Patents

Literature

42 results about "Avgas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Avgas (aviation gasoline, also known as aviation spirit in the UK) is an aviation fuel used in spark-ignited internal-combustion engines to propel aircraft. Avgas is distinguished from mogas (motor gasoline), which is the everyday gasoline used in motor vehicles and some light aircraft. Unlike mogas, which has been formulated since the 1970s to allow the use of platinum-content catalytic converters for pollution reduction, the most commonly used grades of avgas still contain tetraethyllead (TEL), a toxic substance used to prevent engine knocking (detonation), with ongoing experiments aimed at eventually reducing or eliminating the use of TEL in aviation gasoline.

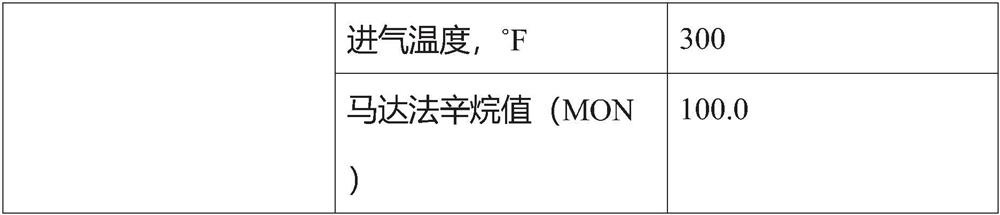

Lead-Free Aviation Fuel

Lead-free aviation fuel composition with a MON greater than 100, made up of a major component of a fuel made from Avgas and a minor component of at least two compounds from the group of esters of at least one mono-or poly-carboxylic acid and at least one mono- or polyol, anhydrides of a least one mono- or poly-carboxylic acid, preferably aromatic ethers at a level of at least 5% w / w and ketones at a level of more than 10% w / w.

Owner:TOTAL PUTEAUX FR

Renewable engine fuel

InactiveUS20080168706A1Efficient propulsion technologiesLiquid carbonaceous fuelsCarbon numberAlkane

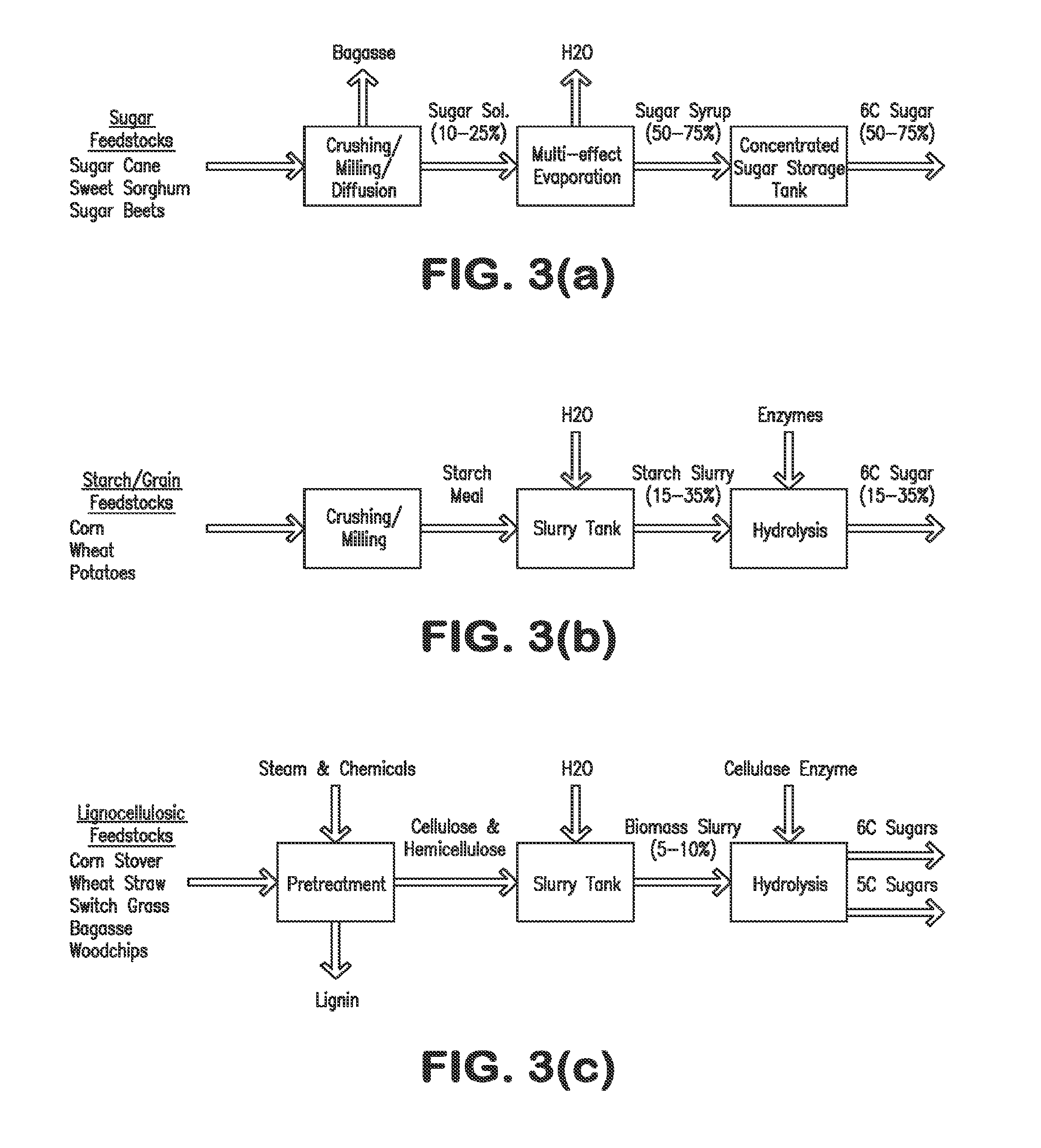

The present invention provides fully renewable engine fuels derived completely from biomass sources. The fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels.

Owner:SWIFT ENTERPRISES

Renewable Engine Fuel

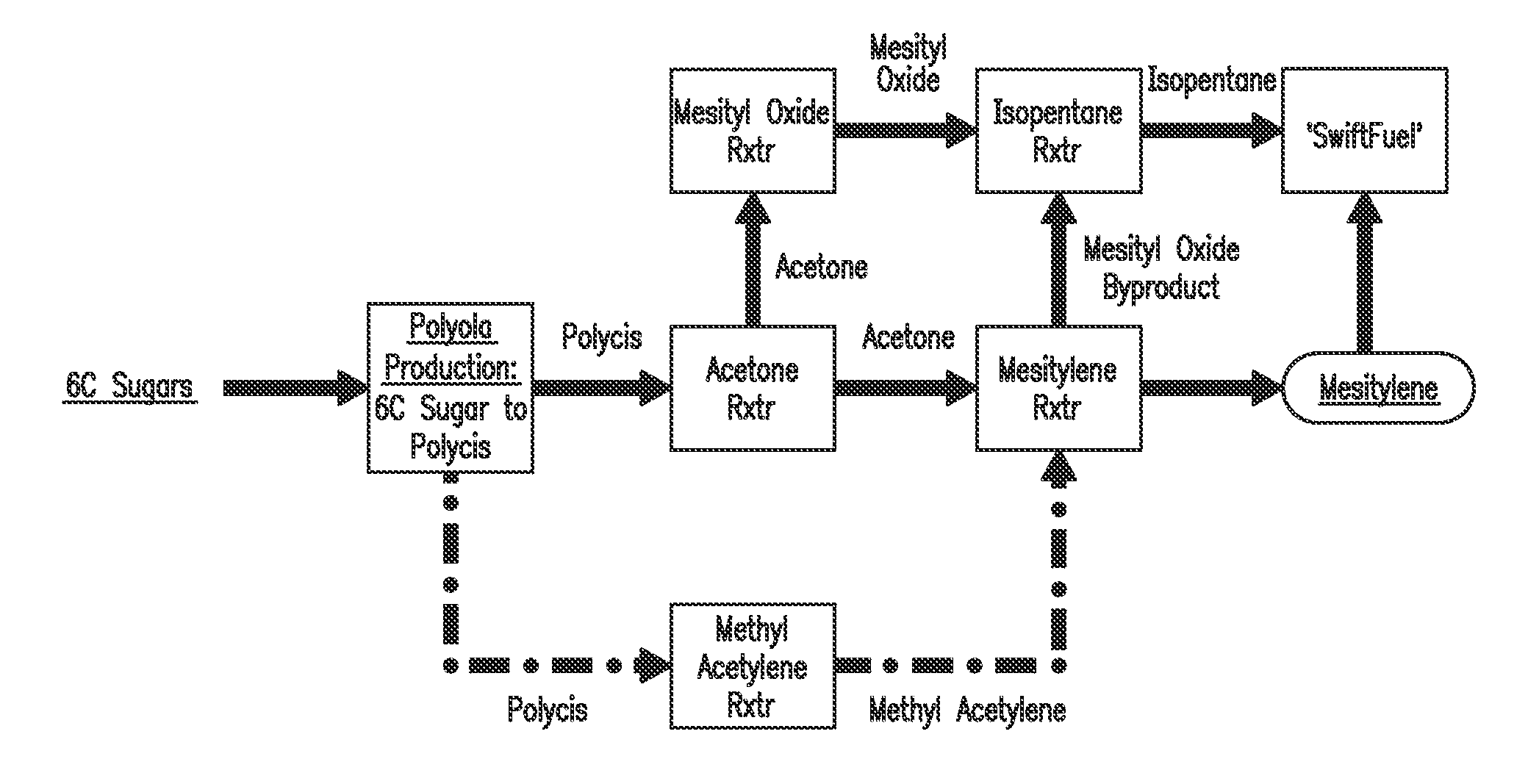

ActiveUS20080244961A1Boost octaneIncrease energy contentHydrocarbon purification/separationBiofuelsFuranCarbon number

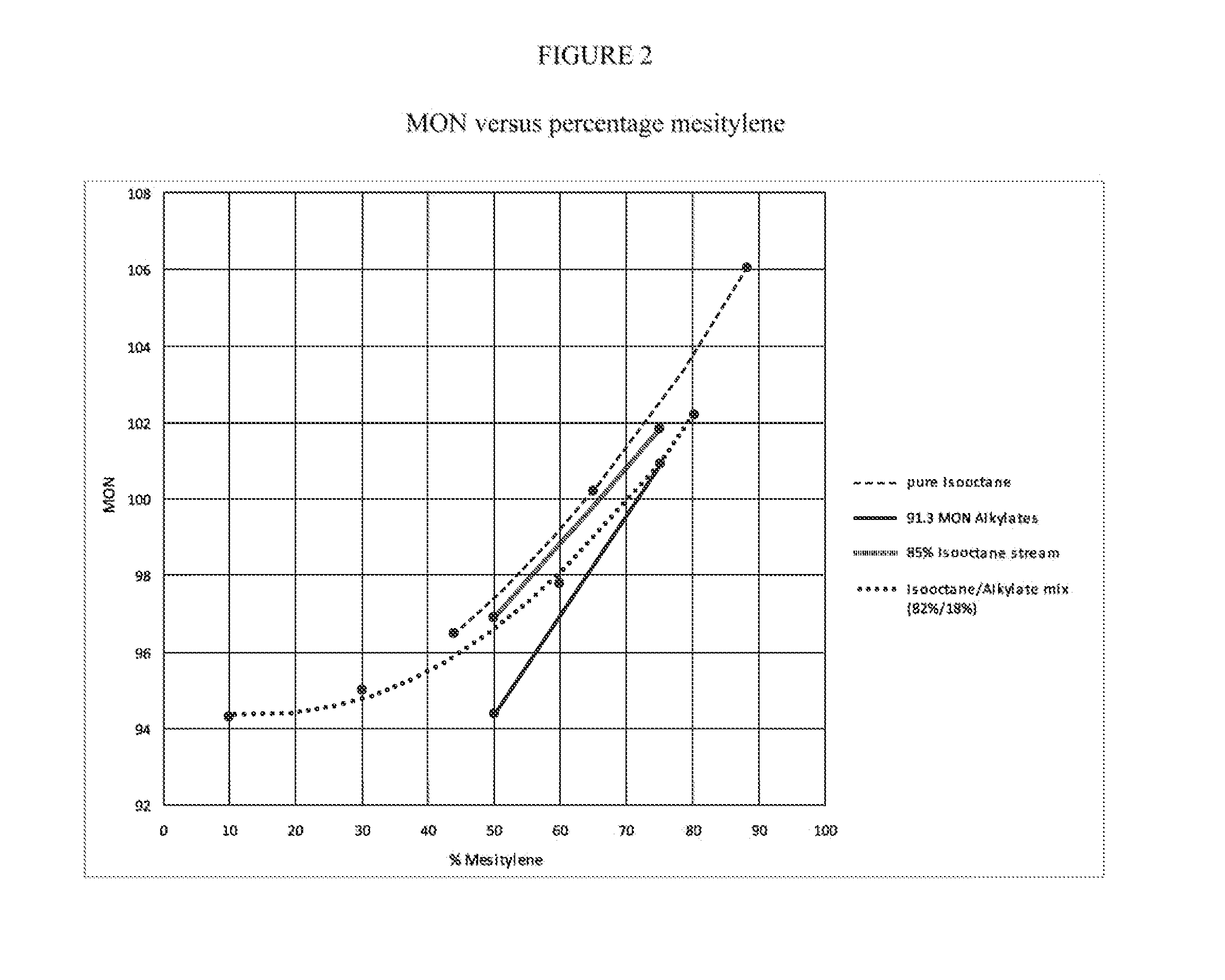

The present invention provides fully renewable engine fuels derived completely from biomass sources. In one embodiment the fully renewable engine fuel is comprised of one or more low carbon number esters, one or more pentosan-derivable furans, one or more aromatic hydrocarbon, one or more C4-C10 straight chain alkanes derivable from polysaccharides, and one or more bio-oils. In addition, the fuel may contain triethanolamine. Such a lower octane renewable fuel may be utilized, for example, in automobile fuel, 100 LL aviation fuel applications, and turbine engine applications. These ethanol-based, fully renewable fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high octane, rocket, diesel, and turbine engine fuels. In another embodiment, there is provided a synthetic high octane aviation fuel comprising isopentane and mesitylene, and process of producing same from a biomass.

Owner:SWIFT ENTERPRISES

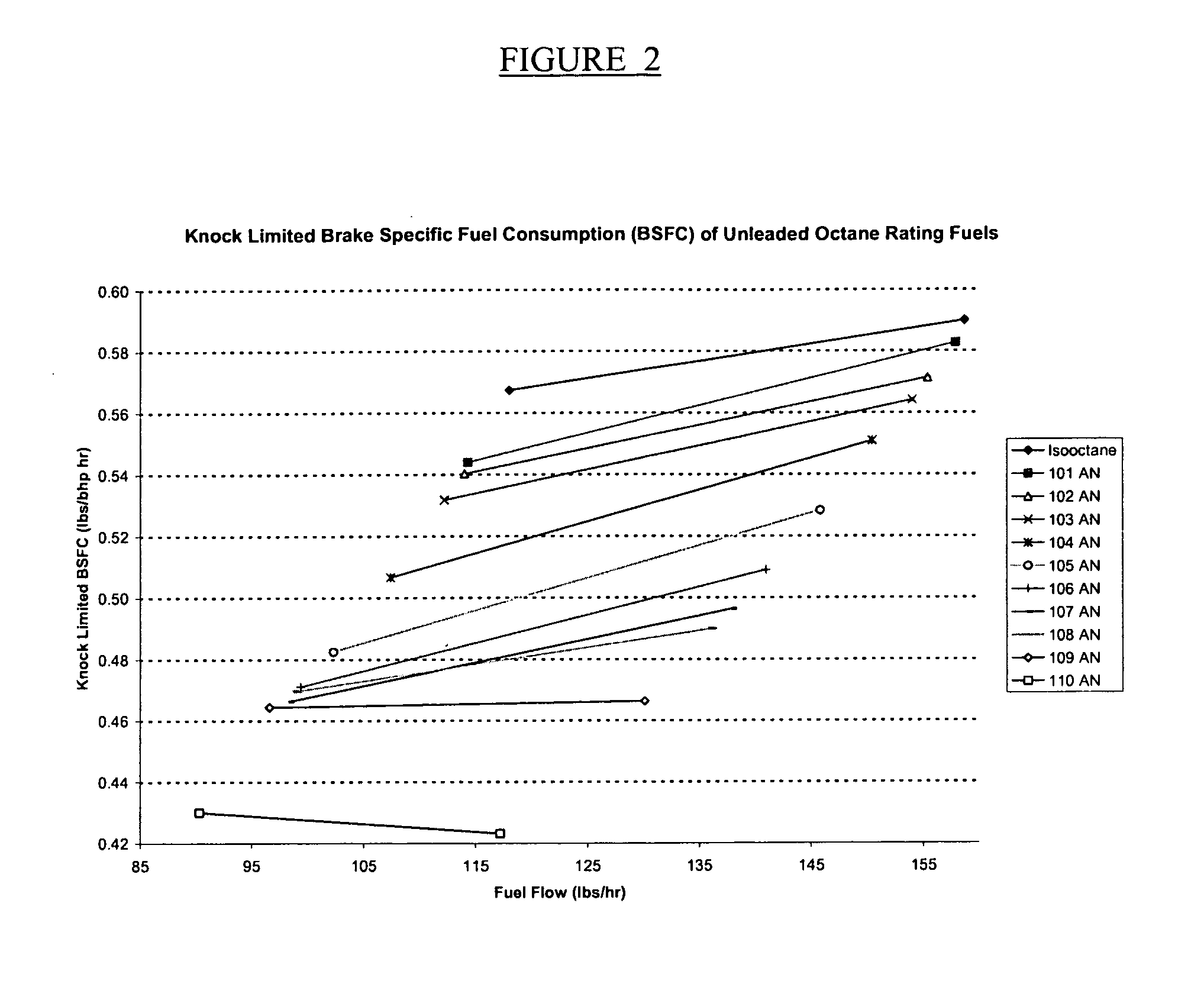

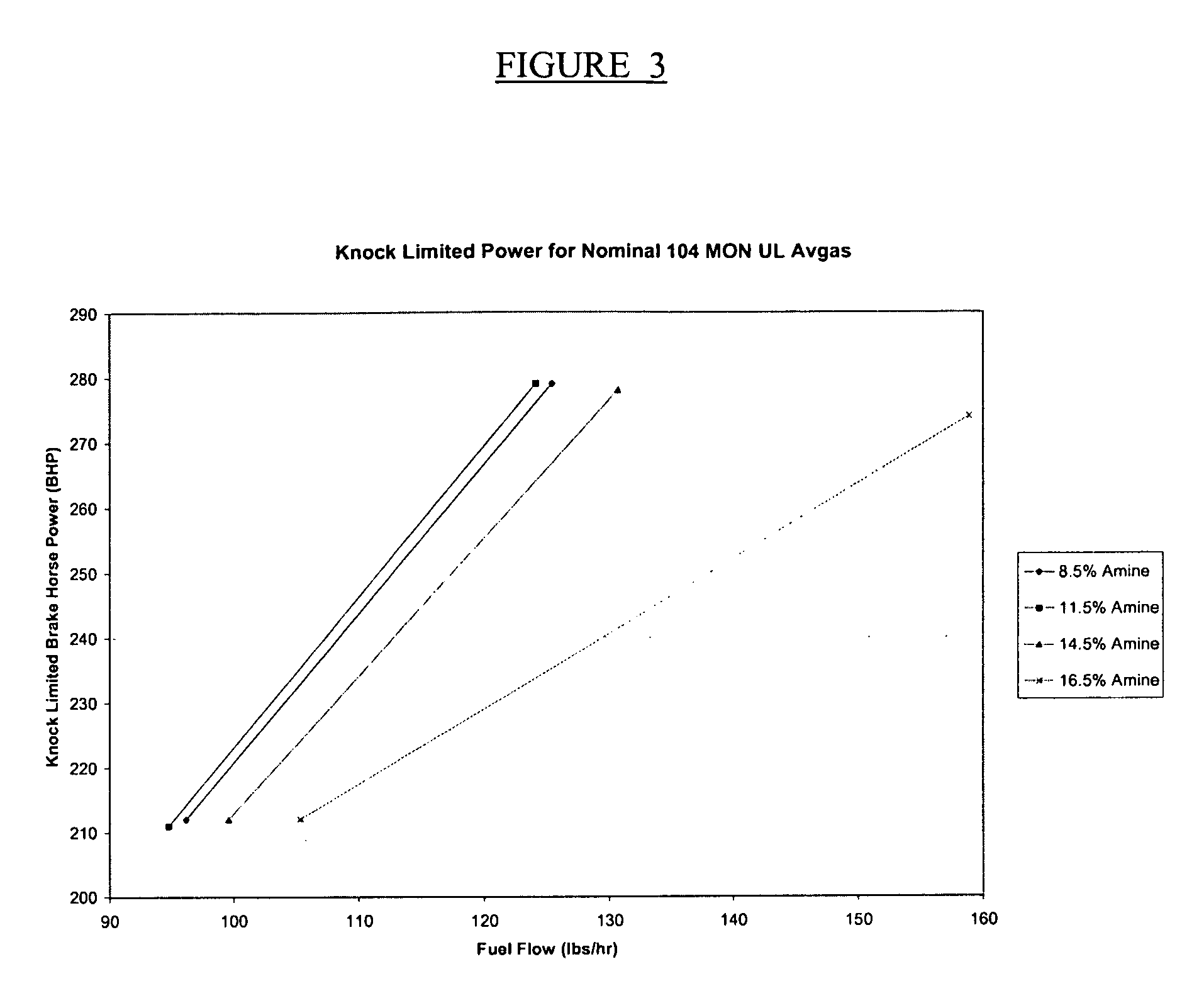

Unleaded aviation gasoline

The present invention relates to an aviation gasoline formed by blending (i) an unleaded base fuel having a base MON of at least 94, with (ii) at least one aromatic amine effective to provide the base fuel with a final MON of at least 100.

Owner:EXXON RES & ENG CO

Renewable engine fuel

Owner:SWIFT ENTERPRISES

Renewable engine fuel and method of producing same

ActiveUS8313540B2Avoid poisoningHydrocarbon from oxygen organic compoundsLiquid carbonaceous fuelsRocketPetroleum

Owner:SWIFT ENTERPRISES

Aviation gasoline formulation

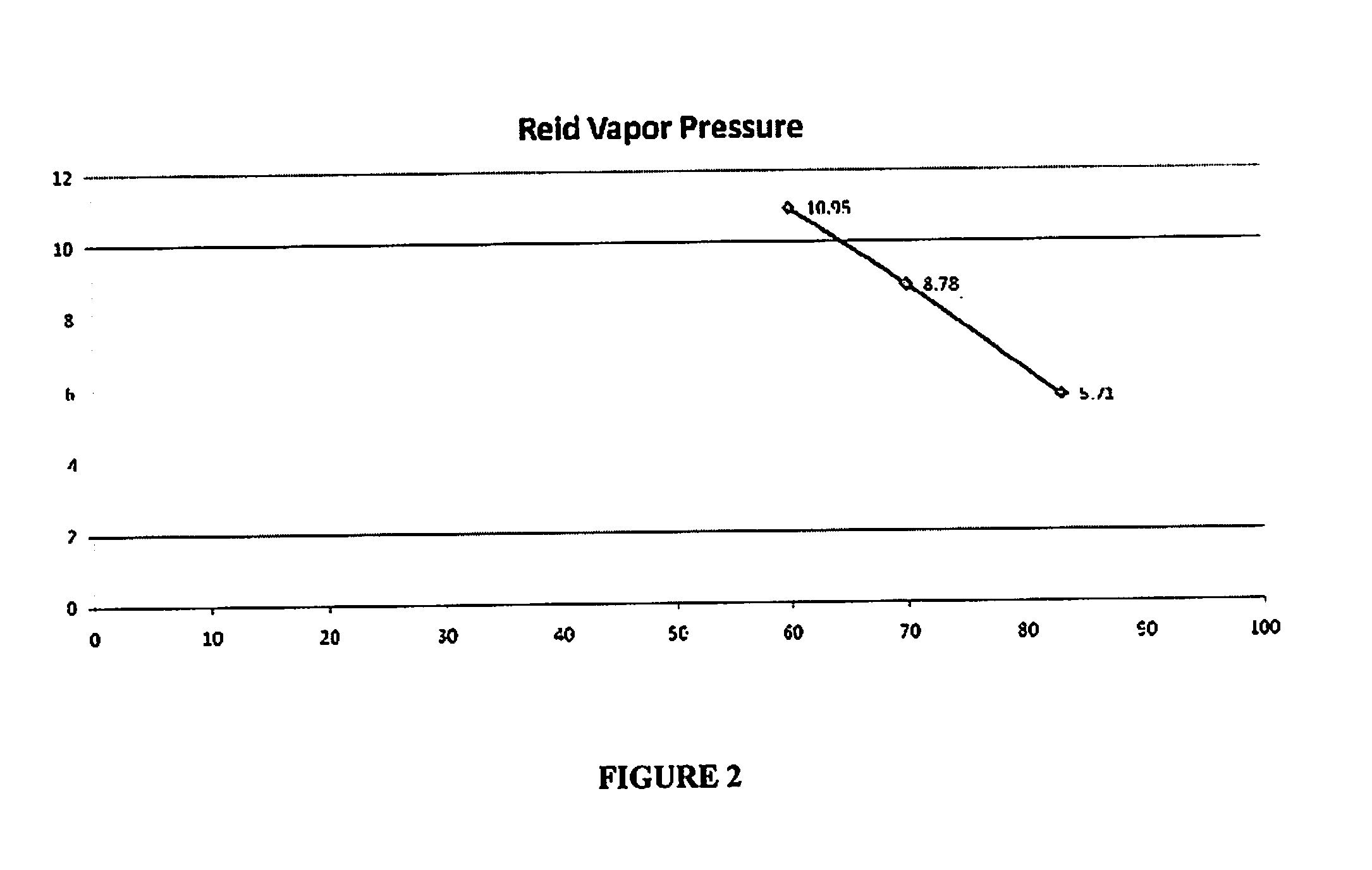

An aviation gasoline (Avgas) formulation free from tetraethyl lead (TEL) for piston driven aircraft is described, the formulation comprising, in volume percent, between 0 and 65.2 base alkylate, between 0 and 50 super-alkylate, between 0 and 25 toluene, between 2 and 10 of a toluidine isomer blend, between 0 and 5 ethyl alcohol, between 0 and 25 C5 cut and between 0 and 10 triptane. The formulations are prepared by admixing the components, with the order of mixing being from the denser to the less dense, except in the case of the toluidine isomer blend, which in spite of being the denser product is the latest to be added to the other streams in order to by-pass homogenization problems.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Renewable Engine Fuel And Method Of Producing Same

The present invention provides non-petroleum high-octane fuel derived from biomass sources, and a method of producing same. The method of production involves reducing the biomass feedstocks to sugars, fermenting the sugars using microorganisms or mutagens thereof to produce ethanol or acetic acid, converting the acetic acid or ethanol to acetone, and converting the acetone to mesitylene and isopentane, the major components of the renewable engine fuel. Trimerization of acetone can be carried out in the presence of a catalyst containing at least one metal selected from the group consisting of niobium, iron and manganese. The ethanol can be converted to mesitylene in a dehydration reaction in the presence of a catalyst of zinc oxide / calcium oxide, and unreacted ethanol and water separated from mesitylene by distillation. These ethanol-based, biomass-derived fuels are fully renewable, may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high-octane, rocket, diesel, turbine engine fuels, as well as two-cycle, spark-ignited engine fuels.

Owner:SWIFT ENTERPRISES

Aviation gasoline for aircraft piston engines, preparation process thereof

InactiveUS20110114536A1Reduce sulfur contentImprove the immunityLiquid carbonaceous fuelsFuel additivesAviationGasoline

The subject of the present disclosure is an aviation gasoline composition that is lead-free and free of oxygenated compounds meeting the specifications of the ASTM standard comprising isopentane, isooctane, and (alkyl)aromatics. The aviation gasoline composition according to the disclosure may be obtained simply and economically from a mixture of hydrocarbon bases usually available in a refinery.

Owner:TOTAL MARKETING SERVICES

Lead-free aviation gasoline and preparation method thereof

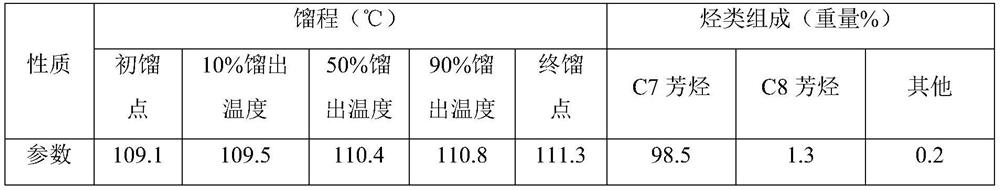

ActiveCN103965974AFulfil requirementsLow vapor pressureLiquid carbonaceous fuelsAviationPetrochemical

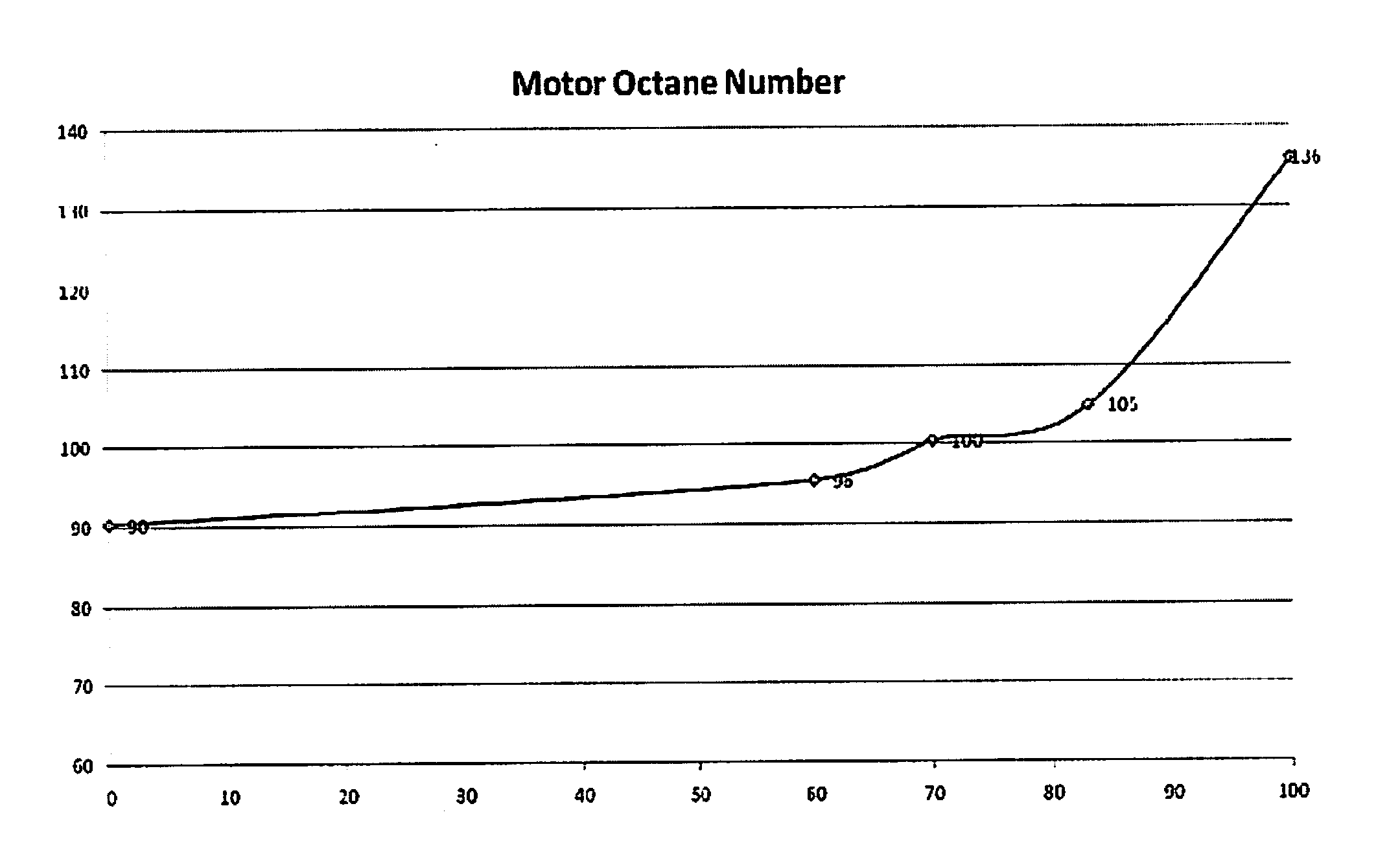

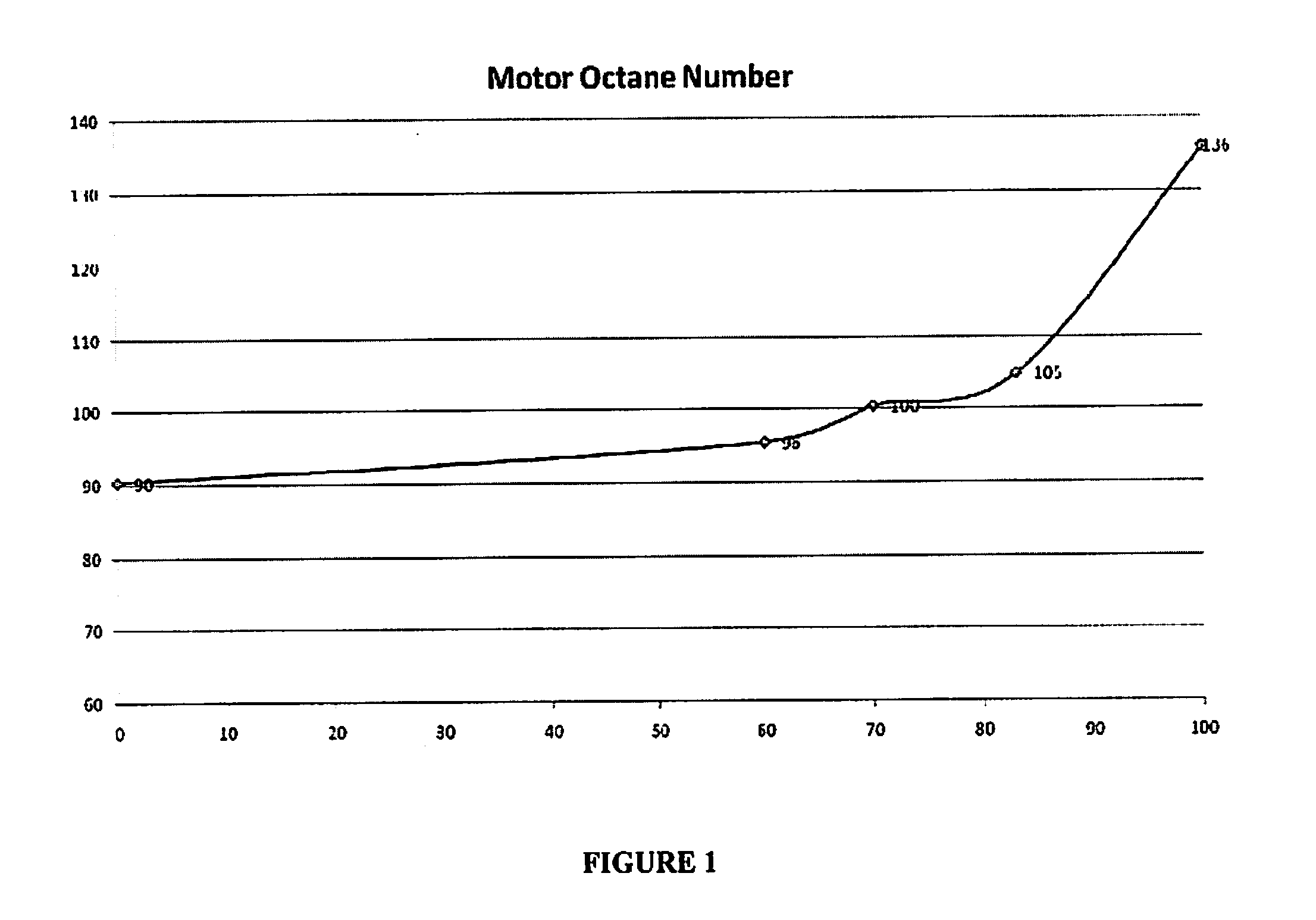

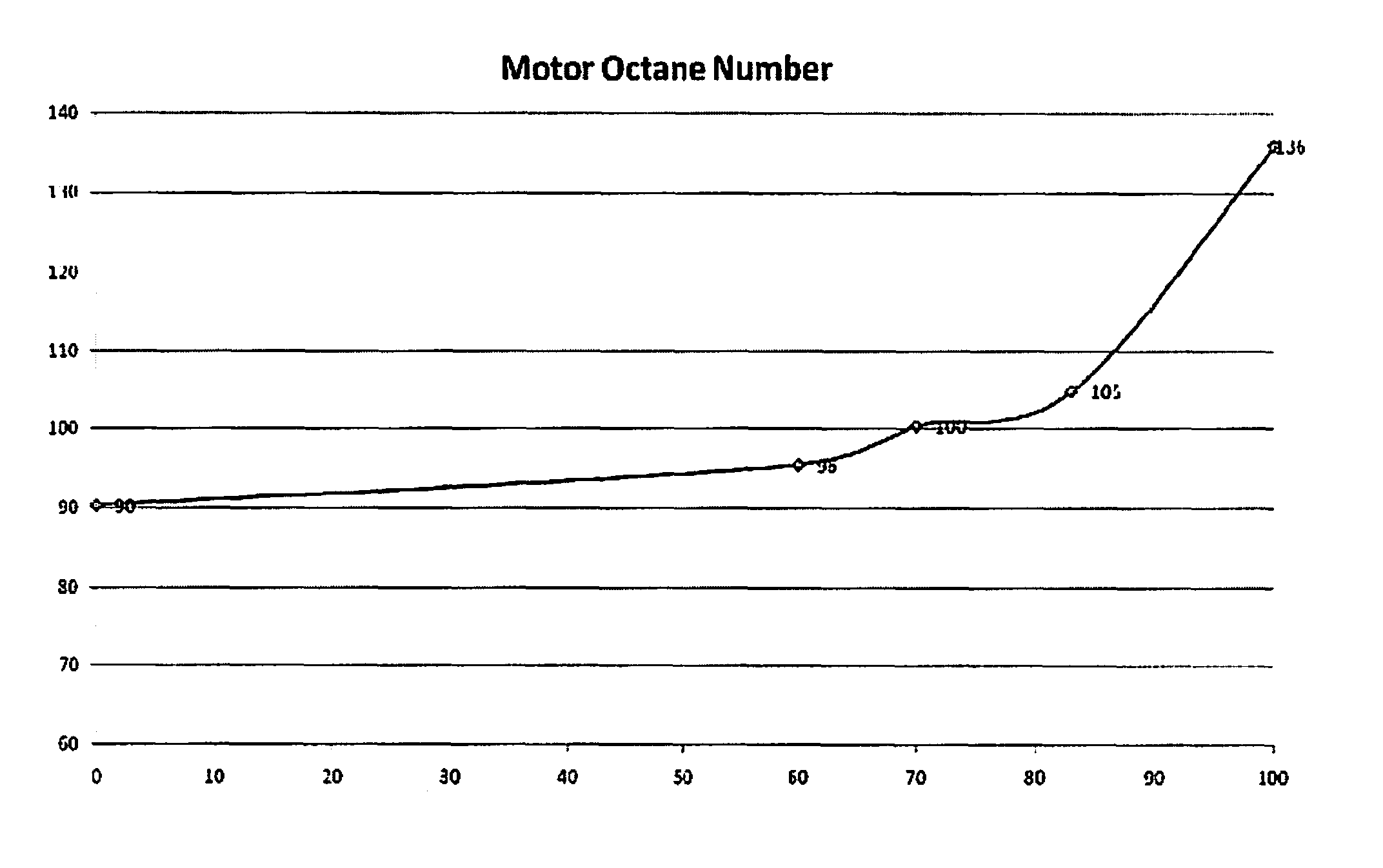

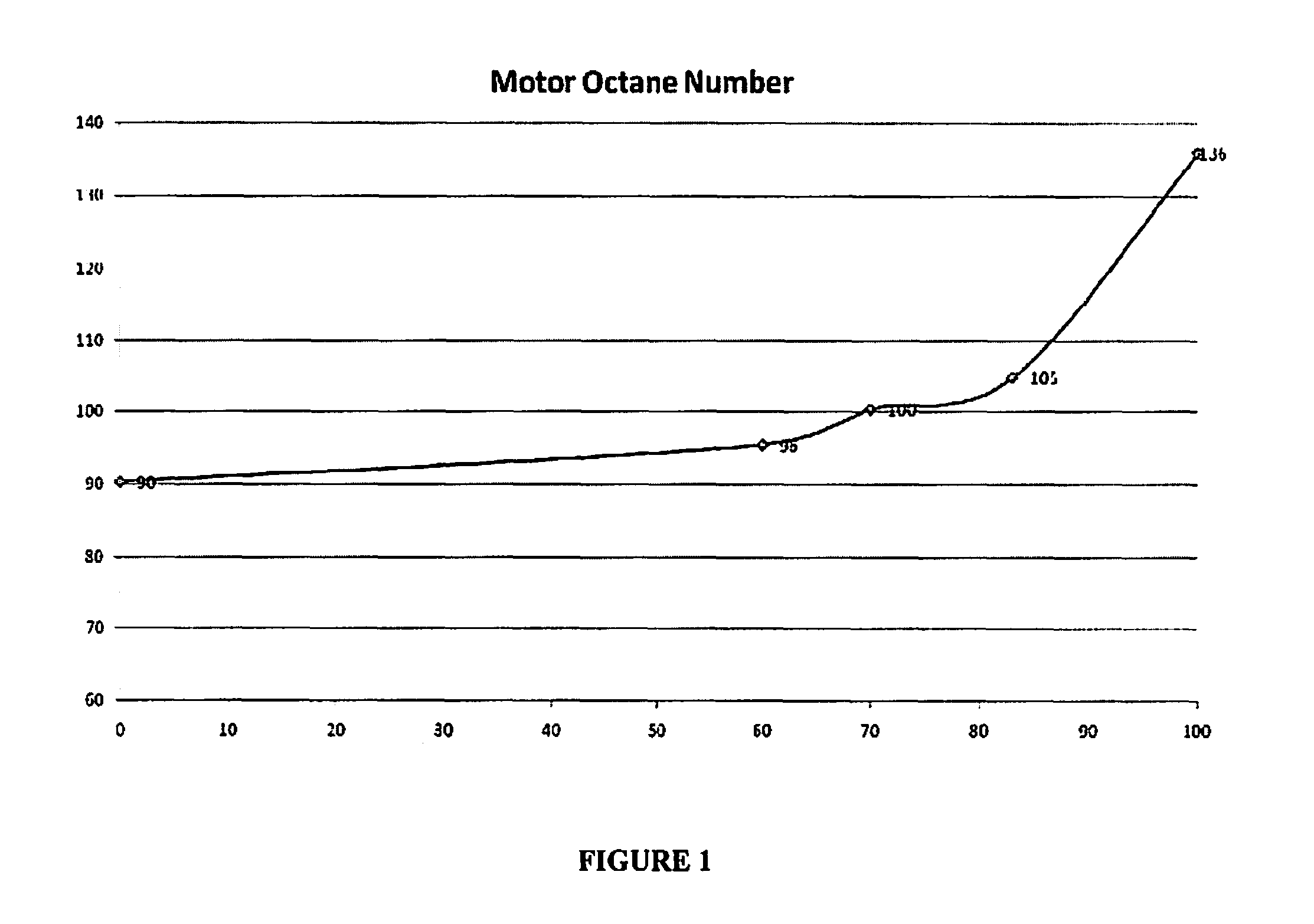

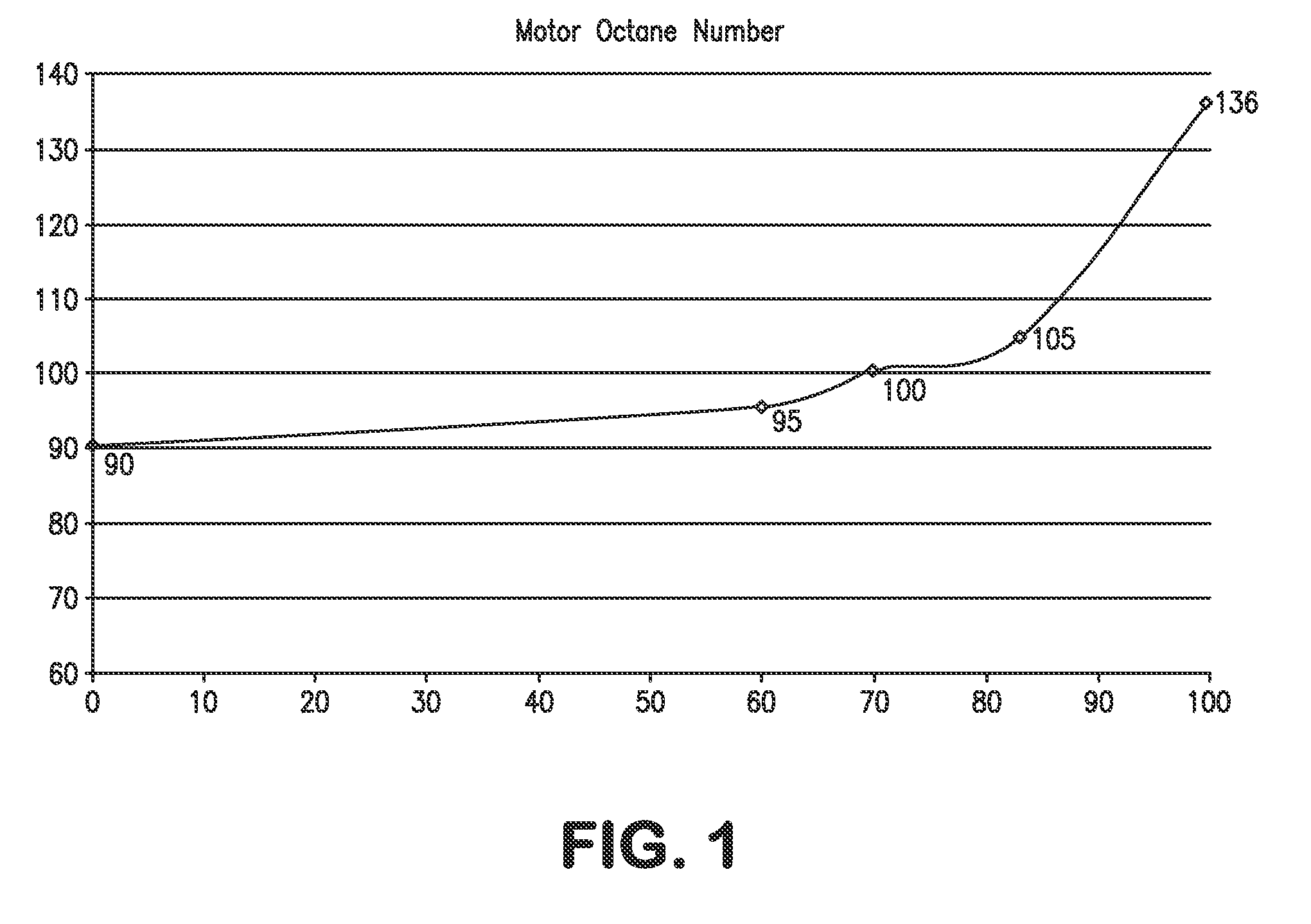

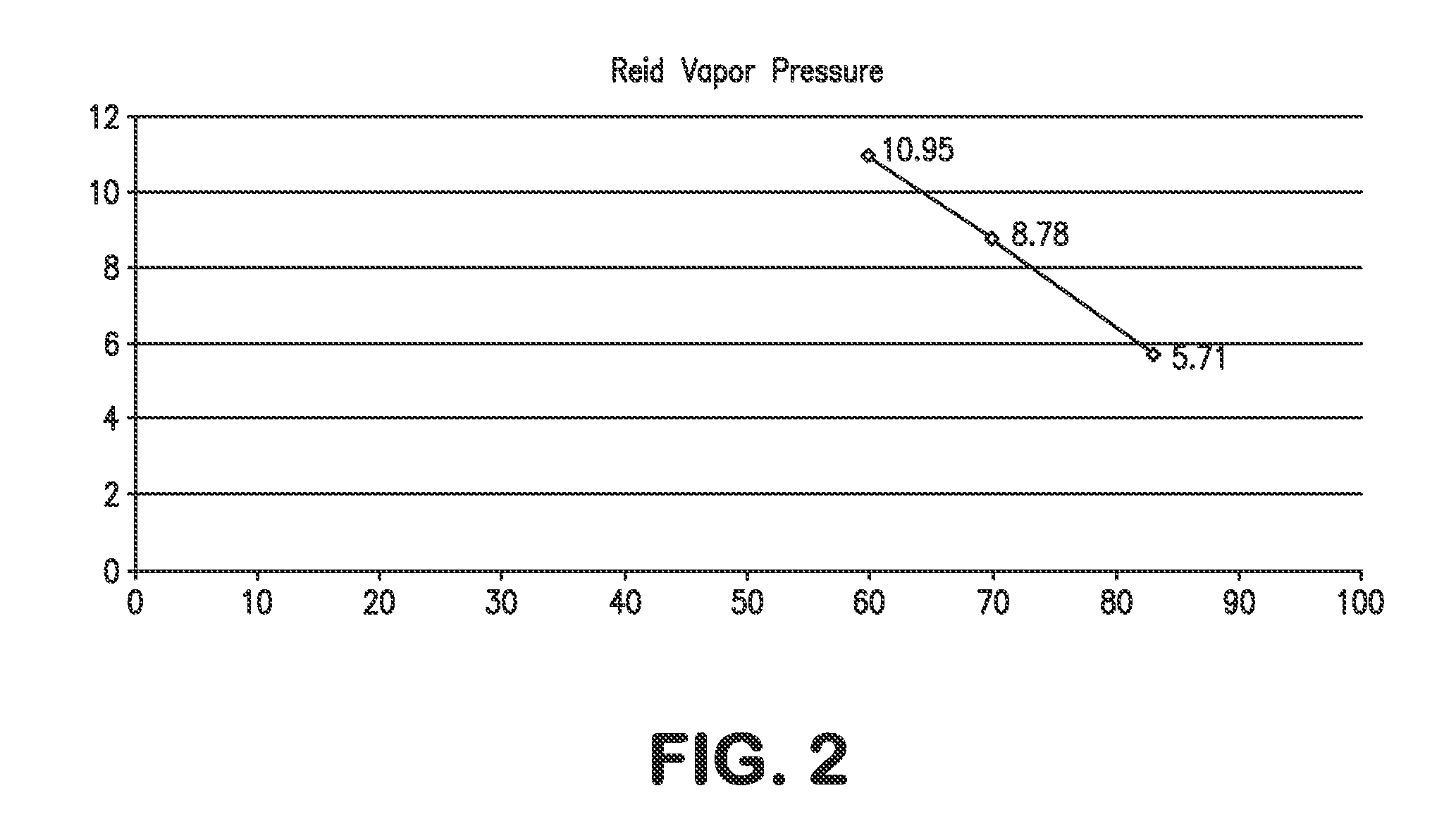

The invention provides a lead-free aviation gasoline and a preparation method thereof. The lead-free aviation gasoline is prepared by blending 20-100% of alkanes, 0-86% of arenes, 0-10% of alkenes, 0-20% of nitrogen-containing organic compounds and 0-20% of oxygen-containing organic compounds in percentage by volume together, or prepared by use of a petrochemical refining technology. The alkanes in the lead-free aviation gasoline mainly include isoalkane and cycloalkane, the two of which are low in vapor pressure, appropriate in boiling range, and thus capable of meeting the requirements of the aviation gasoline; the lead-free aviation gasoline is low in all of the content of arenes, the content of alkenes, the content of nitrogen-containing organic compounds and the content of oxygen-containing organic compounds, and thus low in combustion pollution and advantageous for improving the environmental quality of China; besides, the motor octane number of the lead-free aviation gasoline ranges from 90 to 105, and the lead-free aviation gasoline is further high in yield, low in cost and simple in preparation method.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

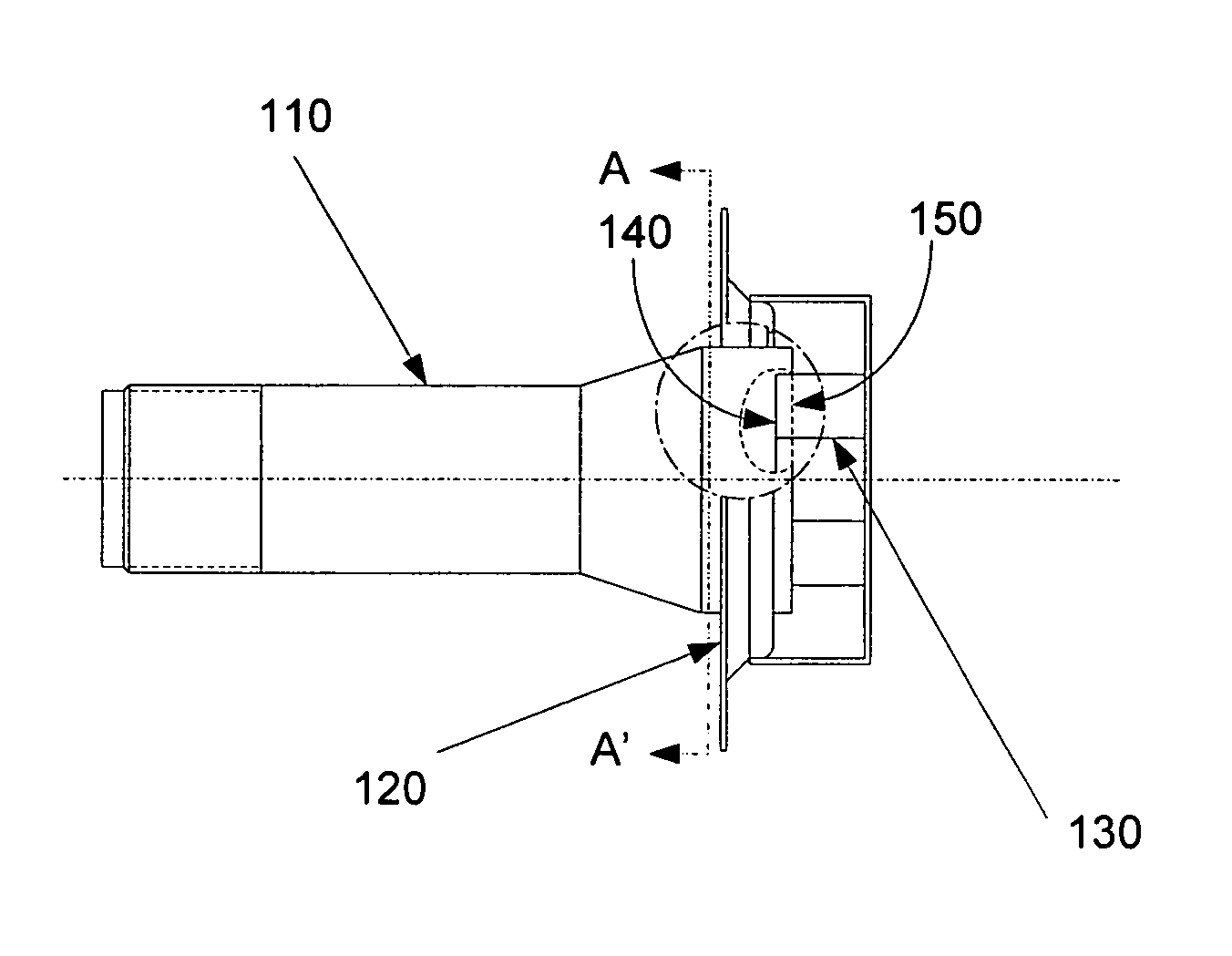

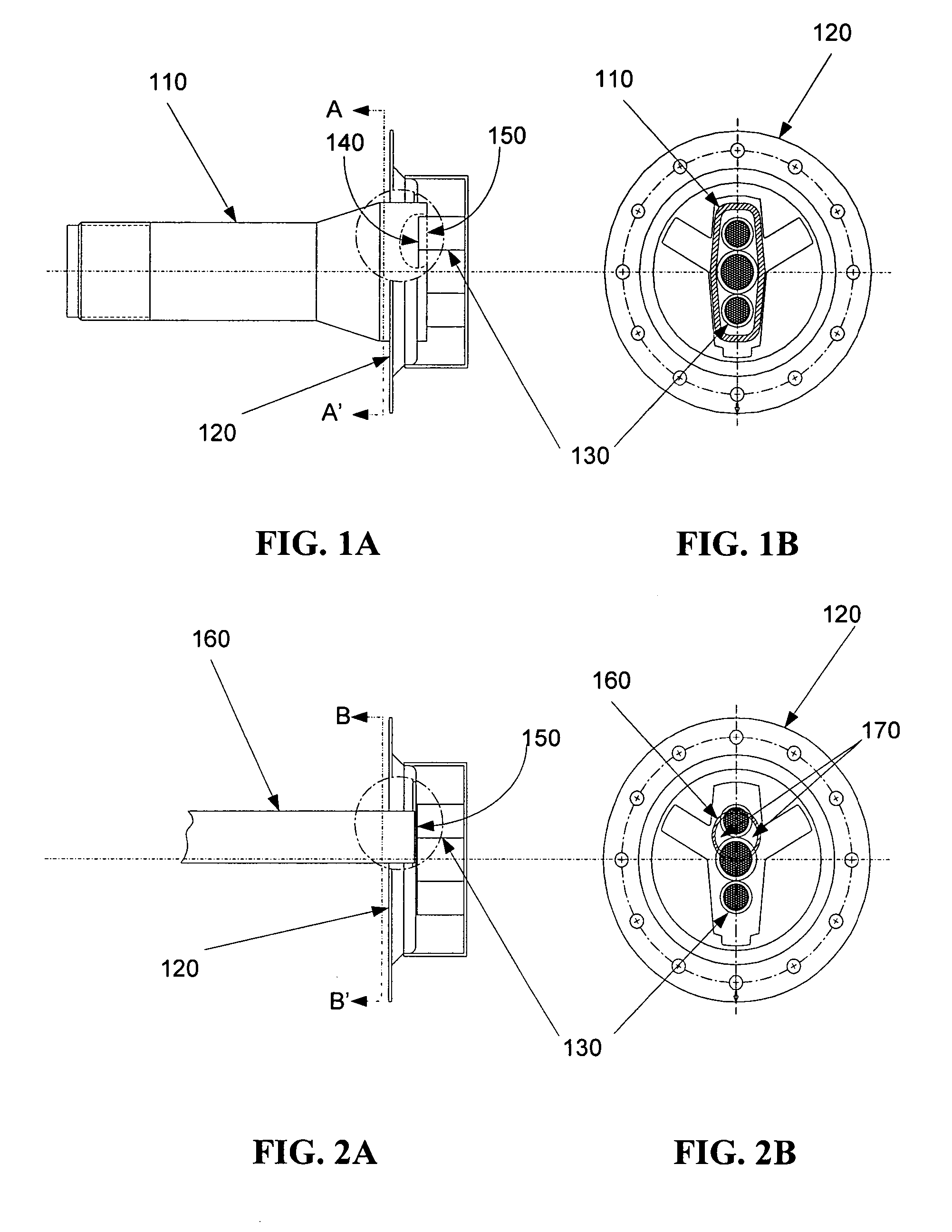

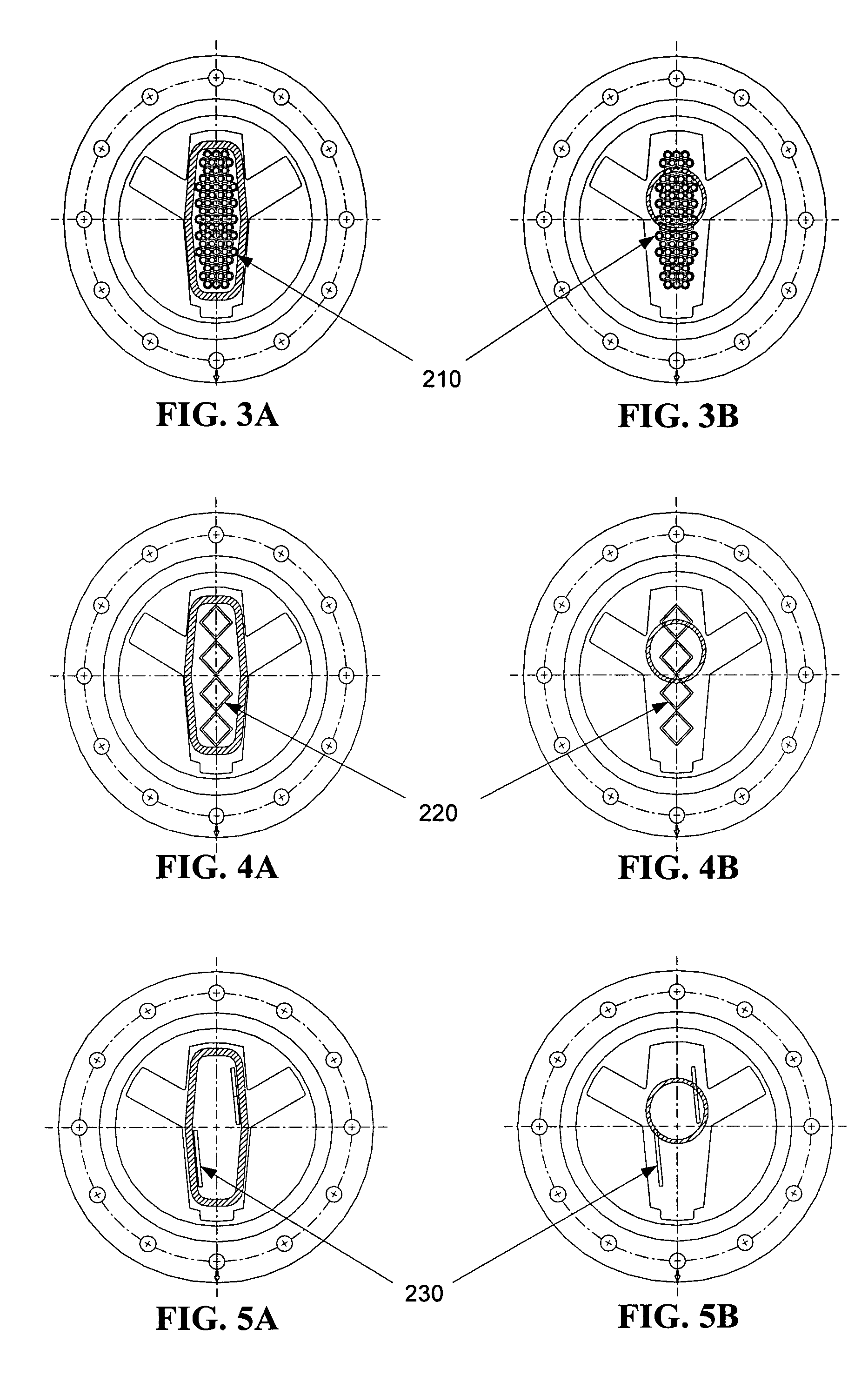

System and method for preventing incorrect aircraft fuel usage

ActiveUS7464736B2Prevent incorrect refuelingPrevent misfuelingPower plant fuel supplyLiquid transferring devicesJet fuelAirplane

Owner:PARKER INTANGIBLES LLC

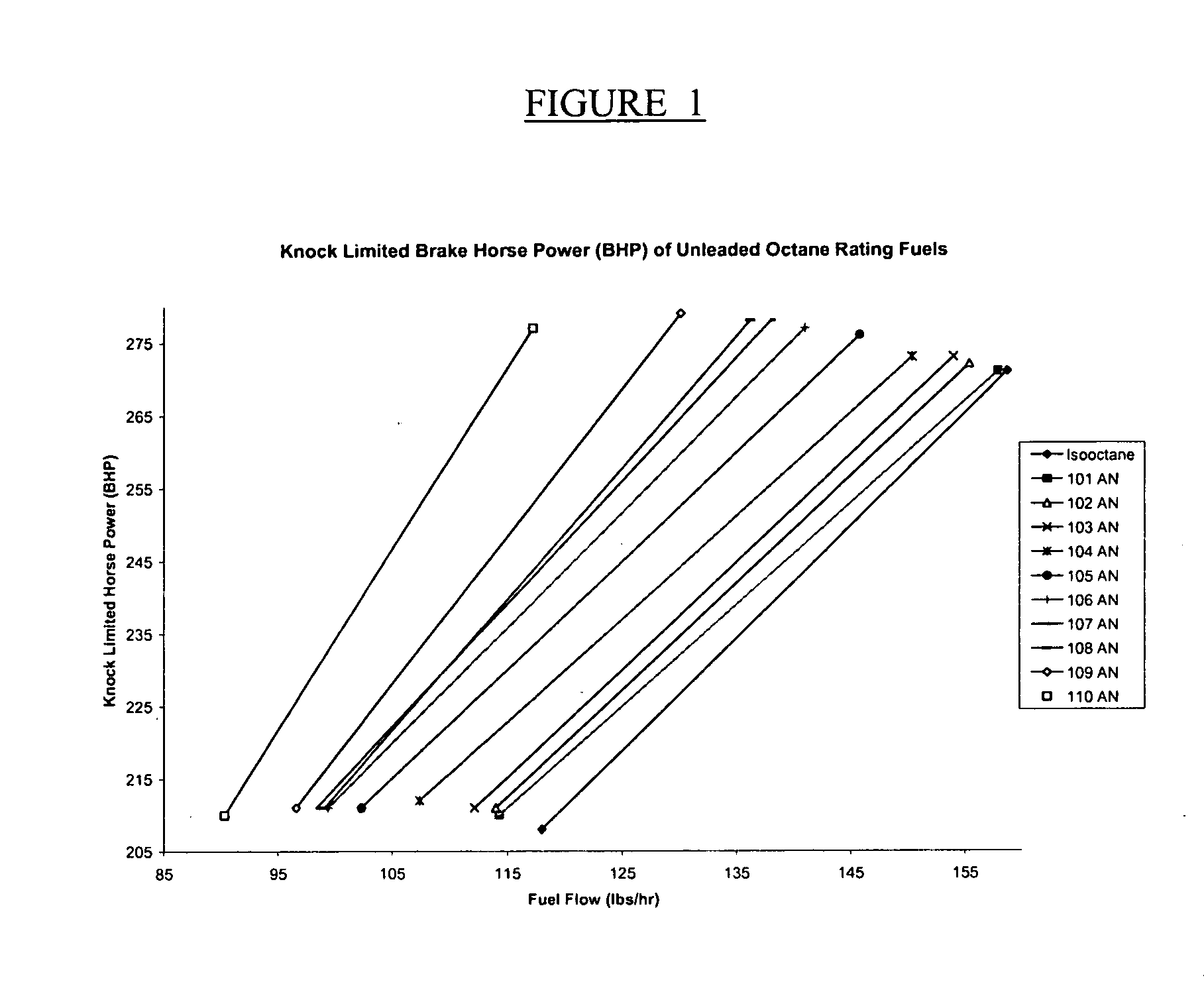

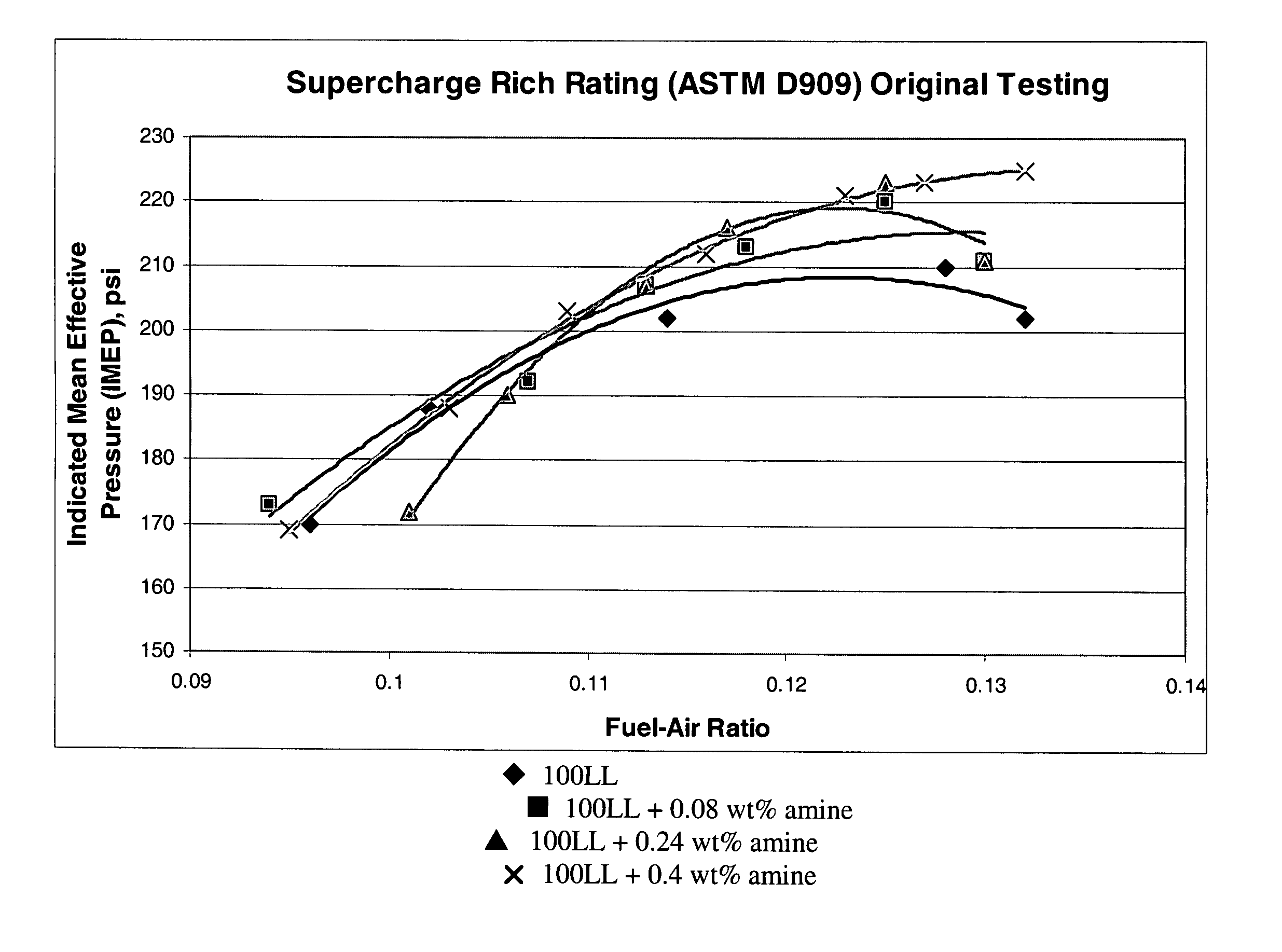

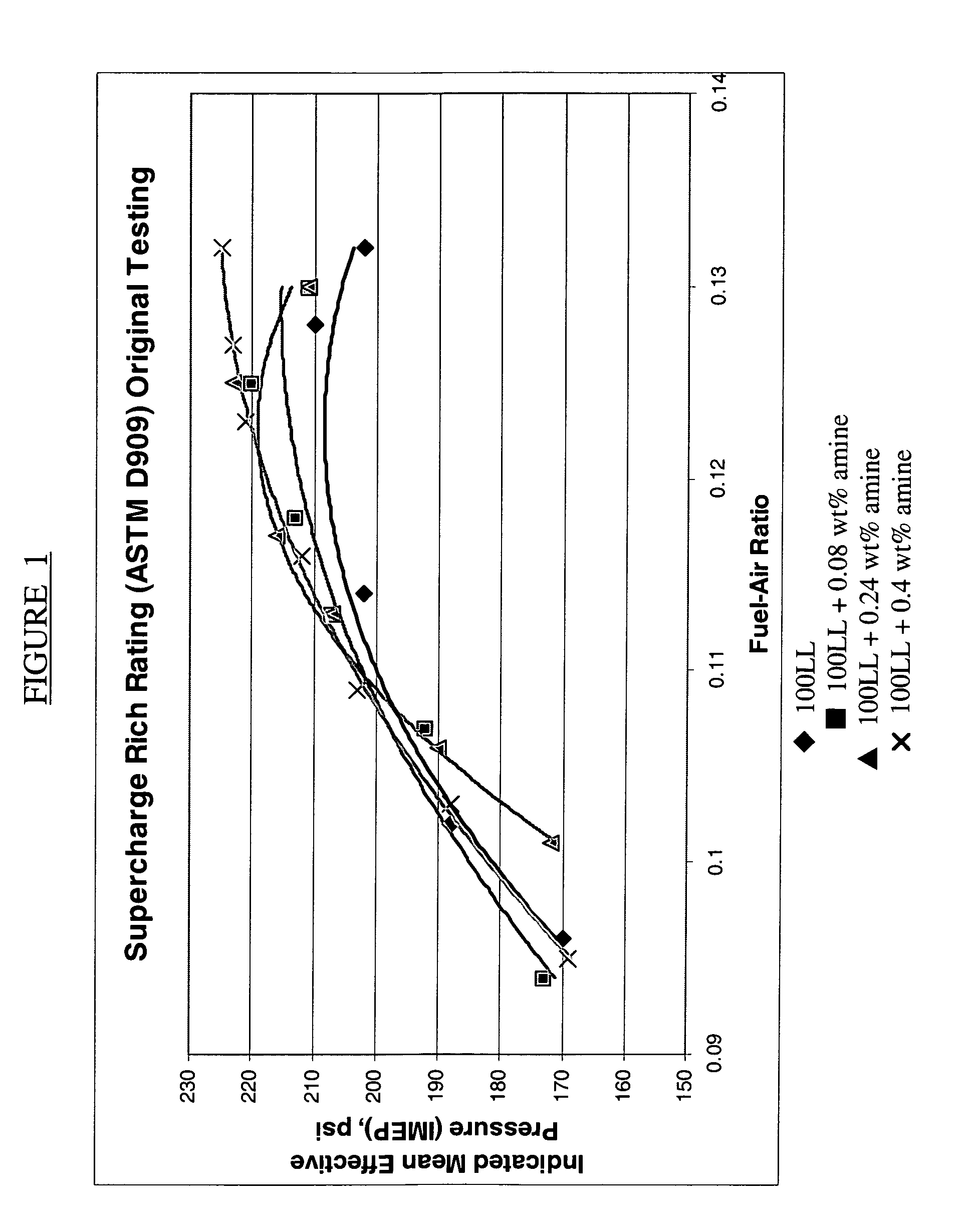

Leaded aviation gasoline

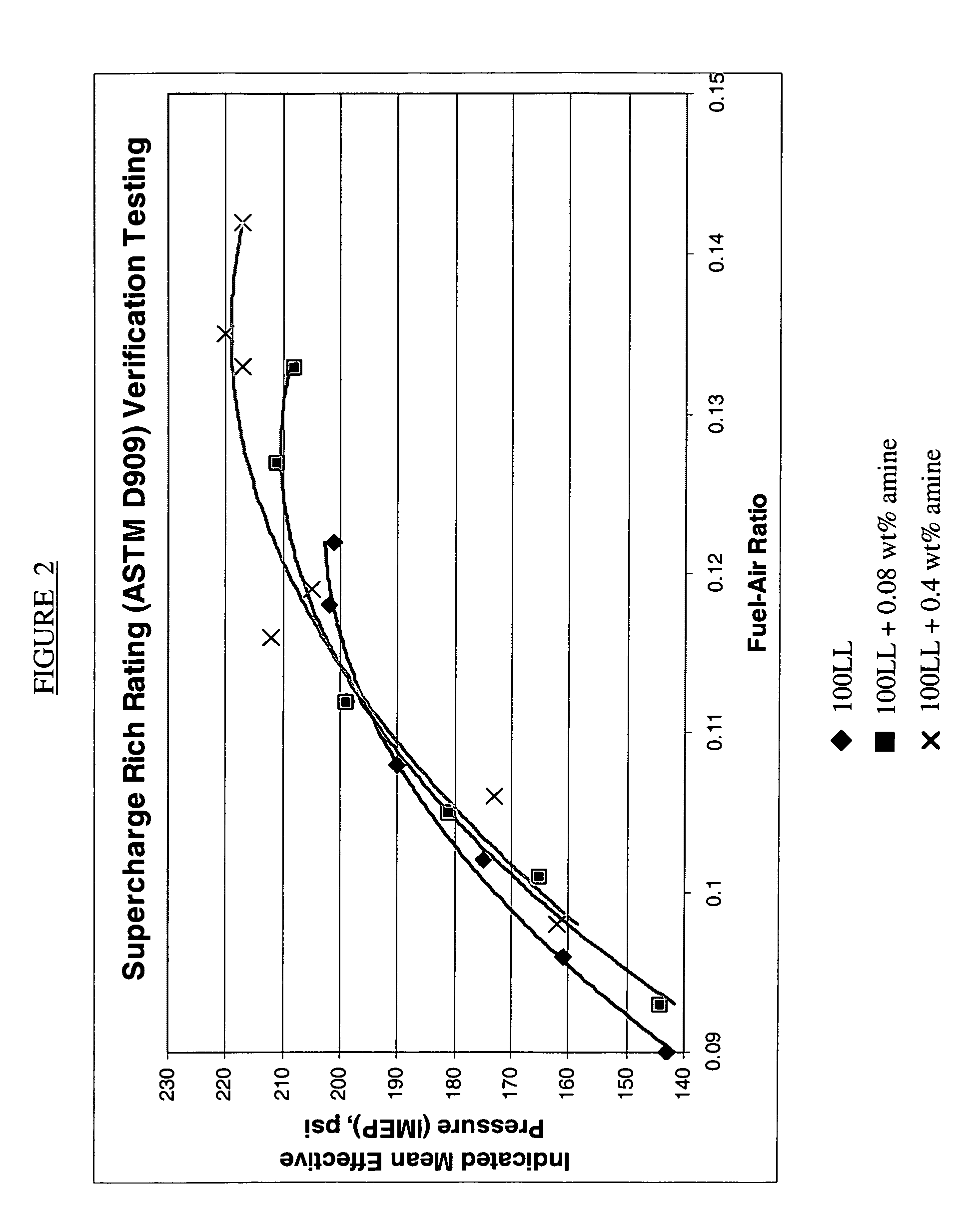

Aviation gasolines having an enhanced peak indicated mean effective pressure are provided by admixing with a leaded base aviation gasoline an aromatic amine of the formula NH2—Ar—(R1)n wherein R1 is selected from C1-C10 alkyl, halogen, and mixtures thereof provided that when R1 is alkyl it occupies the meta- or para-positions on the aromatic ring, Ar is a phenyl aromatic group and n is an integer from 0 to 3 to provide an aviation gasoline having a peak indicated mean effective pressure as determined by ASTM D-909 of greater than about 200 psi.

Owner:EXXON RES & ENG CO

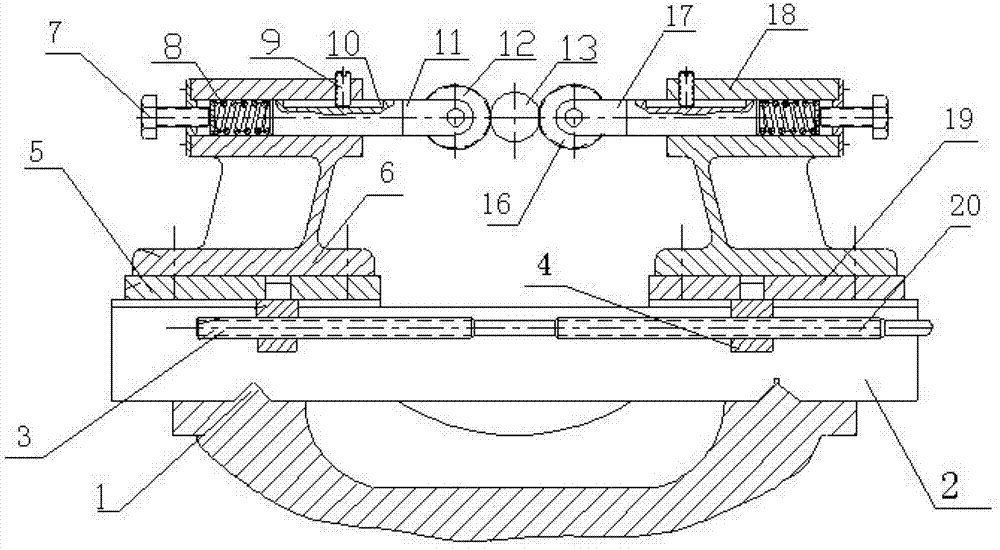

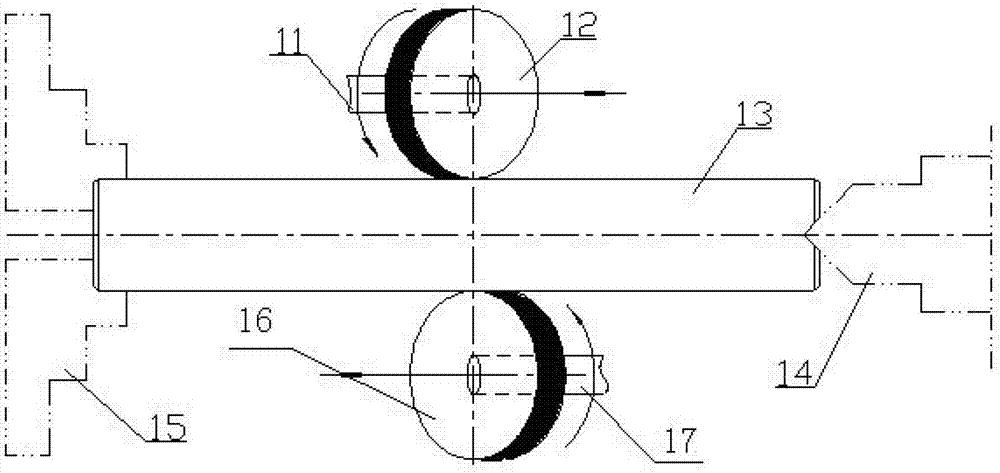

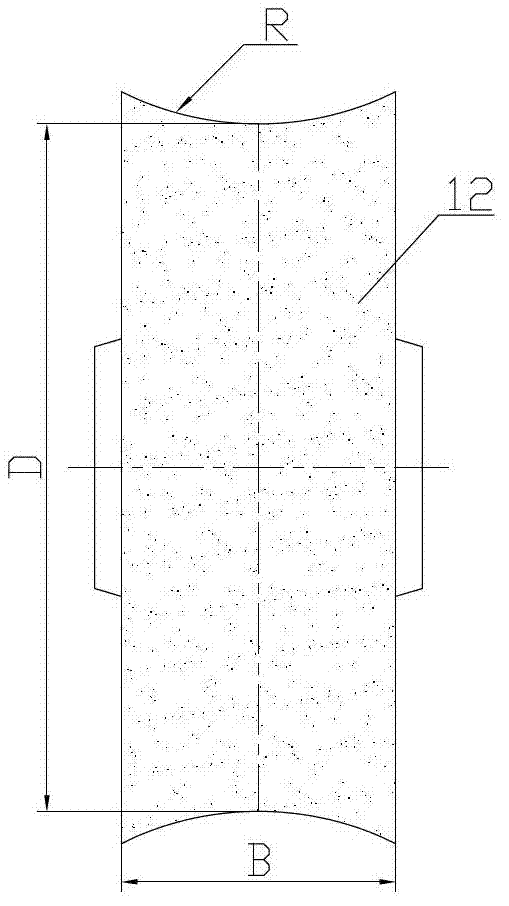

Shaft part double-wheel symmetrical grinding device and process

The invention relates to a shaft part double-wheel symmetrical grinding device and process. The process includes: machining a workpiece on an excircle grinder to Ra0.40, leaving a machining allowance of 0.008-0.12mm, fixing a fixing piece during grinding, screwing a pressure-adjusting bolt compression spring, enabling grinding wheels to contact a workpiece surface to be ground, winding a lead screw, and enabling two grinding wheels to generate transverse feed; when the pressure of the spring on the workpiece is 2-3kg, stopping the transverse feed, starting a lathe, enabling the workpiece to rotate at the speed of 80-150 turns / minute, driving the two grinding wheels to rotate, starting a large carriage, enabling the large carriage to move vertically along a lathe track and drive the grinding wheels to move vertically together, controlling the moving quantity in the way that the grinding wheels move 2-3 mm vertically when the workpiece rotates a circle, washing through aviation gasoline till the workpiece surface roughness parameter meets the technical requirement, detaching the workpiece, and finishing grinding. The shaft part double-wheel symmetrical grinding device and process has the advantage that the process is simple, the roughness can be lower than Ra0.012, and efficiency is high.

Owner:江西铜业集团(德兴)铸造有限公司

Antioxidant for sintering neodymium iron boron jet mill, and use method of antioxidant

InactiveCN104449740AReduced oxidation resistanceLoss is good for compensationInorganic material magnetismChemical inhibitorsMetallurgyStearic acid

The invention discloses an antioxidant for a sintering neodymium iron boron jet mill, and a use method of the antioxidant. The antioxidant consists of an antioxidation agent and an antioxidation assistant, wherein the antioxidation agent consists of one or several of 1-cetyl alcohol, trityl alcohol and zinc stearate and alcohol; and the antioxidation assistant is a mixture of aviation gasoline and petroleum ether. The use method comprises the following steps that (1) 30-65% of the total amount of the antioxidation agent and neodymium iron boron magnetic powder are uniformly mixed and then crushed via the jet mill; (2) fine mixing is performed, and the antioxidation assistant and the rest antioxidation agent are added and uniformly mixed; and (3) compression molding is performed and then antioxidant removal treatment is performed. The antioxidant can improve the antioxidation property of the sintering neodymium iron boron magnetic powder, greatly improve the lubricating property and the orientation degree of the magnetic powder, and improve the magnet property. The use method can reduce loss of the antioxidation agent caused by volatilization, and can ensure continuous antioxidation property of the neodymium iron boron magnetic powder in each production stage.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

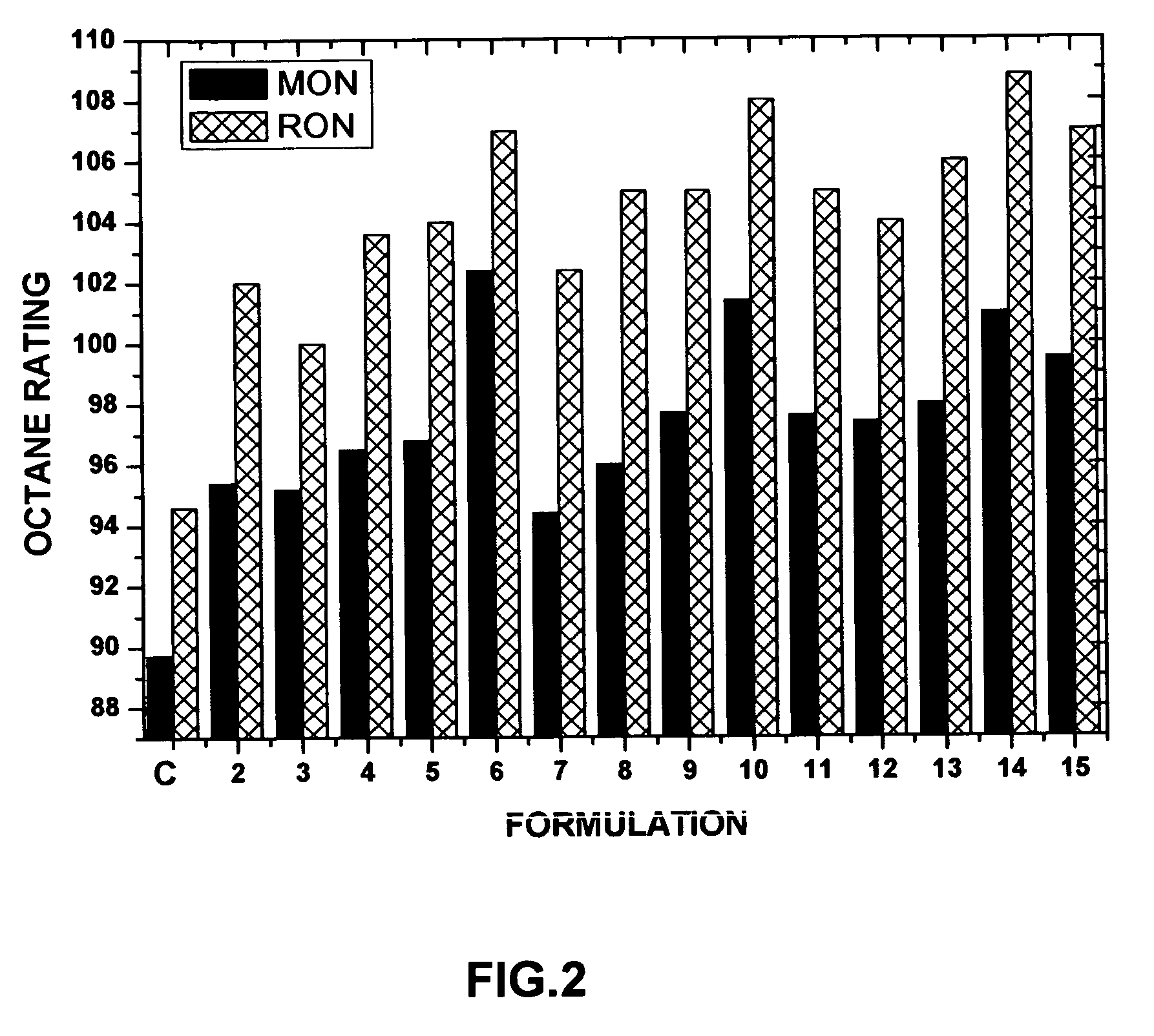

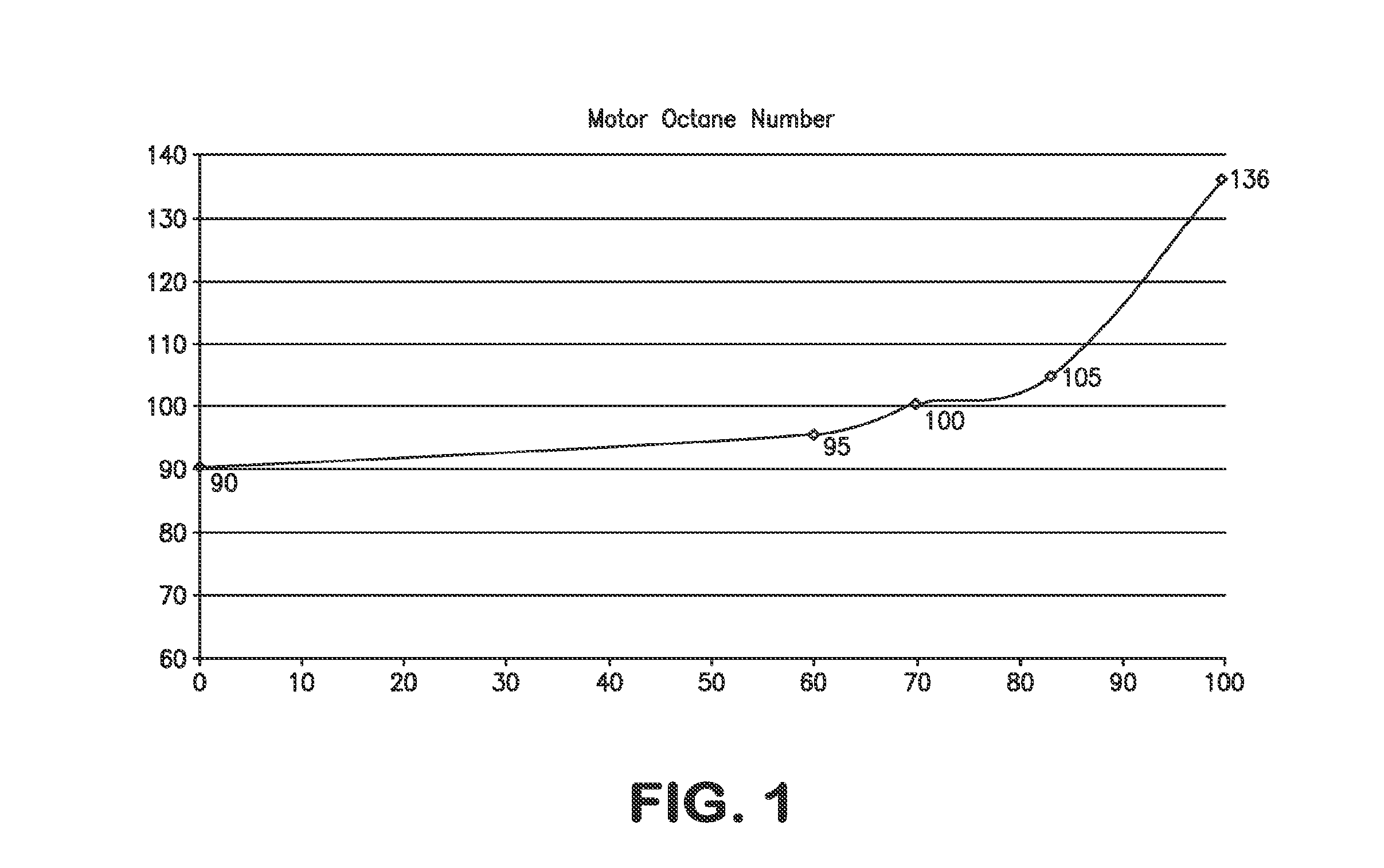

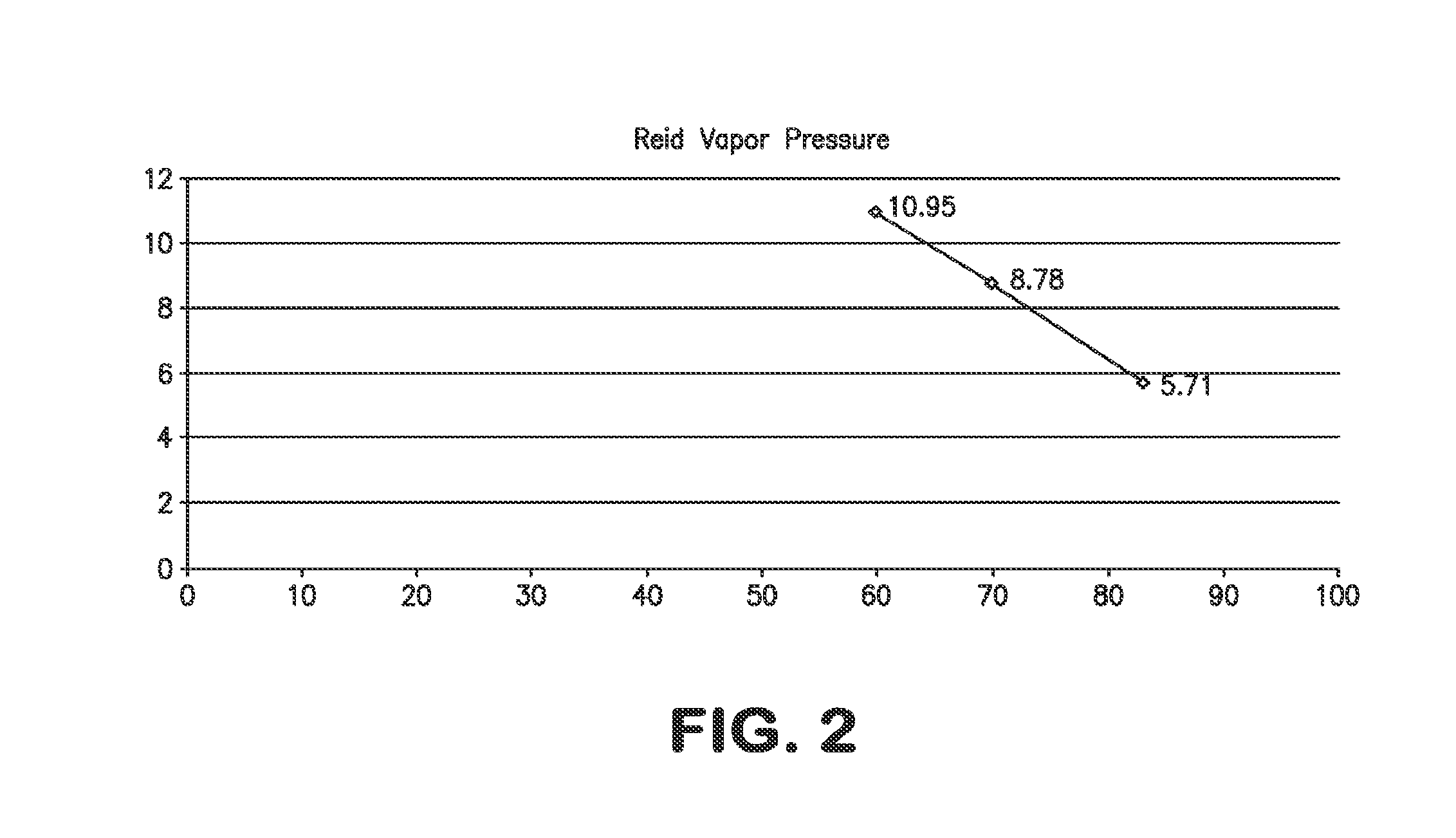

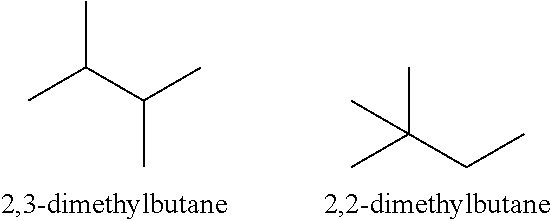

Aviation gasolines containing mesitylene and isopentane

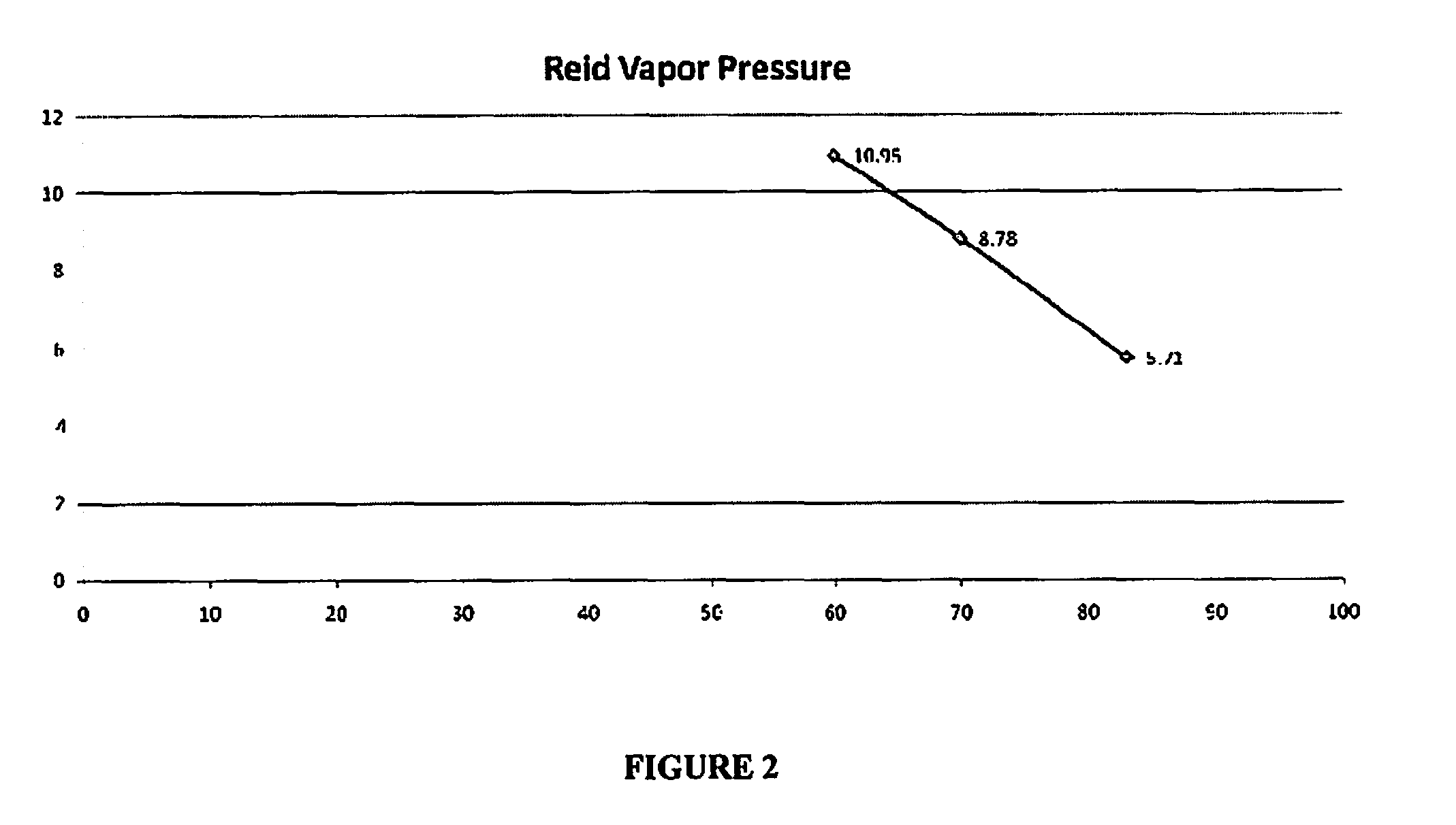

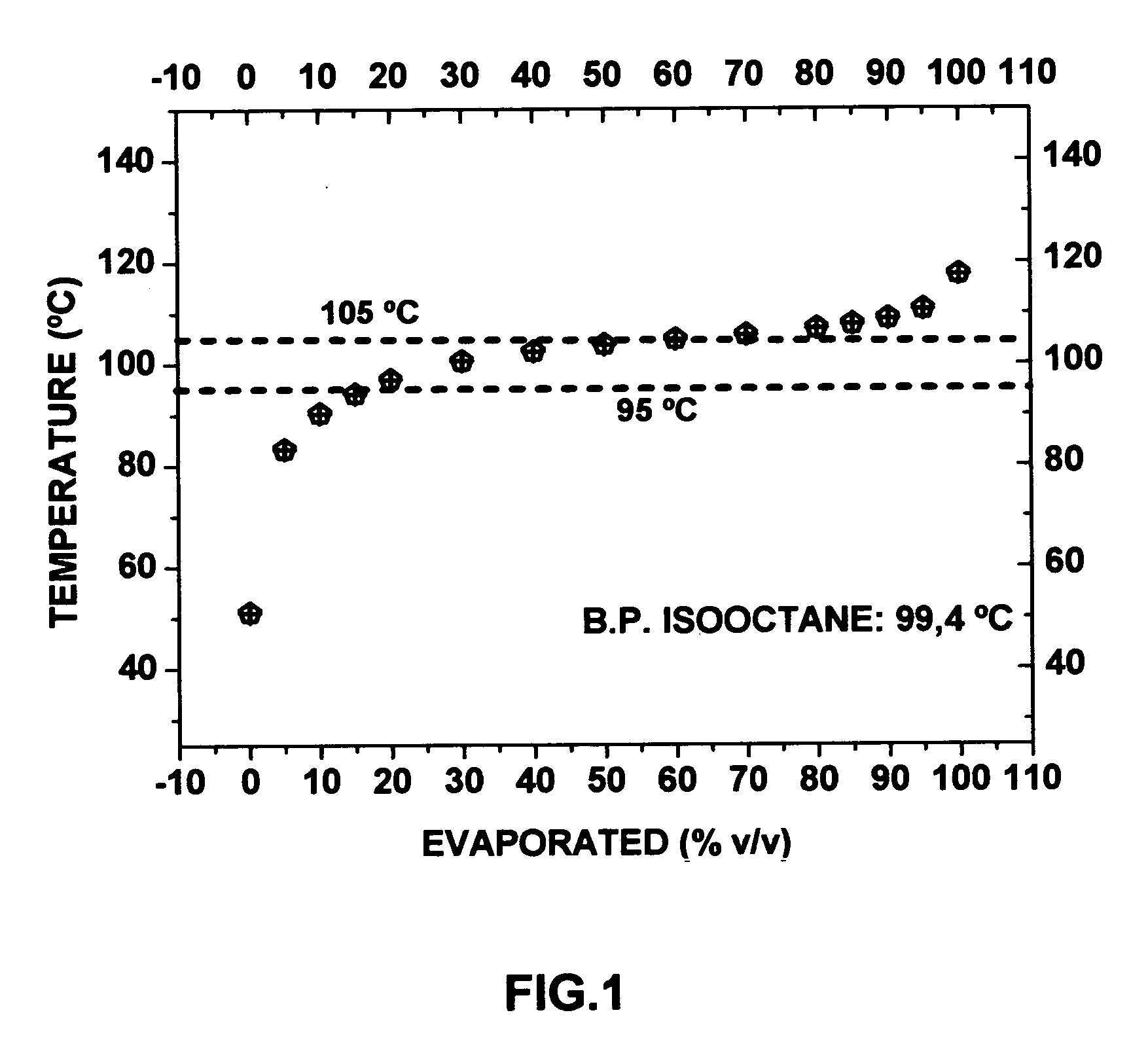

Describe are preferred formulations for Avgas meeting the requirements for use in aircraft, including requirements established under ASTM standards and by the Federal Aviation Administration. In one embodiment, a binary mixture of 1,3,5-trimethyl benzene (mesitylene) and isopentane is used to provide a MON of at least 100, and more preferably at least 102. In other embodiments, the amounts of mesitylene and / or isopentane may be changed, and other fuel components are included. These various Avgas formulations are thereby adjusted to meet a variety of requirements as to octane rating, RVP, cold start, and other fuel characteristics.

Owner:SWIFT FUELS

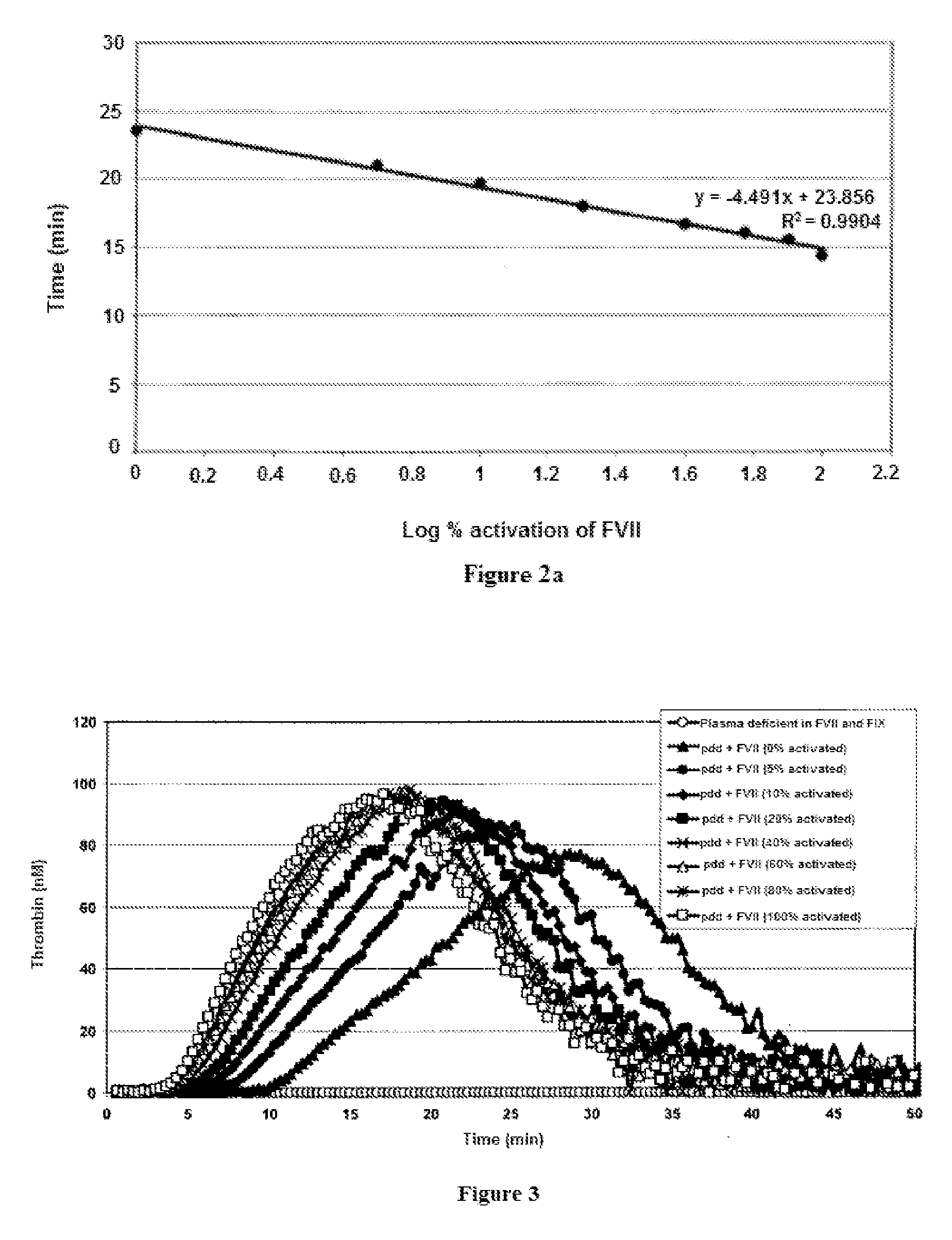

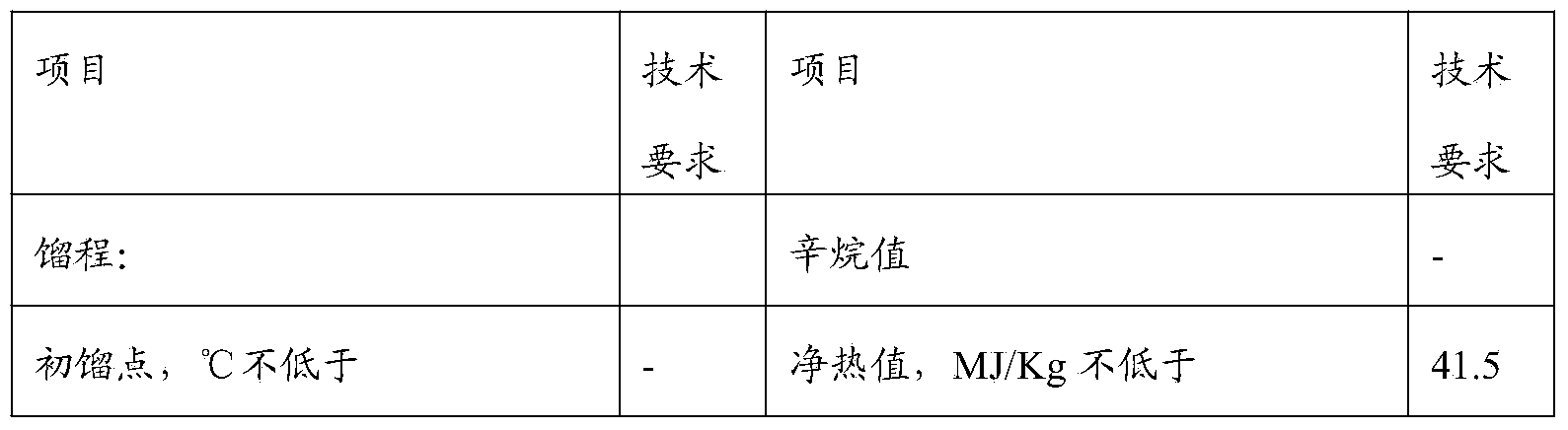

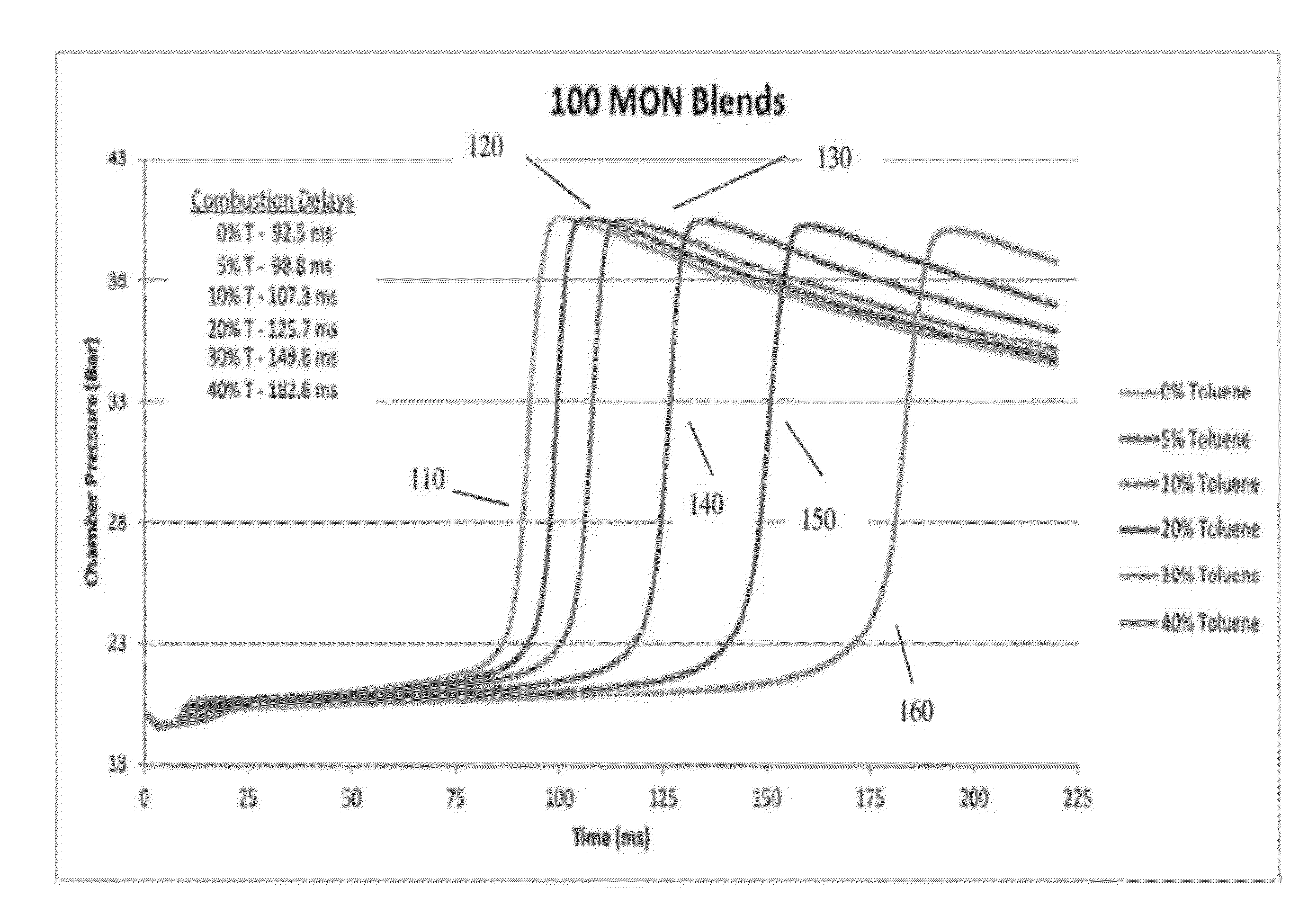

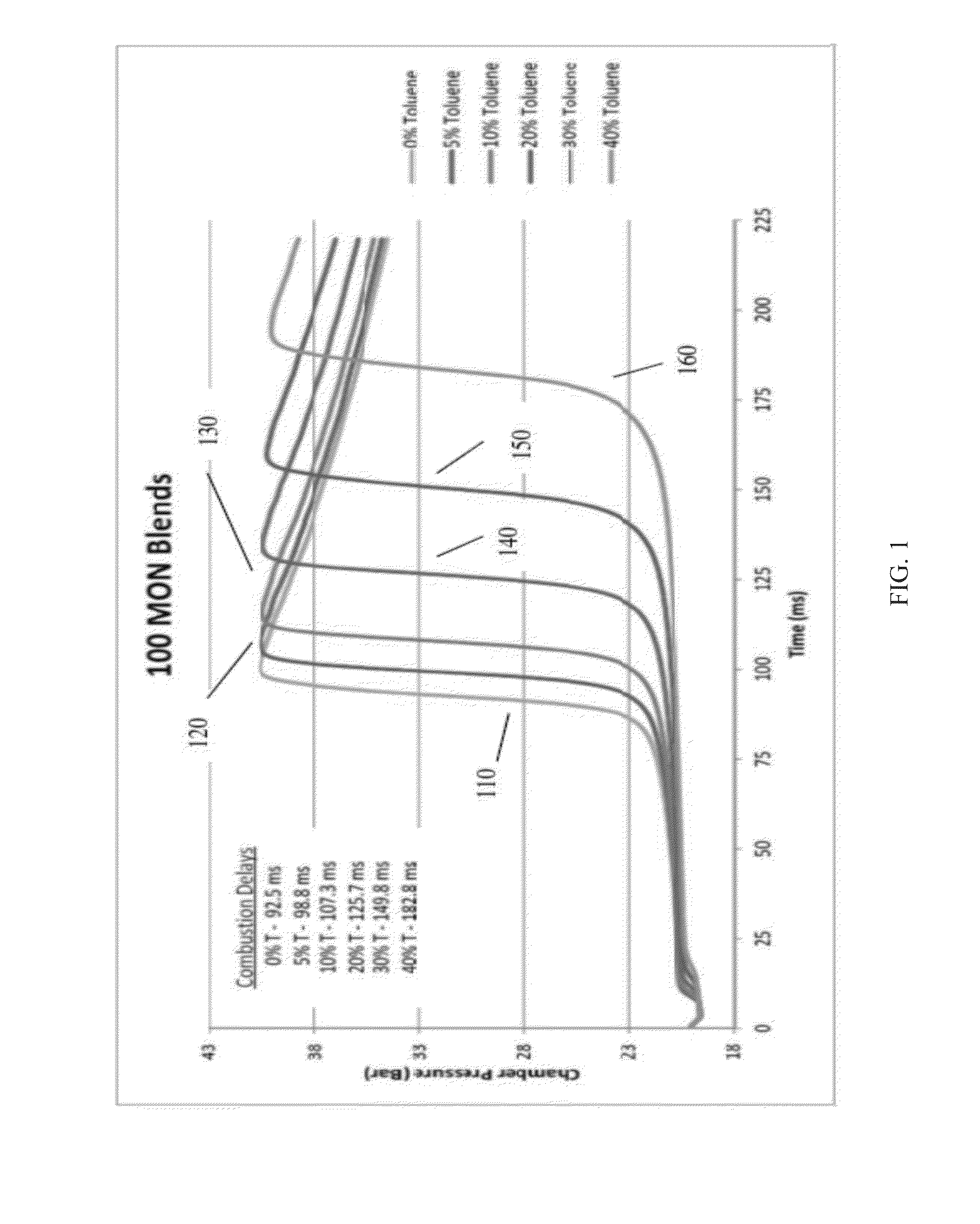

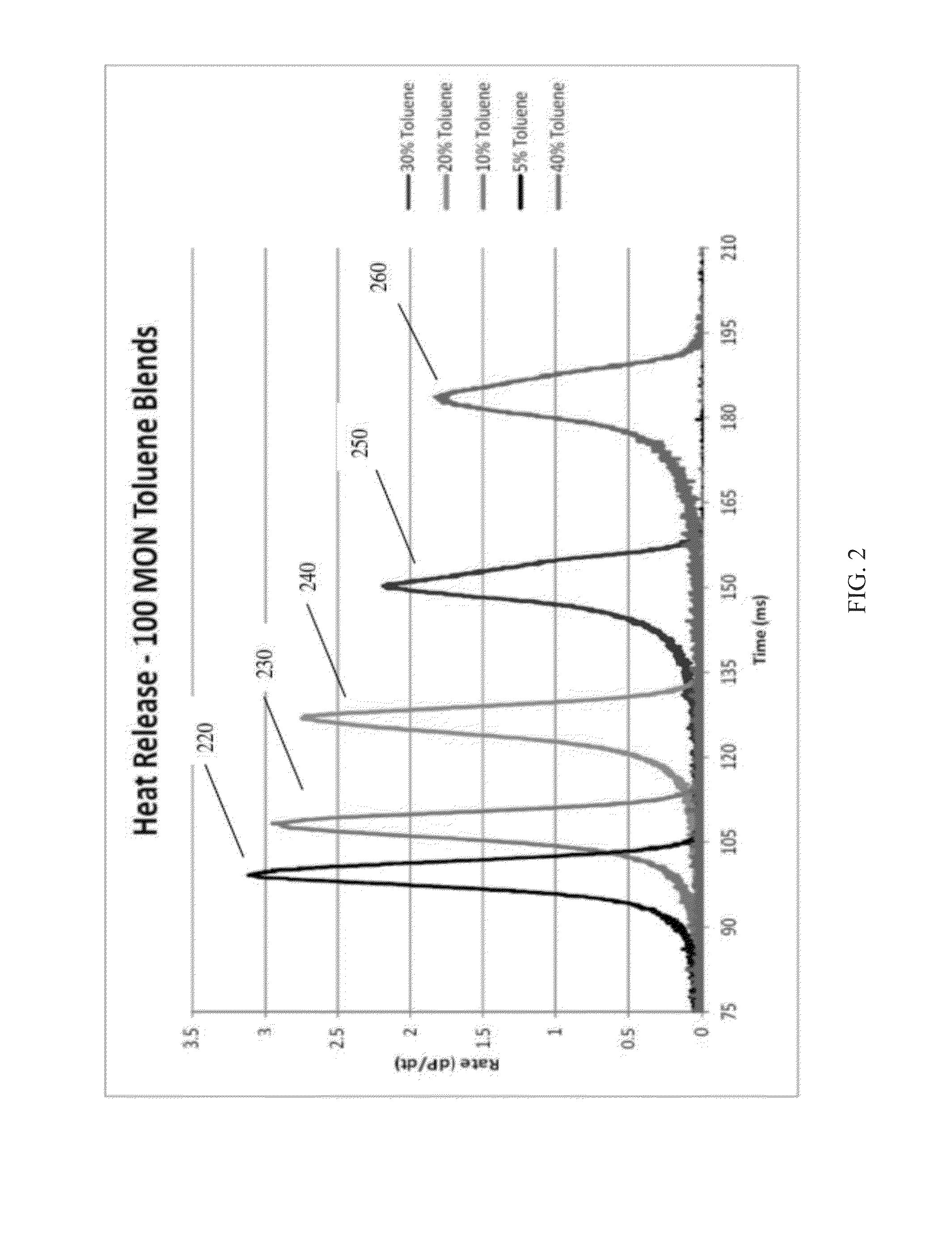

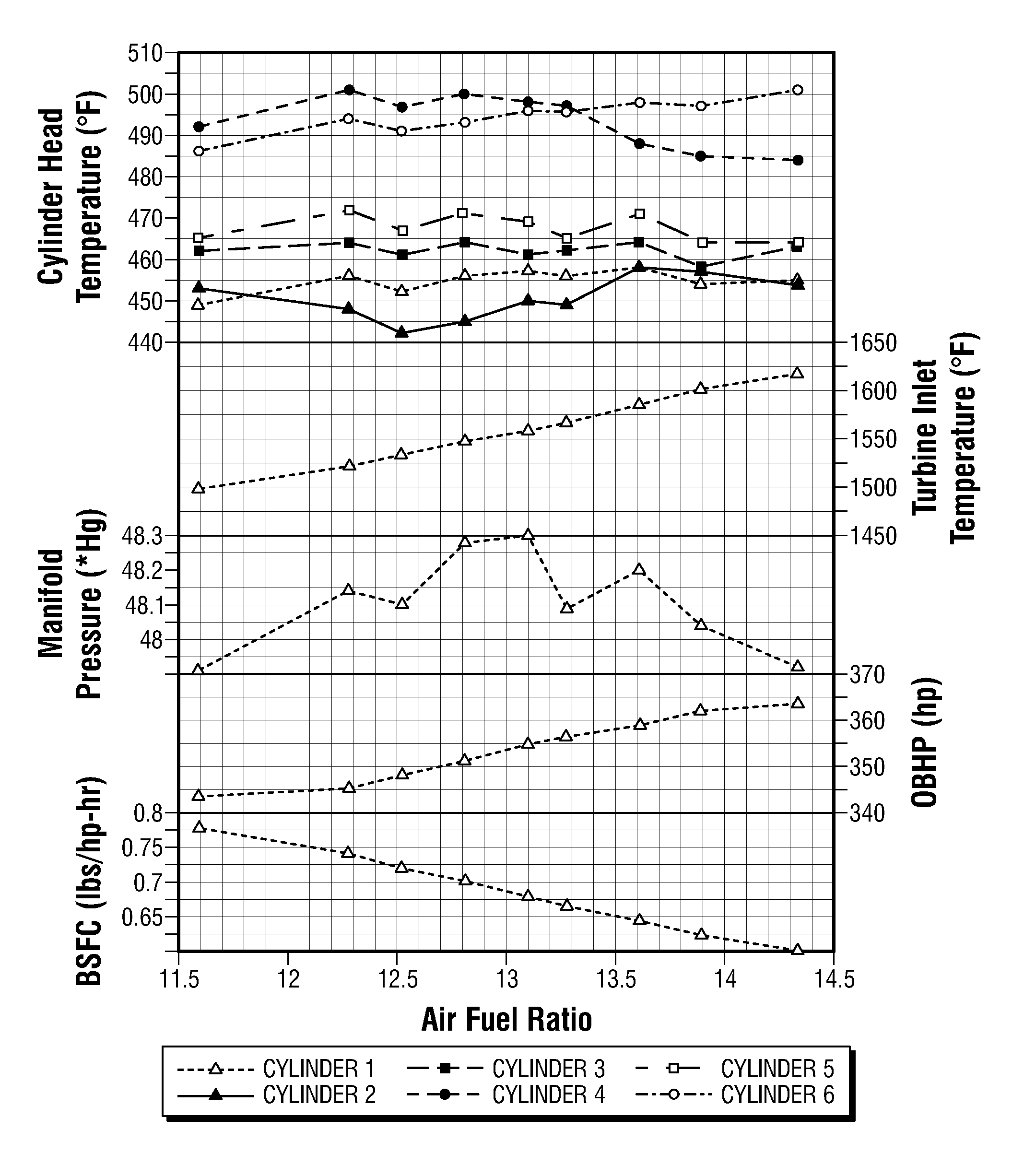

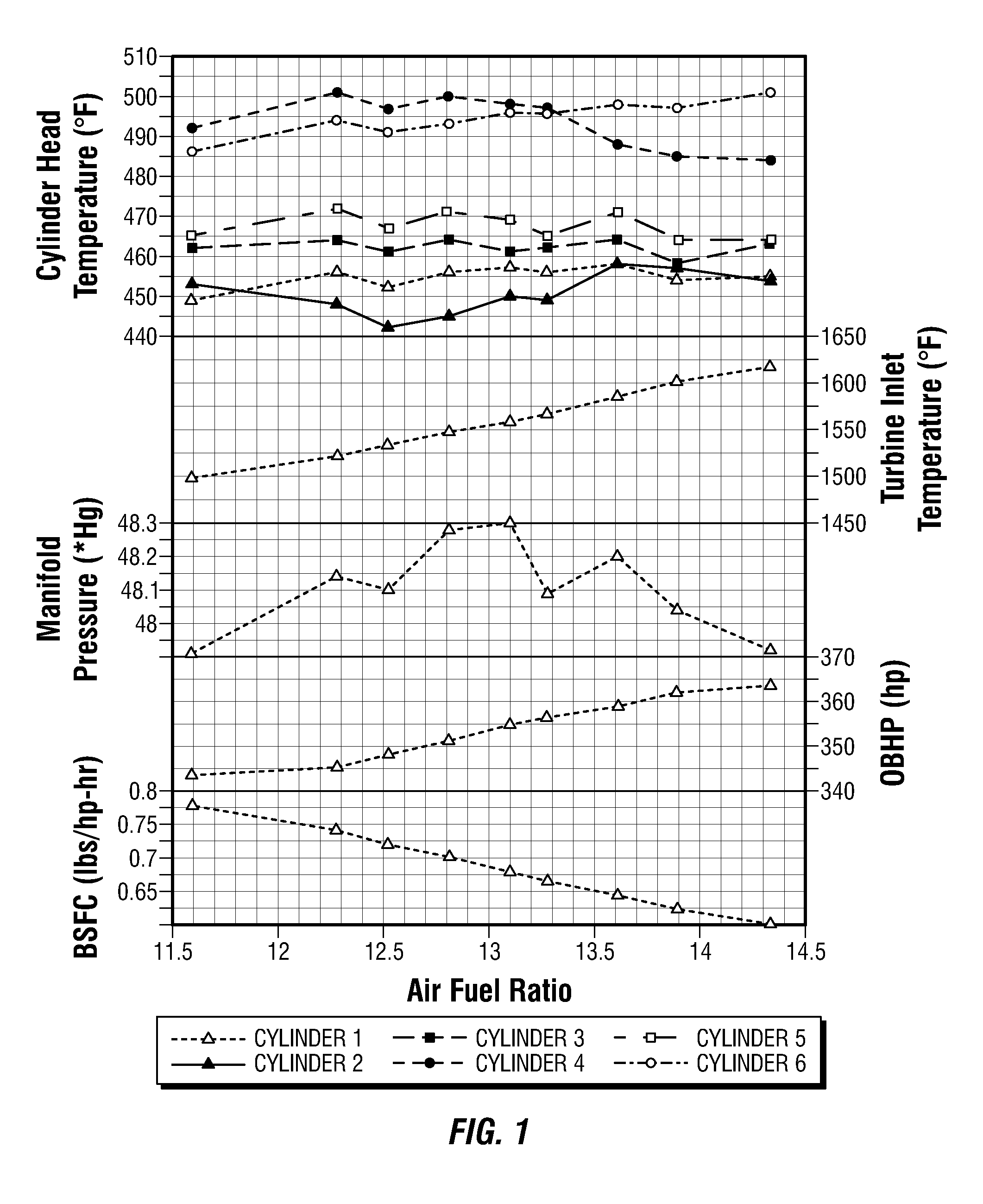

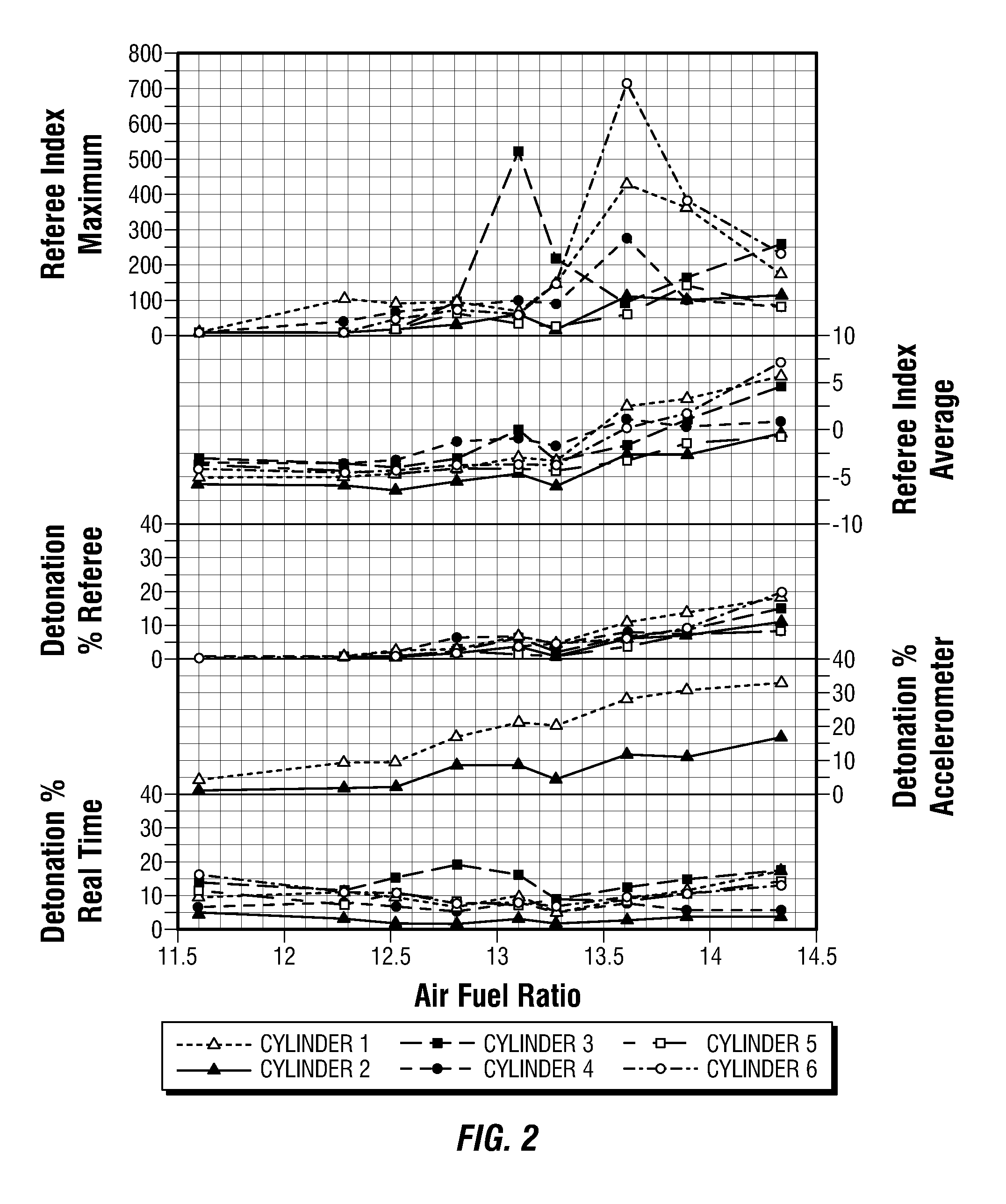

Characterization of aviation gasoline

Methods are provided for characterizing an aviation gasoline for use in a spark-ignited engine based on analysis methods traditionally used for compression-ignition fuels. For example, an aviation gasoline can be characterized based on a combustion delay for the aviation gasoline, a heat release rate for the aviation gasoline, or a combination thereof. Analyzing an aviation gasoline based on characteristics traditionally used for compression-ignition fuels can allow for distinction between types of aviation gasolines that may appear to be similar under conventional octane tests but that have substantially different performance characteristics.

Owner:EXXON RES & ENG CO

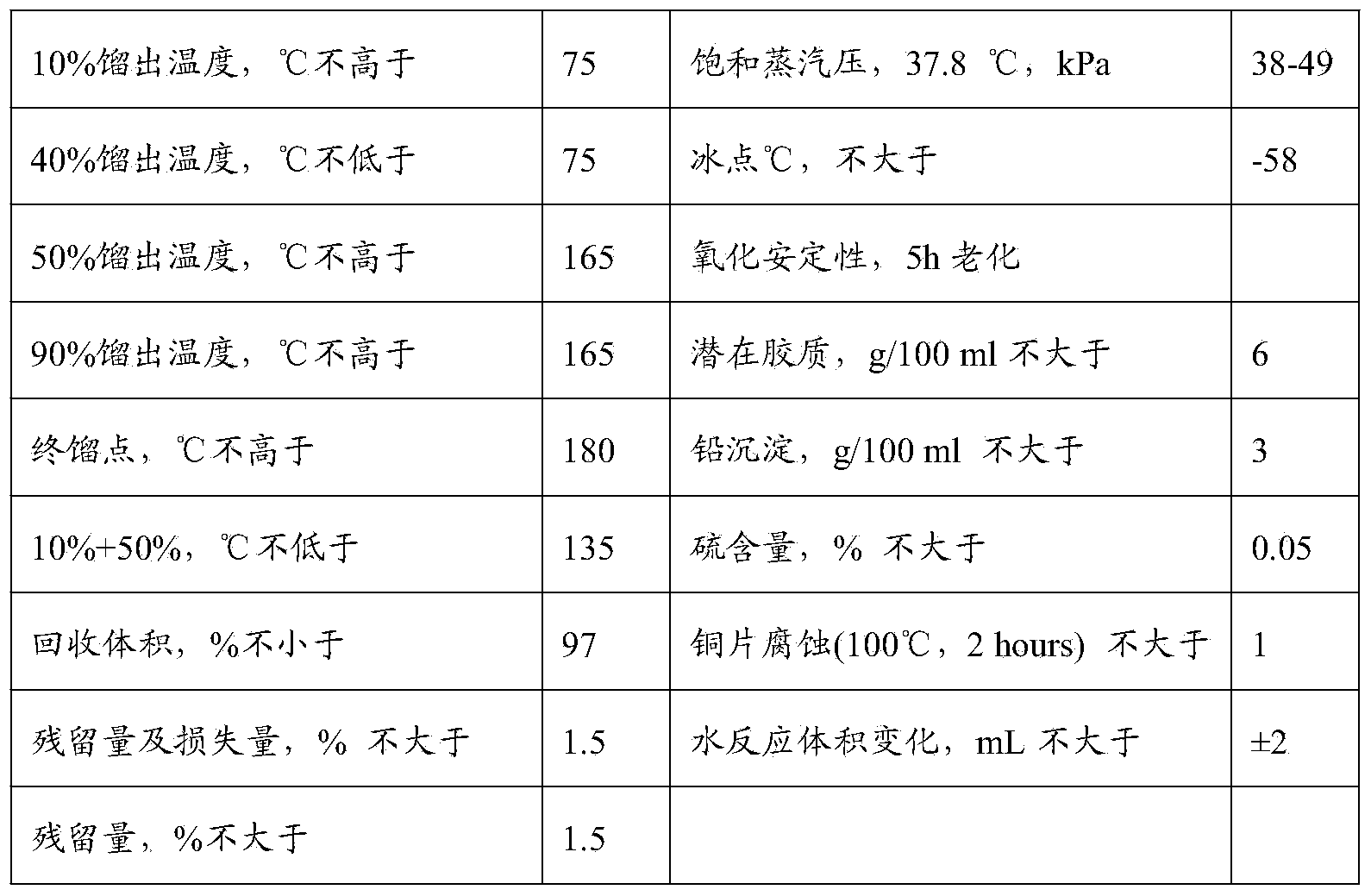

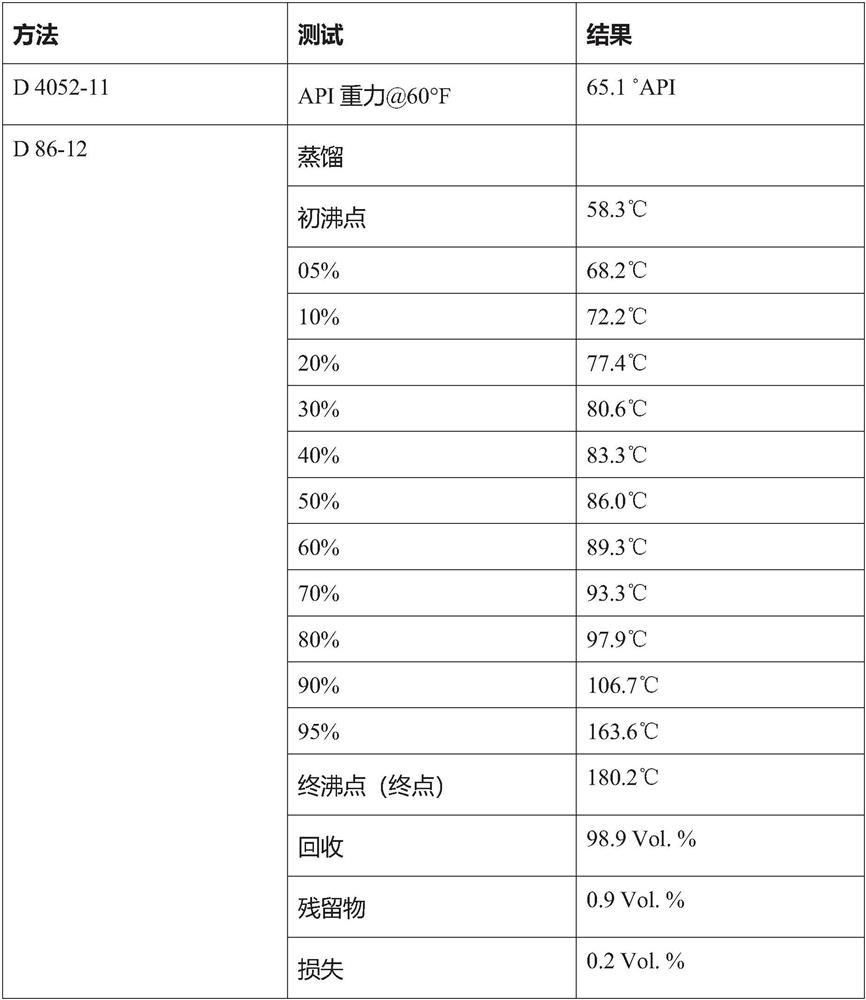

High octane unleaded aviation gasoline

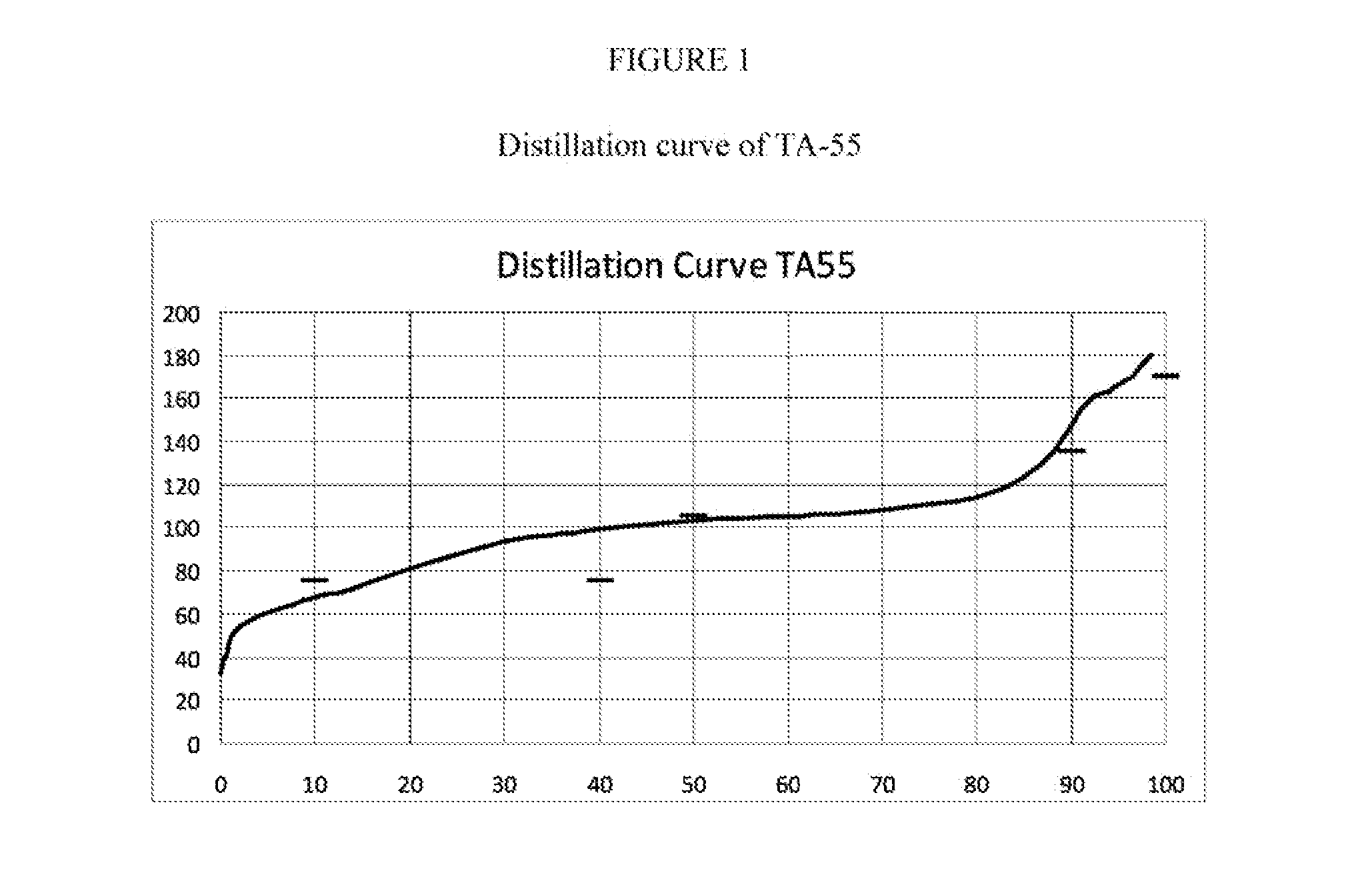

High octane unleaded aviation fuel composition having high aromatics content and CHN content of at least 97.8 wt %, less than 2.2 wt % of oxygen content, a T10 of at most 75° C., T40 of at least 75° C., a T50 of at most 105° C., a T90 of at most 135° C., a final boiling point of less than 190° C., an adjusted heat of combustion of at least 43.5 MJ / kg, a vapor pressure in the range of 38 to 49 kPa is provided.

Owner:SHELL USA INC

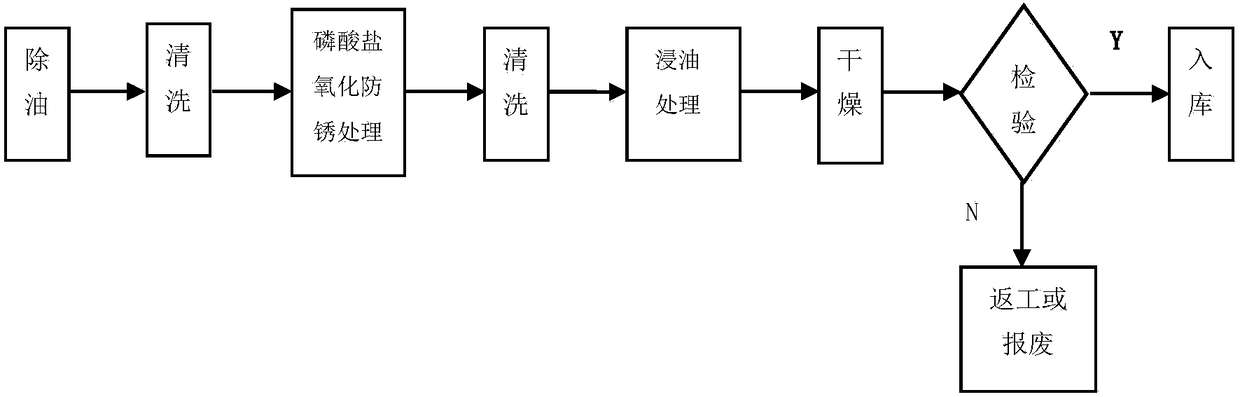

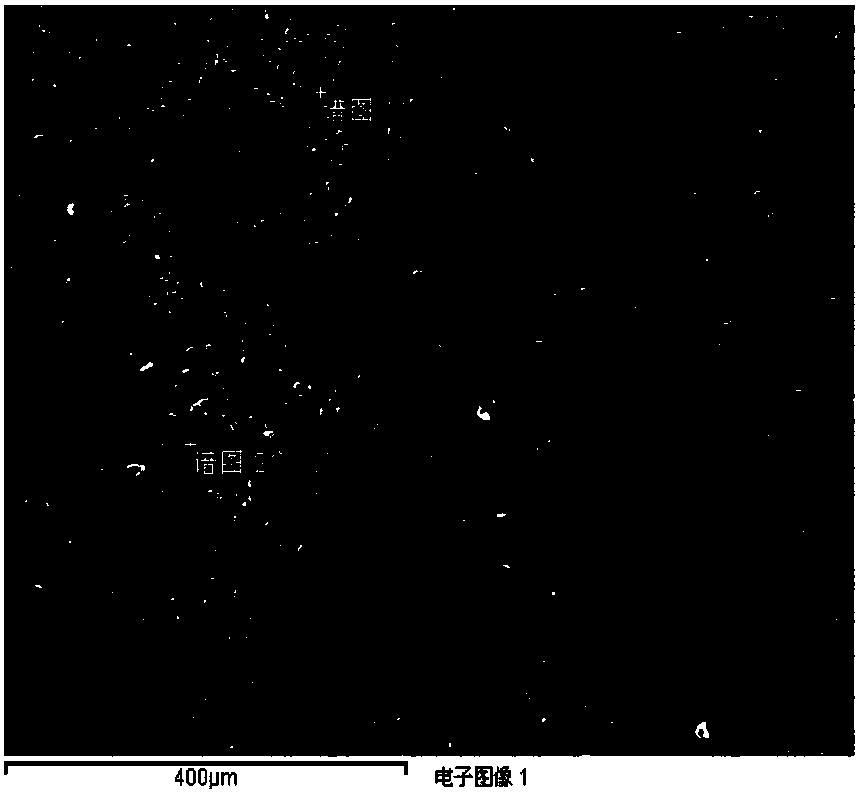

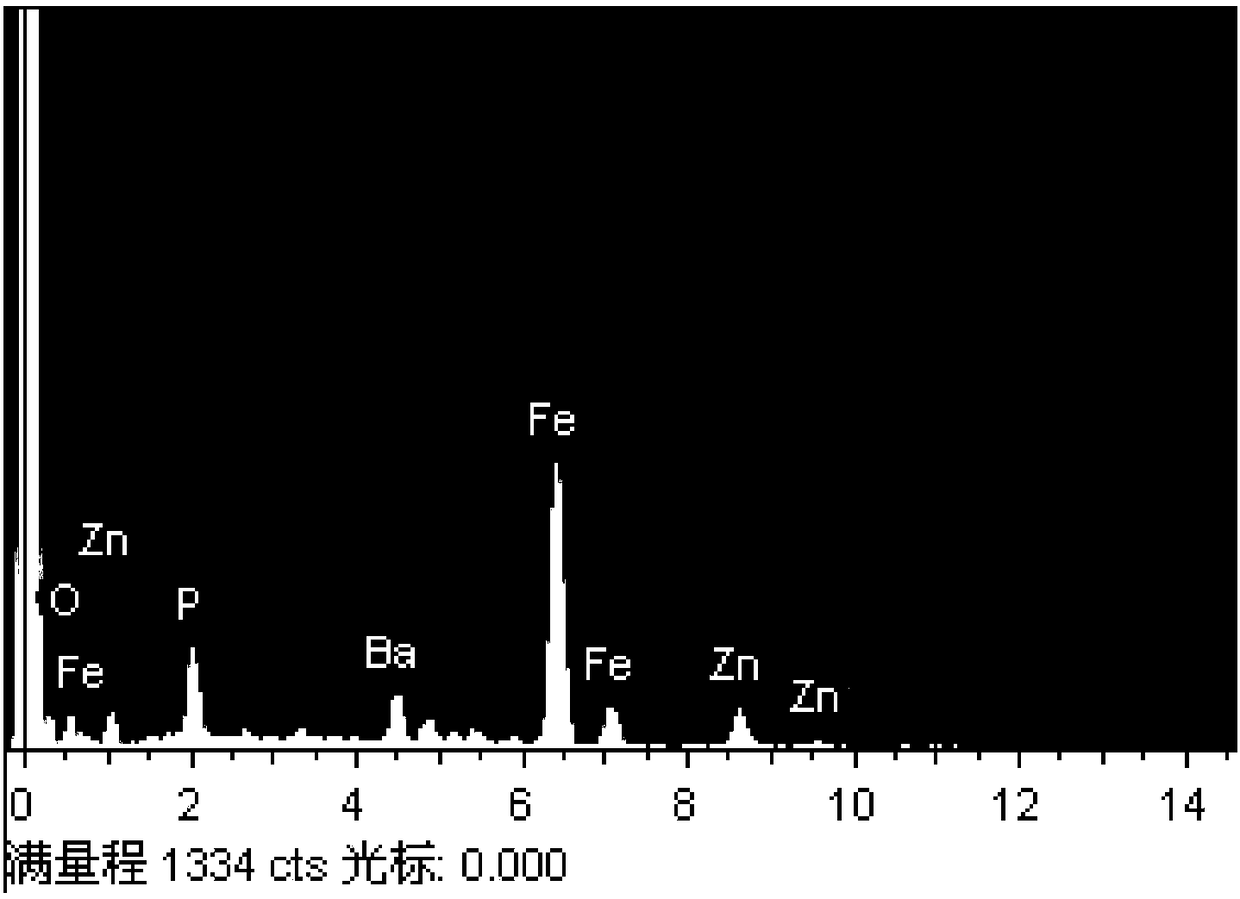

Phosphate oxidation antirust treatment solution and antirust treatment process of steel part

InactiveCN108193200ASolve the problem of reduced corrosion resistanceImprove corrosion resistanceMetallic material coating processesPhosphateRoom temperature

The invention relates to a phosphate oxidation antirust treatment solution and an antirust treatment process of a steel part. The process comprises the steps of (1) cleaning the steel part to be subject to antirust treatment with a degreasing solution; (2) hanging the cleaned steel part for phosphate oxidation antirust treatment, wherein the antirust treatment temperature is 70 DEG C to 90 DEG C,and the antirust treatment time is 3 to 20 minutes; (3) immersing the steel part into mixed oil of HH-20 lubricating oil and No.180 aviation gasoline at room temperature for 10 to 15 minutes; and (4)drying. The phosphate oxidation antirust treatment solution and the antirust treatment process of the steel part have the advantages that no hydrogen embrittlement influence is generated on parts andassemblies, the problem of low corrosion resistance after carburization and nitridation of the surface of the part can be solved, the bichromate passivation treatment of cadmium plating and zinc plating parts can be replaced, films are compact, and the influence on the surface roughness of the parts and the assemblies is less.

Owner:XIAN AERO ENGINE CONTROLS

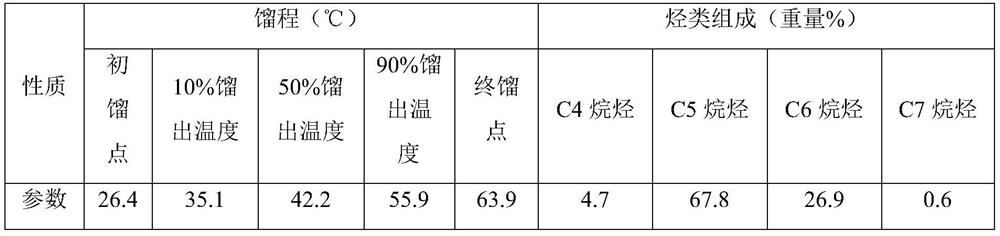

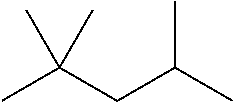

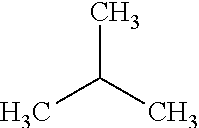

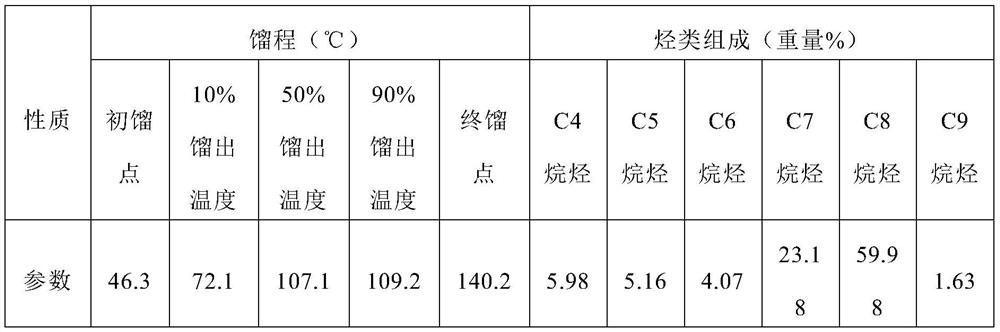

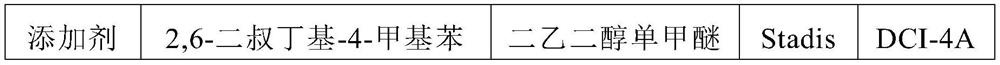

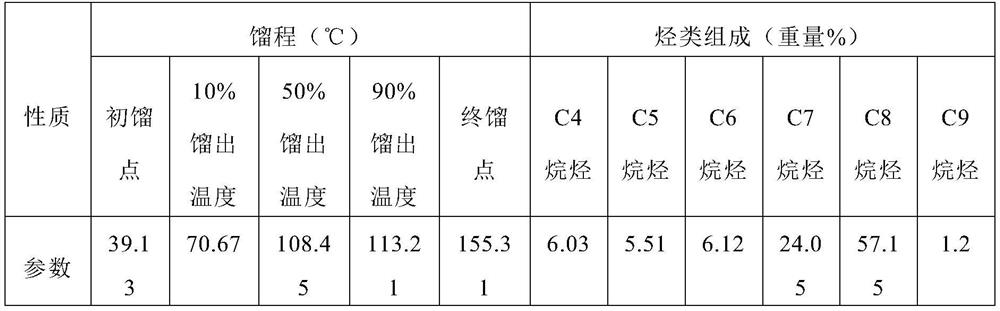

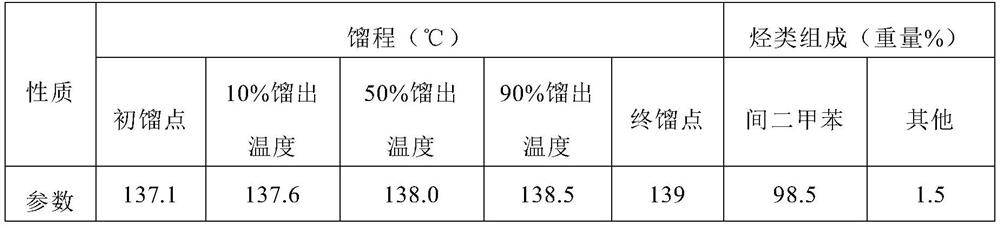

Alkane composition, 100 # lead-free aviation gasoline composition containing alkane composition and production method of 100 # lead-free aviation gasoline composition

The invention provides an alkane composition, a 100 # lead-free aviation gasoline composition containing the alkane composition and a production method of the 100 # lead-free aviation gasoline composition, the alkane composition contains C4 alkane, C5 alkane, C6 alkane, C7 alkane, C8 alkane and C9 alkane, and the aviation gasoline composition contains base oil and an additive, the base oil comprises the alkane composition as a blending component A, a blending component B, a blending component C and a blending component D, and the additive comprises methylcyclopentadienyl manganese tricarbonyl. The aviation gasoline composition disclosed by the invention does not contain tetraethyl lead while meeting various index requirements of anti-knock property, evaporability, stability and the like, can reduce pollution generated during combustion, is environment-friendly, and can meet the requirement of people on environmental protection. The octane number of the aviation gasoline composition is 99.6-103, the vapor pressure and the distillation range meet the requirements, the cost is low, the raw materials are simple and easy to obtain, and the preparation method is simple.

Owner:EAST CHINA UNIV OF SCI & TECH

Renewable engine fuel and method of producing same

The present invention provides high-octane fuel, and a method of producing same. These fuels may be formulated to have a wide range of octane values and energy, and may effectively be used to replace 100 LL aviation fuel (known as AvGas), as well as high-octane, rocket, diesel, turbine engine fuels, as well as two-cycle, spark-ignited engine fuels.

Owner:SWIFT ENTERPRISES

High octane unleaded aviation gasoline

High octane unleaded aviation fuel composition having high aromatics content and CHN content of at least 97.8wt%, less than 2.2 wt% of oxygen content, a T10 of at most 75°C, T40 of at least 75° C, a T50 of at most 105° C, a T90 of at most 135°C, a final boiling point of less than 190°C, an adjusted heat of combustion of at least 43.5 MJ / kg, a vapor pressure in the range of 38 to 49 kPa is provided.

Owner:SHELL INT RES MAATSCHAPPIJ BV

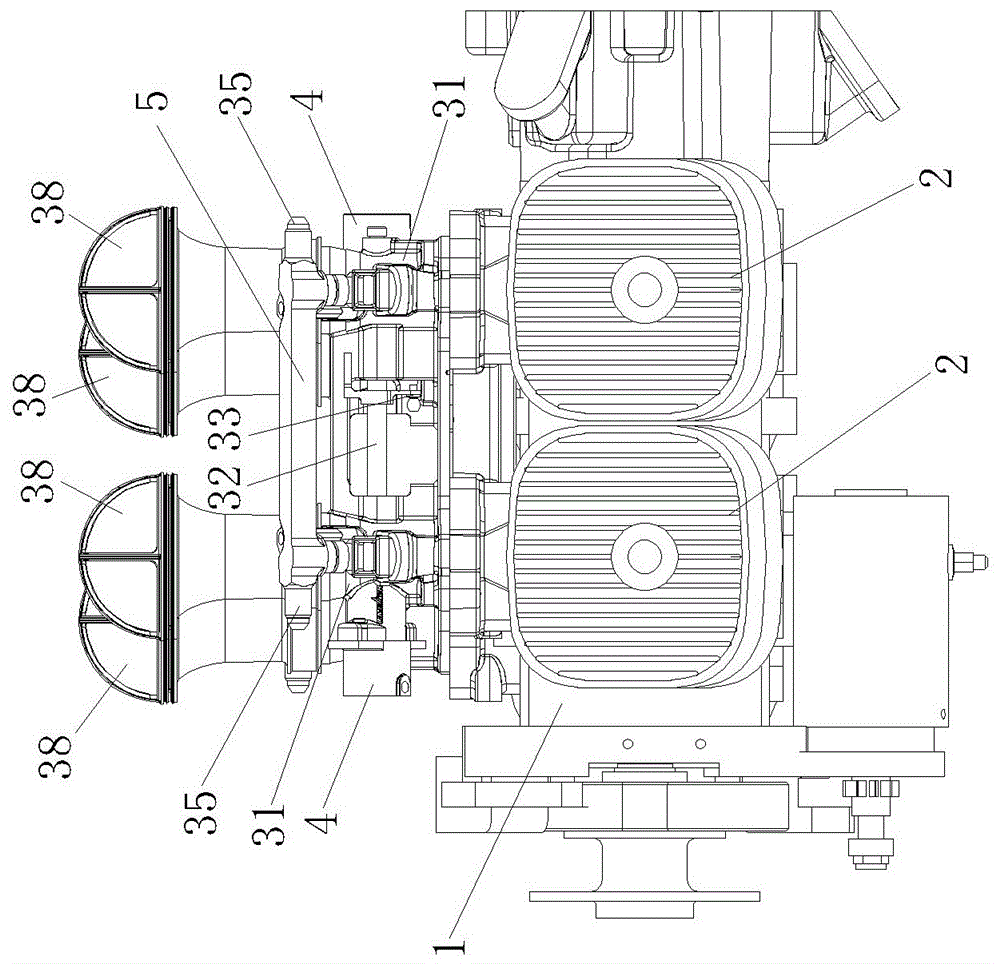

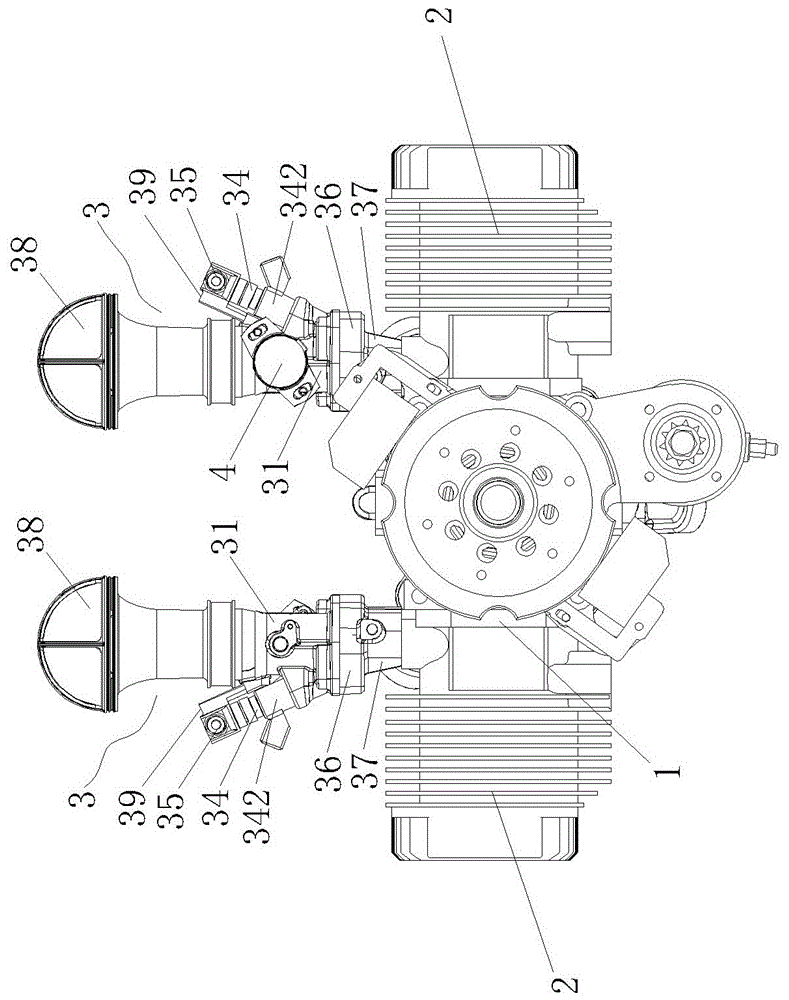

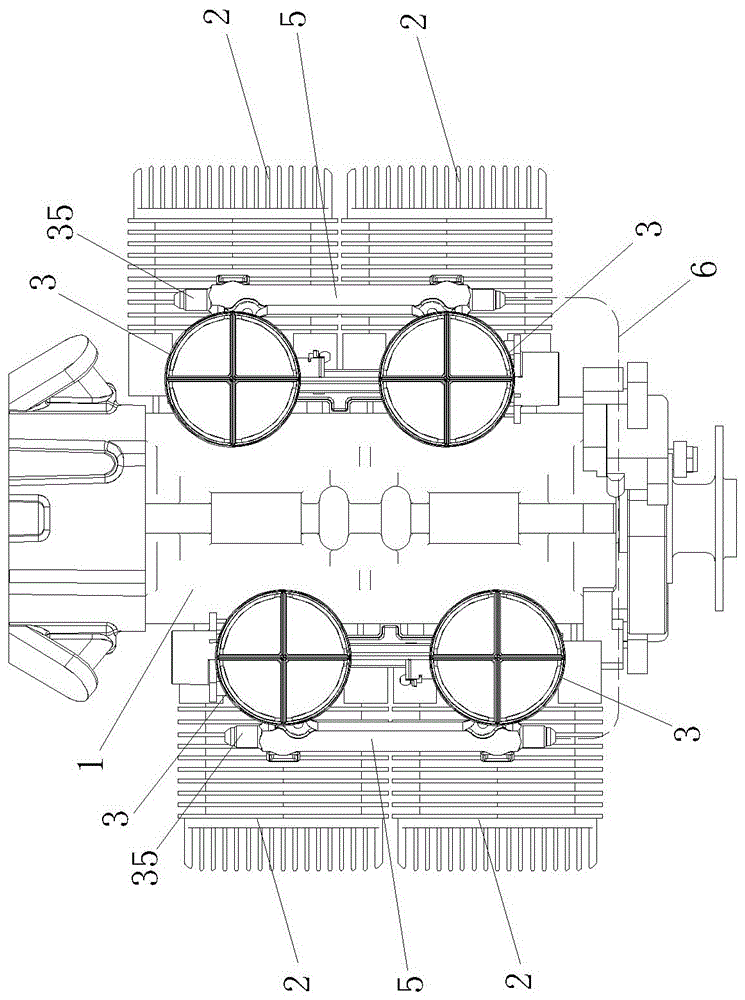

A kind of electro-injection aviation gasoline engine

ActiveCN104343566BInlet pressure balanceStable structureElectrical controlFuel injection apparatusGasoline fuelCrankcase

The invention discloses an electric injection type aviation gasoline engine, which comprises a crankcase and four cylinders. The four cylinders are installed on both sides of the crankcase in pairs horizontally opposed to each other, and the air inlets of the four cylinders are all facing upwards. The air inlet of each cylinder block is connected with an EFI mechanism, and the EFI mechanism includes an intake pipe, a throttle shaft, a driving crank arm, a fuel injector, and an oil inlet pipe, and the throttle shaft passes through the radial direction of the intake pipe. Located in the middle of the intake pipe, the part where the throttle shaft is located in the inner hole of the intake pipe is fixedly connected to the throttle valve, and the end outside the intake pipe is fixedly connected to the driving crank arm, and the fuel injector is installed on the side of the intake pipe inclined to the axis of the intake pipe , the lower part of the fuel injector is equipped with a nozzle, the middle part is equipped with an electromagnetic switch valve, and the upper part is connected to the oil inlet pipe. The nozzle is located in the inner hole of the intake pipe and is located at the lower part of the throttle valve; An air filter is connected; the present invention has wide adaptability and good fuel economy.

Owner:厦门林巴赫航空发动机有限公司

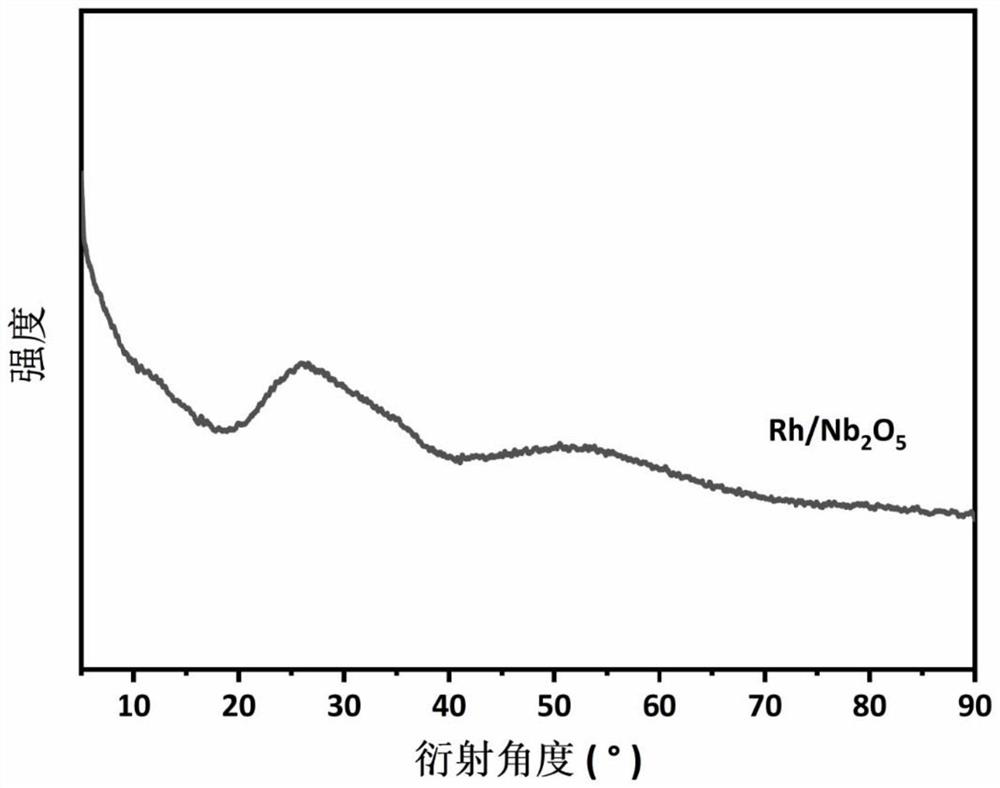

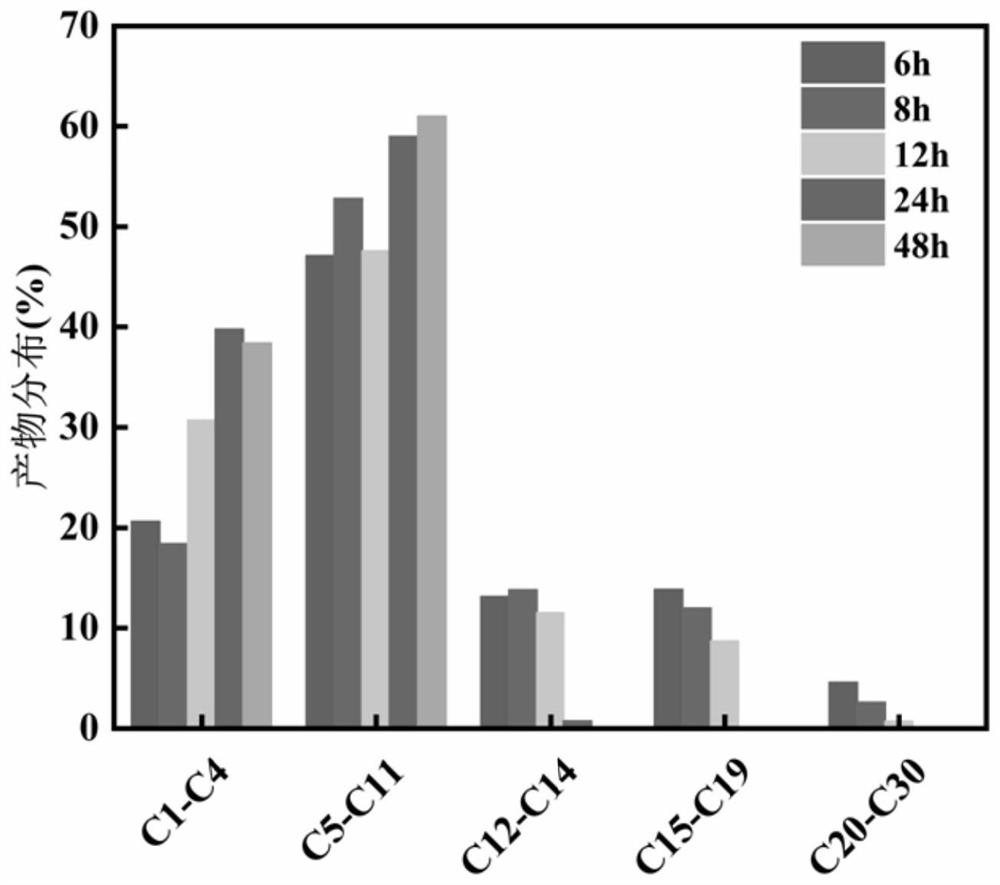

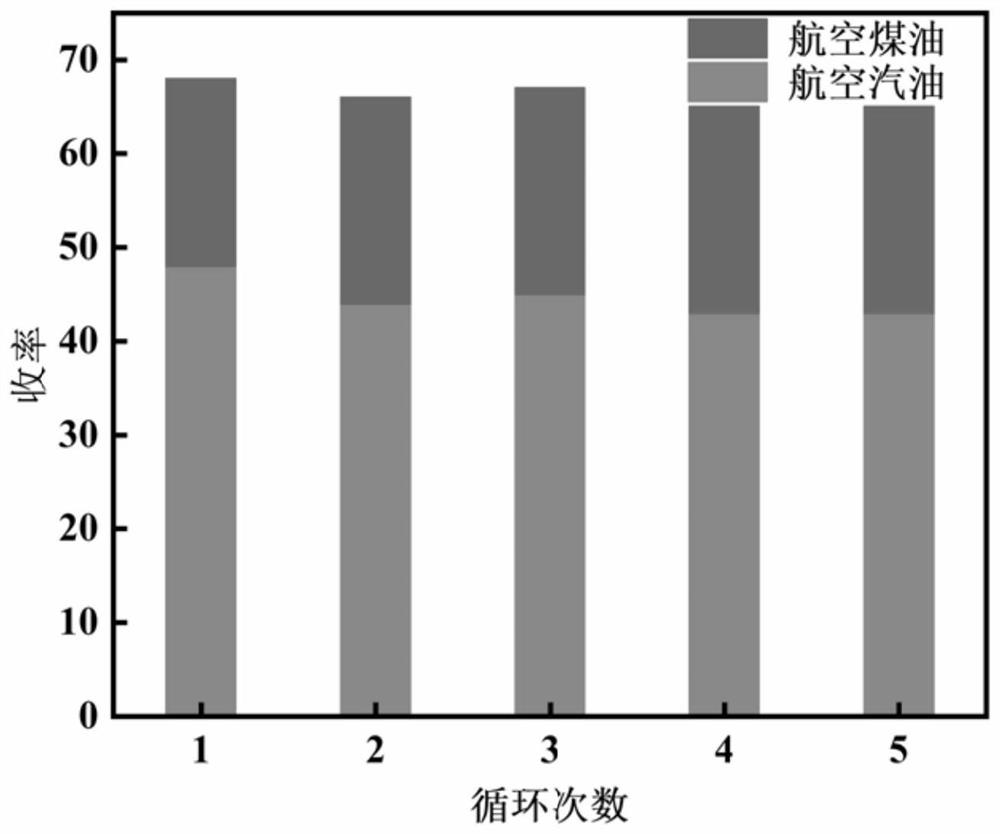

Method for directly preparing aviation gasoline and aviation kerosene from polyolefin waste plastics

ActiveCN113502174AHigh yieldHigh purityLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsPolyolefinIsomerization

The invention discloses a method for directly preparing aviation gasoline and aviation kerosene from polyolefin waste plastics, and belongs to the technical field of resource recycling. According to the method, high-molecular polyolefin waste plastic is taken as a raw material, a bifunctional catalyst composed of noble metal and inorganic solid acid is adopted, coupling of hydrogenation degradation and isomerization reaction of high-molecular-weight polyolefin plastic is realized, preparation of high-value oil from the polyolefin plastic is continuously realized by a one-step method, the conversion rate reaches about 99%, and the the conversion rate of the aviation oil product is as high as 80%. The method has the advantages of mild reaction conditions, simple catalyst preparation process, high activity, high selectivity and good stability, and is suitable for industrial production. The method not only can realize cyclic utilization of resources, but also can alleviate the current environmental pollution problem.

Owner:DALIAN UNIV OF TECH

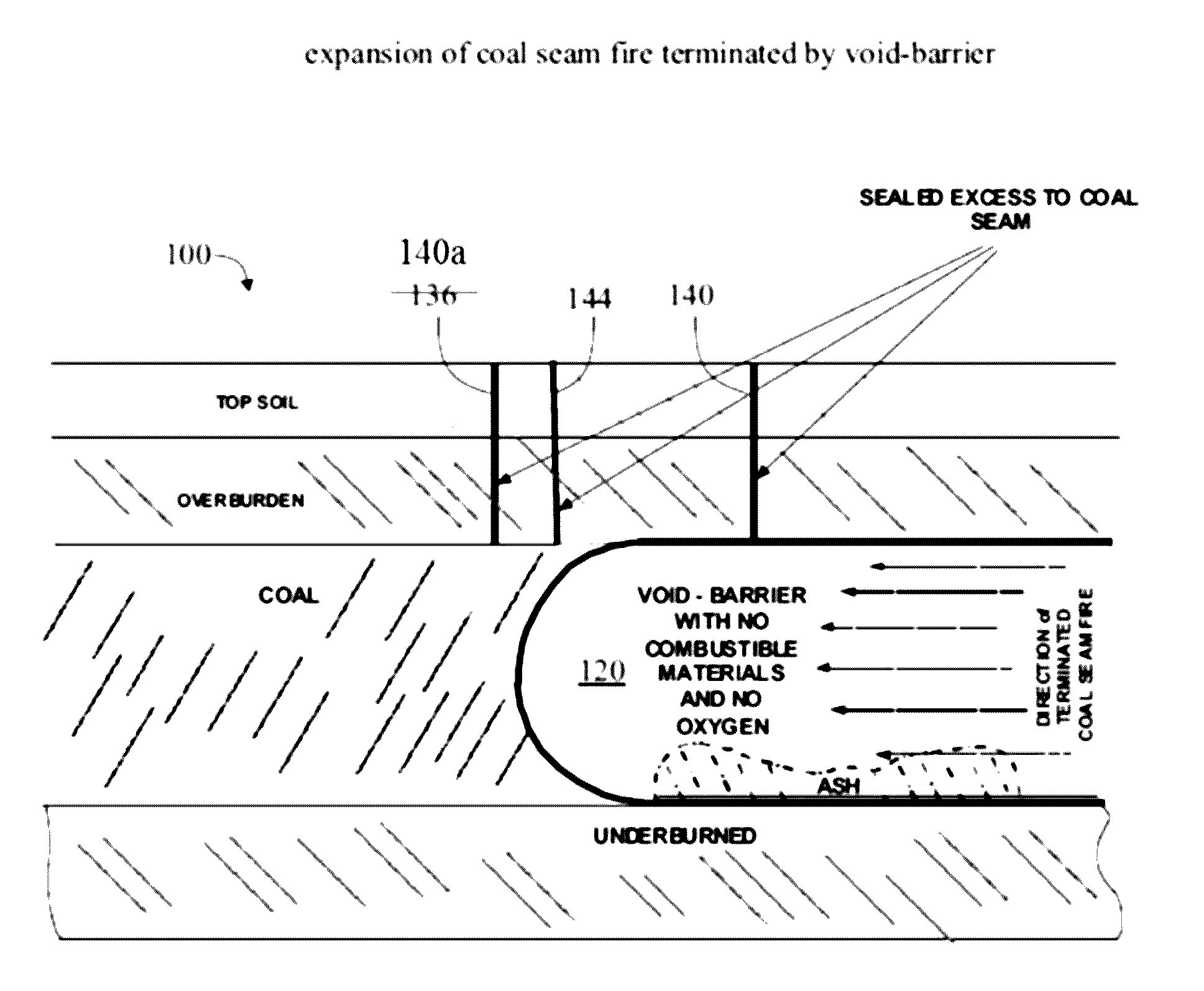

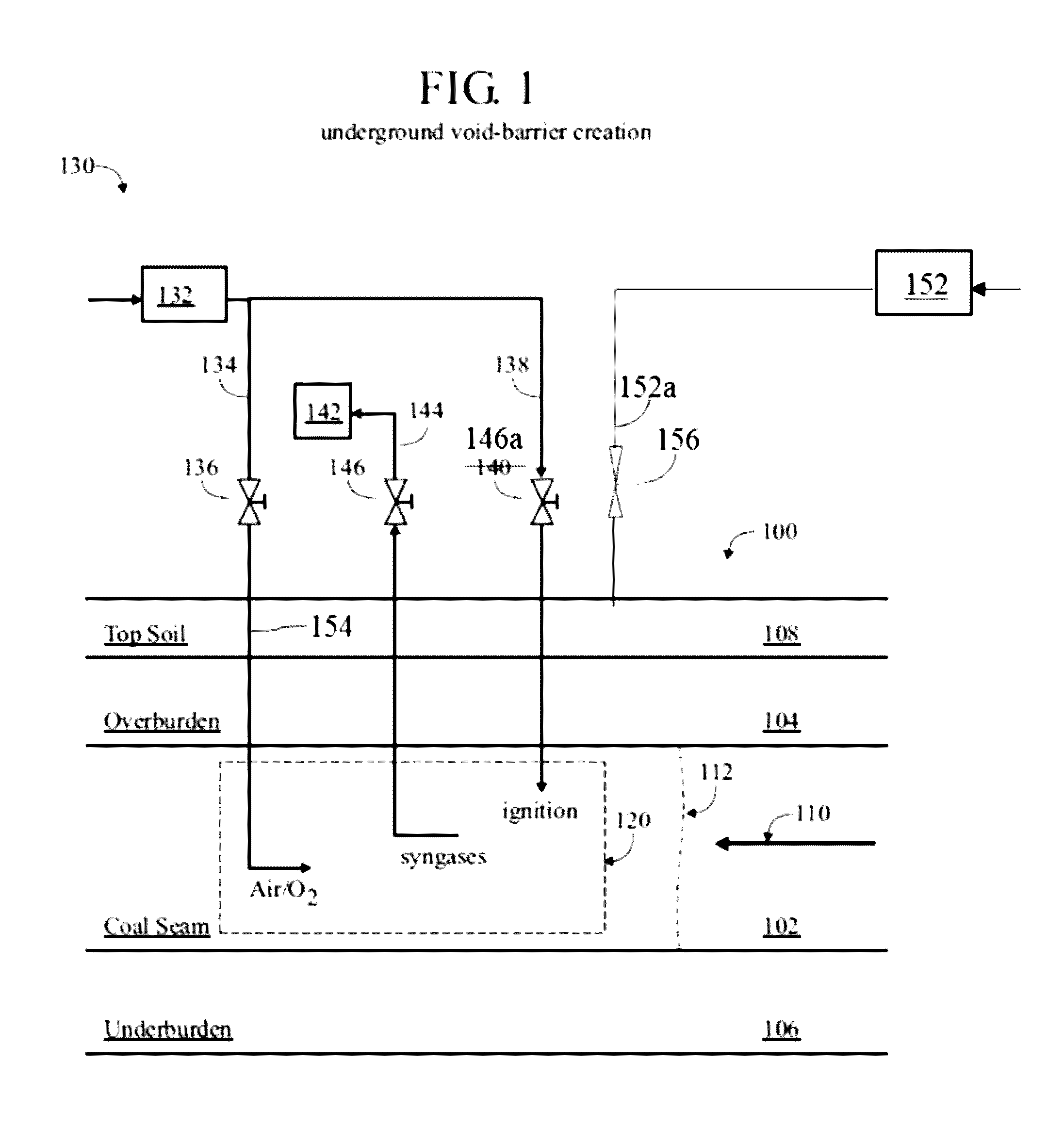

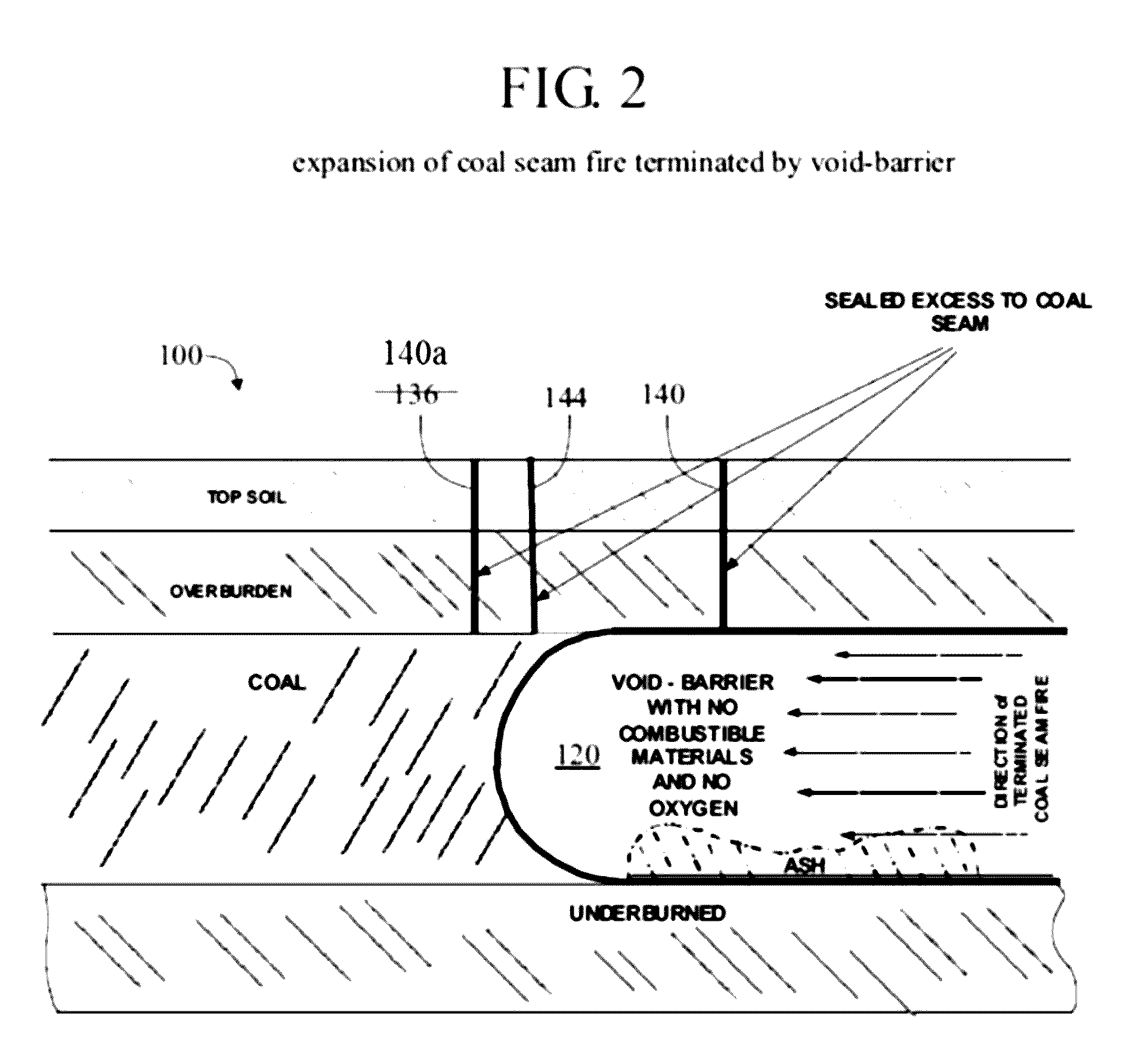

Terminating Expansion Of Underground Coal Fires And Protecting The Environment

InactiveUS20170021207A1Increasing coal calorific valueReduce air pollutionDust removalFire preventionCoal seam fireLiquid fuel

Method and apparatus for environment protection (climate change) from toxic elements and subsidence by existing underground coal seam fires by expansion termination of these fires. The method is based on creating, on the path of or around a burning coal seam fire, a subterranean void-barrier, with non-combustible gases (or fluids) and absence of oxidiser. The void-barrier may be substantially free from combustible material. The void-barrier will prevent further expansion of the existing coal seam fire, and may be created by known methods of coal extraction in gasified form, such as Underground Coal Gasification (USG). By-products from void-barrier creation can be utilized to reduce environmental pollution and for production of useful commercial entities such as gas or liquid fuels like: petrol, diesel, jet fuel, avgas, paraffin or electrical power generation and / or chemicals like CO2 for enrichment of coal or which may be sold.

Owner:LECHTMAN DAVID

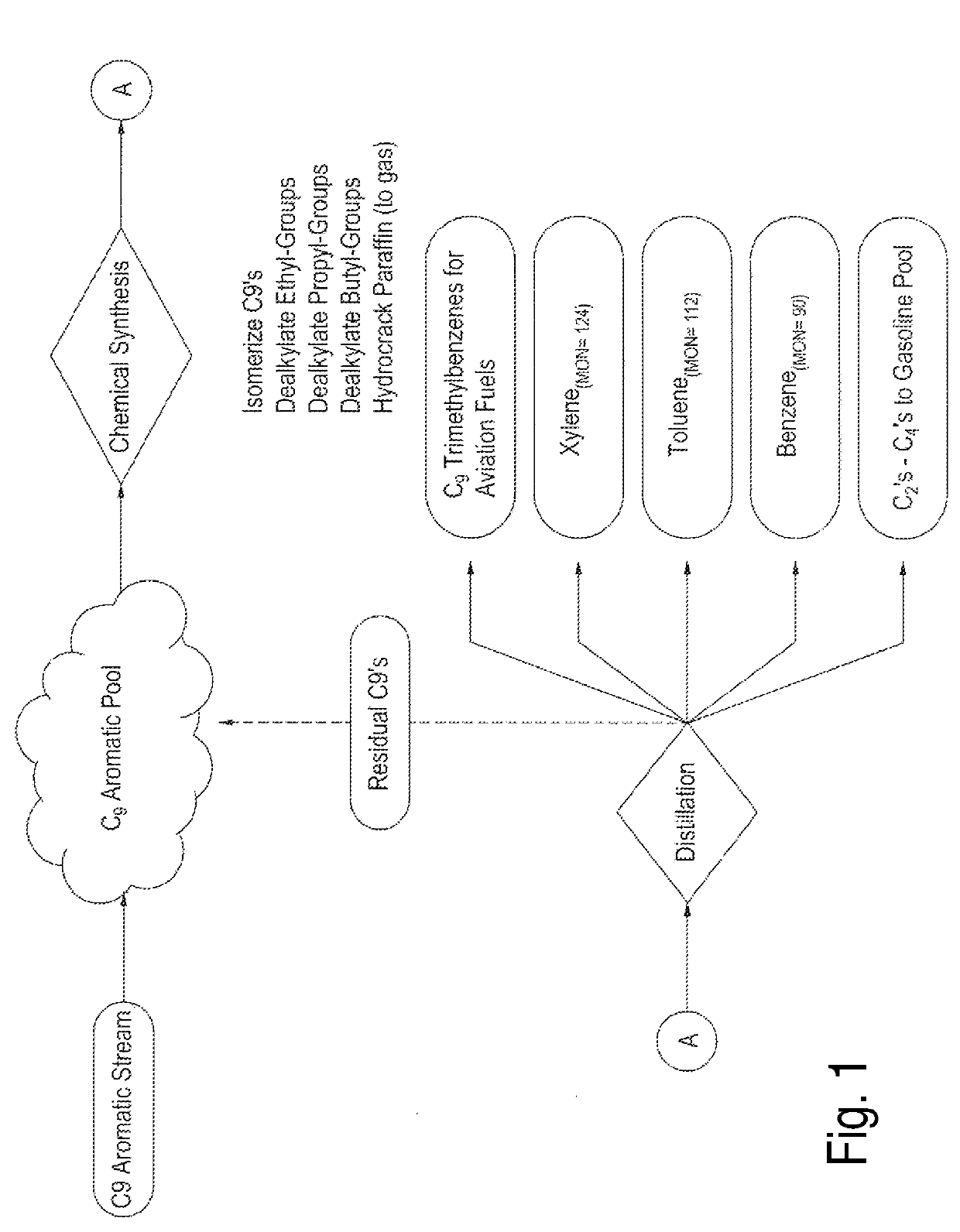

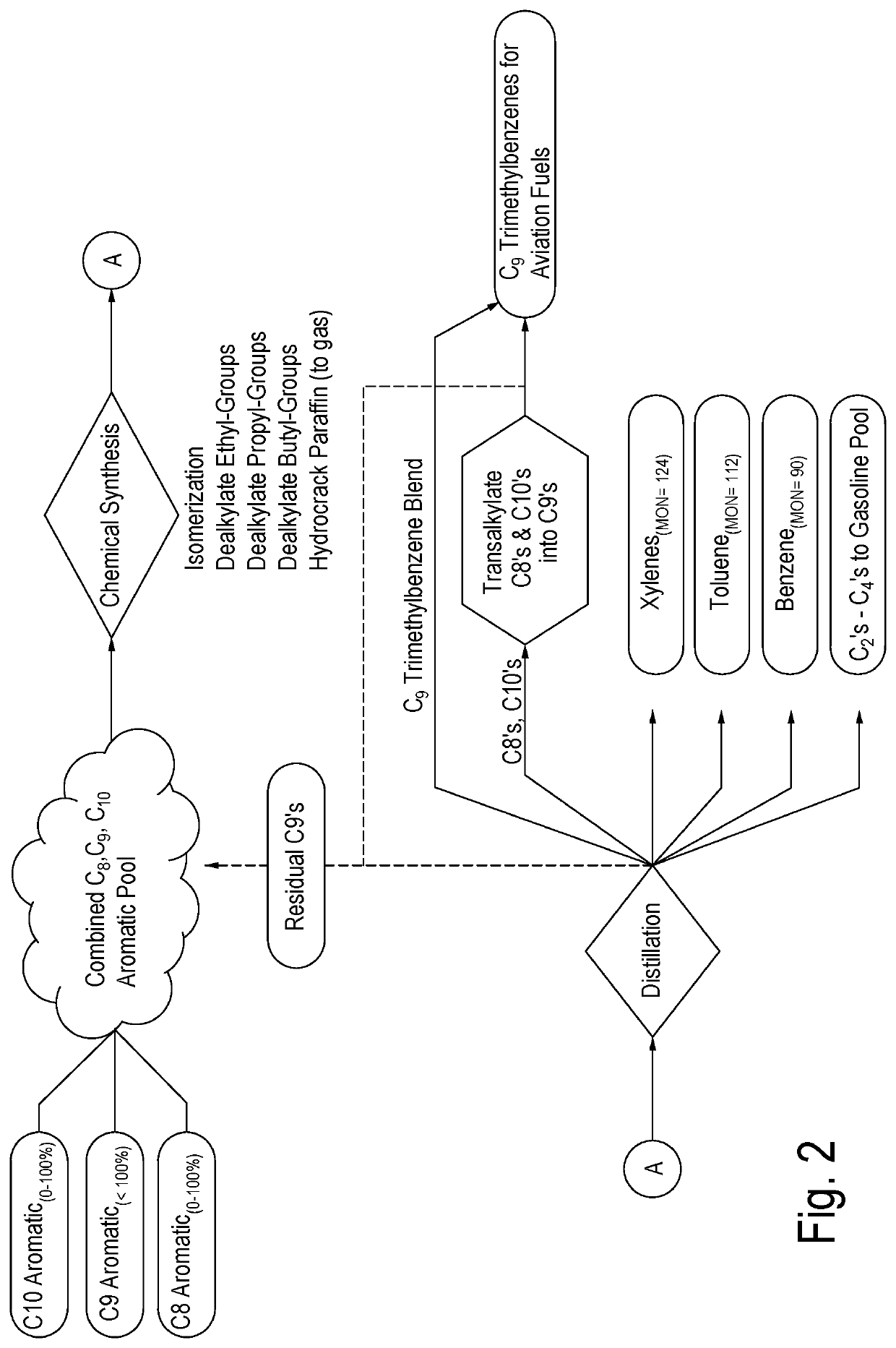

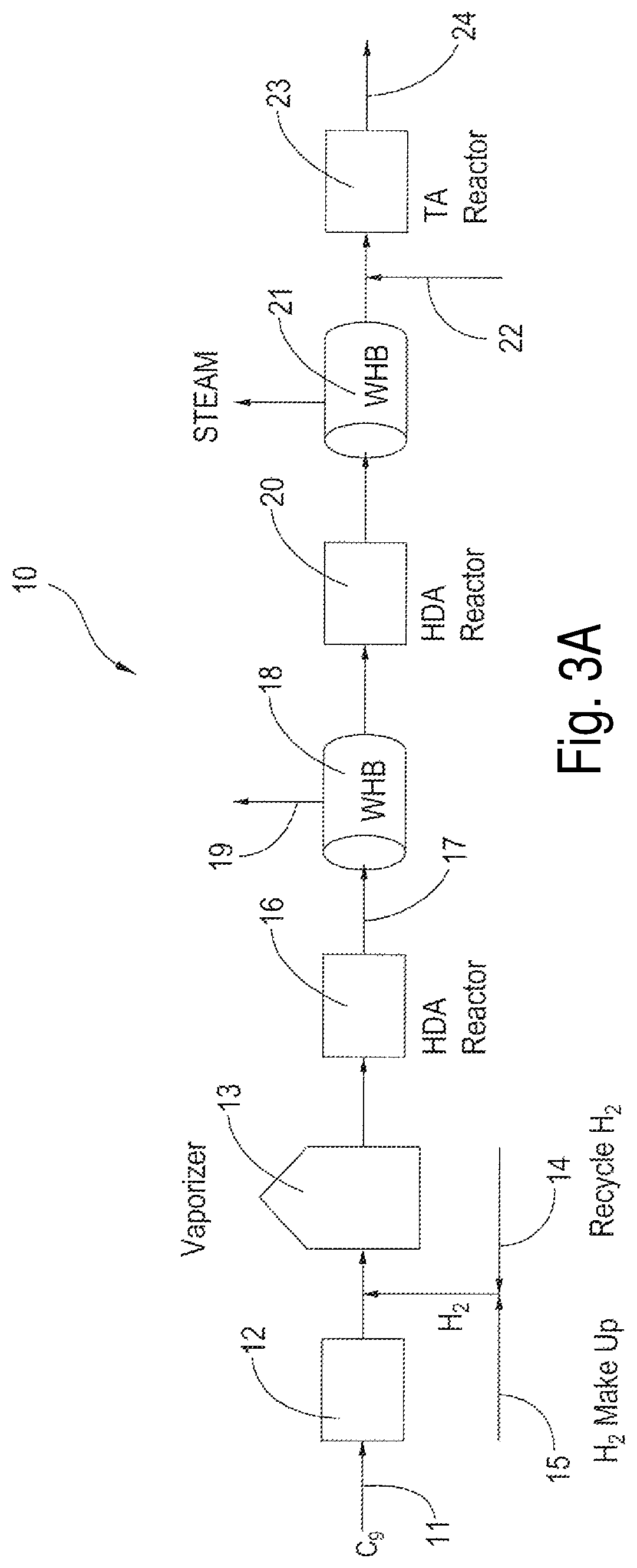

Treating C8-C10 aromatic feed streams to prepare and recover trimethylated benzenes

ActiveUS10526554B2Boost octaneYield maximizationHydrocarbonsTreatment with hydrotreatment processesMethyl benzeneMethyl group

Methods and alternatives for the efficient and cost-effective production of high-octane fuel blends from C9 aromatic feeds including methyl benzenes and C2 and / or higher alkyl benzenes. The fuel blend can serve as a high-octane unleaded fuel or fuel blending component for a wide range of applications, particularly aviation gasoline and other high-performance transportation fuels.

Owner:SWIFT FUELS

Aviation gasoline compositions

ActiveUS10883061B2Optimized formulaLow densityLiquid carbonaceous fuelsFuel additivesMechanical engineeringAvgas

Owner:CALUMET SPECIALTY PROD PARTNERS LP

91 # lead-free aviation gasoline and production method thereof

ActiveCN113736525ABoost octaneReduce manufacturing costLiquid carbonaceous fuelsProcess engineeringBase oil

The invention provides an aviation gasoline composition capable of being used as 91 # lead-free aviation gasoline and a production method thereof, the aviation gasoline composition contains base oil and an additive, and the base oil contains a blending component A, a blending component B and an optional blending component C. The aviation gasoline composition disclosed by the invention meets various index requirements of ASTM D910 standard, ASTM D7547 standard and GB 1787-2018 standard on anti-knock property, evaporability, low-temperature fluidity, stability and the like of 91 # aviation gasoline, meanwhile, the blending components are few, and the components do not need to be highly refined, are cheap and easy to obtain and are wide in source. Besides, the aviation gasoline composition does not contain tetraethyl lead, is environment-friendly, and can meet the requirements of people on environmental protection.

Owner:EAST CHINA UNIV OF SCI & TECH

No.94 lead-free aviation gasoline and production method thereof

ActiveCN113736527ABoost octaneReduce manufacturing costLiquid carbonaceous fuelsProcess engineeringBase oil

The invention provides an aviation gasoline composition capable of being used as No.94 lead-free aviation gasoline and a production method thereof, the aviation gasoline composition contains base oil and an additive, and the base oil contains a blending combination A, a blending component B and a blending component C. The aviation gasoline composition does not contain tetraethyl lead and is environmentally friendly, the motor octane number of the aviation gasoline composition ranges from 94 to 96, the octane number is high, the vapor pressure, the distillation range and other indexes meet the requirements of the ASTM D7547 standard and the ASTM D7592 standard for UL94 # aviation gasoline, and the aviation gasoline composition can be used for most engines used by 100 # low-lead aviation gasoline. The aviation gasoline composition disclosed by the invention has the advantages of few required blending components, wide sources, good fuel performance, low production cost and simple production method.

Owner:EAST CHINA UNIV OF SCI & TECH

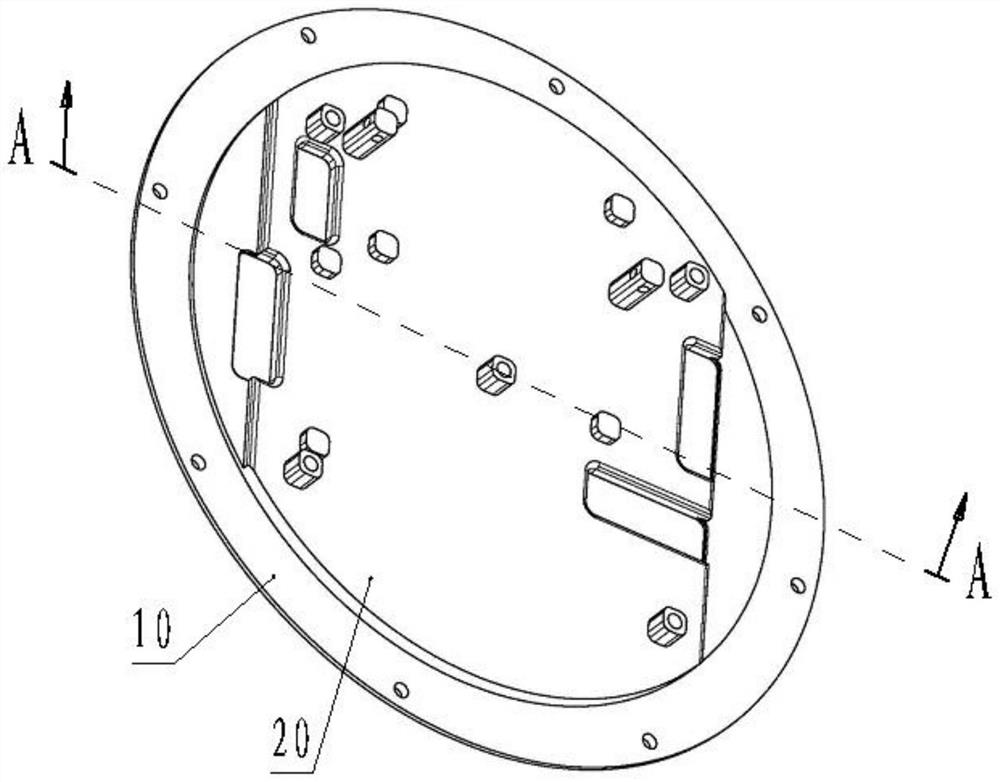

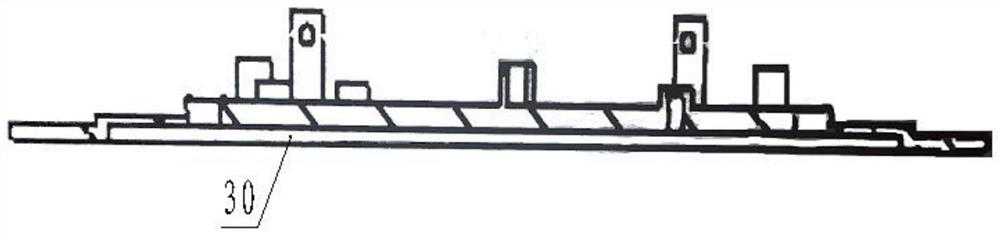

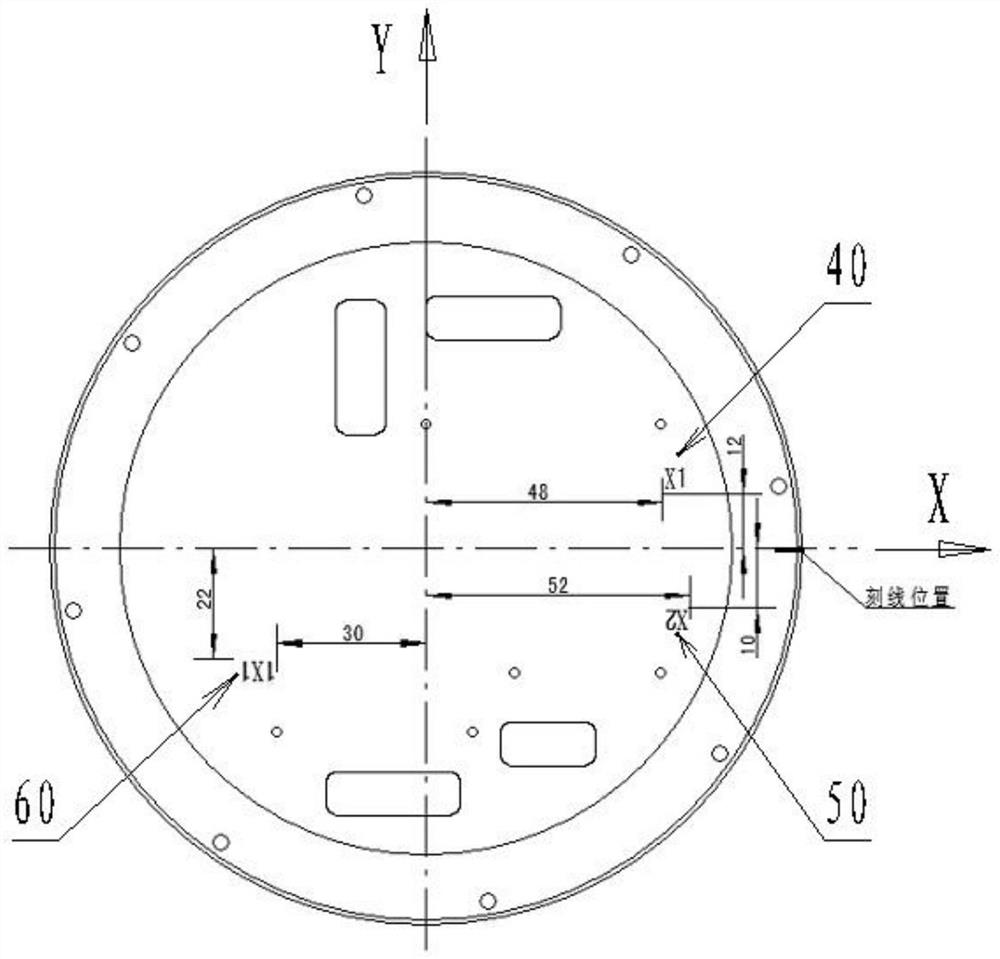

Lettering and paint embedding method for thin plate disc-shaped duralumin bottom plate part

PendingCN114054968AProblems Affecting FlatnessAdditional drying stepsPretreated surfacesLaser beam welding apparatusDuraluminLettering

The invention relates to a lettering and paint embedding method for a thin plate disc-shaped duralumin bottom plate part. The bottom plate part comprises an annular edge plate and a circular truncated cone, and an open bottom hole is formed in the bottom face of the annular edge plate; a plurality of lettering areas are arranged on the plane of the bottom hole; and line carving is performed on the bottom surface of the annular edge plate. The lettering and paint embedding method comprises the following steps that: S1, lettering and line carving are conducted, specifically, the bottom plate part is clamped, lettering contents of different lettering areas are edited, and lettering is conducted on the lettering areas through lettering equipment, line carving is performed on the bottom surface of the annular edge plate, the depth of the lettering and line carving is 0.2-0.3 mm, and the width of the lettering and line carving is 0.3 mm; S2, inspection is performed, specifically, a laser lettering font inspection template is adopted to compare and inspect lettering fonts, and a vernier caliper is adopted to inspect the depth and width of the lettering and line carving; S3, paint embedding is conducted, specifically, a part to be subjected to paint embedding is wiped with aviation gasoline, paint embedding is carried out by adopting C04-42 black alkyd enamel paint, after paint embedding, the part is naturally aired, after being aired, the paint at a non-paint-embedded part is cleaned, and the part is placed in a constant-temperature drying oven to be dried.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

Aviation gasoline compositions

An aviation gasoline composition having: from about 70 vol% to about 80 vol% isooctane; from about 5 vol% to about 9 vol% isopentane; from about 10 vol% to about 20 vol% of one or more dialkyl ether; and from about 1 vol% to about 5 vol% of one or more alcohol, from about 0.02. vol% to about 0.07 vol% of one or more octane enhancer such as MMT, and, optionally, one or more additives selected from the group consisting of: antioxidants, anti-icing agents, antistatic additives, corrosion inhibitors, dyes, lubricants, and mixtures thereof, wherein the aviation gasoline has a motor octane number of at least 99.6.

Owner:LYONDELL CHEM TECH LP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com