Wood surface spraying process

A wood surface and process technology, applied in the field of wood surface spraying technology, can solve the problems of easy decay, deformation, poor durability and high humidity of wooden easels, achieve good sticking effect, strengthen anti-corrosion effect, and reduce moisture content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

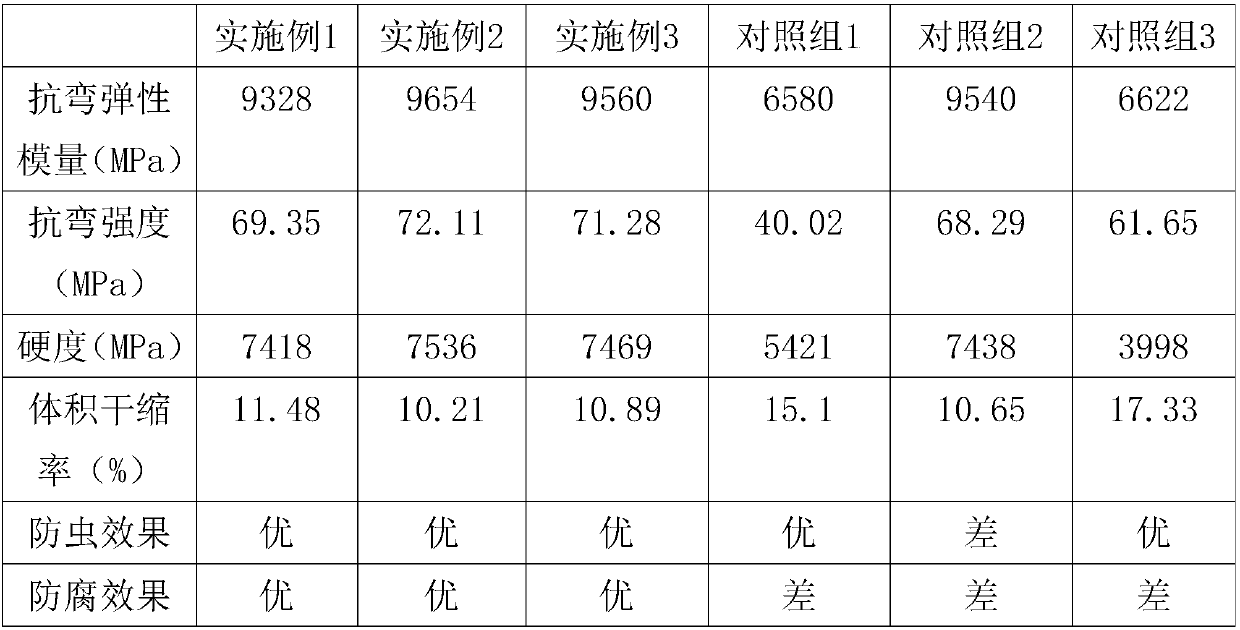

Examples

Embodiment 1

[0026] A kind of spraying technology of wood surface, comprises the following steps:

[0027] (1) Rotate the bought logs into the same size and length, spray the wood with clear water once every other day, put it in a cool and ventilated place to dry after spraying, and treat it for 5 days in total;

[0028] (2) putting the wood after the spraying treatment into the antiseptic solution for cooking, slowly heating to the temperature of the antiseptic solution to 65 degrees, and cooking for 3 hours with heat preservation;

[0029] (3) After the cooking is completed, continue to soak the wood in the preservative solution and cool it to room temperature, and then ultrasonically treat the preservative solution and the wood with an ultrasonic wave, and the processing power is 400W;

[0030] (4) Carry out hot air circulation drying treatment to the wood that has been ultrasonically treated, and the drying temperature is 130-150 degrees, so that the moisture content of the wood after ...

Embodiment 2

[0042] A kind of spraying technology of wood surface, comprises the following steps:

[0043] (1) Rotate the bought logs into the same size and length, spray the wood with clear water once every other day, put it in a cool and ventilated place to dry after spraying, and treat it for 6 days in total;

[0044] (2) put the sprayed wood into the preservative solution for cooking, slowly heat to the temperature of the preservative solution to 70 degrees, and heat-preserve and cook for 4 hours;

[0045] (3) After the cooking is completed, continue to put the wood in the preservative solution to soak and cool to room temperature, and then ultrasonically treat the preservative solution and the wood with an ultrasonic wave, and the processing power is 500W;

[0046] (4) Carry out hot air circulation drying treatment to the wood that has been ultrasonically treated, and the drying temperature is 140 degrees, so that the moisture content of the wood after drying is controlled at 12%;

[0...

Embodiment 3

[0058] A kind of spraying technology of wood surface, comprises the following steps:

[0059] (1) Rotate the bought logs into the same size and length, spray the wood with clear water once every other day, put it in a cool and ventilated place to dry after spraying, and treat it for 6 days in total;

[0060] (2) putting the wood after the spraying treatment into the preservative solution for cooking, slowly heating to the temperature of the preservative solution to 70 degrees, and cooking for 5 hours with heat preservation;

[0061] (3) After the cooking is completed, continue to soak the wood in the preservative solution and cool it to room temperature, and then ultrasonically treat the preservative solution and the wood with an ultrasonic wave, and the processing power is 600W;

[0062] (4) Carry out hot air circulation drying treatment to the wood that has been ultrasonically treated, and the drying temperature is 150 degrees, so that the moisture content of the wood after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com