Flexible interlink steel gate and support opening/closing device thereof

A technology of opening and closing device and gate, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of inconvenient maintenance and maintenance, many rubber dam materials, unfavorable rapid opening and closing, etc., to save steel consumption, charge and discharge water, etc. The effect of small amount and avoiding vibration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

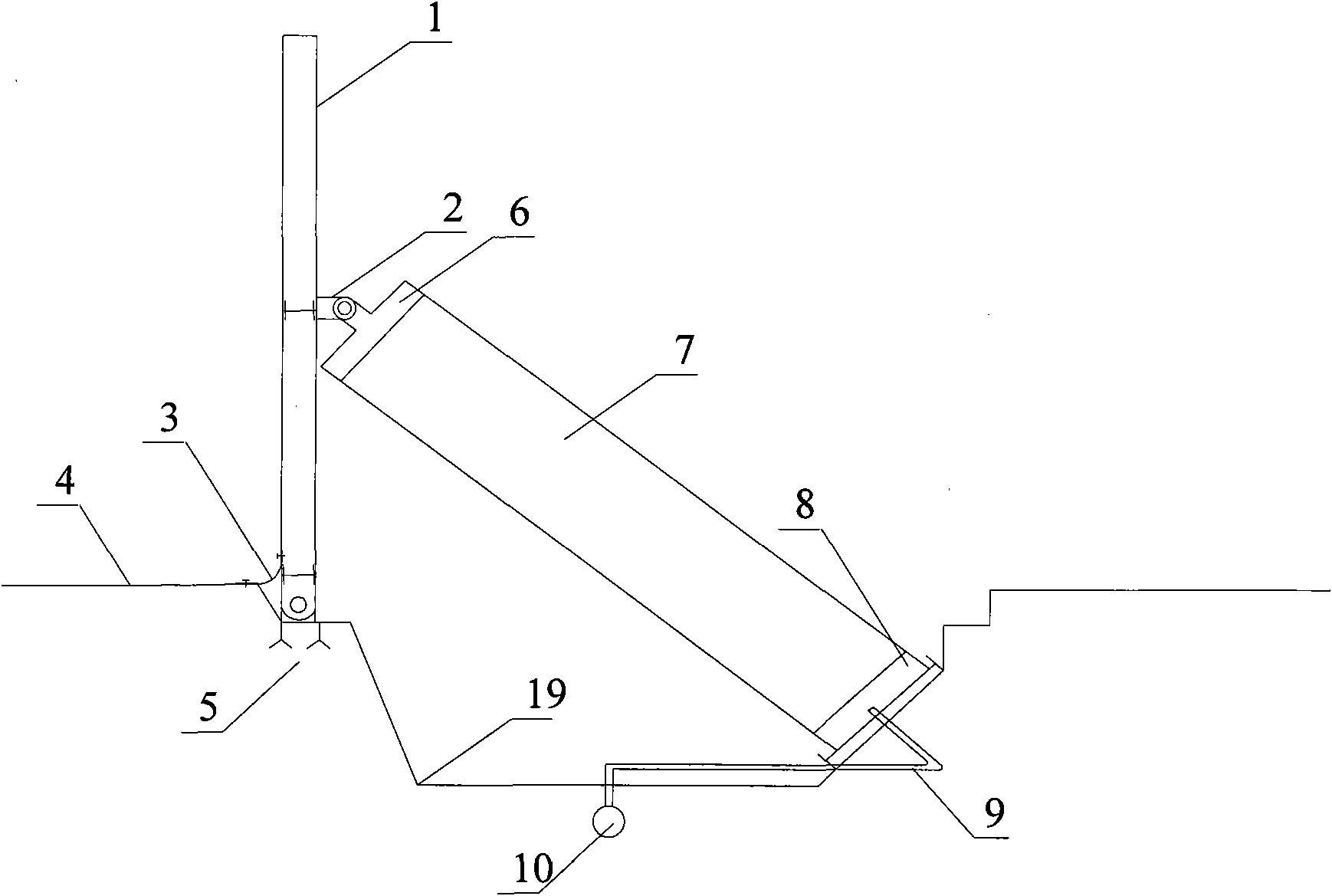

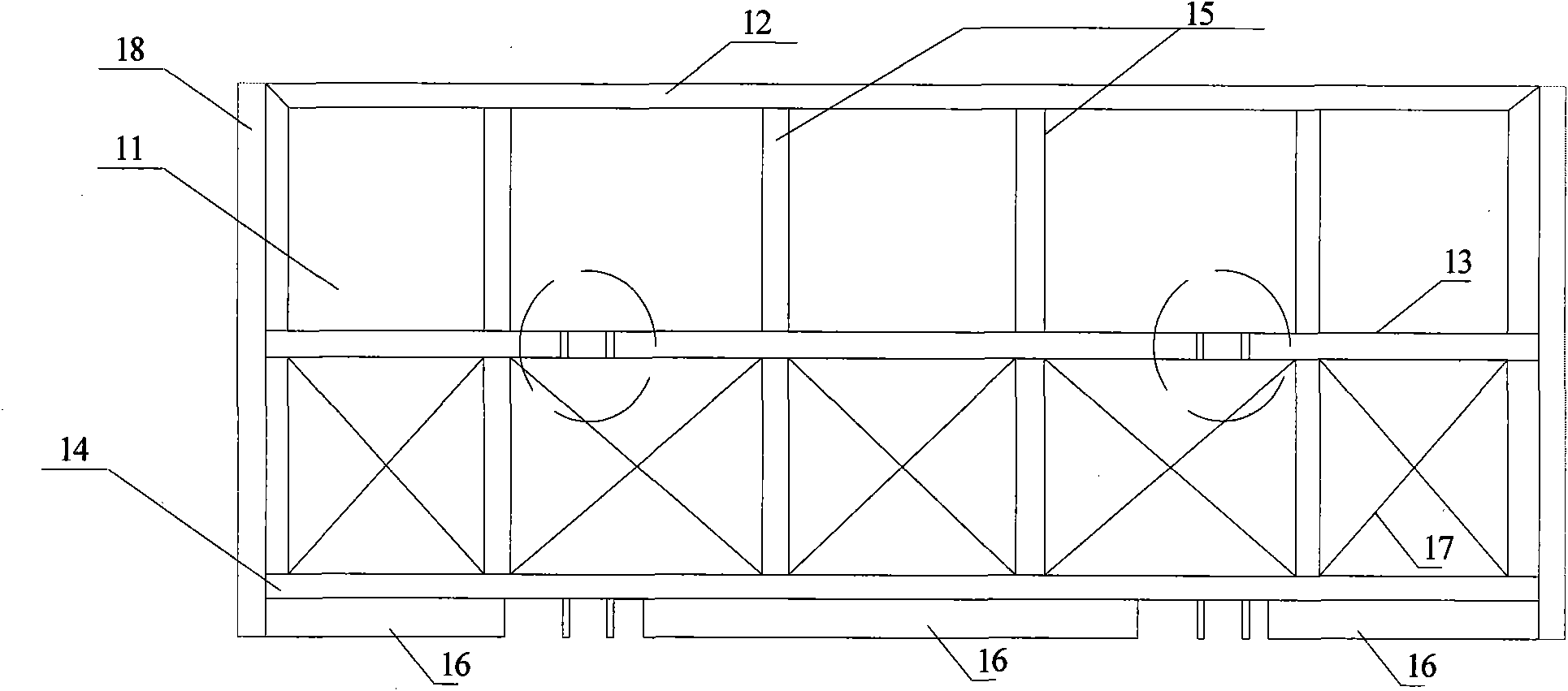

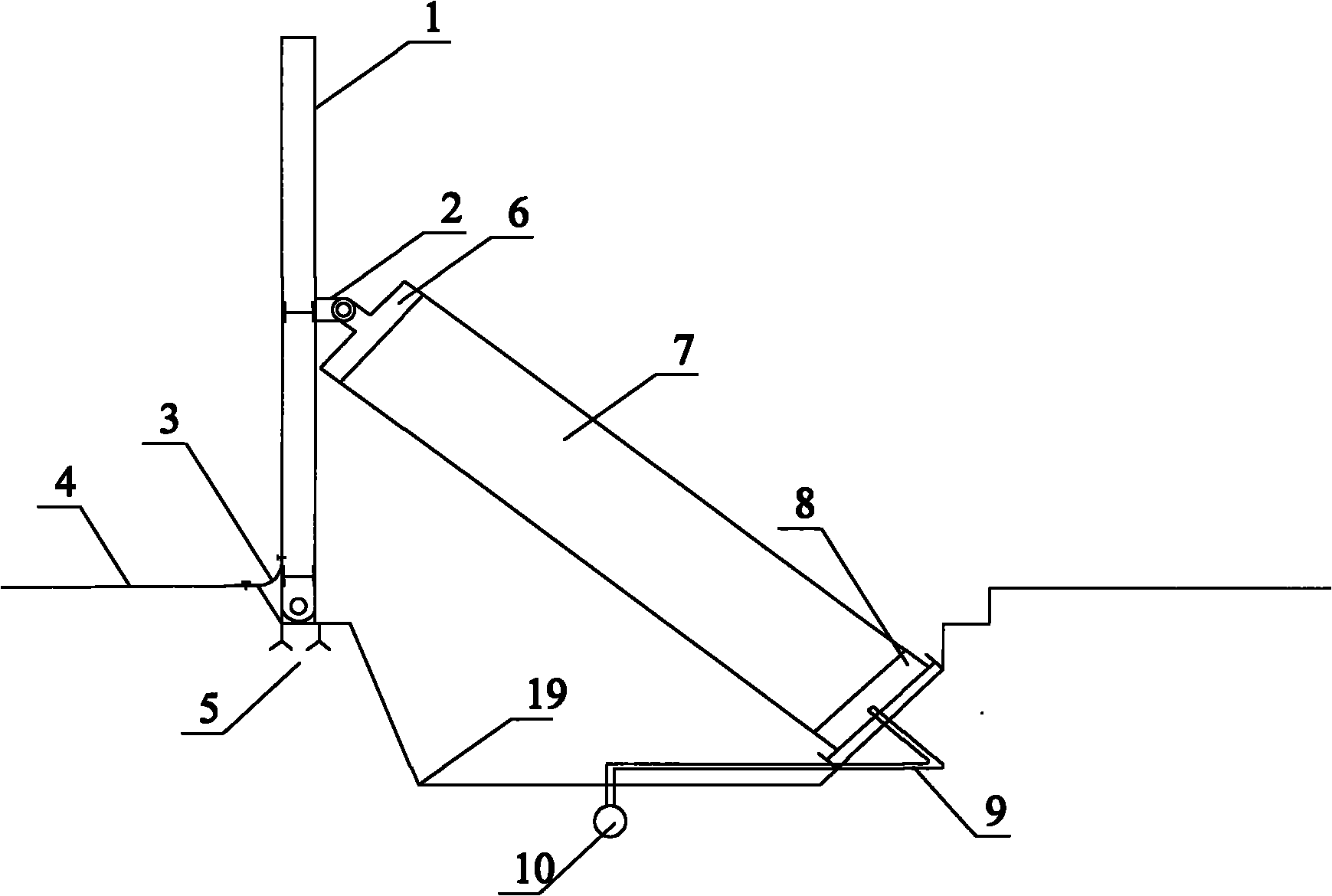

[0012] Such as figure 1 , figure 2 As shown, a series of thin steel gates supported by rubber bags for opening and closing are realized in the following manner: the gate is composed of an upper beam 12, a middle beam 13, a lower beam 14, a plurality of longitudinal beams 15, and cross beams 17. The grid system is welded with steel panels 11 and round steel pipes 16. Rubber waterstops 18 are installed on both sides of the gate through beading and bolts, and are connected to adjacent gates through rubber waterstops and buckles. If the adjacent gate is a pier , replace the rubber waterstop with a P-type waterstop, the bottom of the gate is connected to the bottom plate 4 through the loose leaf and the embedded part 5, and the rubber waterstop 3 is used to connect the gate and the bottom plate on the loose leaf, and the gate hinge 2 is connected to the cylinder rubber The upper flange 6 of the belt is connected, and the grooved flange 6 is socketed with the cylindrical rubber be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com