High-performance gate valve

A high-performance, gate valve technology, applied in the direction of valve details, valve devices, sliding valves, etc., can solve the problems of slow opening and closing speed, poor sealing performance of gate valves, etc., achieve fast opening and closing speed, good sealing performance, and improve opening and closing speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

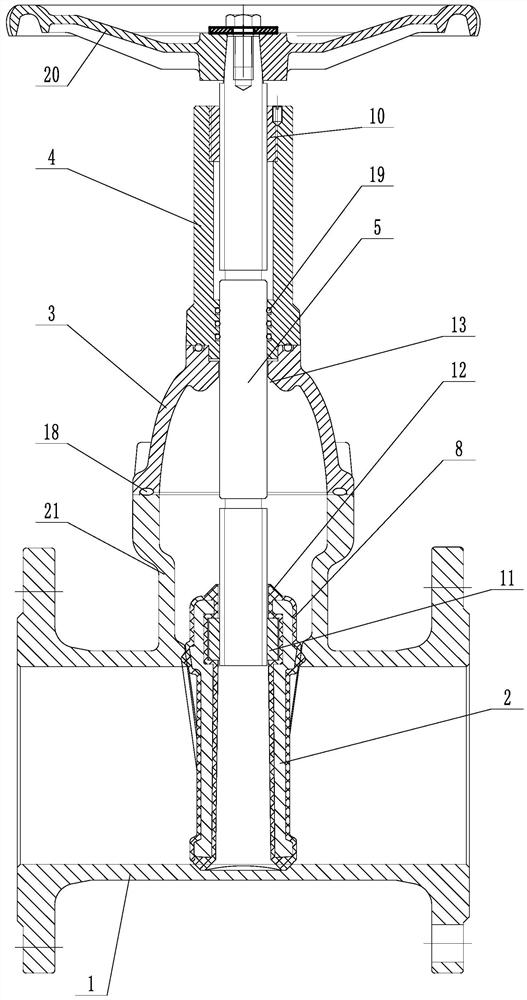

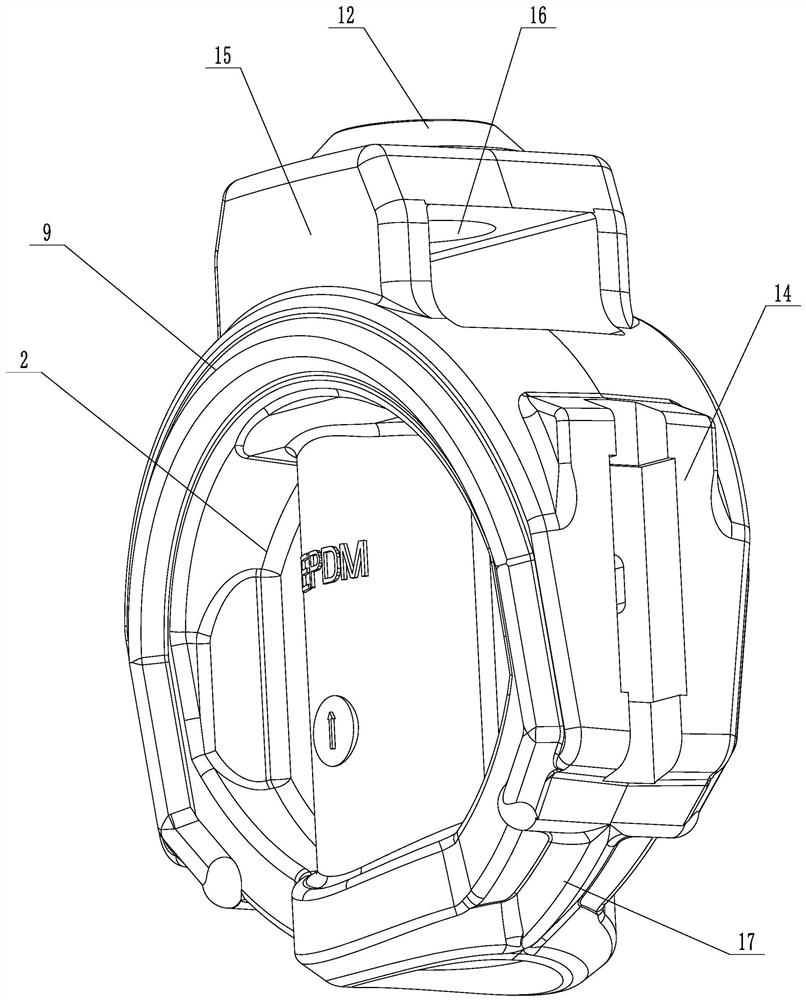

[0027] Embodiment 1: A kind of high-performance gate valve (see attached figure 1 , attached figure 2 , attached image 3 ), including valve body 1, gate plate 2, valve cover 3, bracket 4, the gate plate is adapted to be installed in the valve body, the valve cover is connected between the valve body and the bracket, the gate plate is connected to the valve stem 5, the valve body and the gate The corresponding position of the board is provided with a left sealing surface 6 and a right sealing surface 7. The outer surface of the gate is covered with a sealing layer 8. Both sides of the gate are provided with sealing protrusions 9. The two sealing protrusions are respectively sealed with the left sealing surface and the right sealing surface. The surface fits and seals; a bracket nut 10 is installed on the bracket, and a gate nut 11 is installed on the gate plate. The thread rotation direction of the bracket nut is opposite to that of the gate nut, and both the bracket nut and...

Embodiment 2

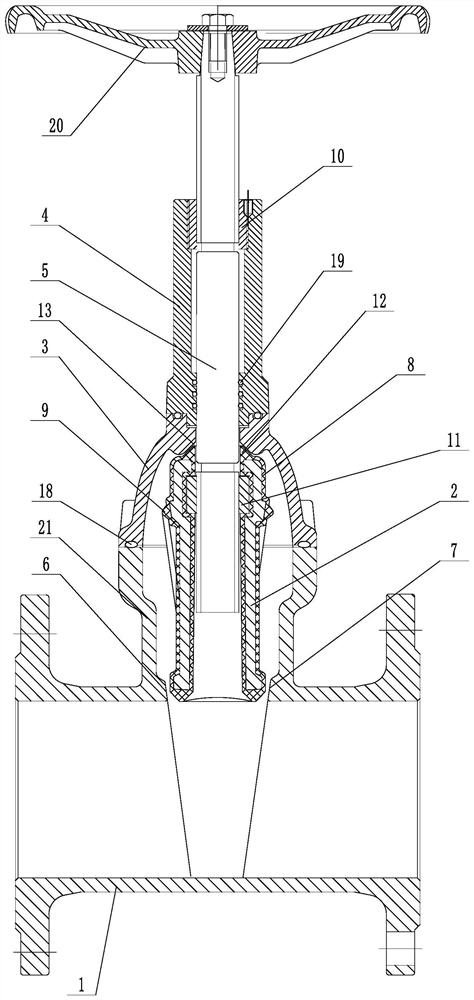

[0035] Embodiment 2: A kind of high-performance gate valve (see attached Figure 4 , attached Figure 5 , attached Image 6 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, a through hole is provided in the middle of the gate plate, the lower end of the valve stem is placed in the through hole, and a sealing boss 22 is provided on the inner wall of the valve corresponding to the through hole, A ring of sealing grooves 23 is provided on the edge of the sealing boss on the inner wall of the valve, and a chamfer 24 is provided at the opening of the lower end of the through hole. 25. The section of the sealing protruding ring is V-shaped, the chamfer closely fits on the surface of the sealing boss, and the sealing protruding ring closely fits in the sealing groove. A positioning column 26 is arranged on the sealing boss, and the lower part of the positioning column is rotated to install a swivel sleeve 27. The upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com