Heat preservation exhaust pipe structure

A technology for exhaust pipes and exhaust manifolds, which is applied in the field of auto parts, can solve problems such as exhaust pipe rupture failure and limited shock absorption effect, achieve the effect of preventing rupture failure, preventing fracture failure, and meeting layout requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

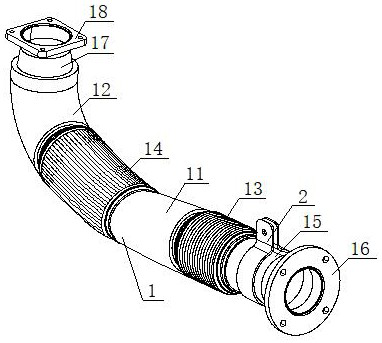

[0021] see figure 1 , a thermal insulation exhaust pipe structure The exhaust pipe 1 is an L-shaped structure, including a No. No. 1 thermal insulation pipe section 11 and No. 2 thermal insulation pipe section 12 are thermal insulation clad steel pipes. The manufacturing materials of the longitudinal high-frequency steel wire texture pipe section 13 and the transverse high-frequency steel wire texture pipe section 14 are all thermal insulation materials. The No. 1 thermal insulation pipe section 11 1. The longitudinal high-frequency steel wire pattern pipe section 13 is a straight pipe structure, and one end of the longitudinal high-frequency steel wire pattern pipe section 13 is connected with the engine exhaust manifold through the first welded steel pipe 15 and the circular French wheel disc 16 successively. The other end of the pipe section 13 is connected to one end of the horizontal high-frequency steel wire line pipe section 14 through the No. 1 thermal insulation pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com