Catalyst for light hydrocarbon desulfanization based on control of alumina crystal plane and its preparation method

A light hydrocarbon, alumina technology, applied in carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of deep desulfurization of light petroleum processing products. Problems such as environmental pollution, inability to achieve deep desulfurization of petroleum products, environmental pollution, etc., achieve the effects of good industrial application prospects, long operation cycle and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a light hydrocarbon sweetening catalyst based on γ-alumina crystal face regulation and its preparation method, which is implemented through the following steps:

[0070] (1) Hydrothermal treatment of γ-alumina raw material

[0071] Mix 1L of deionized water and 1g of concentrated nitric acid with a mass fraction of 65% to prepare a nitric acid solution, and then add 250g of γ-Al to it 2 o 3 powder, the γ-Al 2 o 3 The specific surface area of the powder is 280m 2 / g, the pore volume is 0.71cm 3 After mixing evenly, put it into a reaction kettle, and after hydrothermal treatment at a constant temperature of 170°C in an oven for 7 hours, filter out the solid product, dry it at 120°C for 2 hours, and then roast it at 520°C for 4 hours to obtain the hydrothermally treated product of this example. gamma-alumina powder.

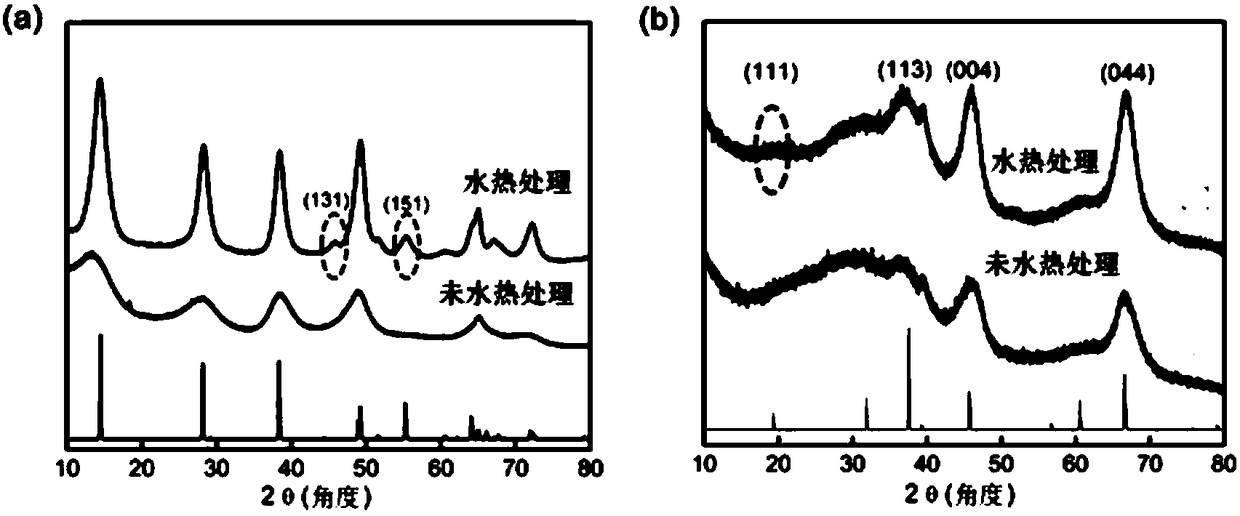

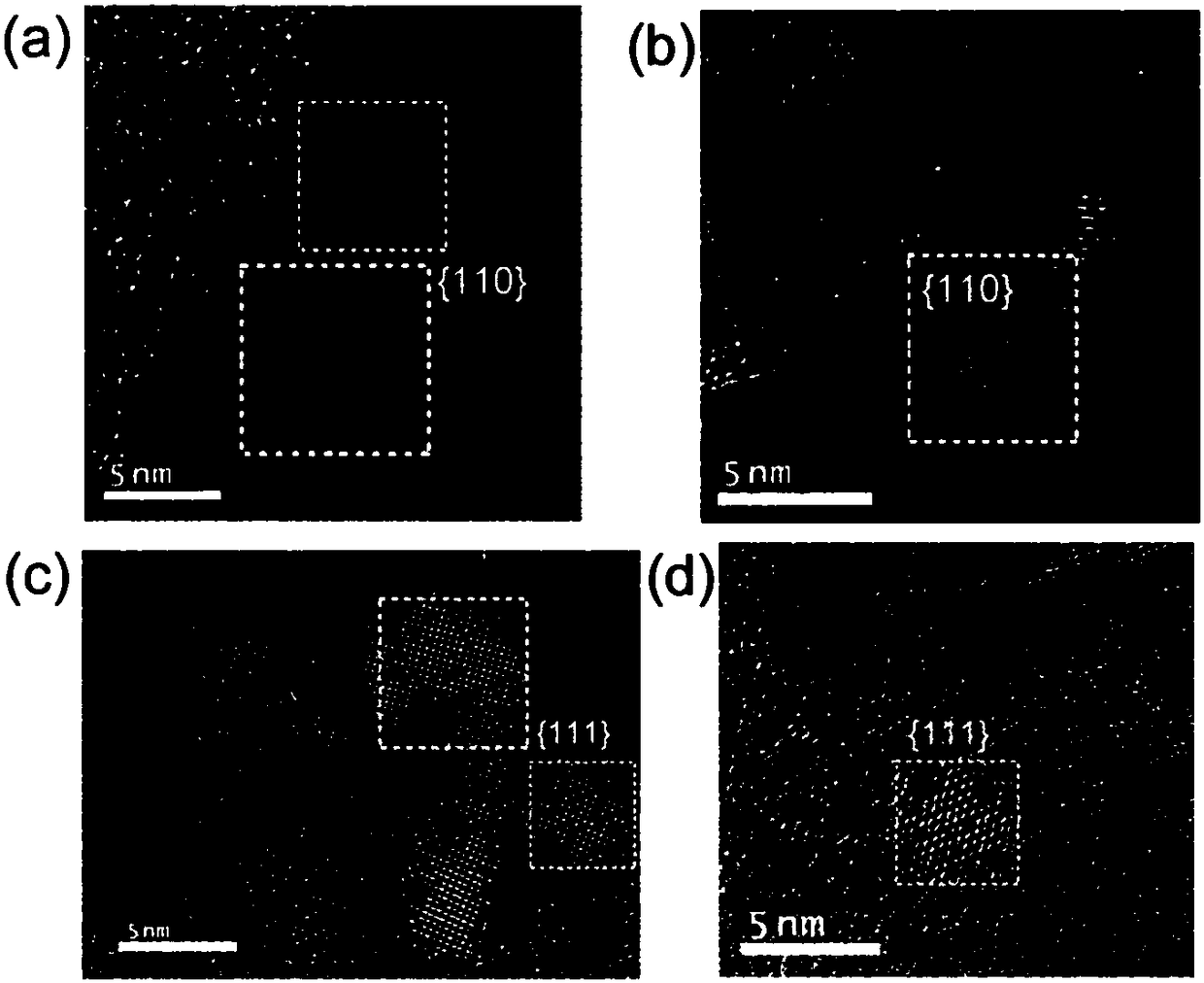

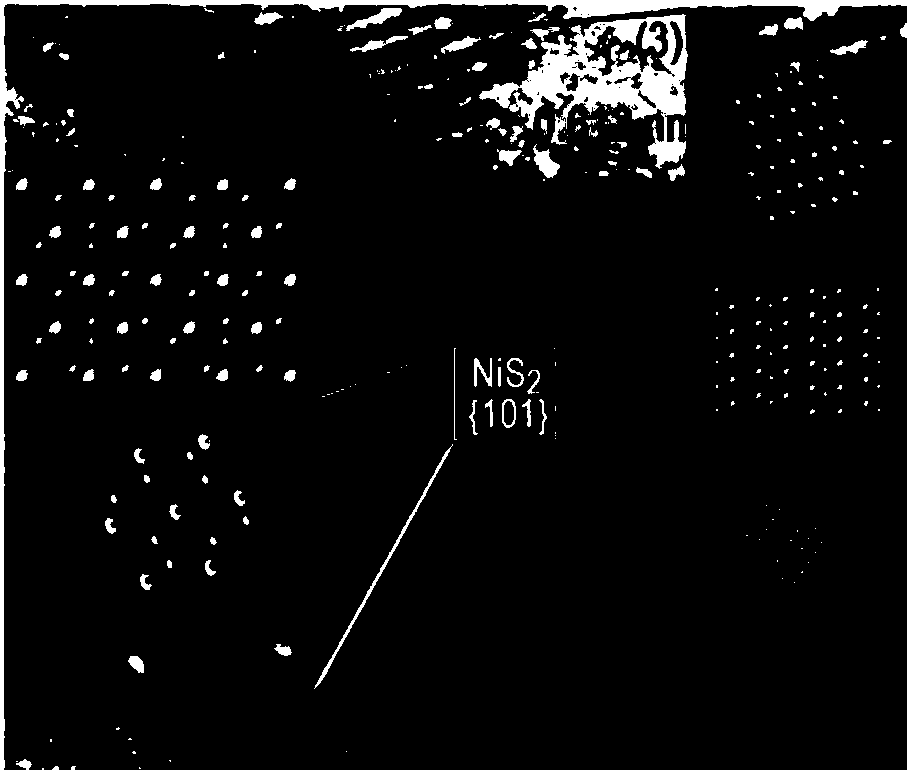

[0072] figure 1 The XRD spectra of gamma-alumina after hydrothermal treatment and gamma-alumina without hydrothermal treatm...

Embodiment 2

[0080] This example provides a light hydrocarbon sweetening catalyst based on γ-alumina crystal face regulation and its preparation method, which is implemented through the following steps:

[0081] (1) Hydrothermal treatment of γ-alumina raw material

[0082] Mix 1L of deionized water and 2g of acetic acid to prepare an acetic acid solution, and then add 400g of γ-Al to it 2 o 3 powder, the γ-Al 2 o 3 The specific surface area of the powder is 320m 2 / g, the pore volume is 0.75cm 3 After mixing evenly, put it into a reaction kettle, heat it in an oven at a constant temperature of 190°C for 5 hours, filter out the solid product, dry it at 120°C for 4 hours, and roast it at a constant temperature of 520°C for 4 hours to obtain the hydrothermal treatment of this example. gamma-alumina powder.

[0083] (2) Preparation of catalyst carrier

[0084] Mix 100g of the above-mentioned γ-alumina powder after hydrothermal treatment with 2g of turnip powder, 4.5g of concentrated n...

Embodiment 3

[0088] This example provides a light hydrocarbon sweetening catalyst based on γ-alumina crystal face regulation and its preparation method, which is implemented through the following steps:

[0089] (1) Hydrothermal treatment of γ-alumina raw material

[0090] Mix 1L of deionized water and 1g of concentrated nitric acid with a mass fraction of 65% to prepare a nitric acid solution, and then add 400g of γ-Al to it 2 o 3 powder, the γ-Al 2 o 3 The specific surface area of the powder is 260m 2 / g, the pore volume is 0.78cm 3 After mixing evenly, put it into a reaction kettle, heat it in an oven at a constant temperature of 180°C for 6 hours, filter out the solid product, dry it at 120°C for 4 hours, and roast it at a constant temperature of 500°C for 4 hours to obtain the hydrothermal treatment of this example. gamma-alumina powder.

[0091] (2) Preparation of catalyst carrier

[0092] 100g of the above hydrothermally treated γ-alumina powder was kneaded with 2g of turni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com