Multi-layer board integral hot pressing process

A hot-pressing process and multi-layer board technology, which is applied in decorative arts, painting tools, manufacturing tools, etc., can solve the problems of high price of solid wood boards, difficulty in mass promotion, unfavorable environmental protection, etc., and achieve good bonding effect and good release effect , the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

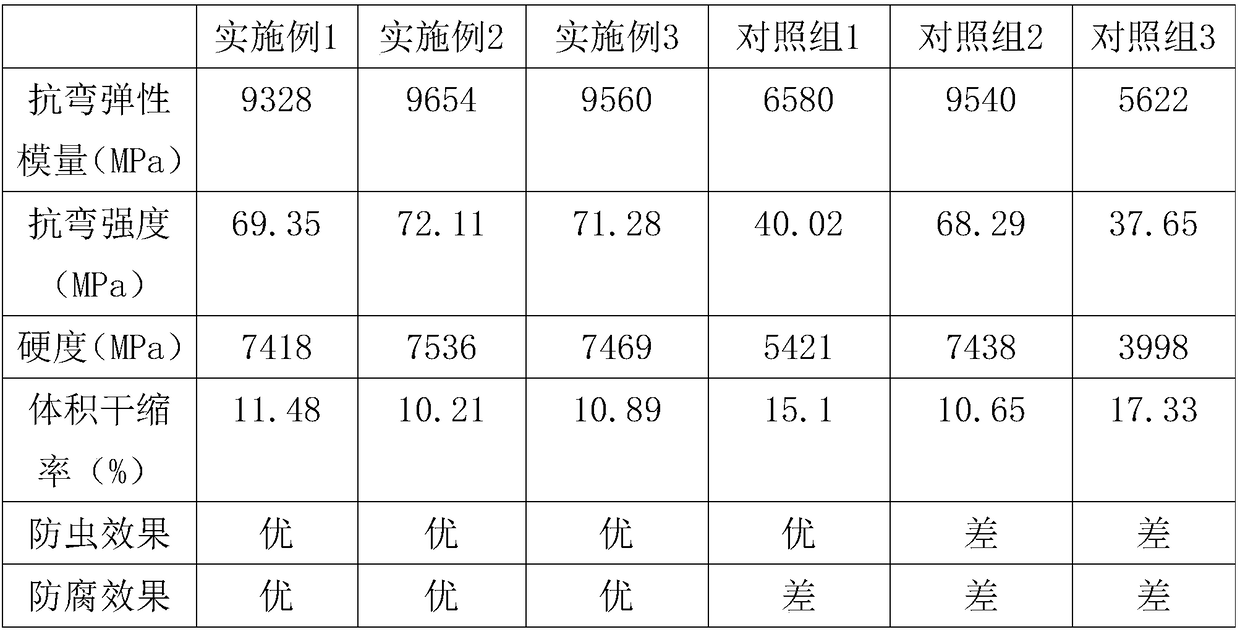

Examples

Embodiment 1

[0026] An overall hot pressing process for multilayer boards, including the following steps:

[0027] (1) Rotate the purchased logs into 5mm thick boards, spray the boards with clean water, spray once every other day, and place them in a cool and ventilated place to dry after spraying for a total of 5 days;

[0028] (2) Put the spray-treated board into the antiseptic solution for cooking, slowly heat it until the temperature of the antiseptic solution reaches 65 degrees, and keep it warm for 3 hours;

[0029] (3) After the cooking is completed, continue to immerse the board in the antiseptic solution to cool to room temperature, and then ultrasonically treat the antiseptic solution and the board with a processing power of 400W;

[0030] (4) Carry out hot air circulation drying treatment on the ultrasonically processed panels, and the drying temperature is 130 degrees, so that the moisture content of the dried panels is controlled at 8%;

[0031] (5) Pass the dried plate through the gap ...

Embodiment 2

[0042] An overall hot pressing process for multilayer boards, including the following steps:

[0043] (1) Rotary cut the purchased logs into 4mm thick boards, spray the boards with clean water, spray every other day, and dry them in a cool and ventilated place for a total of 6 days after spraying;

[0044] (2) Put the spray-treated board into the antiseptic solution for cooking, slowly heat it to the temperature of the antiseptic solution to 68 degrees, and keep it warm for 4 hours;

[0045] (3) After the cooking is completed, continue to soak the board in the antiseptic solution to cool to room temperature, and then ultrasonically treat the antiseptic solution and the board with a processing power of 500W;

[0046] (4) Carry out hot air circulation drying treatment on the ultrasonically processed panels, the drying temperature is 140 degrees, so that the moisture content of the panels after drying is controlled at 12%;

[0047] (5) Pass the dried plate through the gap between the disch...

Embodiment 3

[0058] An overall hot pressing process for multilayer boards, including the following steps:

[0059] (1) Rotary cut the purchased logs into 3mm thick boards, spray the boards with clean water, spray once every other day, and put them in a cool and ventilated place to dry after spraying for a total of 6 days;

[0060] (2) Put the spray-treated board into the antiseptic solution for cooking, slowly heat it to the temperature of the antiseptic solution to 70 degrees, keep it warm and cook for 5 hours;

[0061] (3) After the cooking is completed, continue to soak the board in the antiseptic solution to cool to room temperature, and then ultrasonically treat the antiseptic solution and the board with an ultrasonic treatment power of 600W;

[0062] (4) Carry out hot-air circulation drying treatment on the ultrasonically processed panels, and the drying temperature is 150 degrees, so that the moisture content of the dried panels is controlled at 14%;

[0063] (5) Pass the dried plate through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com