Anti-explosion container

A container and container body technology, which is applied in the direction of weapon accessories, ammunition storage, ammunition, etc., can solve the problems of large device mass and extensive design of anti-explosion containers, and achieve the effects of light weight, improved anti-explosion performance, and quick opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

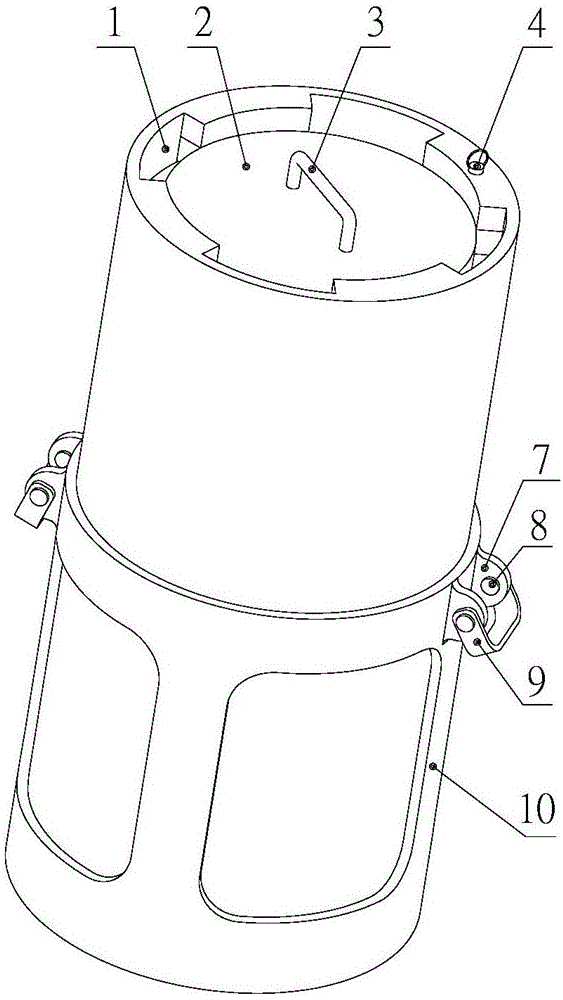

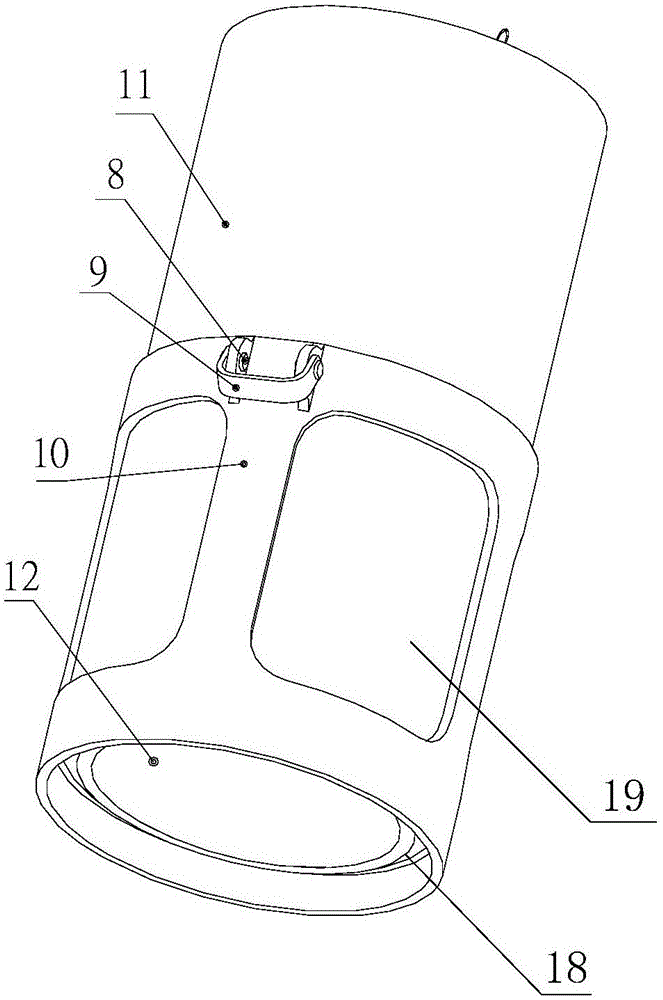

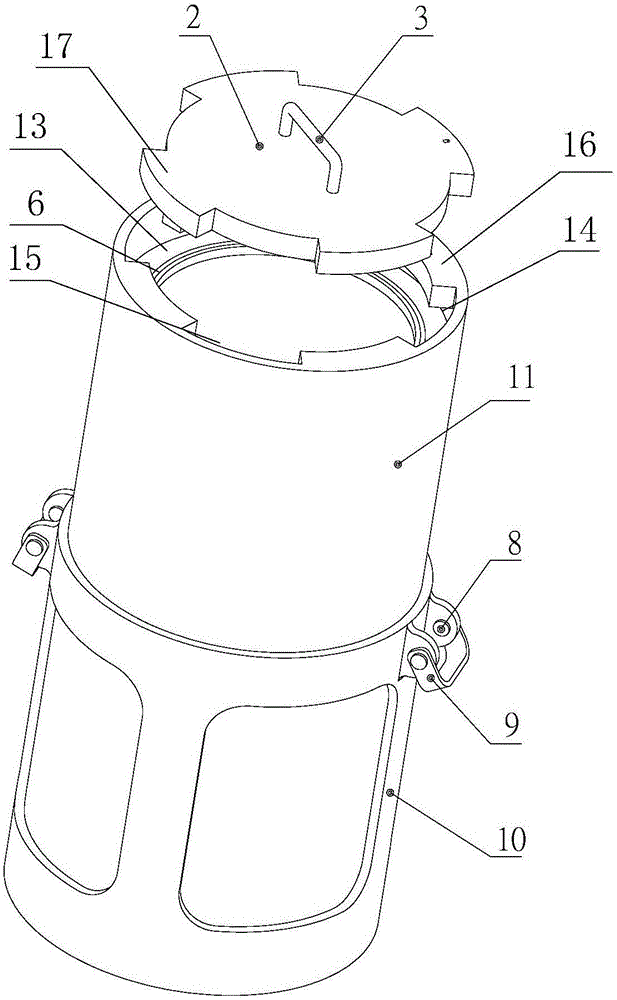

[0028] Such as Figure 1 to Figure 5 As shown, an anti-explosion container includes a container body and a peripheral support 10; the container body includes a shell 11, an end flange 1, a cover plate 2 and a head 12, and the end of the shell 11 is provided with a head 12 , the head 12 can be an ellipsoidal head, etc., the other end of the housing 11 is provided with an end flange 1, and the end flange 1 and the head 12 are preferably fixed on both ends of the housing 11 by welding, and the peripheral bracket 10 Set on the casing 11, the peripheral bracket 10 is inserted from one end of the casing 11 to the middle, and the explosion load of the anti-explosion container is controlled at the center of the container. The peripheral bracket 10 wraps the container body in a circumferential direction, which impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com