102 # lead-free aviation gasoline and production method thereof

An aviation gasoline and steam technology, which is used in the petroleum industry, liquid carbon-containing fuels, fuels, etc., and can solve problems such as shortened life of rubber parts or gaskets, wear of metal materials of engine valve seats, and engine wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] In some embodiments, the preparation method of the aviation gasoline composition of the present invention further includes the step of obtaining blending component D. The step of obtaining the blending component D may be: gently drying the sweet orange peel in an oven at 40-50°C, such as 46°C, through flowing air for 8-16 hours, such as 12 hours, and drying it at 170-180°C, 7 After extraction into a stable oil-in-water emulsion by steam explosion at -9 bar, the distillation operation is performed for 25-35 minutes, for example, 30 minutes, and the obtained component is blending component D.

[0076] The various parameters of the aviation gasoline composition of the present invention meet the requirements of the ASTM-D7719 standard for No. 102 unleaded aviation gasoline. The motor octane number of the aviation gasoline composition of the invention is not less than 102, which meets the antiknock requirement. The Reid vapor pressure of the aviation gasoline composition of...

Embodiment 1

[0087] Blending component B of 7 mass % (its properties are shown in Table 1-1), 10 mass % of blending component C oil (its properties are shown in Table 1-2), 80 mass % of mesitylene (its properties See Table 1-3) and 3% by mass of sweet orange peel oil (its properties are shown in Table 1-4), then add other additives according to Table 1-5, after blending evenly, obtain aviation gasoline, the aviation gasoline The properties of are shown in Table 1-6 below.

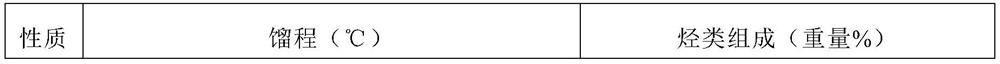

[0088] Table 1-1

[0089]

[0090]

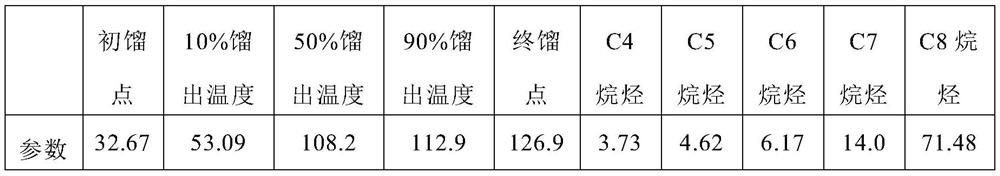

[0091] Table 1-2

[0092]

[0093] Table 1-3

[0094]

[0095] Table 1-4

[0096]

[0097] Table 1-5

[0098]

[0099] Table 1-6

[0100]

Embodiment 2

[0102] Mix 5% by mass of blending component B (see Table 2-1 for its properties), 10% by mass of blending component C (see Table 2-2 for its properties), and 82% by mass of mesitylene (see Table 2-2 for its properties Table 2-3) and 3 mass % of sweet orange peel oil (its properties are shown in Table 2-4) mix, then add other various additives according to Table 1-5, after blending evenly, obtain aviation gasoline, the aviation gasoline The properties are shown in Table 2-5 below.

[0103] table 2-1

[0104]

[0105] Table 2-2

[0106]

[0107]

[0108] Table 2-3

[0109]

[0110] Table 2-4

[0111]

[0112] Table 2-5

[0113]

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| motor octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com