemical F03D. Polypropylene, antistatic agent model 1083, purchased from Jiangsu Langfu Co., Ltd.; composite layer composition is polypropylene, specific model is Lanzhou Petrochemical T28FE, anti-sticking agent model 9019.

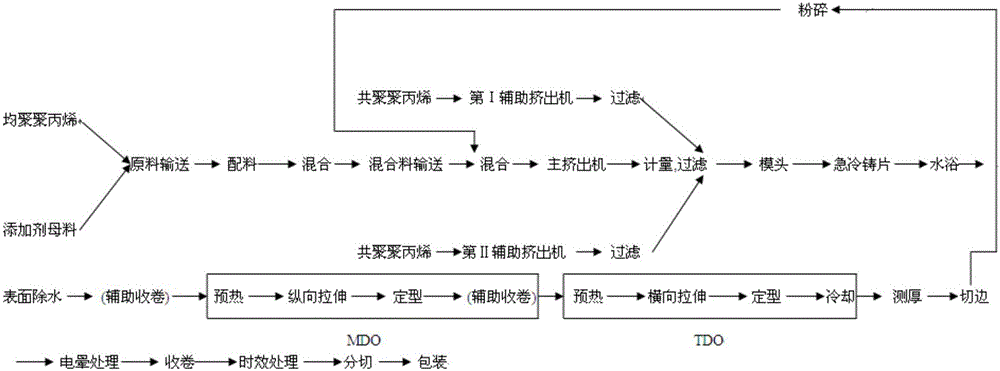

[0027] Such as figure 1 As shown, the invention discloses a method for preparing a special film for a double-sided corona automatic film laminating machine, comprising the following steps:

[0028] After conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com