Organic waste gas-smoke channel switching equipment and channel switching method

A technology of flue gas passage and organic waste gas, which is applied in the combustion method, lighting and heating equipment, combustion type, etc., can solve the problem of unreasonable setting of flue gas-exhaust gas passage of two-chamber regenerative thermal oxidation furnace, rotary valve or tee Valve wear life, exhaust gas discharge, etc., to achieve the effect of continuous operation, good sealing, and fast switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

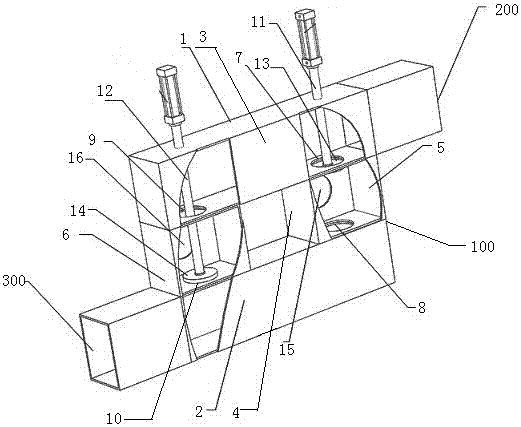

[0024] Such as figure 1 A device for switching between organic waste gas and flue gas channels is shown, including a body 100, which includes an upper gas channel 1, a lower gas channel 2, and a vertical channel 3, wherein one side of the upper gas channel is connected to the intake chamber 200, and the lower gas channel The other side is connected to the air outlet chamber 300 . The vertical passage is divided into the first vertical passage 5 and the second vertical passage 6 by the partition plate 4, the first vertical passage includes the first upper passage opening 7 arranged on the top, the first lower passage opening 8 arranged at the bottom, and the second vertical passage The channel includes a second upper channel port 9 arranged at the top, a second lower channel port 10 arranged at the bottom, a first hydraulic valve 11 is arranged between the upper gas channel and the first vertical channel, and the upper gas channel and the second vertical channel There is a sec...

Embodiment 2

[0031] A channel switching method of an organic waste gas-flue gas channel switching device. In Example 1, an organic waste gas-flue gas channel switching device, in the working state, the upper channel opening of the first vertical channel is closed and the lower channel opening is opened, The upper channel of the second vertical channel is opened and the lower channel is closed, so that the exhaust gas enters the second vent from the air inlet chamber, and then flows out from the first vent to the outlet chamber through the main body of the RTO equipment; when the valve is switched, the first vertical channel The upper channel is opened and the lower channel is closed, the upper channel of the second vertical channel is closed and the lower channel is opened, so that the exhaust gas enters the first vent from the air inlet chamber, and then flows out from the second vent to the outlet chamber through the main body of the RTO equipment ; Such reciprocating opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com