Lead-free aviation gasoline and preparation method thereof

A technology of unleaded aviation and gasoline, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of polluting the environment, harming the human body, entering air, soil and water sources, etc., and achieves low combustion pollution, low cost, and The effect of low nitrogen compound content and low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

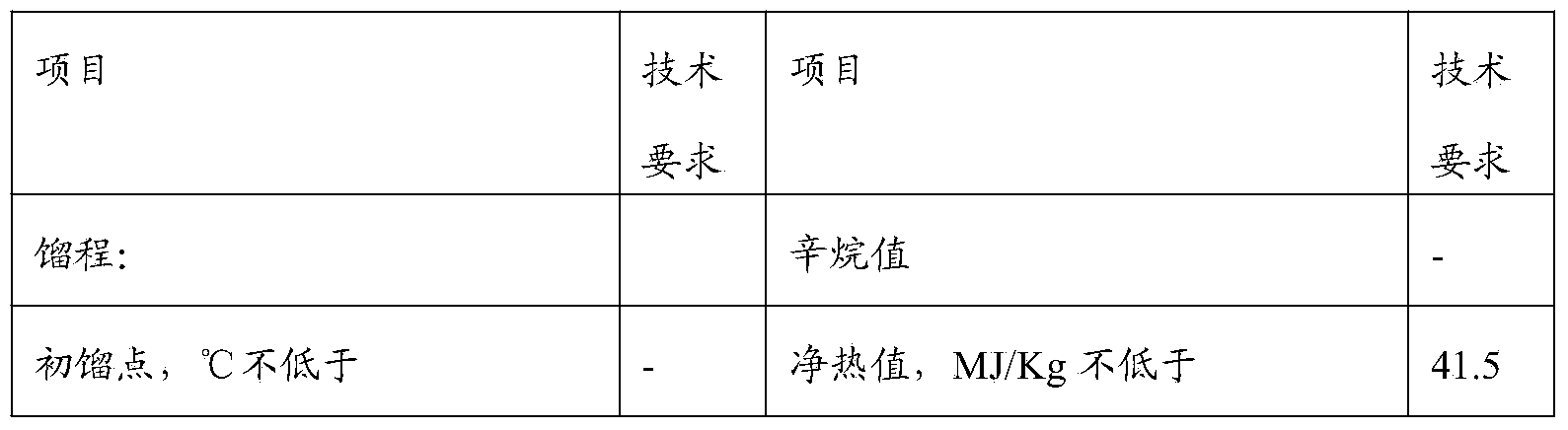

[0033] 60% by volume of isooctane prepared by isomerization, 3% of isobutane, 7% of isopentane, 2% of toluene, 18% of xylene, 5% of toluidine and 5% After the methyl tert-butyl ether is mixed and blended, unleaded aviation gasoline is obtained, and some physical and chemical property indicators of this unleaded aviation gasoline are shown in Table 2 below:

[0034] Part of the physical and chemical properties of unleaded aviation gasoline prepared in Table 2

[0035]

[0036]

Embodiment 2

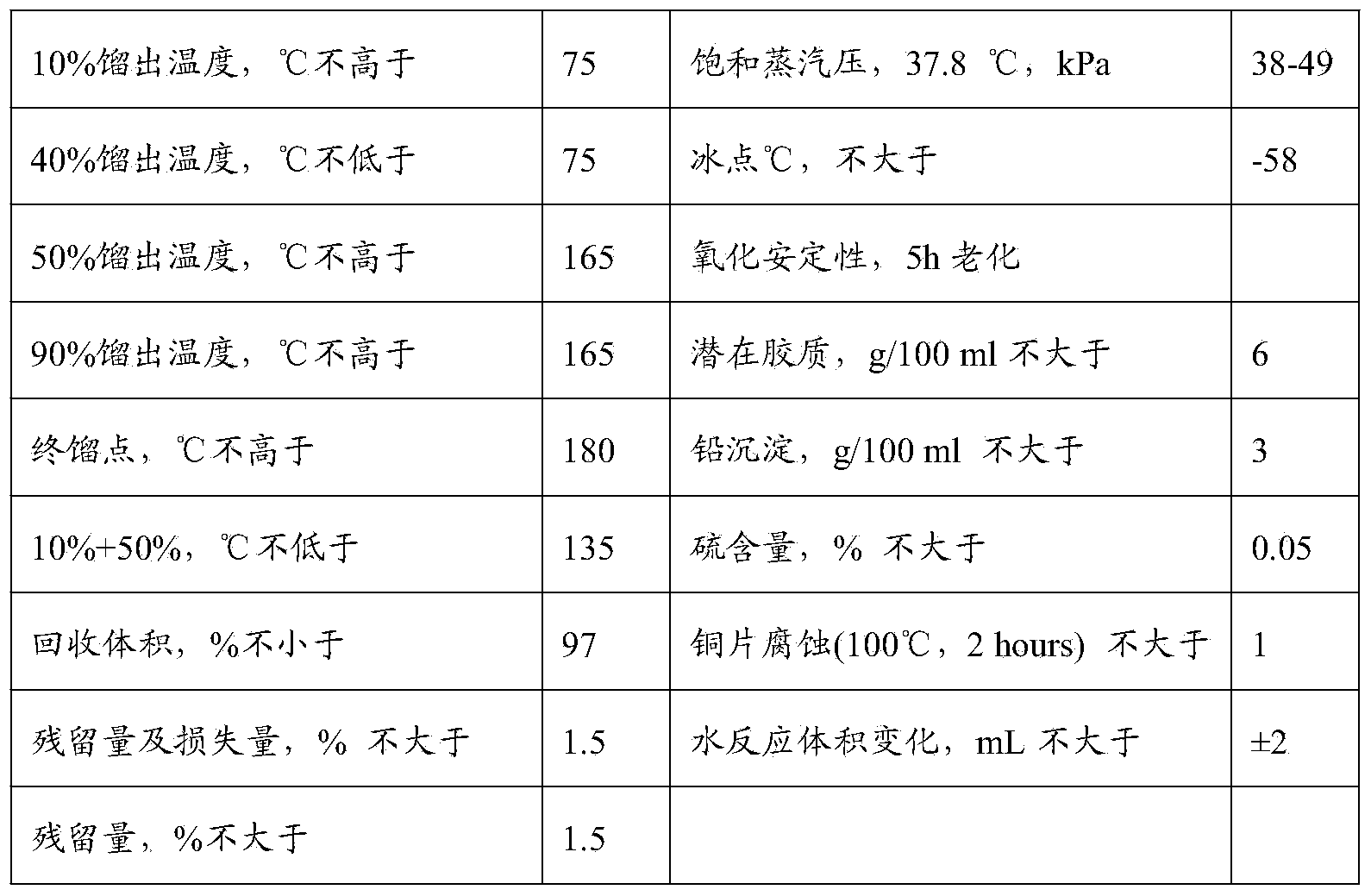

[0038] In terms of volume percentage, 58% of C4-C10 alkanes prepared by catalytic cracking, hydrofining and distillation cutting, 34% of C7-C9 aromatics prepared by aromatization and distillation cutting, 2% of aniline and 6% of ether After the methyl tert-amyl ether prepared by compounding is mixed and blended uniformly, unleaded aviation gasoline is obtained, and some physical and chemical property indexes of this unleaded aviation gasoline are shown in Table 3 below:

[0039] Some physical and chemical properties of unleaded aviation gasoline prepared in table 3

[0040]

Embodiment 3

[0042] An unleaded aviation gasoline is composed of C4-C12 alkanes prepared by alkylation and distillation cutting. Some physical and chemical properties of the unleaded aviation gasoline are shown in Table 4 below:

[0043] Some physical and chemical properties of unleaded aviation gasoline prepared in table 4

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com