Double-locking trap

A trap and double-locking technology, applied in steam traps, mechanical equipment, etc., can solve the problems of insufficient locking force on the sealing surface, slow response speed of the floating ball, slow opening action, etc., to achieve improved sealing performance and simple structure , The effect of fast opening and closing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

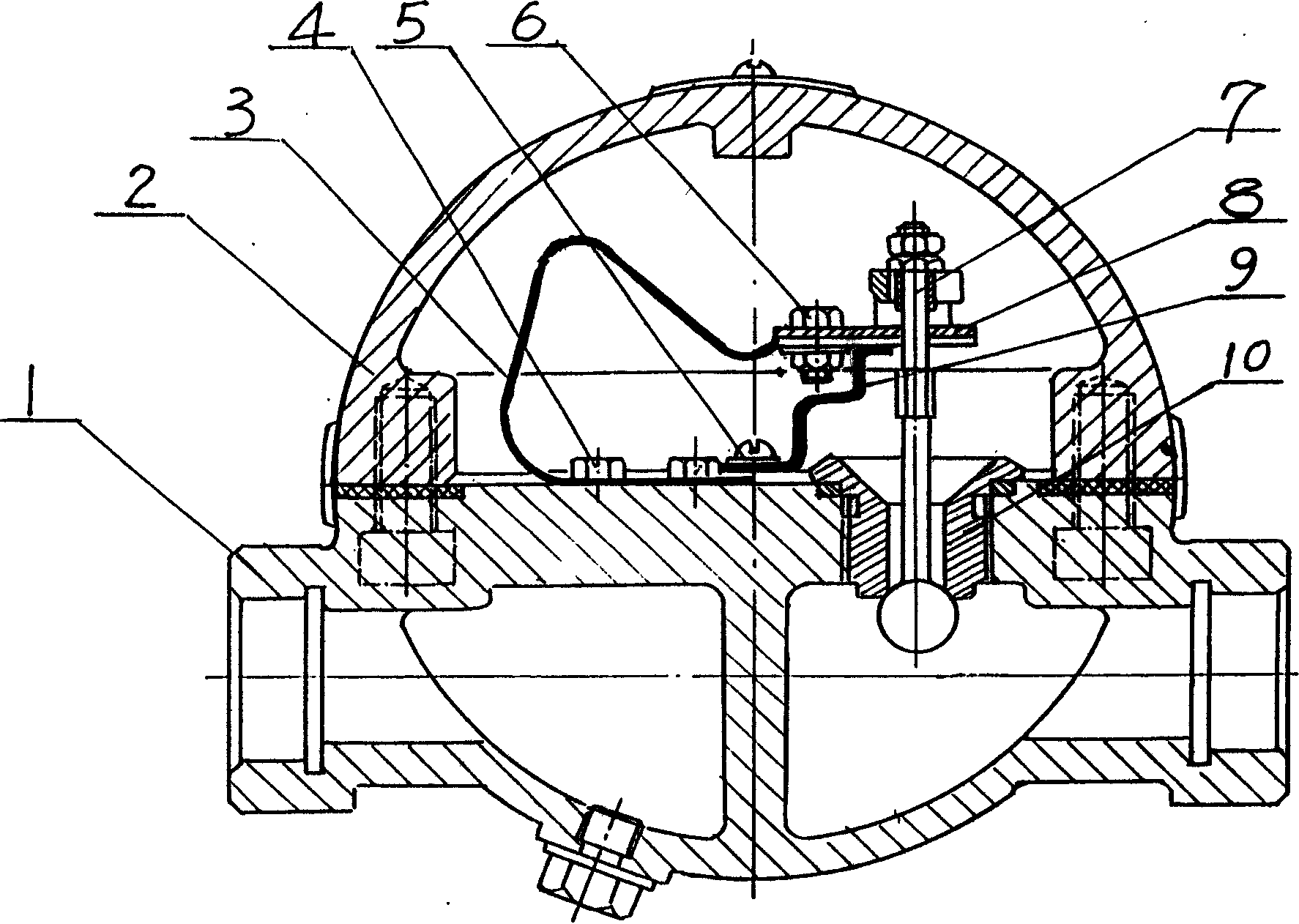

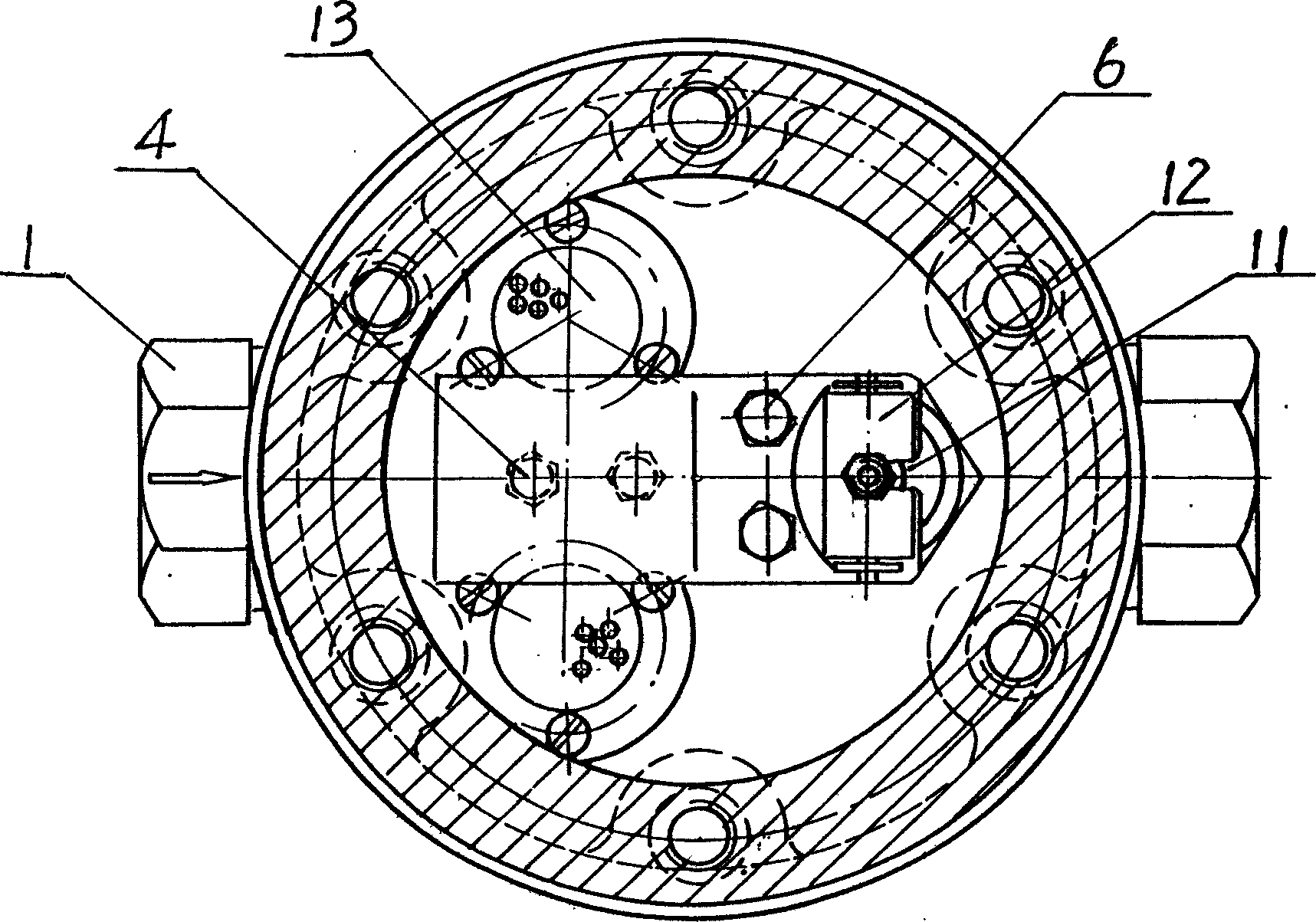

[0015] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0016] This embodiment is mainly composed of a valve body 1, a valve casing 2, a "C"-shaped composite metal sheet 3, a plane composite metal sheet 8, a support sheet 9, a valve core 7, and a valve seat 10. "C"-shaped composite metal sheet 3, flat composite metal sheet 8, support sheet 9, and valve core 7 are set in the valve chamber composed of valve body 1 and valve casing 2, and the valve seat 10 is placed in the valve body at the outlet of the valve chamber. 1, the valve core 7 is placed in the valve seat 10, and can move up and down in the valve seat 10. The upper end of the spool 7 and the flat composite metal sheet 8 are connected by a shifting fork, and the lower end of the spool 7 passes through the valve seat 10, so that the sealing surface formed between the spool 7 and the valve seat 10 is set on the valve seat. 10 The lower port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com