Quick opening and closing mechanism for horizontal type pressure container

A pressure vessel and opening and closing mechanism technology, applied in the field of pressure vessels, can solve the problems of inability to transplant horizontal pressure vessels, troublesome installation and use, complex overall structure, etc., and achieve reliable locking, simplified overall structure, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

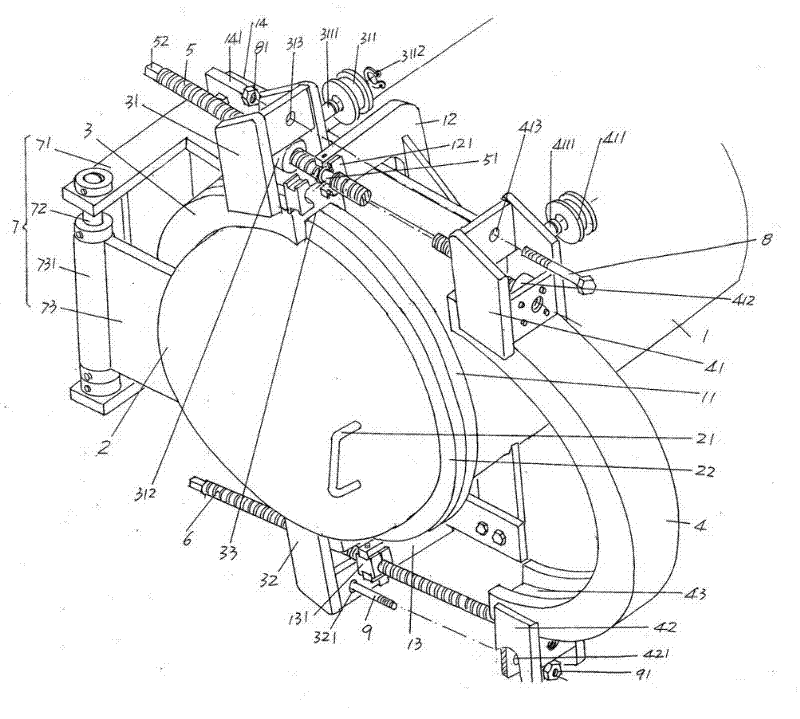

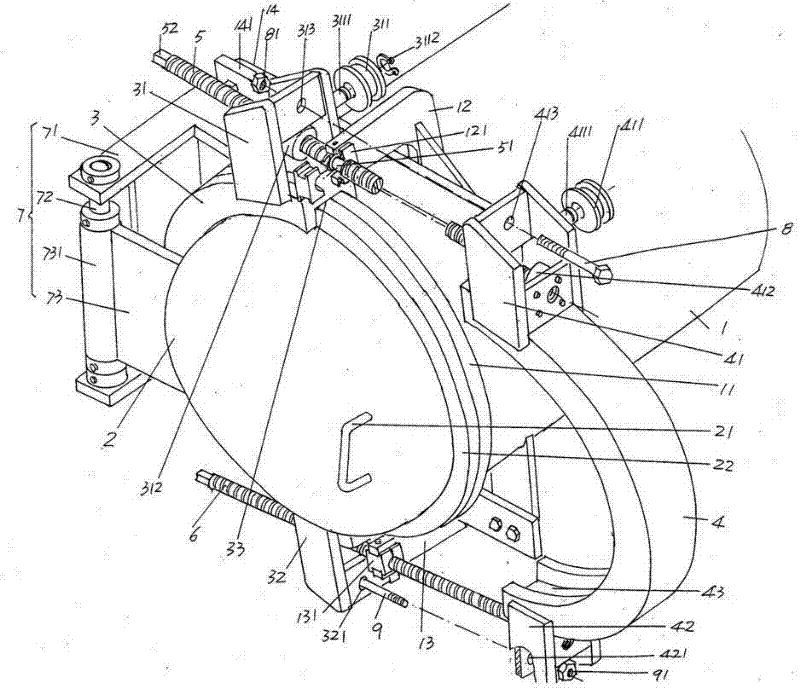

[0018] See figure 1 , provides a cylinder 1, the cylinder 1 is the body of the pressure vessel tank, on the side of the cylinder 1 facing the cover 2, that is, expanding outward in the circumferential direction of the opening of the cylinder 1 to form a Cylinder flange 11, and a first two-way screw support frame 12 is fixed on the outer wall of the cylinder body 1. The overall shape of the first two-way screw support frame 12 is a 7-shaped. A first screw seat 121 is fixed on it. In addition, a guide rail fixing plate 14 is fixed on the cylinder body 1 at a position accompanying the first two-way screw support frame 12 , and a guide rail 141 is fixed on the guide rail fixing plate 14 . And, a second two-way screw support frame 13 is fixed on the cylinder body 1, and the second two-way screw support frame 13 is separated from the first two-way screw support frame 12 by 180° (taking the circumferential direction of the cylinder body 1 as an example). A second screw seat 131 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com