Transformation technology for catalytic diesel

A technology for catalyzing diesel oil and a process, which is applied in the petroleum industry, molecular sieve catalyst, hydrotreating process, etc., can solve the problem of unfavorable hydrogenation conversion to produce high-octane gasoline, strong gasoline component saturation ability, and gasoline product octane loss. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

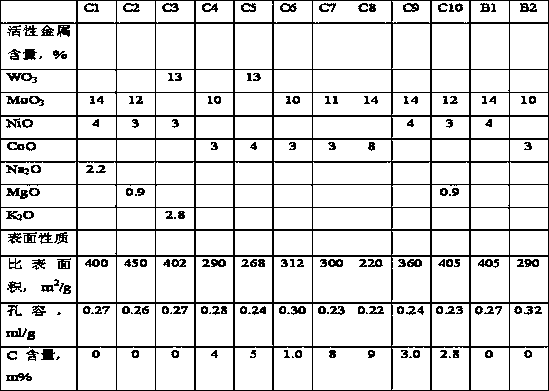

Embodiment 1

[0043] (1) Configure NaNO 3 Aqueous solution, NaNO 3 Concentration as Na 2 O is calculated as 8g / 100ml;

[0044] (2) NaNO obtained in step 1 3 The aqueous solution was impregnated with industrially produced macroporous alumina powder according to the liquid / solid ratio of 3:1 for 2 hours, and after filtration, it was calcined at 120 °C for 2 hours, and then calcined at 550 °C for 3 hours;

[0045] (3) Take 40 g of alumina obtained in step (2), 80 g of modified Y molecular sieve for industrial production, and 80 g of MoO 3 Mix 20g of nickel nitrate with 20g of nickel nitrate, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, extrude and shape on an extruder, dry and roast to obtain catalyst C1.

Embodiment 2

[0047] (1) Configure Mg (NO 3 ) 2 Aqueous solution, Mg(NO 3 ) 2 The concentration is calculated as 4g / 100ml with MgO;

[0048] (2) Mg(NO) obtained in step 1 3 ) 2 The aqueous solution was impregnated with industrially produced macroporous alumina powder according to the liquid / solid ratio of 2:1 for 2 hours, and after filtration, it was calcined at 110 °C for 4 hours and at 500 °C for 4 hours;

[0049] (3) Mix 30 g of alumina obtained in step (2) and 90 g of modified Y molecular sieve for industrial production, add 4 g / 100 ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and extrude it on an extruder. carrier;

[0050] (4) Configure Mo-Ni impregnation solution, MoO 3 , basic nickel carbonate is added to distilled water to prepare partial Mo-Ni impregnation solution, and MoO is adjusted in the mixed solution according to the oxide of metal salt. 3 23g / 100ml, nickel oxide 8g / 100ml;

[0051] (5) Take the Mo-Ni impregnation solution obtained in...

Embodiment 3

[0053] (1) Configure KNO 3 Aqueous solution, KNO 3 Concentration as Na 2 O is calculated as 10g / 100ml;

[0054] (2) NaNO obtained in step 1 3 The aqueous solution was impregnated with industrially produced macroporous alumina powder according to the liquid / solid ratio of 2:1 for 2 hours, and after filtration, it was calcined at 110 °C for 4 hours and at 500 °C for 4 hours;

[0055] (3) Mix 50 g of alumina obtained in step (2), 100 g of modified Y molecular sieve for industrial production, 25 g of metatungstic acid and 20 g of nickel nitrate, add 4 g / 100 ml of dilute nitric acid, mix and roll in a mixer until it can be extruded Catalyst C3 is obtained by extruding, molding, drying and calcining on an extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com