Catalyzed oxidation desulfuration process of petroleum products

A technology for catalytic oxidation desulfurization and petroleum products, applied in the petroleum industry, refined hydrocarbon oil, etc., can solve problems such as damage to oil quality, difficult operation, equipment corrosion, etc., achieve high selectivity and oxidation efficiency, wide application prospects, and reaction The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

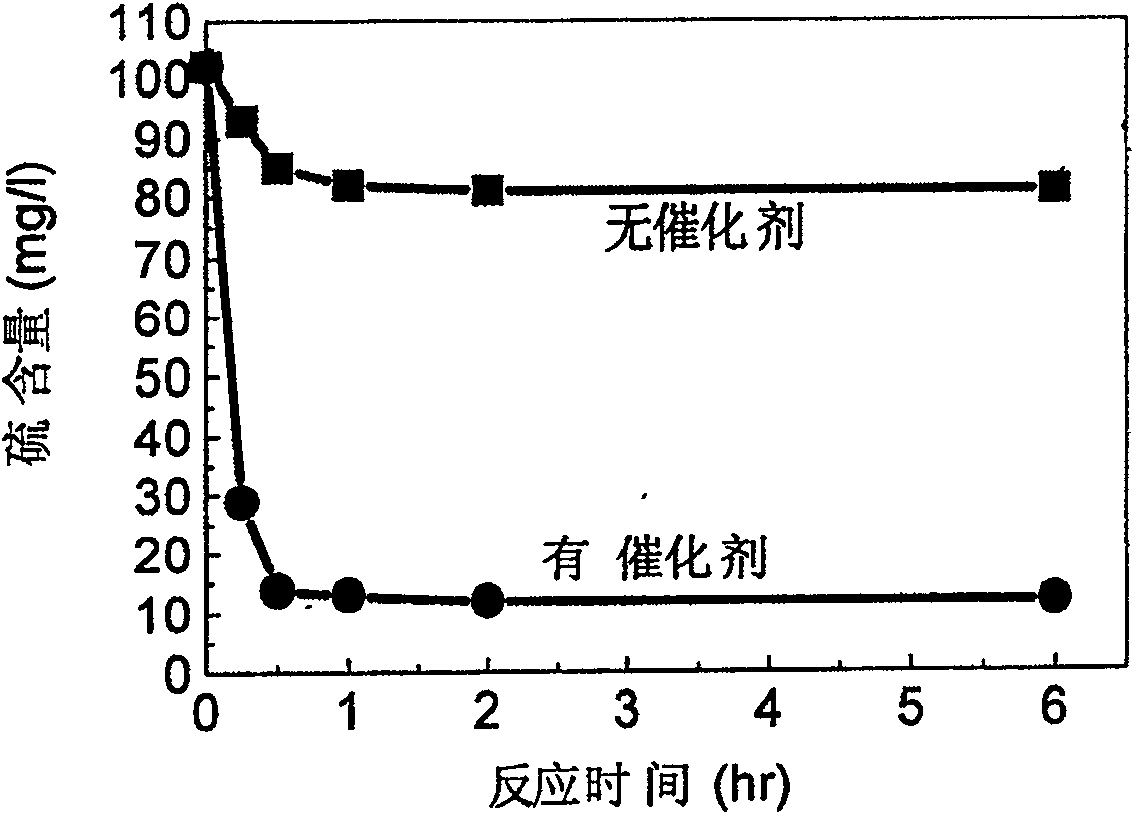

[0016] Embodiment 1, styrene / divinylbenzene copolymer-potassium permanganate catalytic gasoline desulfurization

[0017] Choose commercially available styrene / divinylbenzene copolymer with quaternary ammonium group strong anion exchange resin (U.S. Aldrich Reagent Company Amberlite IRA 900 type) 10g, add in the reaction vessel after washing pretreatment, under stirring, Slowly add potassium permanganate (KMnO 4 , mass 60mg) aqueous solution is loaded and bonded until there is no purple in the aqueous solution, then filtered and set aside.

[0018] Add 30ml of commercial gasoline with a sulfur content of 102mg / L (octane number 90.1 (RON), sulfur content 120mg / L) in a 250ml stainless steel reactor, add a desulfurization catalyst in an amount of 0.05% of the gasoline mass ratio, and then add ethanol 50ml, after mixing, add H 2 o 2 (30%) 1.5ml, airtight reaction, maintain reaction temperature 75 ℃, and with the gasoline that does not add catalyst as contrast, the change of gaso...

Embodiment 2

[0019] Embodiment 2, dodecyltrimethylammonium chloride-sodium tungstate catalytic gasoline desulfurization

[0020] Take 0.1g of commercially available cationic surfactant dodecyltrimethylammonium chloride, dissolve it in 2.5mlHO 2 o 2 (30%), mix this solution with 50ml raw gasoline (octane number 90.1 (RON), sulfur content 120mg / L), add 80ml ethanol, add sodium tungstate 15mg after mixing, and heat up to React at 80°C for 30 minutes. After separating ethanol and water, measure the quality and sulfur content of the treated oil. The result is that the octane number is 90.07 (RON) and the sulfur content is 23mg / L.

Embodiment 3

[0021] Embodiment 3, rhodamine-cerium ammonium sulfate catalytic gasoline desulfurization

[0022] Dissolve 0.05g of commercially available cationic dye Rhodamine B in 50ml of acetonitrile, mix with 50g of gasoline (octane number 93.2 (RON), sulfur content 79mg / L), add cerium ammonium sulfate 0.05g, add isopropanol after mixing 50ml, stir and add 5mlH 2 o 2 , heated up to 80°C in a stainless steel reactor and reacted for 30 minutes. After isopropanol and water were separated, the quality and sulfur content of the treated oil were measured. The result was an octane number of 93.3 (RON) and a sulfur content of 16.2 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com