Patents

Literature

55results about How to "Octane reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

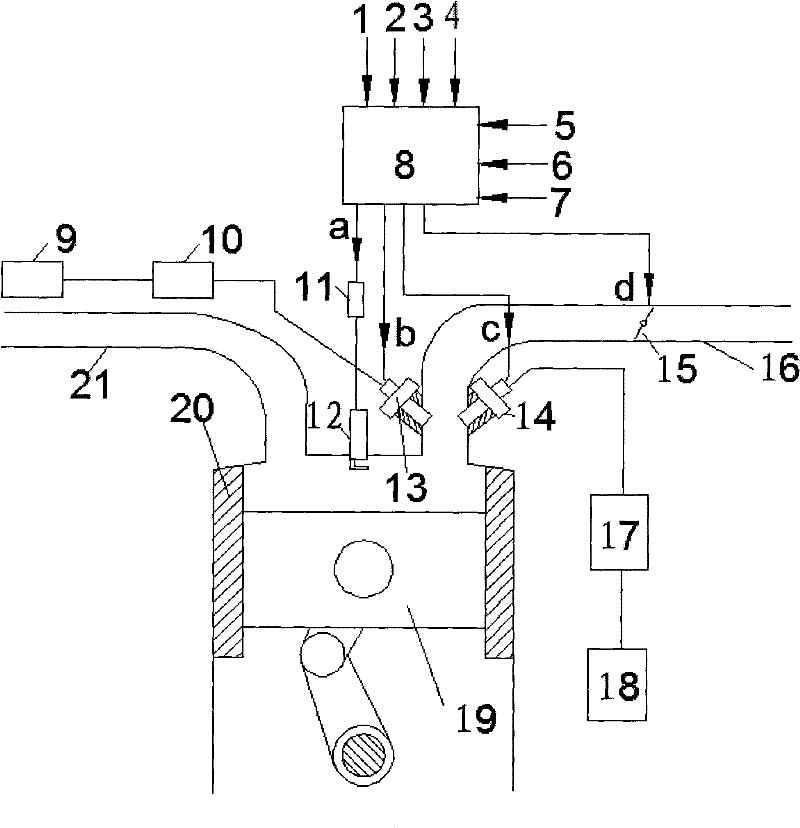

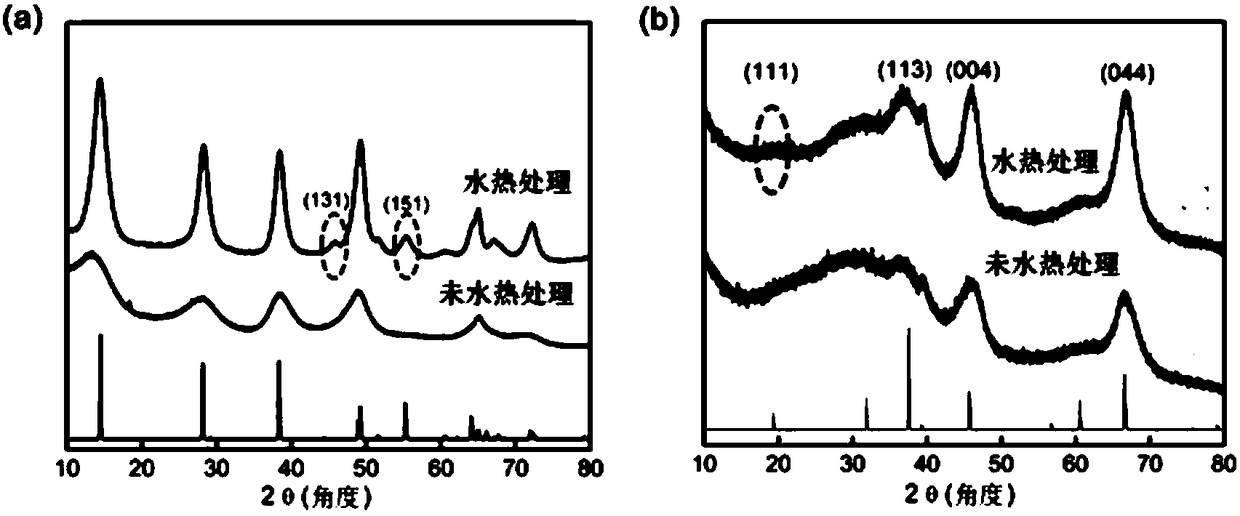

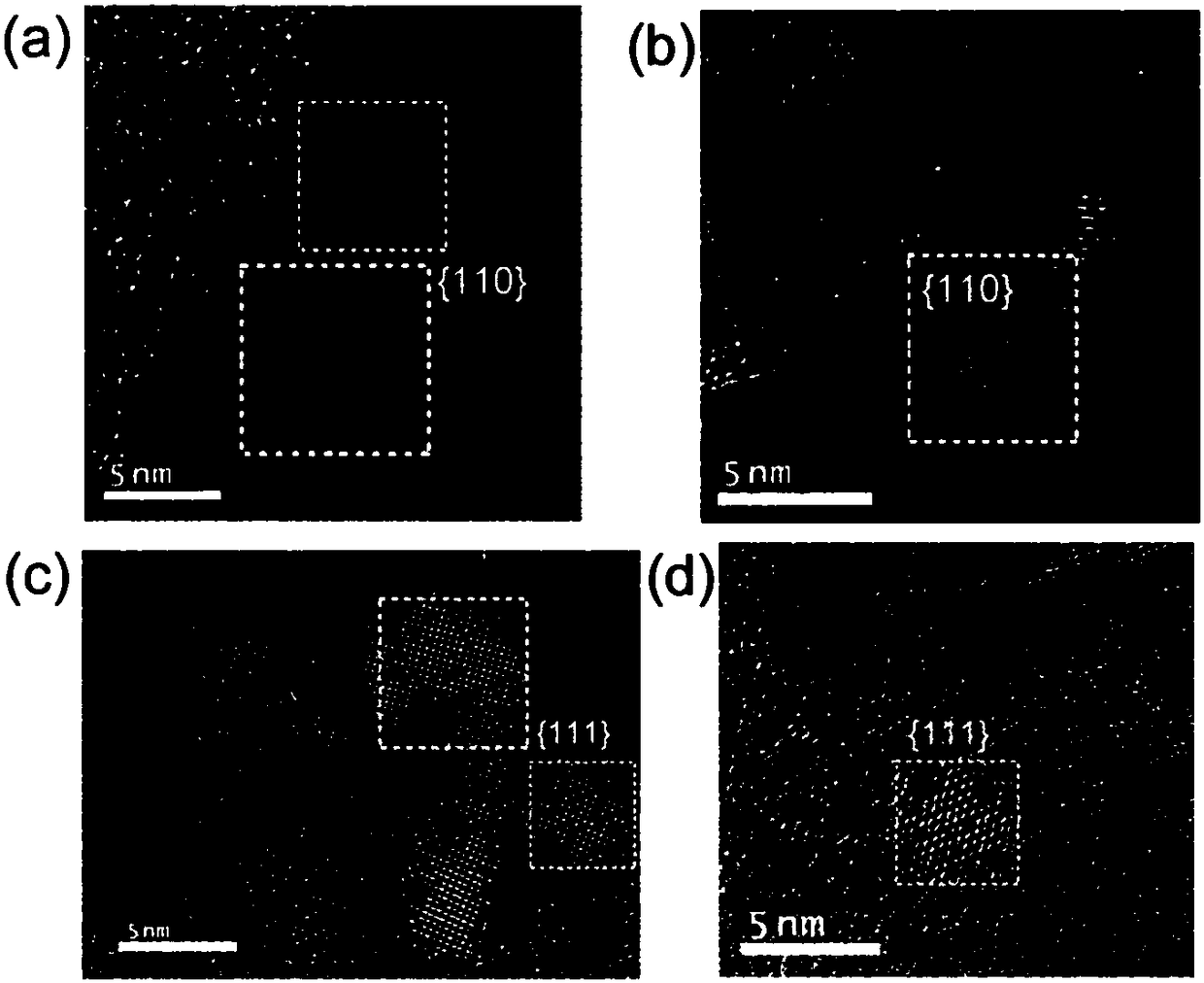

Light hydrocarbon sweetening catalyst based on aluminum oxide crystal face regulation and control and preparation method of light hydrocarbon sweetening catalyst

ActiveCN105618073AHigh activityHigh selectivityCatalyst carriersHydrocarbon by hydrogenationHigh activityHigh selectivity

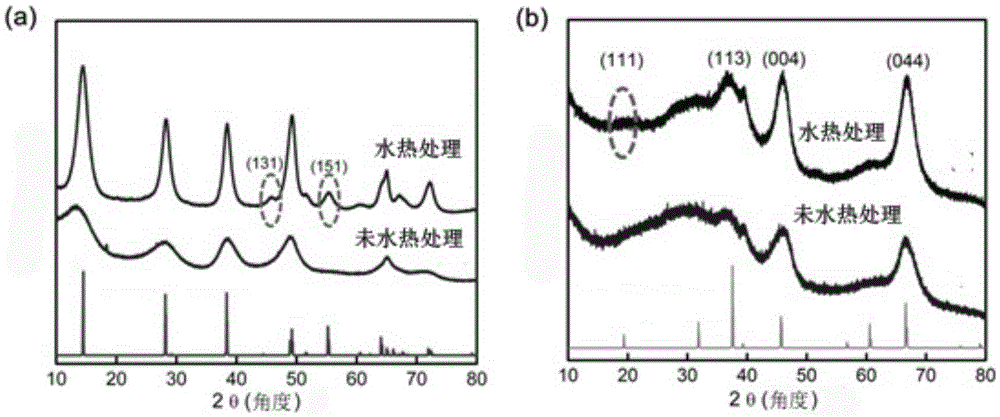

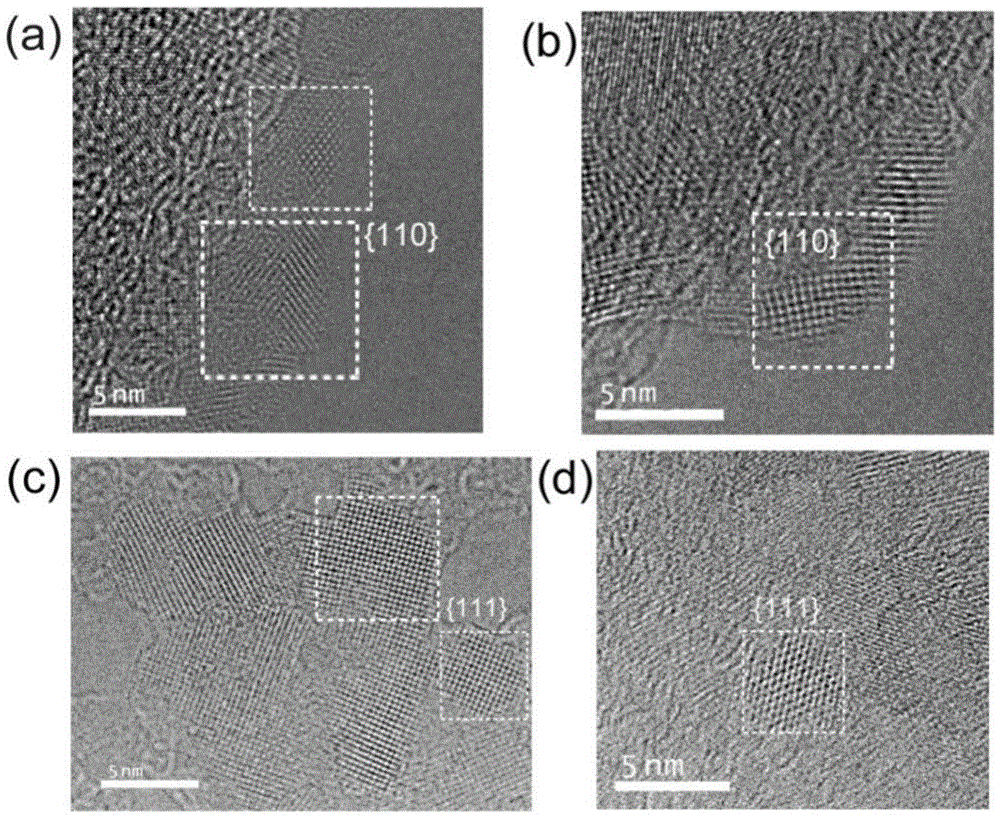

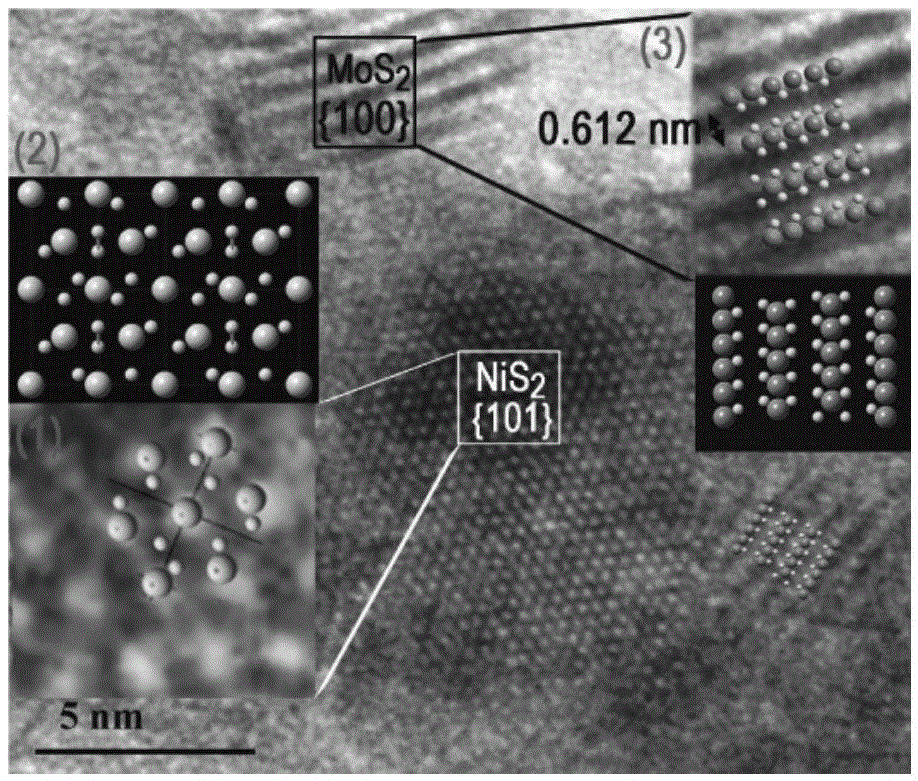

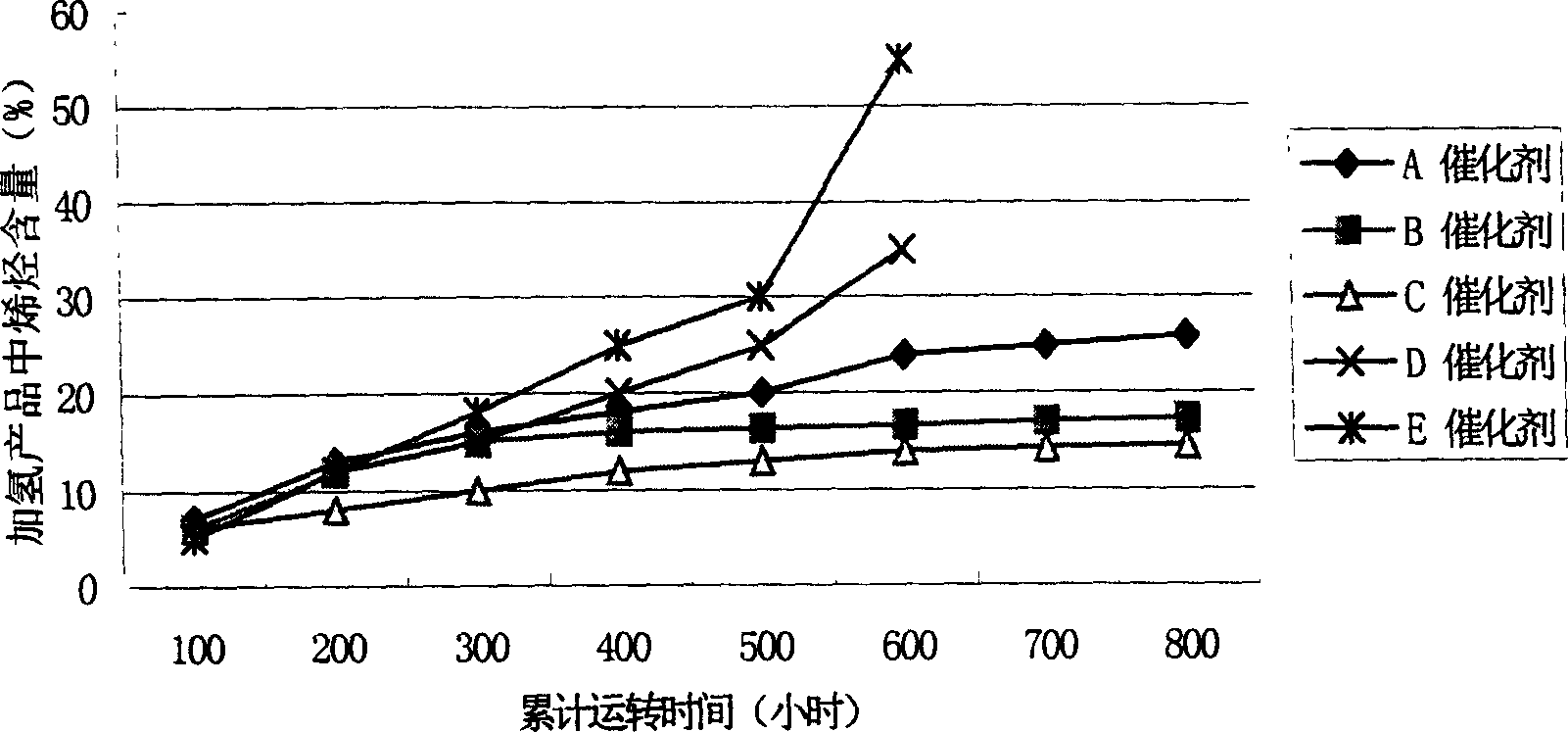

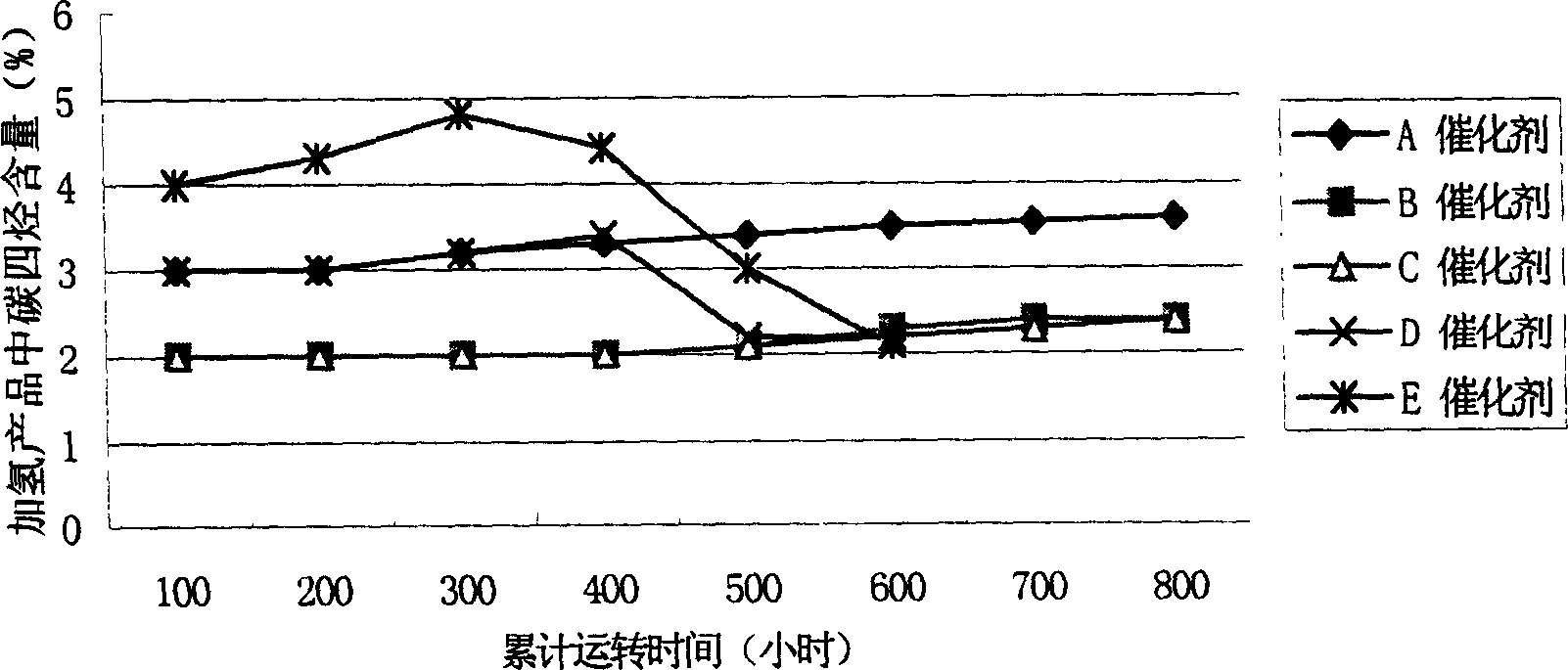

The invention provides a light hydrocarbon sweetening catalyst based on aluminum oxide crystal face regulation and control and a preparation method of the light hydrocarbon sweetening catalyst. The light hydrocarbon sweetening catalyst is prepared by taking gamma-aluminum oxide after hydro-thermal treatment regulation and control as a carrier and nickel and molybdenum and active metals. The light hydrocarbon sweetening catalyst provided by the invention is a high-activity and high-selectivity catalyst, can be used for catalyzing thiol and alkadiene in light hydrocarbon to act to generate large-molecular sulfide, can be also used for catalyzing selective hydrogenation saturation of diolefin, is high in sweetening activity and high in diolefin hydrogenation selectivity when being compared with a conventional catalyst and is long in circulation period and relatively good in industrial application prospect as active components are not lost and low in probability of inactivation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1718687AReduce saturation rateLow desulfurization activityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

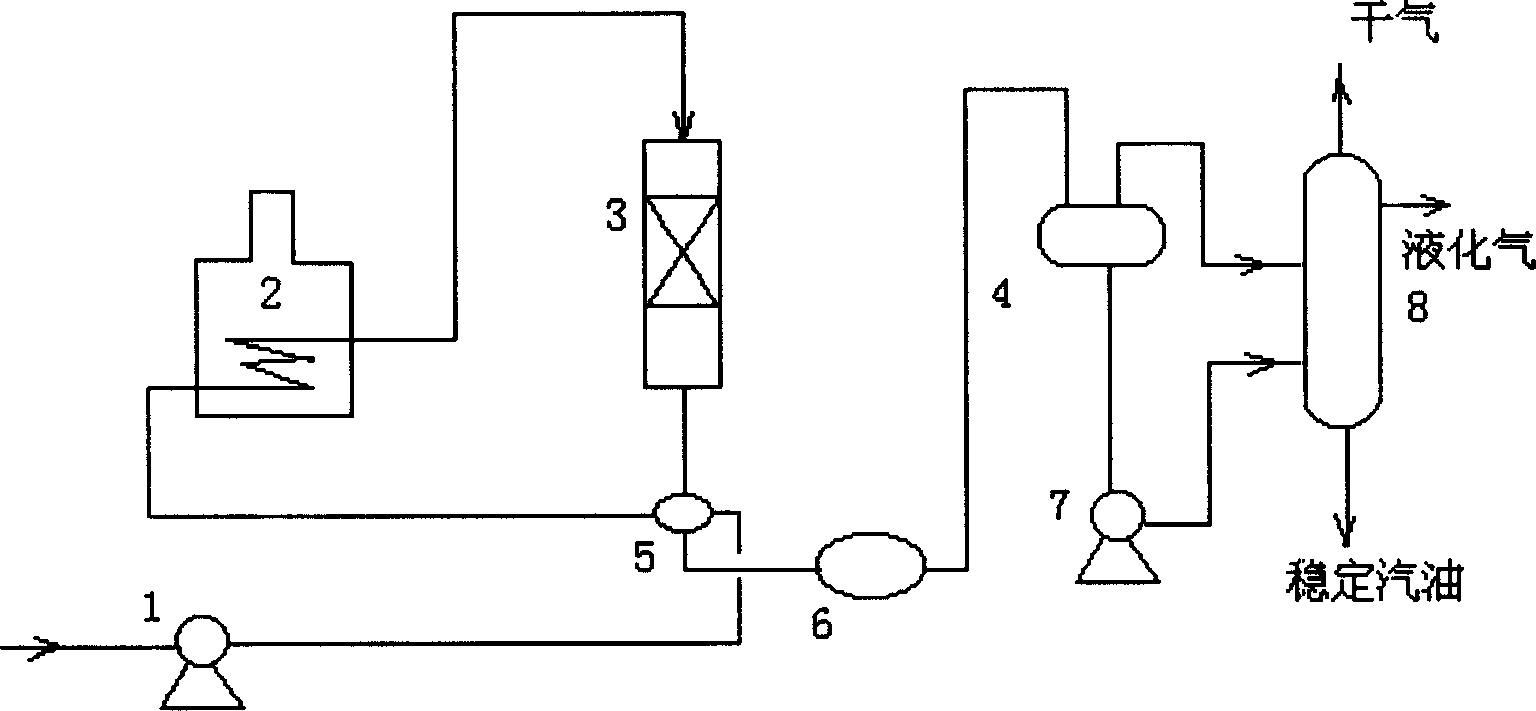

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

Light hydrocarbon non-hydrogenation modified catalyst, preparing process and application thereof

InactiveCN1524930AGood selective cleavage activityImprove stabilityTreatment with hydrotreatment processesPolymer scienceHydrocarbon mixtures

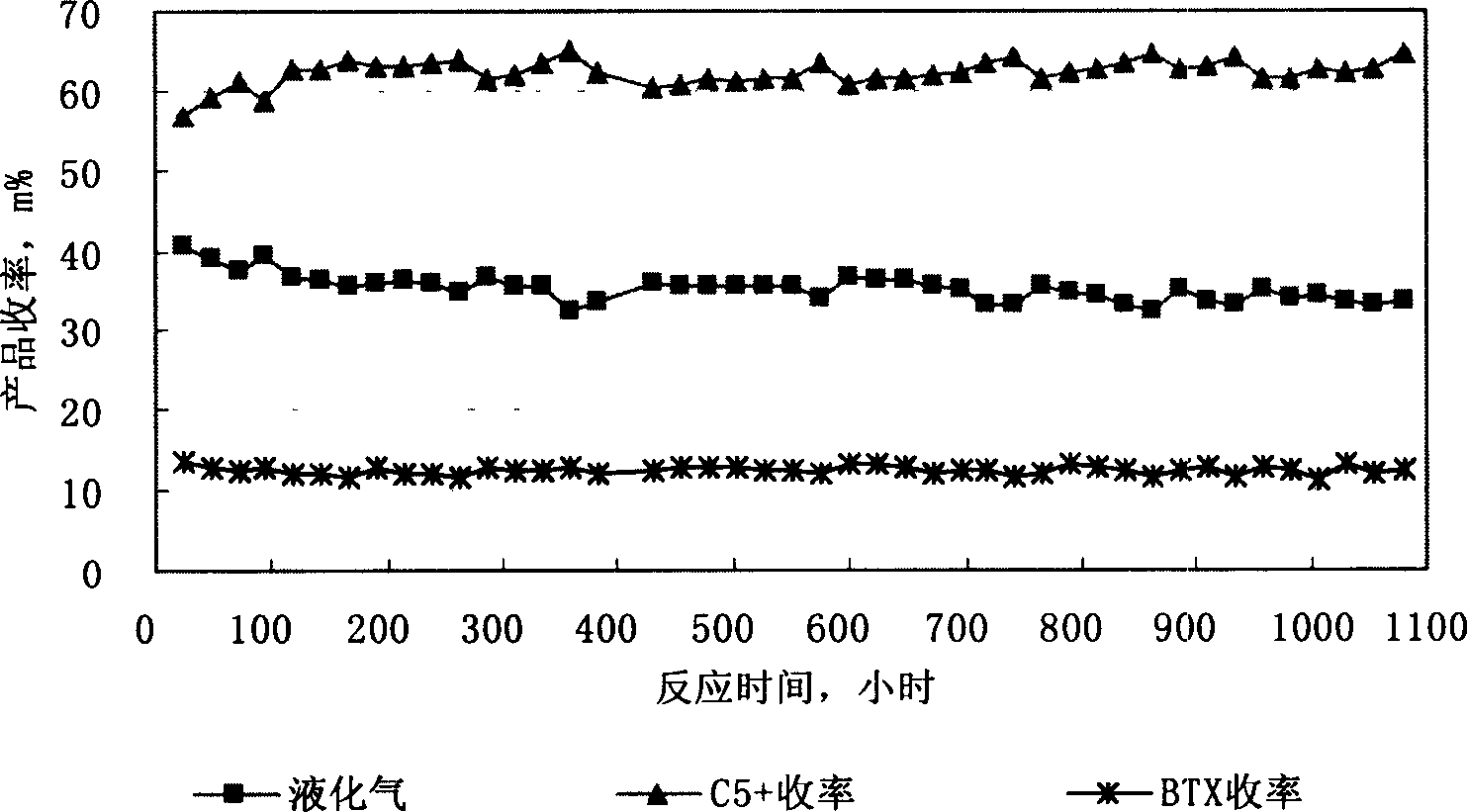

A modified catalyst of C3-C11 petroleum spirit, comprising 0.1-5.0 mass% of mixed rare-earth oxide or antimony trioxide, 95.0-99.1 mass% of carrying agent, wherein the carrying agent comprises 50-80 mass% of HZSM-5 zeolite and 20-50 mass% of gamma-aluminum oxide. The catalyst fits for low octane rating gasoline modification for boosting the octane and lowering olefin content.

Owner:CHINA PETROLEUM & CHEM CORP +1

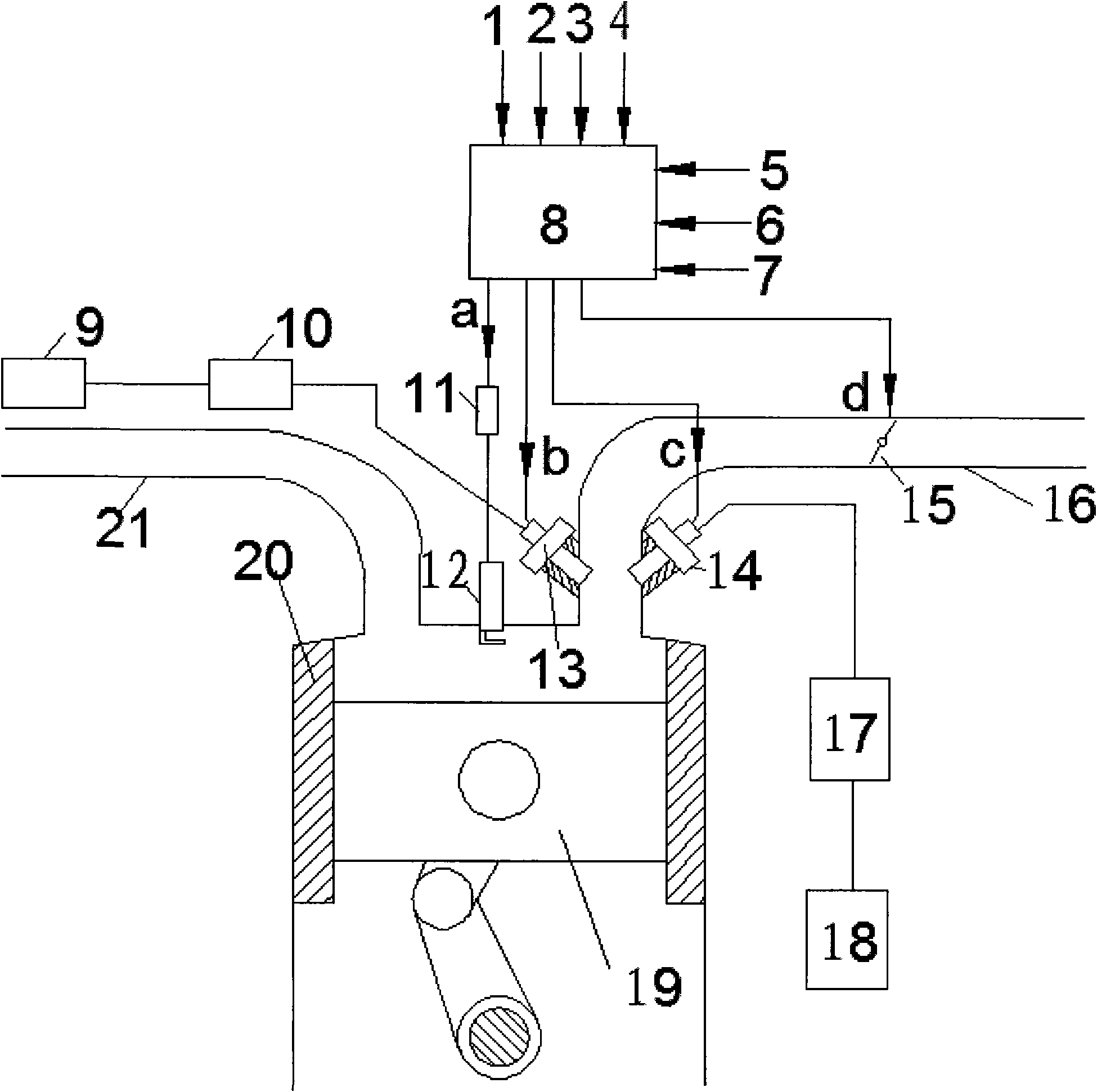

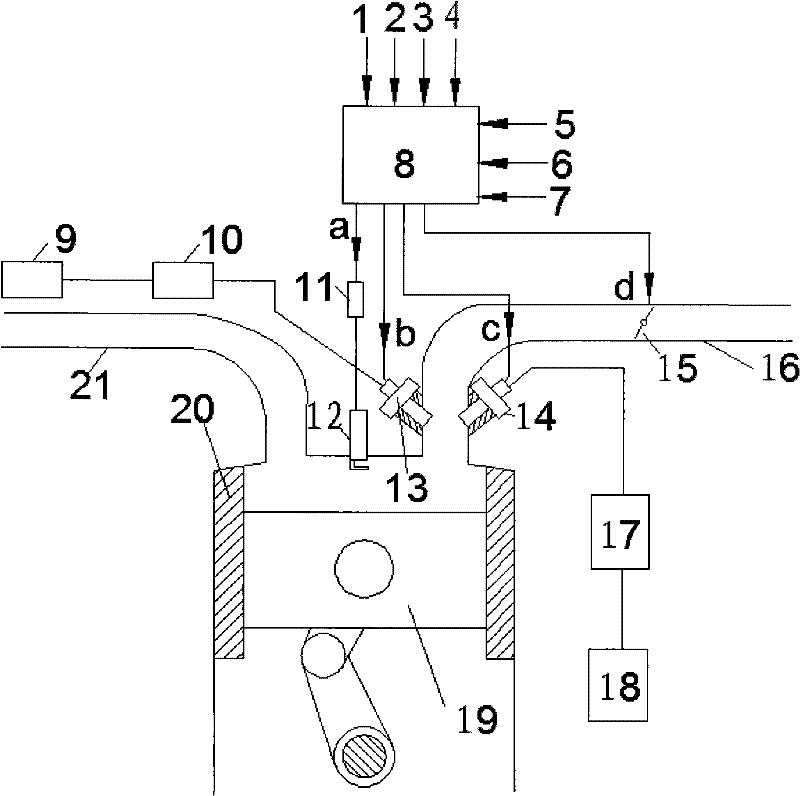

Internal combustion engine with fuels being mixed and ignited on the spot and control method thereof

ActiveCN101649785AMeet octane requirementsLive mix implementationElectrical controlMachines/enginesMixed fuelElectronic control unit

The invention provides an internal combustion engine with fuels being mixed and ignited on the spot and a control method thereof, in particular preparation, feeding and combustion control of fuels ofa combustion engine. A set of high-cetane and high-octane fuel feed and control system is additionally arranged in the internal combustion engine, and the system comprises a mixed fuel electronic control unit (8), a high-octane fuel box (9), a high-octane fuel pressure regulator (10), a high-octane fuel nozzle (13), a high-cetane fuel nozzle (14), a high-cetane fuel pressure regulator (17) and a high-cetane fuel box (18); and by controlling the high-octane flue nozzle, the high-cetane fuel nozzle and an ignition module, the spot mixing, the mixing ratio control, the excess air coefficient control and the ignition control of high-octane fuel and high-cetane fuel are achieved. The invention avoids accidental fire of the traditional single-fuel spark-ignition internal combustion engine in a cold starting process, improves the idling performance and the intermediate-speed and high-speed performance of the internal combustion engine effectively, and achieves the aims of energy saving and emission reduction of all working conditions of the internal combustion engine.

Owner:BEIJING UNIV OF TECH

Method for removing sulfur-containing compound from catalytically cracked gasoline by using polyglycol extraction process

InactiveCN1341698AOctane reductionImprove desulfurization efficiencyHydrocarbon oils refiningPEG 400Mass ratio

The present invention uses polyglycol 400 as desulfurizing solvent to make multi-stage countercurrent extraction of gasoline. The mass ratio of extracting agent and gasoline is 1-3.5:1. Extracting temp. is 20-70 deg.C. Extracting time is 10-50 min. and constant temperature standing time is 10-30 min. Then. the gasoline phase taken out is the desulfurized gasoline. Said invented solvent possesses the advantages of high desulfurizing efficiency, less toxicity, low mutual solubility with gasoline, simple and convenient for recovering solvent. As compared with hydrogenation process said invented extraction process features small equipoment investment, low cost and simple operation. The loss in octane number of the treated gasoline is small.

Owner:TSINGHUA UNIV

Method for reducing sulfur content in gasoline

ActiveCN103074106AHigh olefin contentReduce olefin contentTreatment with hydrotreatment processesCatalytic reformingHydrodesulfurization

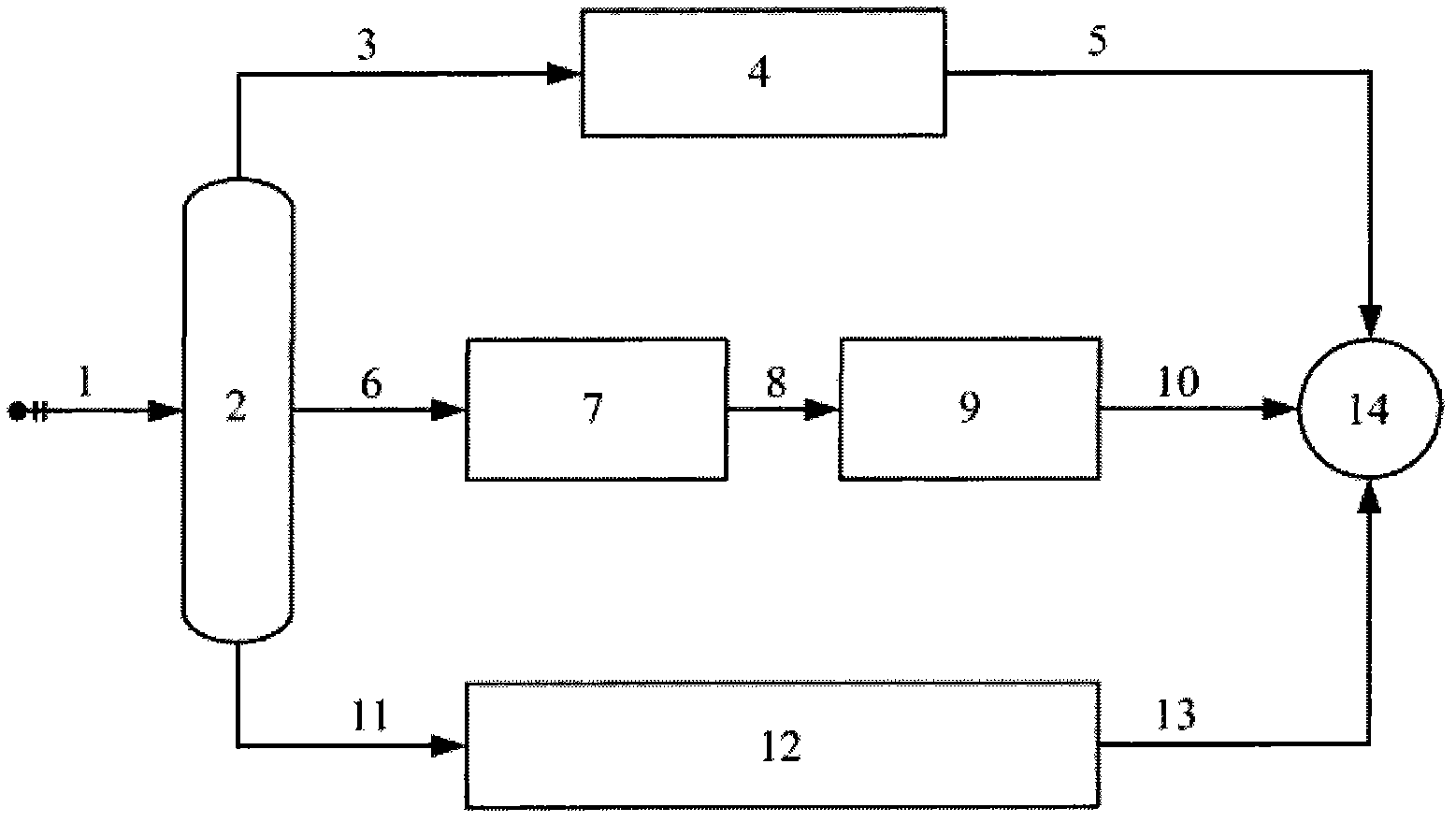

The invention provides a method for reducing sulfur content in gasoline. According to the invention, full-fraction gasoline is fractionated to obtain a light gasoline fraction, an intermediate gasoline fraction and a heavy gasoline fraction, wherein the light gasoline fraction is subjected to alkali washing and refining so as to remove mercaptan sulfur therein, the intermediate gasoline fraction enters into a first hydrogenation unit for catalytic reforming so as to obtain a reformed intermediate gasoline fraction with an increased octane number, the heavy gasoline fraction enters into a second hydrogenation unit and contacts with a selective hydrodesulfurization catalyst for selective hydrodesulfurization, and the refined light gasoline fraction, the reformed intermediate gasoline fraction and the hydrogenated heavy gasoline fraction are mixed to obtain a full-fraction gasoline fraction with ultra low content of sulfur. The obtained full-fraction gasoline product has total sulfur content of less than 10 mu g / g, and compared with a full-fraction gasoline raw material, loss of the octane number ROC of the full-fraction gasoline product is less than 1.0 unit.

Owner:CHINA PETROLEUM & CHEM CORP +1

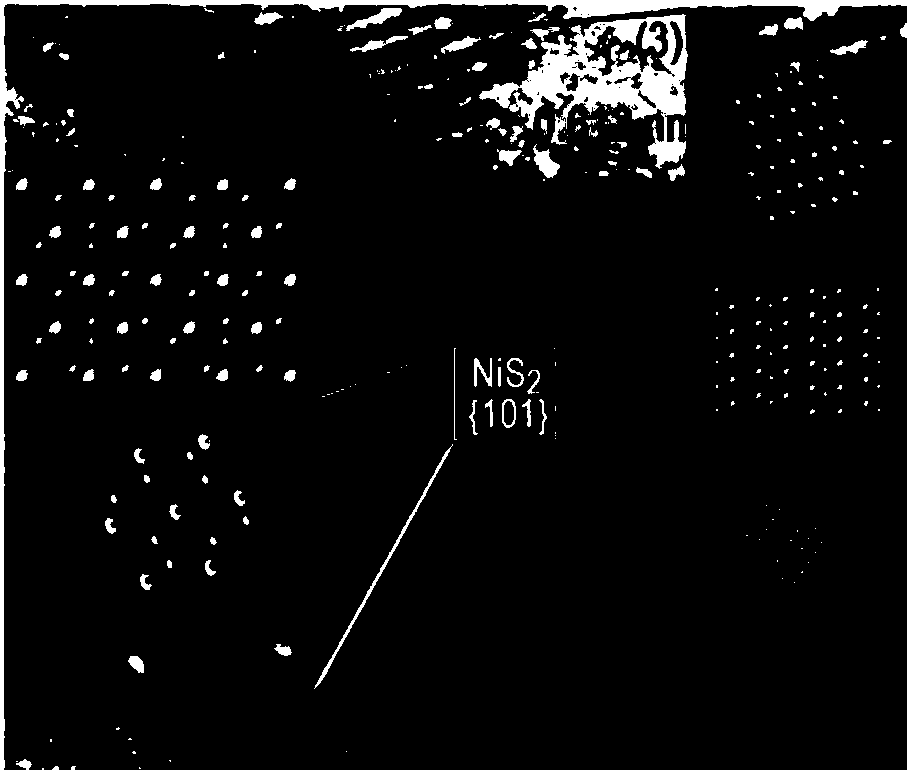

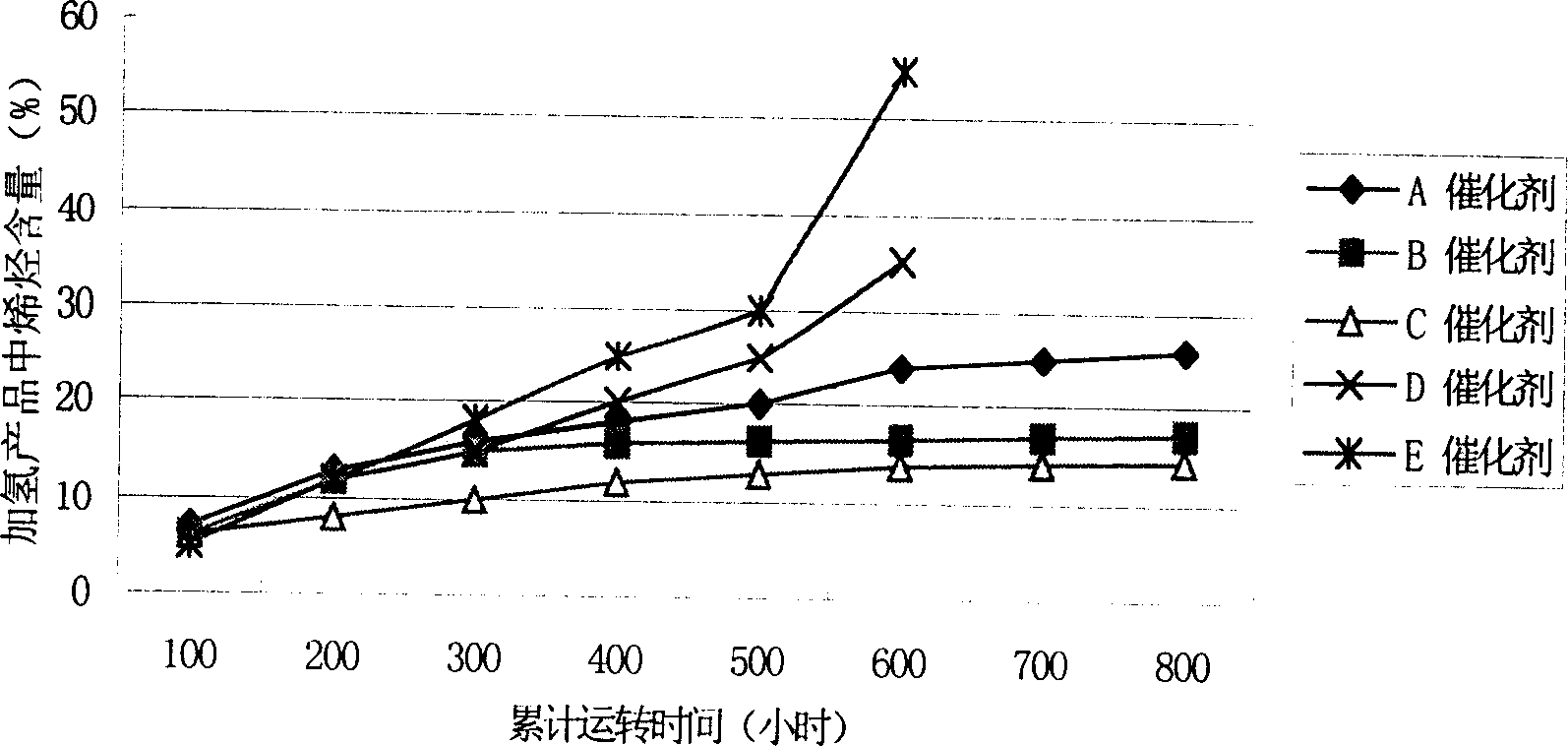

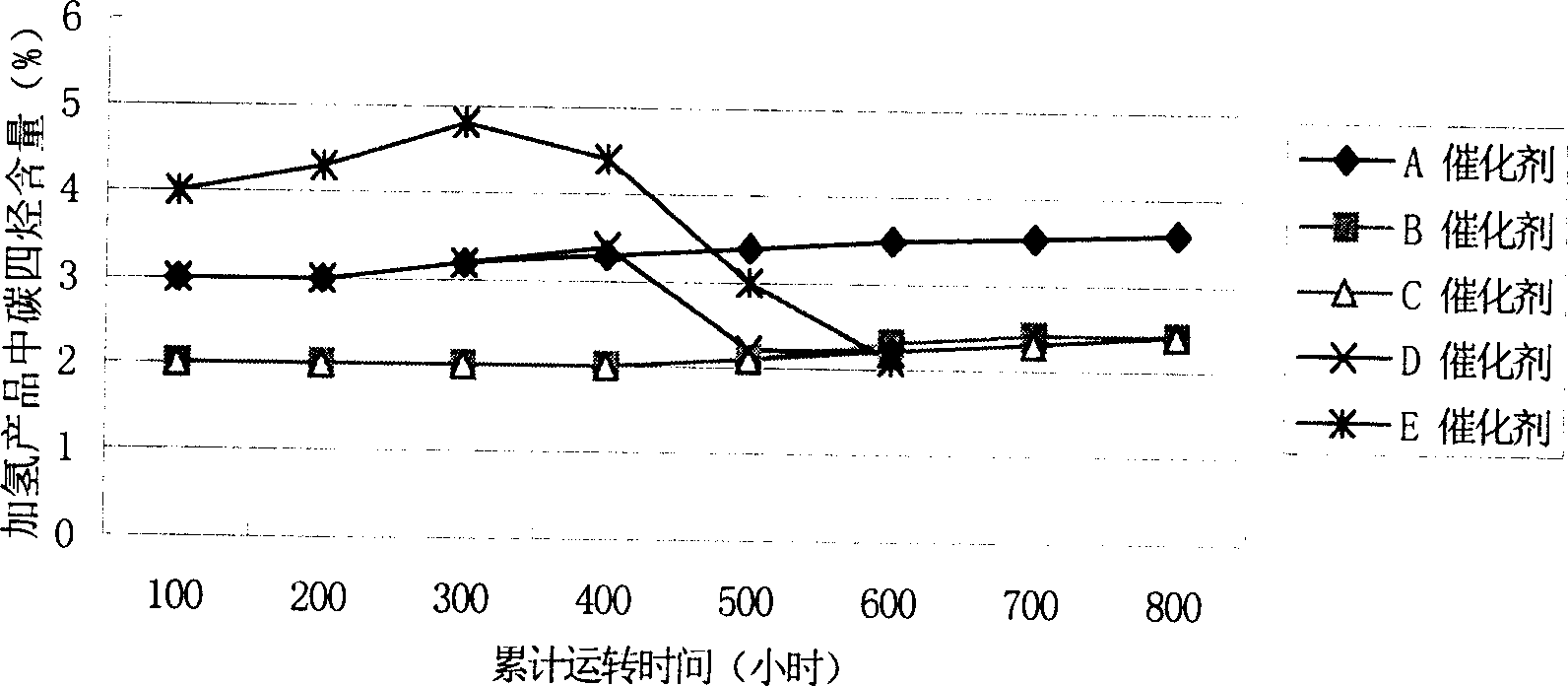

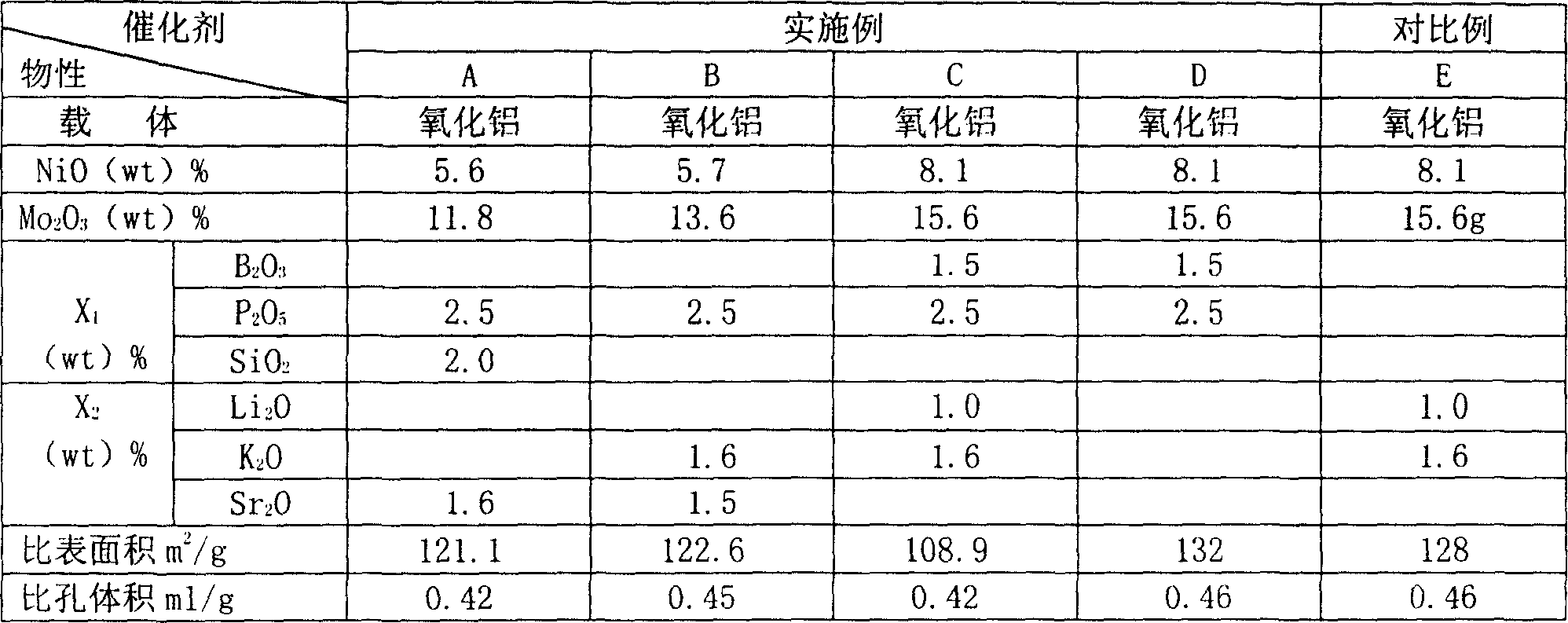

Catalyst for fatty monoolefin hydrogenation saturation, and its preparing method and use

InactiveCN1470488ALess side effectsLow octane reductionHydrocarbons from unsaturated hydrocarbon additionChemistryAdjuvant

The catalyst for aliphatic mono-olefine hydrosaturation catalyst is formed from active component and carrier, in which active component comprises (wt%) Mo2O3 5-20%, NiO 4-15% and X1 1-5%, in which X1is one or several kinds selected from B, P and Si, besides, it also can include adjuvant X2, the weight percentage content of X2 is 0-5%, and its carrier is active alumina. Said catalyst is applicable to hydrosaturation of C4-C20 fatty olefines, specially applicable to hydrosaturation of light olefines, such as ethylene, propylene and butylene oligomer gasoline to produce gasoline with high octane value. Its hydrogenation condition includes: temp. is 180-300 deg.C, pressure is 1.5-4.0 MPa, liquid hourly space velocity is 1.0-5.0 h(-1) and mole ratio of hydrogen and olefine is 1.5-2.5.

Owner:PETROCHINA CO LTD

Light hydrocarbon non-hydrogenation modified catalyst, preparing process and application thereof

InactiveCN1212376CGood selective cleavage activityImprove stabilityTreatment with hydrotreatment processesPolymer scienceHydrocarbon mixtures

A modified catalyst of C3-C11 petroleum spirit, comprising 0.1-5.0 mass% of mixed rare-earth oxide or antimony trioxide, 95.0-99.1 mass% of carrying agent, wherein the carrying agent comprises 50-80 mass% of HZSM-5 zeolite and 20-50 mass% of gamma-aluminum oxide. The catalyst fits for low octane rating gasoline modification for boosting the octane and lowering olefin content.

Owner:CHINA PETROLEUM & CHEM CORP +1

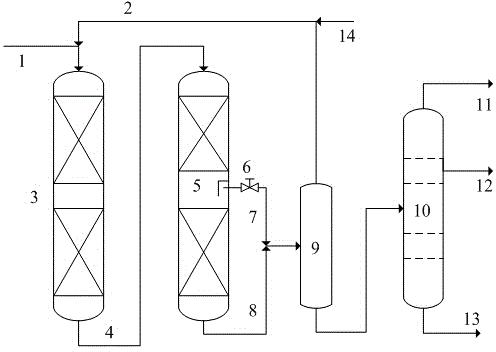

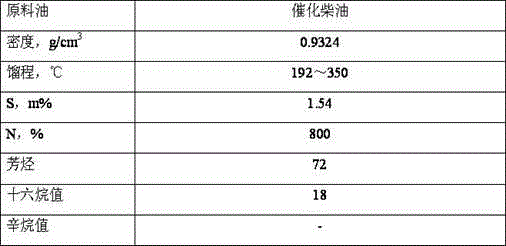

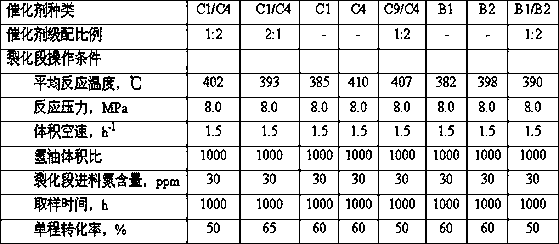

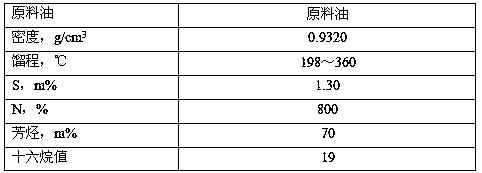

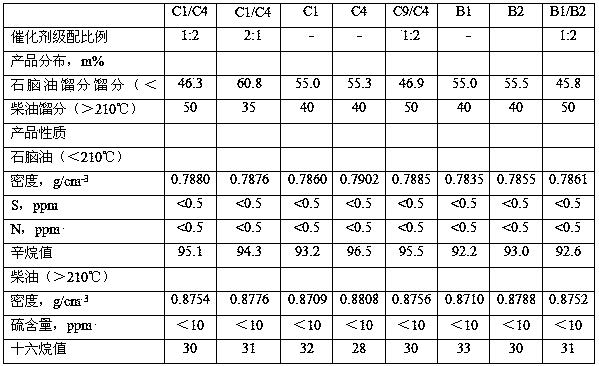

Transformation technology for catalytic diesel

ActiveCN108624357AReduce overcrackingReduce saturationMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveNaphtha

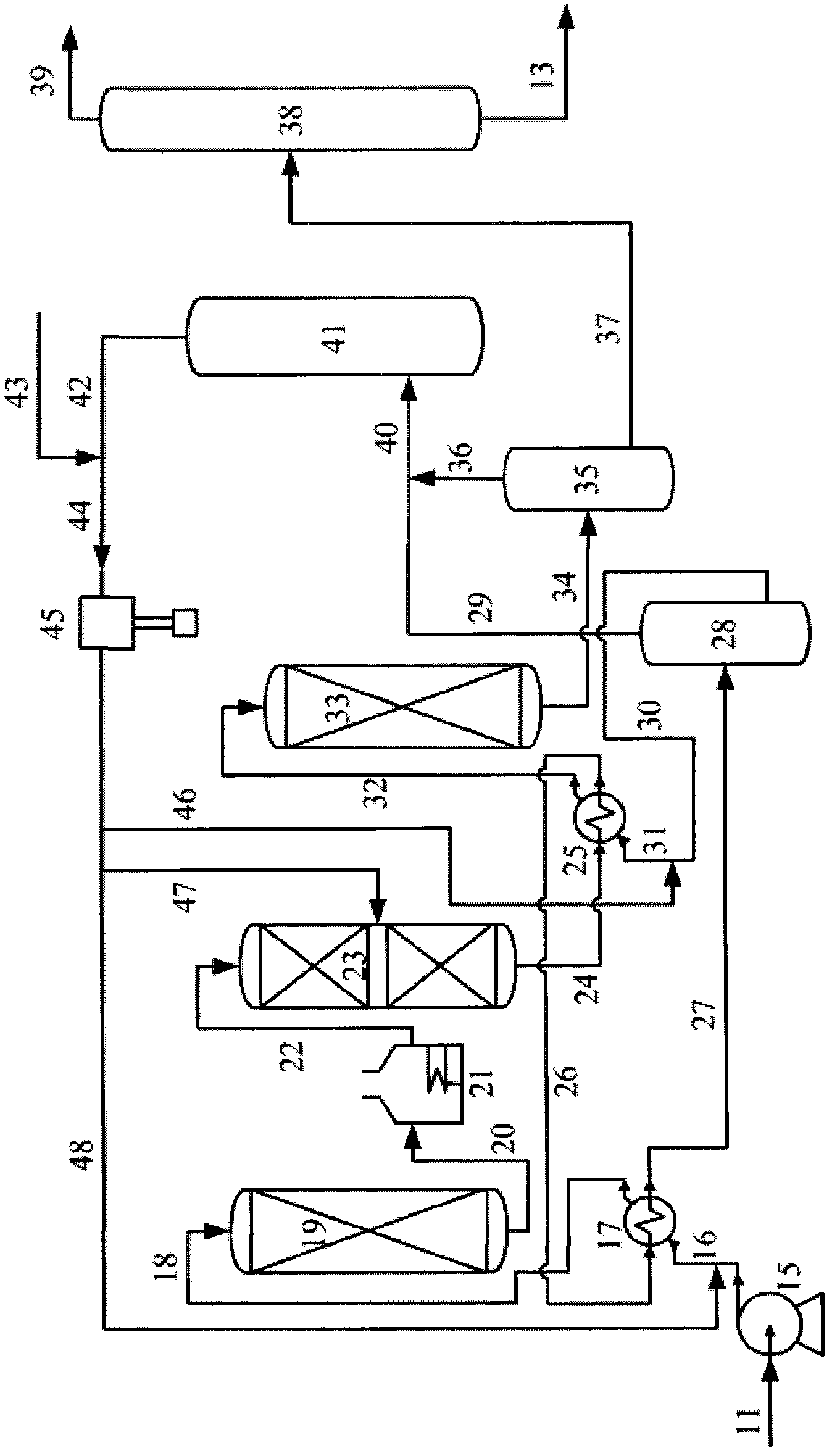

The invention discloses a conversion technology for catalytic diesel. The conversion technology comprises the following steps that (1) mixed materials of catalytic cracking diesel and hydrogen enter ahydrogenation reactor for hydrofining reaction; (2) hydrofining reaction effluent directly enters a cracking reactor and is subjected to contact reaction with hydrocracking catalyst beds in the cracking reactor, wherein a hydrocracking reactor is filled with an upper hydrocracking catalyst bed and a lower hydrocracking catalyst bed in a grading manner, a catalyst of the upper bed takes W-Ni and / or Mo-Ni as an active metal component and takes a modified Y molecular sieve and / or alkali metal or alkaline earth metal modified aluminum oxide as a carrier, and a catalyst of the lower bed takes Mo-Co as an active metal component and takes the modified Y molecular sieve and carbon deposit aluminum oxide as a carrier; and (3) the hydrocracking reaction effluent obtained in the step (2) is subjected to separation and fractionation so as to obtain a naphtha component and a diesel component. According to the conversion technology, on the premise that the conversion rate of the catalytic diesel isbetter met, the hydrogenation saturation of a generated gasoline component is reduced, and the octane value of the gasoline component is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of catalyst catalyzing diesel hydro-conversion, and hydrogenation process

ActiveCN105618111AGood dispersionFavorable for hydrogenation saturationMolecular sieve catalystsHydrocarbon oil crackingLiquid productMolecular sieve

The invention discloses a preparation method of a catalyst catalyzing diesel hydro-conversion, and a hydrogenation process. The method comprises the following steps: (1) an impregnation liquid containing active metal is used for impregnating Y molecular sieve; (2) the Y molecular sieve obtained in the step (1) and amorphous aluminosilicate and / or aluminum oxide are well mixed; dilute nitric acid is added, such that a slurry is formed; extrusion molding is carried out, and drying and roasting are carried out, such that the catalyst catalyzing diesel hydro-conversion is obtained. With the method provided by the invention, active metal effective utilization rate is improved, catalyst overall hydrogenation capacity is controlled, and catalyst hydrogenation reaction selectivity and stability are improved. The invention also provides a hydrogenation process matching the hydro-conversion catalyst. With the hydrogenation process, gasoline further hydrogenation or cracking reaction is reduced to a certain extent, gasoline octane number can be improved, and hydro-cracking liquid product yield can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1294240CReduce saturation rateLow selectivityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

HDS (hydrodesulfurization) technology of FCC (fluid catalytic cracking) gasoline

InactiveCN106433758AOctane reductionMolecular sieve catalystsHydrocarbon oils refiningHydrogen pressureHydrodesulfurization

The invention discloses an HDS (hydrodesulfurization) technology of FCC (fluid catalytic cracking) gasoline. According to the technology, a fixed bed reactor is adopted and filled with an HDS catalyst which comprises a carrier and an active component; the carrier is a compound or a mixture of MSU-G, SBA-15 and HMS; the active component is a mixture of MO2N, W2N, Mo2C and WC; the catalyst further contains a catalytic promoter which is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4; the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300-420 DGE C, the hydrogen pressure is 2.5-3.5 MPa, the hydrogen oil volume ratio is 500-800, and the volume airspeed is 1.5-4 h<-1>. The total sulfur content in the FCC gasoline can be reduced to 5 ppm or below to meet national five gasoline standards with the technology. Meanwhile, the octane number of the FCC gasoline is not reduced obviously with the technology.

Owner:过冬

Internal combustion engine with fuels being mixed and ignited on the spot and control method thereof

ActiveCN101649785BMeet octane requirementsLive mix implementationElectrical controlMachines/enginesExternal combustion enginePressure regulator

The invention provides an internal combustion engine with fuels being mixed and ignited on the spot and a control method thereof, in particular preparation, feeding and combustion control of fuels of a combustion engine. A set of high-cetane and high-octane fuel feed and control system is additionally arranged in the internal combustion engine, and the system comprises a mixed fuel electronic control unit (8), a high-octane fuel box (9), a high-octane fuel pressure regulator (10), a high-octane fuel nozzle (13), a high-cetane fuel nozzle (14), a high-cetane fuel pressure regulator (17) and a high-cetane fuel box (18); and by controlling the high-octane flue nozzle, the high-cetane fuel nozzle and an ignition module, the spot mixing, the mixing ratio control, the excess air coefficient control and the ignition control of high-octane fuel and high-cetane fuel are achieved. The invention avoids accidental fire of the traditional single-fuel spark-ignition internal combustion engine in a cold starting process, improves the idling performance and the intermediate-speed and high-speed performance of the internal combustion engine effectively, and achieves the aims of energy saving and emission reduction of all working conditions of the internal combustion engine.

Owner:BEIJING UNIV OF TECH

Catalyst for light hydrocarbon desulfanization based on control of alumina crystal plane and its preparation method

ActiveCN105618073BOctane reductionDifferent physical and chemical propertiesCatalyst carriersHydrocarbon by hydrogenationCrystal planeSulfide

The present invention provides a light hydrocarbon demercaptanization catalyst based on the control of alumina crystal planes and a preparation method thereof. The catalyst uses γ-alumina after hydrothermal treatment and control as described in the present invention as a carrier, and uses nickel and molybdenum as active metals. The light hydrocarbon demercaptanization catalyst of the present invention is a highly active and highly selective catalyst. It can be used to catalyze the reaction between mercaptans and diolefins in light hydrocarbons to generate macromolecular sulfides, and can also catalyze the selectivity of diolefins. Hydrogenation saturation. Compared with existing catalysts, the catalyst provided by the present invention has high mercaptan removal activity and diolefin hydrogenation selectivity, and the active components are not lost and are not easily deactivated. Therefore, the catalyst operation cycle is long and has better performance. industrial application prospects.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Composite support hydrodesulfurization catalyst

InactiveCN106622358AOctane reductionExtended service lifeMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationActive component

The invention discloses a hydrodesulfurization catalyst, comprising a support and an active component; the support is a composite or mixture of MSU-G, SBA-15 and HMS, the active component is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC, the total content of the active component accounts 1-15% of the weight of the support, the catalyst also comprises a cocatalyst, and the cocatalyst is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4. The catalyst is capable of reducing total sulfur content of FCC (fluid catalytic cracking) gasoline to 5 ppm and below so that the gasoline meets the gasoline standard G5. In addition, by using the catalyst, octane value of FCC gasoline is not significantly decreased.

Owner:过冬

Catalyst for fatty monoolefin hydrogenation saturation, and its preparing method and use

InactiveCN1221496COctane reductionLow costHydrocarbons from unsaturated hydrocarbon additionAdjuvantHydrogen

Owner:PETROCHINA CO LTD

FCC (fluid catalytic cracking) gasoline hydrodesulfurization process

InactiveCN106190233AReduce sulfur contentOctane reductionMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationHydrogen pressure

The invention discloses an FCC (fluid catalytic cracking) gasoline hydrodesulfurization process. The FCC gasoline hydrodesulfurization process is characterized in that a fixed bed reactor is adopted, hydrodesulfurization catalyst is filled in the fixed bed reactor, and the catalyst includes a carrier and an activated component; the carrier is characterized in that a synthesized skeleton structure is doped with SAPO (silicoaluminophosphate)-5 of heteroatom Co<2+>; the activated component is a mixture of MO2N, W2N, Mo2C and WC; the fixed bed reactor is under reaction conditions that reaction temperature is 300-420DEG C, hydrogen pressure is 2.5-3.5MPa, hydrogen to gasoline volume ratio is 500-800, and volume space velocity is 1.5-4 hours<-1>. By the process, total sulfur content in the FCC gasoline can be reduced to less than 10ppm, and the national five standards of the gasoline are met; meanwhile, the process further enables octane value of the FCC not to be reduced significantly.

Owner:锡山区绿春塑料制品厂

Hydrodesulfurization catalyst

InactiveCN106311323AOctane reductionMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationActive component

The invention discloses a hydrodesulfurization catalyst. The hydrodesulfurization catalyst comprises a carrier, an active component and a catalysis aid, wherein the carrier is SAPO-5 with a synthetic skeleton structure doped with a heteroatom Cu<2+>, and the doping amount is 0.56%-0.75% by weight of SAPO-5; the active component is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and wolfram carbide WC; the total content of the active component is 1%-15% of the weight of SAPO-5; and the catalysis aid is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4. According to the hydrodesulfurization catalyst, the total sulfur content of FCC gasoline can be decreased below 10 ppm, so as to meet China 5 standard; and meanwhile, the octane value of the FCC gasoline is not obviously decreased.

Owner:锡山区绿春塑料制品厂

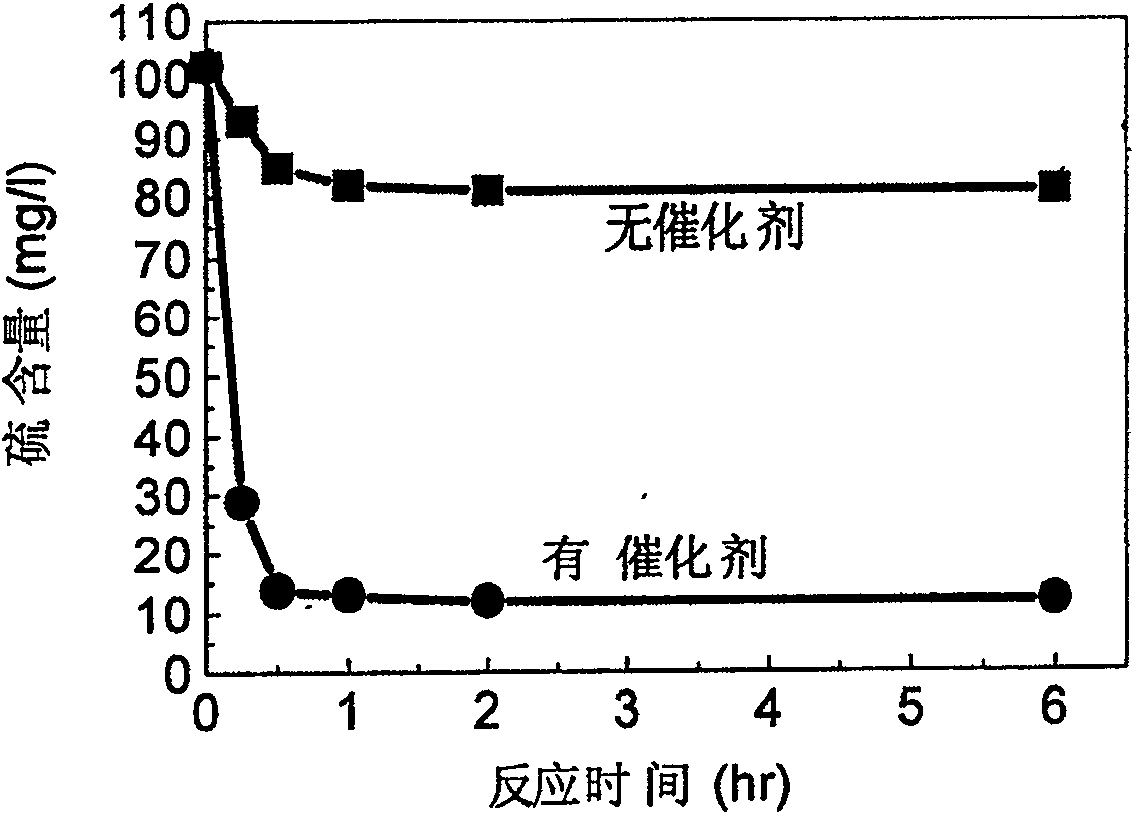

Catalyzed oxidation desulfuration process of petroleum products

This invention discloses a catalytic oxidative desulfurization method for petroleum products. In the method, oxidant, catalyst and solvent are added in the petroleum products for desulfurization. The catalyst is oxyacid salt of Mn, Sb, W, Ce, Sn, Mo, V or Cr. The catalyst as well as reaction conditions are only effective to organic sulfur and nitrogen compounds while have no effect on unsaturated hydrocarbons such as olefins and aromatic hydrocarbons. After the desulfurization method, the content of sulfur in the petroleum products can be less than 15 mg / L, while the octane number of the petroleum products is not changed. The desulfurization method is simple, and has such advantages as mild reaction conditions and high desulfurization efficiency, thus has wide potential applications.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Hydrofining catalyst

InactiveCN106423248AOctane reductionMolecular sieve catalystsHydrocarbon oils treatmentHydrodesulfurizationTungsten nitride

The invention discloses a hydrodesulfurization catalyst. The catalyst contains a carrier and an active ingredient, wherein the carrier is MCM-41, of which a synthesized skeleton structure is doped with heteroatoms Co<2+>, and the doped amount of the heteroatoms Co<2+> is 0.56% to 0.75 the weight of the MCM-41; and the active ingredient is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC, and the total content of the active ingredient is 1% to 15% the weight of the carrier MCM-41. The catalyst further contains a catalytic promoter, wherein the catalytic promoter is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4. By the catalyst, the total sulfur content of FCC gasoline can be lowered to be lower than 10ppm, so as to meet national gasoline standards V. Meanwhile, by the catalyst, the octance value of the FCC gasoline cannot be lowered obviously.

Owner:锡山区绿春塑料制品厂

A hydrofining catalyst

InactiveCN106378174AOctane reductionMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationActive component

A hydrodesulfurization catalyst is disclosed. The catalyst comprises a carrier and an active component. The carrier is MCM-41 the synthesis skeleton of which is doped with Co<2+> that is a heteroatom, with the doping amount being 0.56-0.75% by weight of the MCM-41. The active component is a mixture of dimolybdenum nitride (Mo<2>N), tungsten nitride (W2N), molybdenum carbide (Mo<2>C) and tungsten carbide (WC). The total weight of the active component is 1-15% of the weight of the carrier MCM-41. The catalyst also comprises a catalytic promoter that is a mixture of TiO2, CeO2, V2O5 and NbOPO4. The catalyst can reduce the total sulfur content of FCC gasoline to 10 ppm or below, thus meeting the national V emission standard of gasoline in China. In addition, through adoption of the catalyst, the octane number of the FCC gasoline is not obviously reduced.

Owner:锡山区绿春塑料制品厂

Hydrodesulfurization process for FCC gasoline

InactiveCN106221764AOctane reductionMolecular sieve catalystsTreatment with hydrotreatment processesFixed bedActive component

The invention discloses a hydrodesulfurization process for FCC gasoline. A fixed bed reactor is adopted in the process and is filled with a hydrodesulfurization catalyst, wherein the catalyst comprises a carrier and an active component; the carrier is SAPO-5 doped with heteroatom Co<2+> in a synthesized framework structure; the active component is a mixture of MO2N, W2N, Mo2C and WC; the catalyst further contains a catalytic promoter; the catalytic promoter is a mixture of TiO2, CeO2, V2O5 and NbOPO4; reaction conditions of the fixed bed reactor are that the reaction temperature is 300 to 420DEG C, the hydrogen pressure is 2.5 to 3.5MPa, the volume ratio of hydrogen to gasoline is 500 to 800, and the volume space velocity is 1.5 to 4h<-1>. By using the process, the content of total sulfur in the FCC gasoline is reduced to below 10ppm so as to meet national V emission standard of the gasoline. Meanwhile, by means of the process, an octane value of the FCC gasoline is not remarkably reduced.

Owner:锡山区绿春塑料制品厂

A hydrodesulfurization catalyst

InactiveCN106378175AOctane reductionMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationActive component

A hydrodesulfurization catalyst is disclosed. The catalyst comprises a carrier and an active component. The carrier is KIT-1 the synthesis skeleton of which is doped with Cu<2+> that is a heteroatom, with the doping amount being 0.56-0.75% by weight of the KIT-1. The active component is a mixture of dimolybdenum nitride (Mo<2>N), tungsten nitride (W2N), molybdenum carbide (Mo<2>C) and tungsten carbide (WC). The total weight of the active component is 1-15% of the weight of the carrier KIT-1. The catalyst also comprises a catalytic promoter that is a mixture of Cr<2>O3, ZrO2, CeO2, V2O5 and NbOPO4. The catalyst can reduce the total sulfur content of FCC gasoline to 10 ppm or below, thus meeting the national V emission standard of gasoline in China. In addition, through adoption of the catalyst, the octane number of the FCC gasoline is not obviously reduced.

Owner:锡山区绿春塑料制品厂

Hydrogen desulfurization catalyst

InactiveCN106318455AOctane reductionMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationMolybdenum carbide

The invention discloses a hydrogen desulfurization catalyst. The catalyst includes a carrier and an active component; the carrier is MCM-41 mixed with heteroatom Cu2+ in a compounded skeleton structure, and the mixing amount is 0.56-0.75% of MCM-41 by weight; the active component is mixture of dimolybdate nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the total content of the active component is 1-15% of the carrier MCM-41 by weight; the catalyst further includes catalytic addictive, and the catalytic addictive is the mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4. The catalyst can be applied to reduce total catalytic addictive in FCC (family car China) gasoline to 10 ppm below, so as to meet the five national standards of gasoline; meanwhile, the application of the catalyst can prevent the octane value of FCC gasoline from obviously reducing.

Owner:锡山区绿春塑料制品厂

Hydrofining catalyst

InactiveCN106336895AOctane reductionMolecular sieve catalystsHydrocarbon oils treatmentHydrodesulfurizationActive component

The invention discloses a hydrofining catalyst. The catalyst comprises a carrier and an active component. According to the carrier, KIT-1 of heteroatom Co<2+> is doped in a synthetic skeleton structure, wherein the doping content is 0.56%-0.75% of weight of KIT-1. The active component is a mixture of molybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC. Total content of the active component is 1-15% of weight of the carrier KIT-1. The catalyst also contains a catalytic addictive, which is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4. By the use of the catalyst, total sulfur content of FCC gasoline can be reduced to 10 ppm and below so as to meet gasoline ''China 5''standard. Meanwhile, by the adoption of the catalyst, octane number of FCC gasoline is not obviously reduced.

Owner:锡山区绿春塑料制品厂

Fluid catalytic cracking (FCC) gasoline hydrogen desulfurization process

InactiveCN106190237AReduce sulfur contentOctane reductionMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationHydrogen pressure

The invention discloses a fluid catalytic cracking (FCC) gasoline hydrogen desulfurization process. The process adopts a fixed bed reactor, a hydrogen desulfurization catalyst is filled in the fixed bed reactor and the catalyst comprises a carrier and an active component; the carrier is KIT-1 formed by doping heteroatom Co2+ into a synthetic skeleton structure; the active component is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300 to 420 DEG C, the hydrogen pressure is 2.5 to 3.5 MPa, the volume ratio of hydrogen to oil is 500-800 and the volume space velocity is 1.5-4 / h. By the process, the total sulfur content of the FCC gasoline can be reduced to be below 10 ppm so as to reach the national five-level standard. Meanwhile, by the process, the octane value of the FCC gasoline is not reduced obviously.

Owner:锡山区绿春塑料制品厂

FCC gasoline hydrodesulfurization technology

InactiveCN106244196AOctane reductionMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationReaction temperature

The invention discloses a FCC gasoline hydrodesulfurization technology. The technology employs a fixed bed reactor, the fixed bed reactor is filled with a hydrodesulfurization catalyst, the catalyst comprises a carrier and an active component; the carrier is hetero atom Co<2+>-doped KIT-1 in a synthesis frame structure; the active component is a mixture of nitrided dimolybdate MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst contains a catalysis auxiliary agent, the catalysis auxiliary agent is a mixture of TiO2, CeO2, V2O5 and NbOPO4; the reaction condition of the fixed bed reactor is characterized in that the reaction temperature is 300-420 DEG C, the hydrogen partial pressure is 2.5-3.5 MPa, the volume ratio of hydrogen to oil is 500-800, and the volume space velocity is 1.5-4h < -1>. The technology can reduce the total sulfur content in FCC gasoline to less than 10 ppm which can reach the national V standard. According to the technology, the octane number of the FCC gasoline is not obviously reduced.

Owner:锡山区绿春塑料制品厂

Hydrogenating desulfurization catalyst

InactiveCN106268911AOctane reductionMolecular sieve catalystsRefining to eliminate hetero atomsSulfurActive component

The invention discloses a hydrogenating desulfurization catalyst. The catalyst comprises a carrier and an active component, wherein the carrier is formed by doping heteroatoms Cu<2+> to KIT-1 in a synthesizing skeleton structure, wherein the doping quantity is 0.56wt%-0.75wt% of the KIT-1; and the active component is a mixture of bimolybdenum nitride MO2N, wolfram nitride W2N, molybdenum carbide Mo2C and wolfram carbide WC, wherein the content of the active component is 1wt%-15wt% of the carrier namely the KIT-1. The catalyst can enable the content of total sulfur in FCC gasoline to be reduced to 10ppm or below, and besides, the catalyst is used, so that the octane rating of the FCC gasoline is not reduced obviously.

Owner:锡山区绿春塑料制品厂

FCC (fluid catalytic cracking) gasoline hydrodesulfurization process

InactiveCN106221755AOctane reductionMolecular sieve catalystsHydrocarbon oils treatment productsHydrogen pressureHydrodesulfurization

The invention discloses a FCC (fluid catalytic cracking) gasoline hydrodesulfurization process employing a fixed bed reactor; the fixed bed reactor is filled with a hydrodesulfurization catalyst that includes a support and an active ingredient; the support is KIT-1 with frame structure doped with heteroatom Co2+; the active ingredient is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst also comprises a catalysis aid that is a mixture of Cr2O3, ZrO3, CeO2, V2O5 and NbOPO4; the fixed bed reactor carries out reaction under the following conditions: reaction temperature 300-420 DEG C, hydrogen pressure 2.5-3.5 MPa, hydrogen-oil volume ratio 500-800, volume air speed 1.5-4 h<-1>; the process may provide total sulfur content of FCC gasoline reduced to 10 ppm and below to meet the gasoline standard GB5; the process also provides not evidently reduced octane value of FCC gasoline.

Owner:锡山区绿春塑料制品厂

A catalytic diesel conversion process

ActiveCN108624357BReduce overcrackingReduce saturationMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveAlkaline earth metal

The invention discloses a conversion technology for catalytic diesel. The conversion technology comprises the following steps that (1) mixed materials of catalytic cracking diesel and hydrogen enter ahydrogenation reactor for hydrofining reaction; (2) hydrofining reaction effluent directly enters a cracking reactor and is subjected to contact reaction with hydrocracking catalyst beds in the cracking reactor, wherein a hydrocracking reactor is filled with an upper hydrocracking catalyst bed and a lower hydrocracking catalyst bed in a grading manner, a catalyst of the upper bed takes W-Ni and / or Mo-Ni as an active metal component and takes a modified Y molecular sieve and / or alkali metal or alkaline earth metal modified aluminum oxide as a carrier, and a catalyst of the lower bed takes Mo-Co as an active metal component and takes the modified Y molecular sieve and carbon deposit aluminum oxide as a carrier; and (3) the hydrocracking reaction effluent obtained in the step (2) is subjected to separation and fractionation so as to obtain a naphtha component and a diesel component. According to the conversion technology, on the premise that the conversion rate of the catalytic diesel isbetter met, the hydrogenation saturation of a generated gasoline component is reduced, and the octane value of the gasoline component is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com