Method for preparing carbon fiber precursor by employing sodium thiocyanate through dry and wet spinning process

A carbon fiber precursor, dry-wet spinning technology, applied in the direction of spinning solution preparation, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem that it is difficult to meet the requirements of high concentration and high viscosity of spinning stock solution, low viscosity of stock solution , low solvency and other problems, to achieve the effect of high quality, high strength, and small dispersion of the original silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

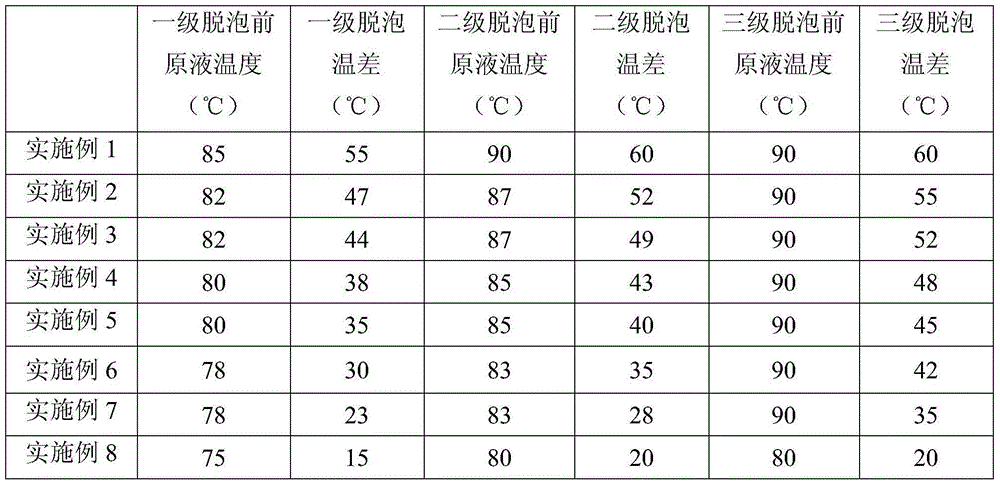

[0028] With 51.5wt% aqueous sodium thiocyanate as solvent, the polymerized monomers include acrylonitrile (AN), the second monomer methyl acrylate (MA) and the third monomer itaconic acid (ITA). The feed mass ratio is 97:2:1. In the system, azobisisobutyronitrile is used as the initiator, and the addition amount is 0.25wt% of the total mass of polymerized monomers. Isopropanol is used as a molecular weight regulator, and the added amount is 4.5 wt% of the total mass of polymerized monomers. With thiourea dioxide as the light coloring agent, the addition amount is 0.3wt% of the total mass of polymerized monomers. The above mixture is polymerized at 78-80°C, and the reaction time is 2 hours. The obtained polymerization stock solution enters the vacuum falling-film type high-efficiency single-removal column for single removal. The crude stock solution after single removal is preheated After reaching 80°C, the order was removed for the second time. The original liquid after the ...

Embodiment 9~16

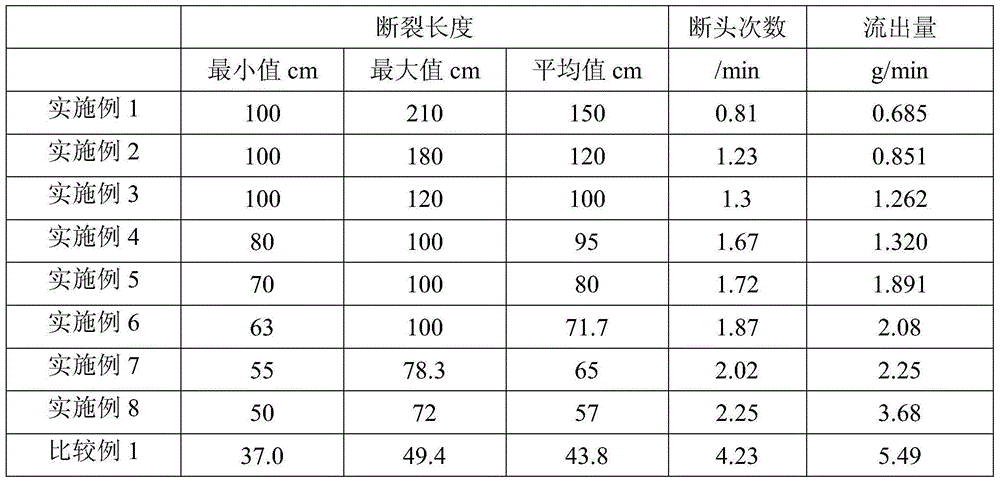

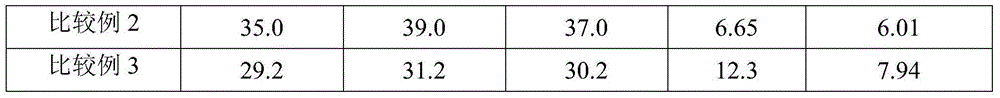

[0043] The spinning dope of Examples 1 to 8 were respectively spun, and the specific steps were as follows:

[0044] (1) The stock solution obtained in Examples 1 to 8 was adjusted in temperature and pressure, and supplied to the spinning assembly in the heat preservation for extrusion spinning. The adjusted temperature was 10-50℃, the pressure was 1.0-2.0MPa, and the spinning The heat preservation temperature of the components is the same as the temperature of the spinning dope, which is 10~50℃;

[0045] (2) The spinning dope is extruded from the spinneret, passes through an air layer of about 1-10 mm, and then enters into a NaSCN aqueous solution with a concentration of 0-10% by weight and a temperature of 0-10°C to solidify and form. The thin stream of raw liquid extruded from the spinneret is stretched 0.2-1.1 times in the air layer;

[0046] (3) The thread from the coagulation bath is air drawn, washed with water, drawn in boiling water, oiled, densified, steam drawn, dried, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com