Gradient sandwiched anti-explosion pot

An explosion-proof tank, gradient type technology, applied in blasting and other directions, can solve the problems of heavy structure, heavy structure of explosion-proof tank, lack of flexibility and mobility, etc., to achieve good anti-explosion performance and reduce impact damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

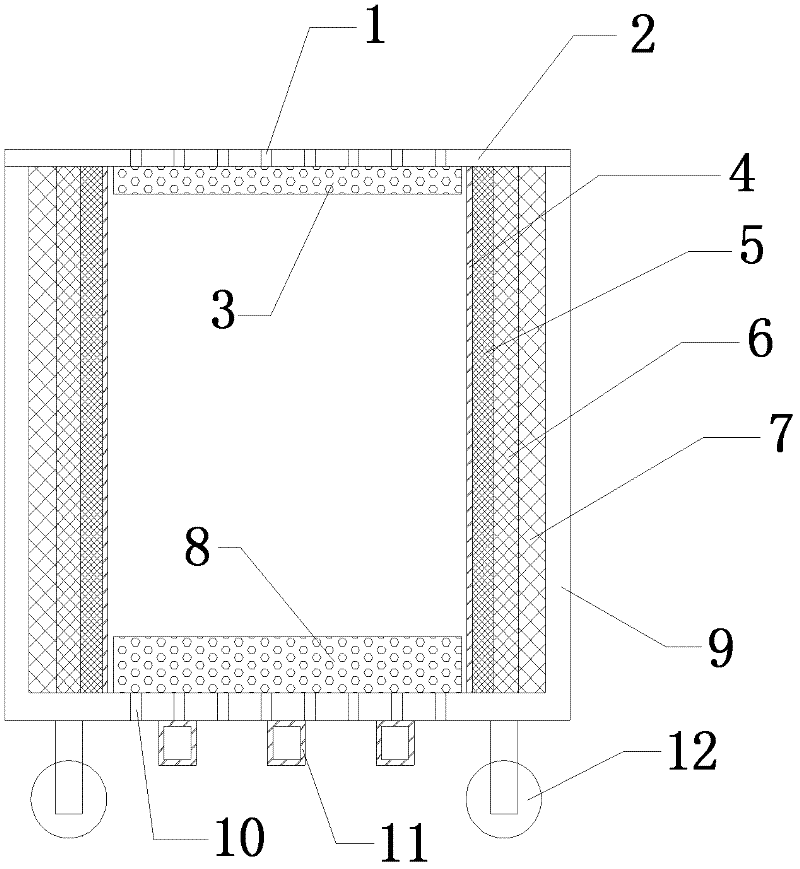

[0021] The structural principle and working principle of the present invention will be described in more detail below in conjunction with the accompanying drawings.

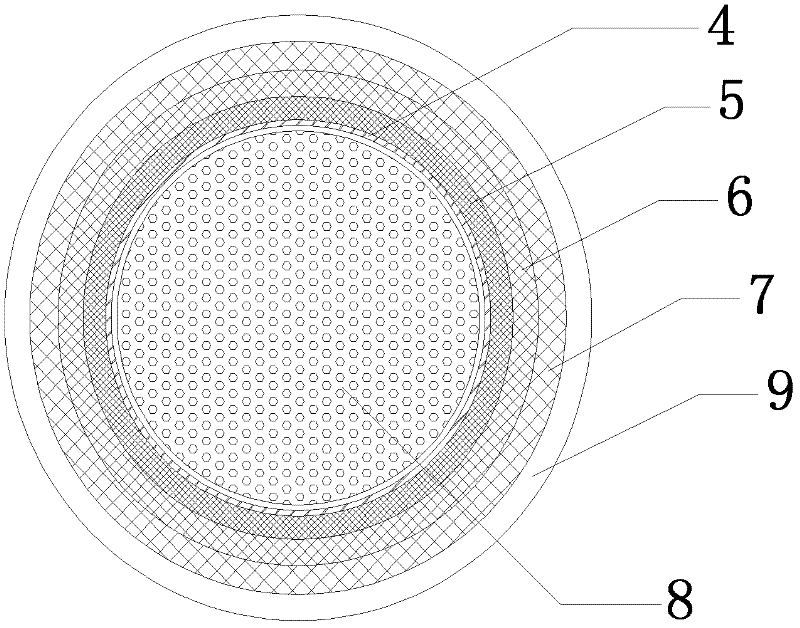

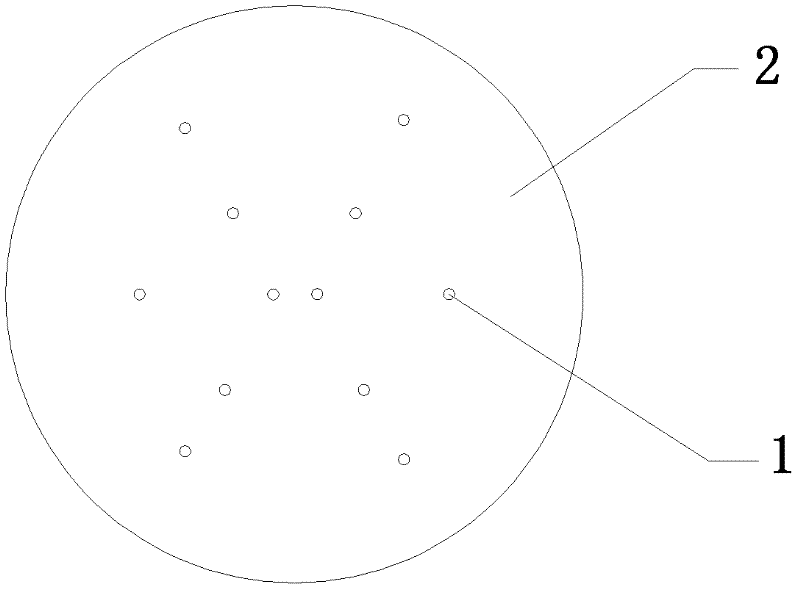

[0022] like figure 1 As shown, a gradient type sandwich explosion-proof tank of the present invention includes a cover plate pressure relief hole 1, a cover plate 2, a buffer lining plate 3, an inner cylinder 4, an inner buffer layer 5, a middle buffer layer 6, an outer buffer layer 7, Buffer plate 8, outer cylinder 9, outer cylinder pressure relief hole 10, reinforcing rib 11 and caster 12, cover plate 2 and buffer lining plate 3 form the top cover and cover plate pressure relief hole 1 is opened on the cover plate 2, and the inner The cylinder 4, the inner buffer layer 5, the middle buffer layer 6, the outer buffer layer 7 and the outer cylinder 9 form a tank body and have an outer cylinder pressure relief hole 10 on the bottom plate of the outer cylinder 9, and the inner buffer layer 5, the middle buffer layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com