Patents

Literature

30results about How to "Keep octane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

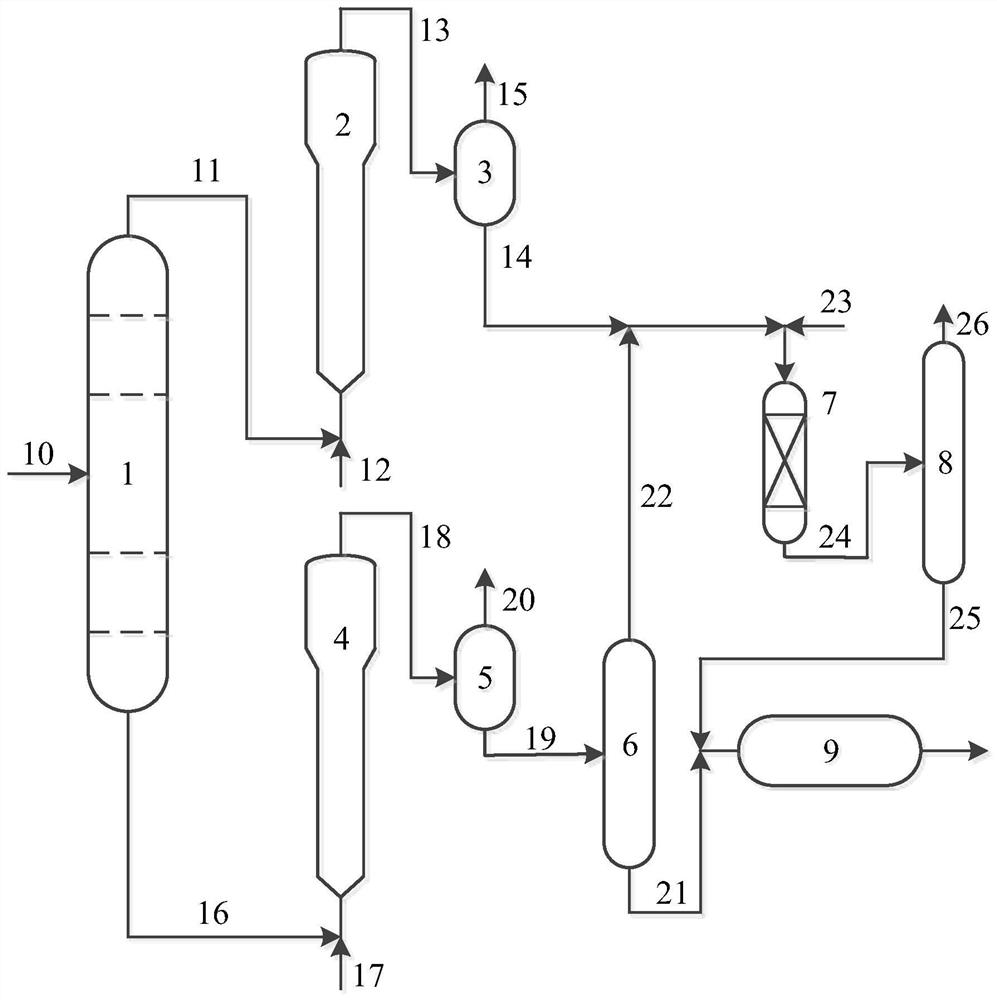

Cleaning method of full-range FCC (Fluid Catalytic Cracking) gasoline

ActiveCN108219841AKeep octaneRealize ultra-deep desulfurizationMolecular sieve catalystsTreatment with hydrotreatment processesIsomerizationCleaning methods

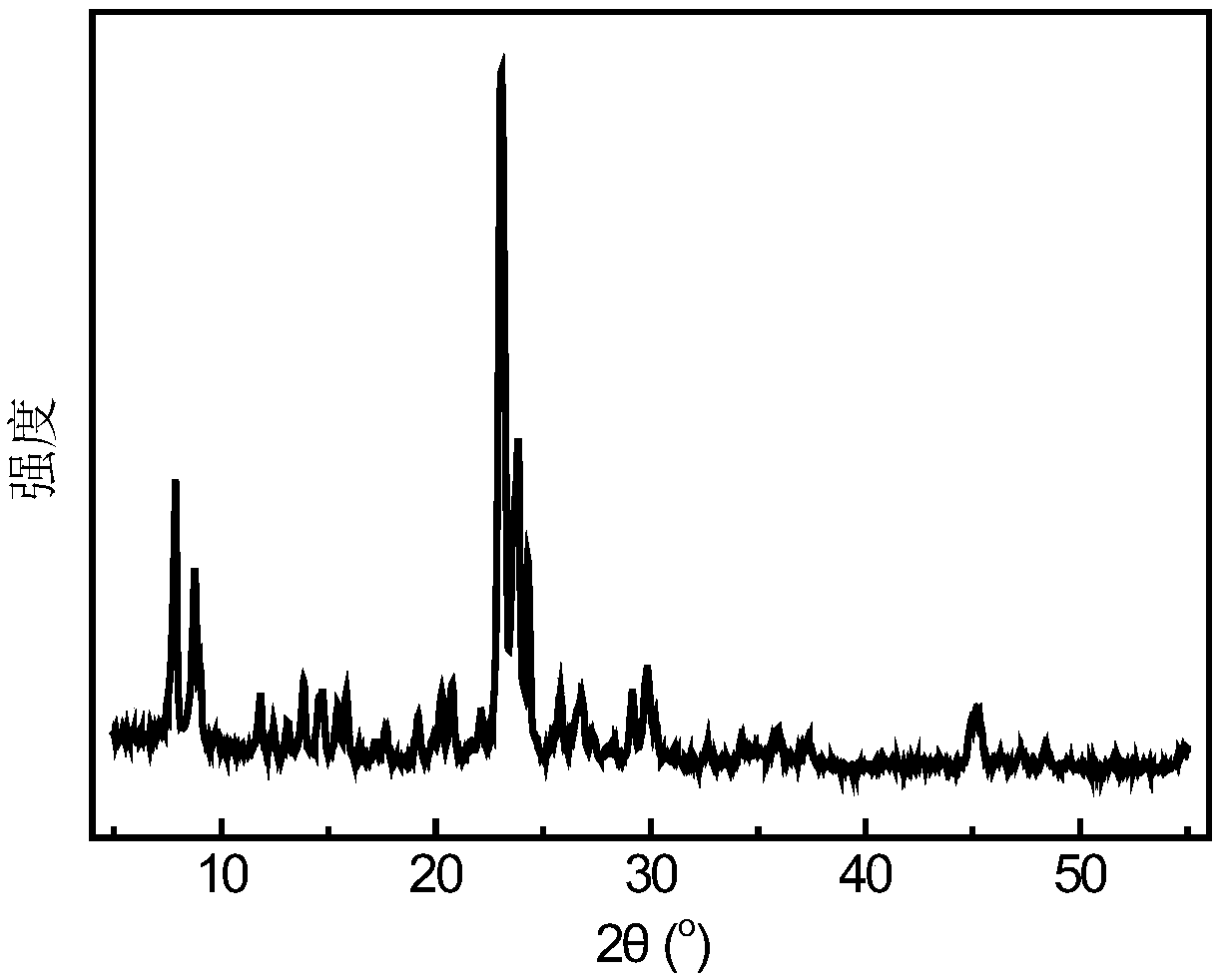

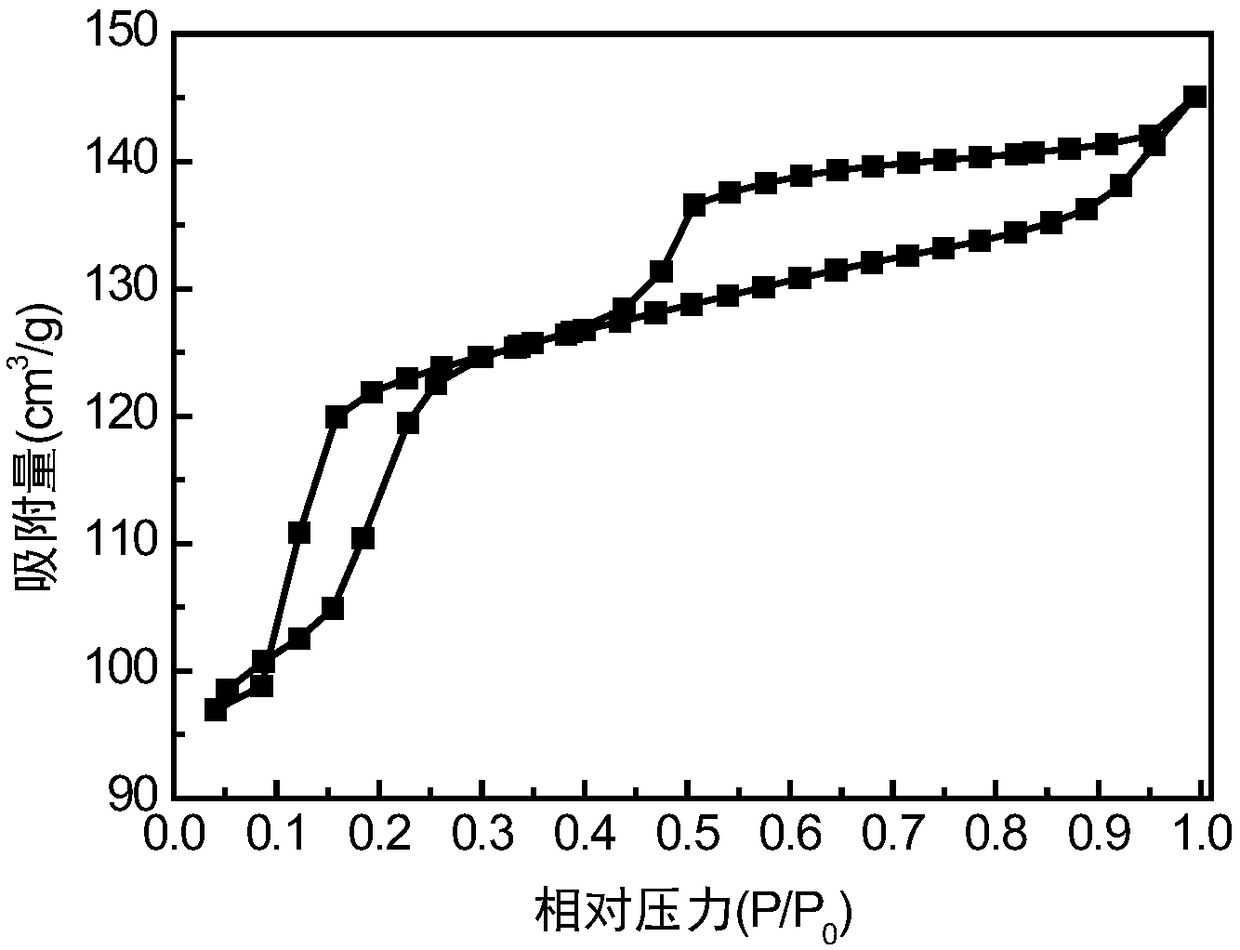

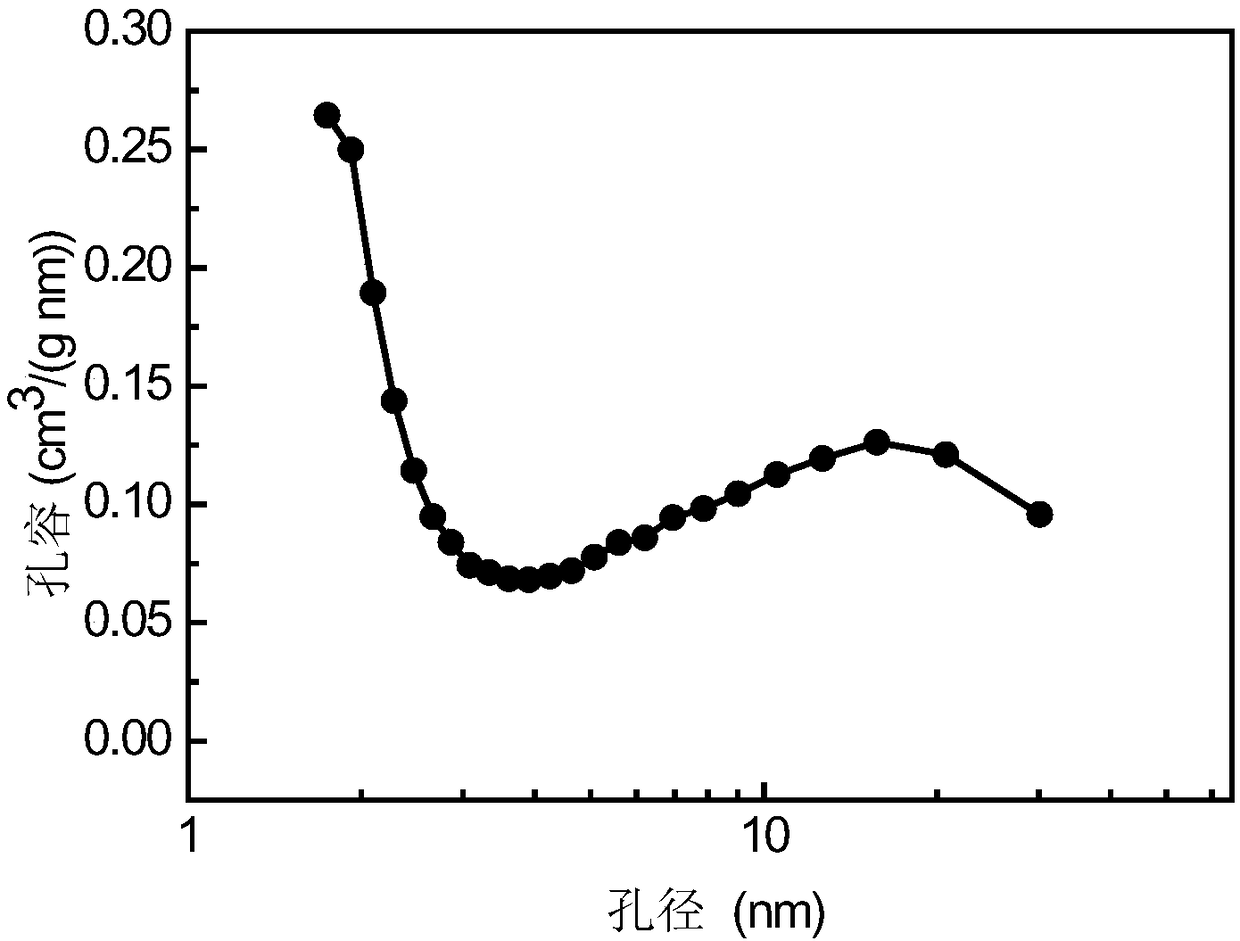

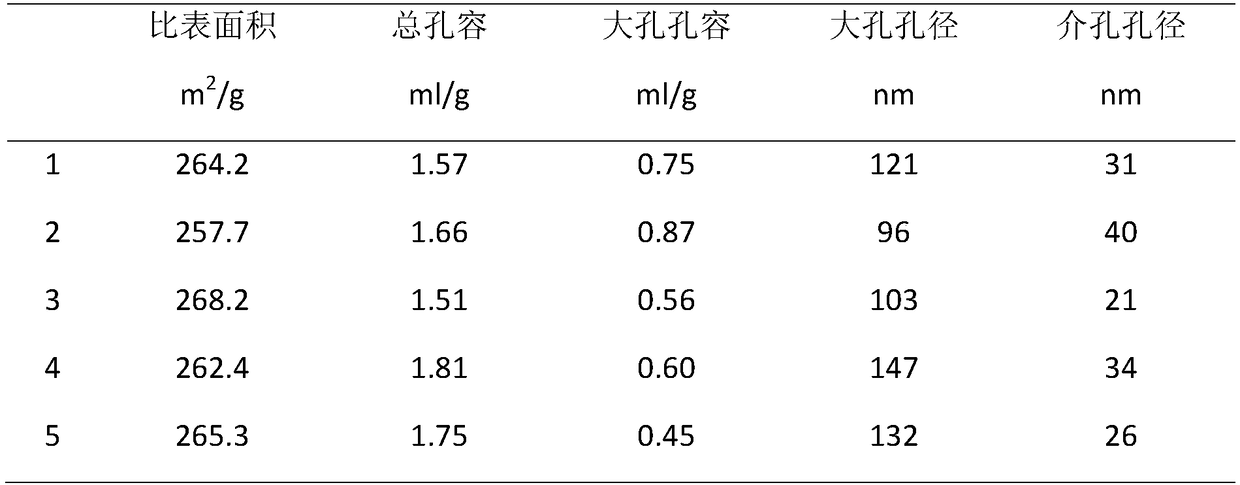

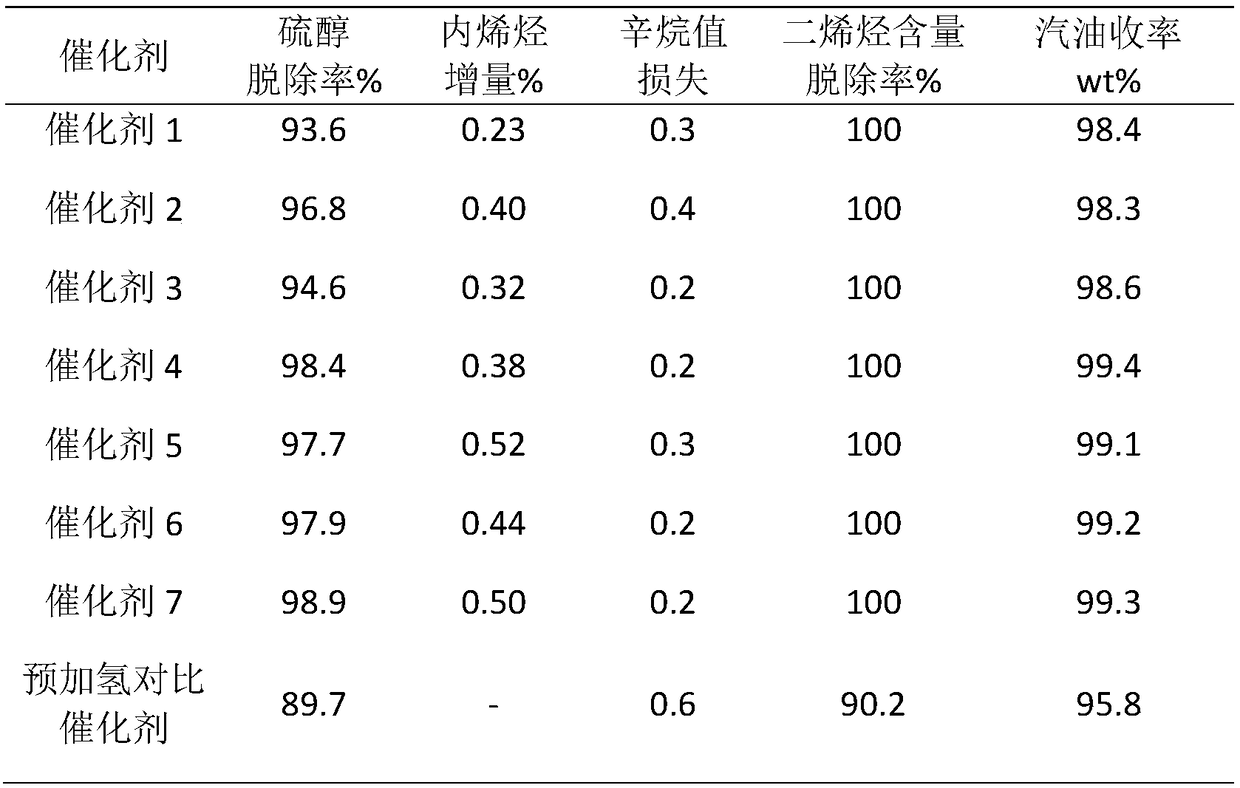

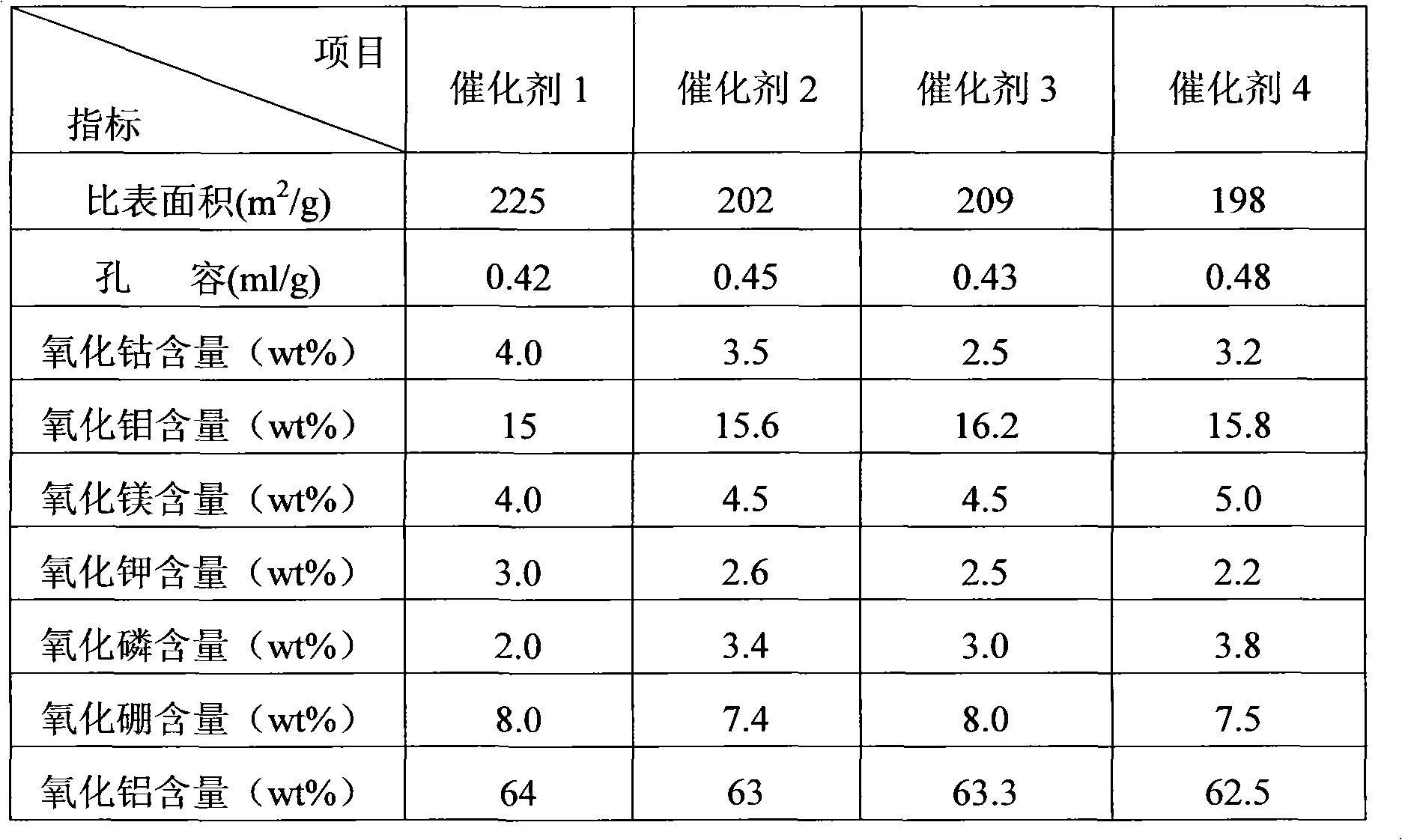

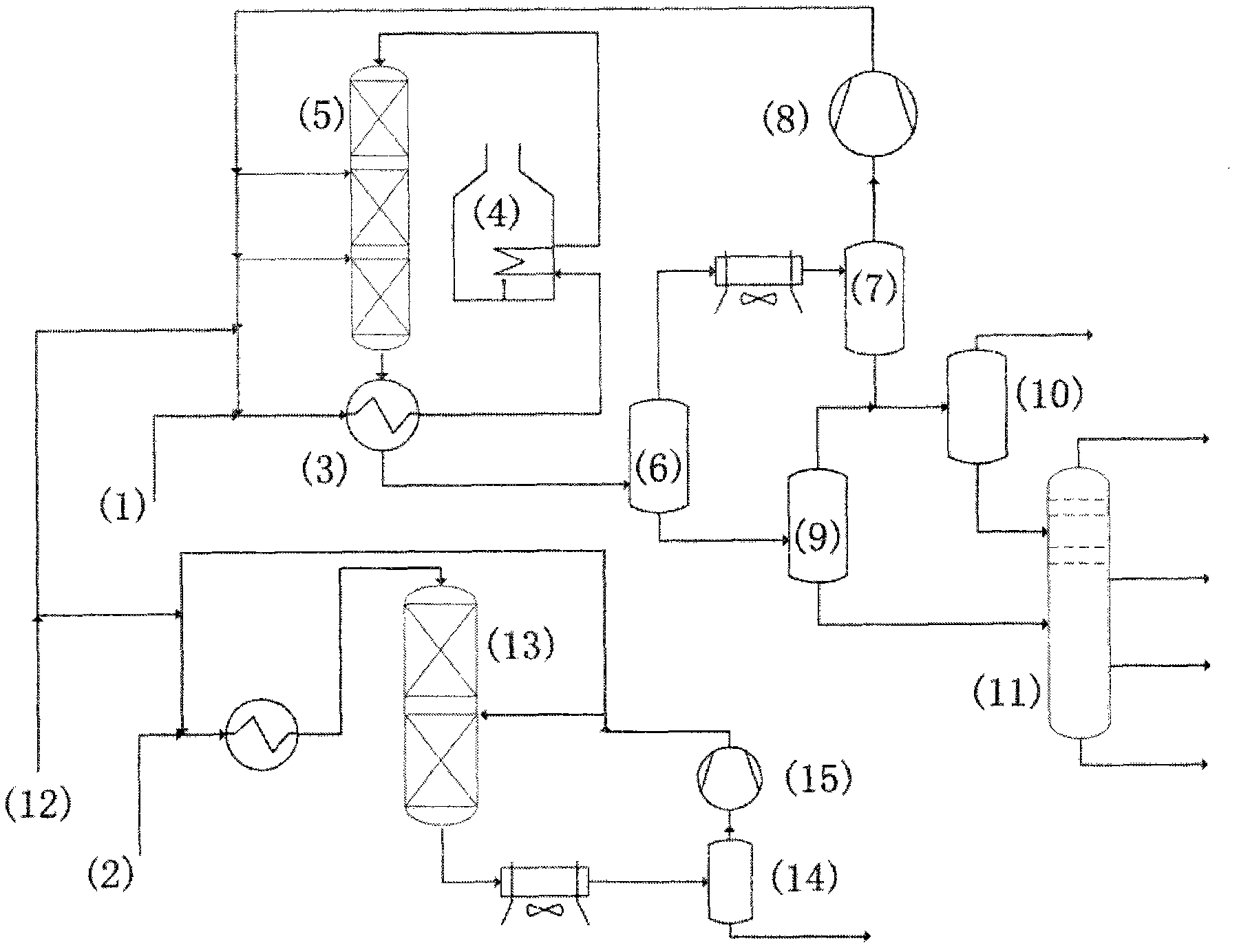

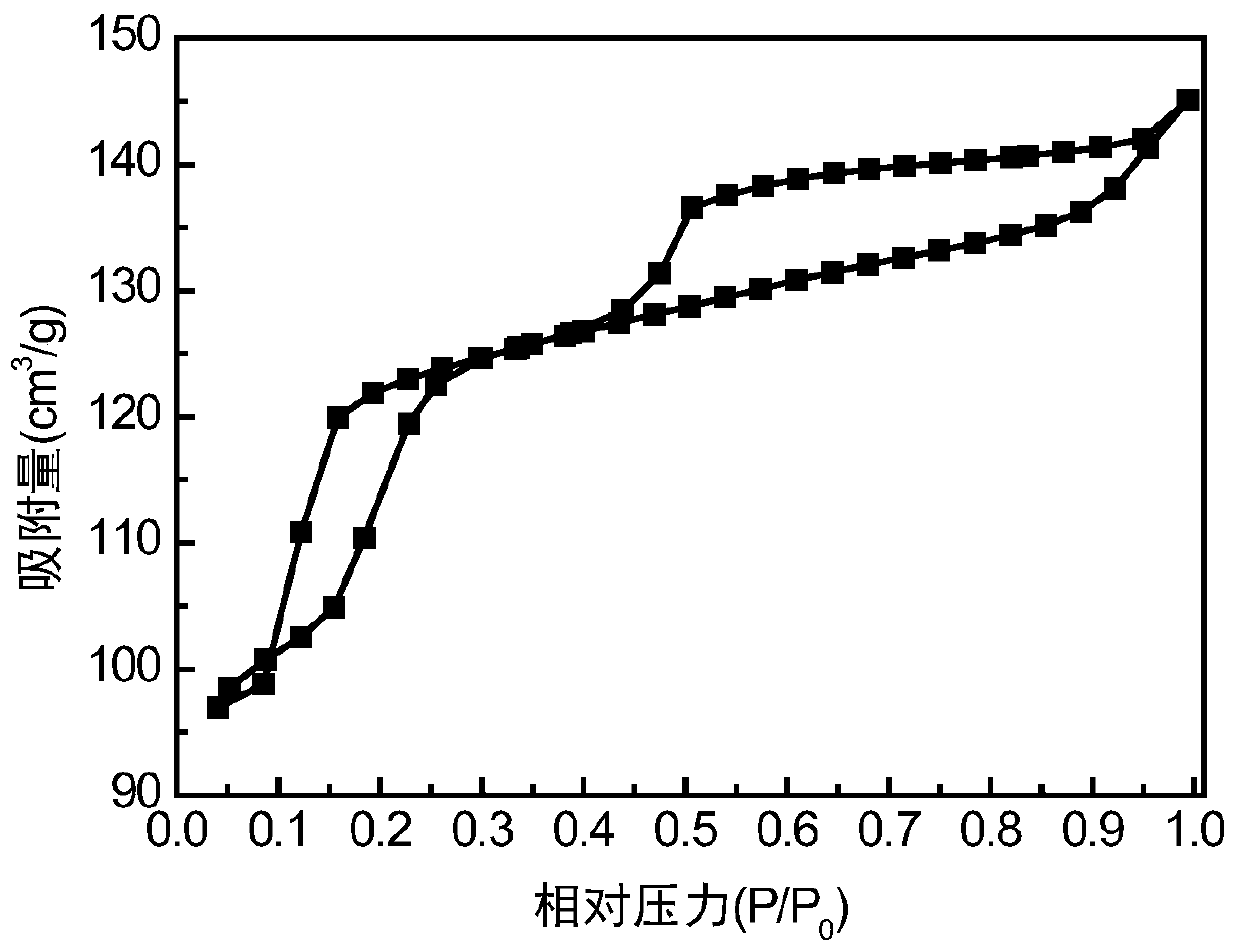

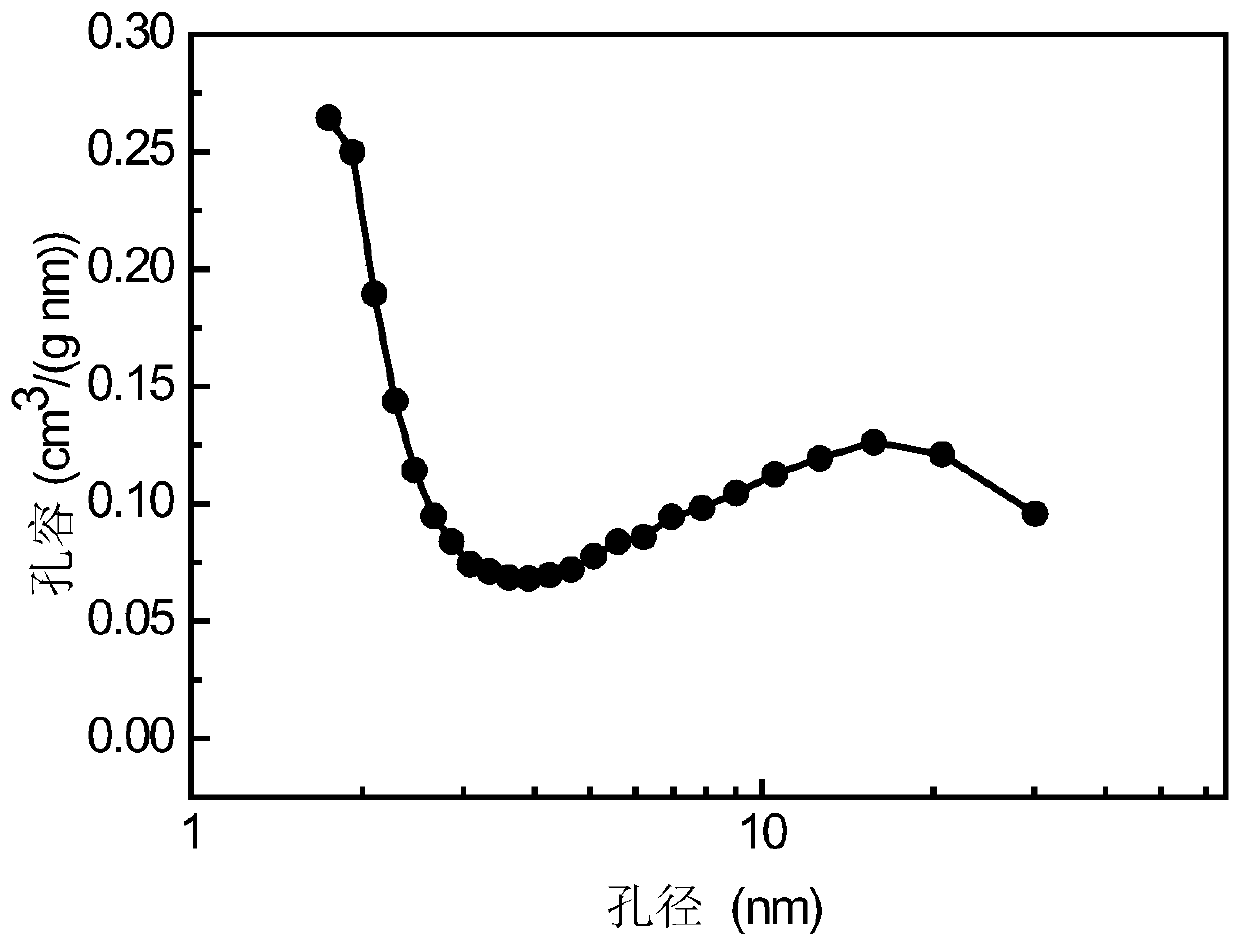

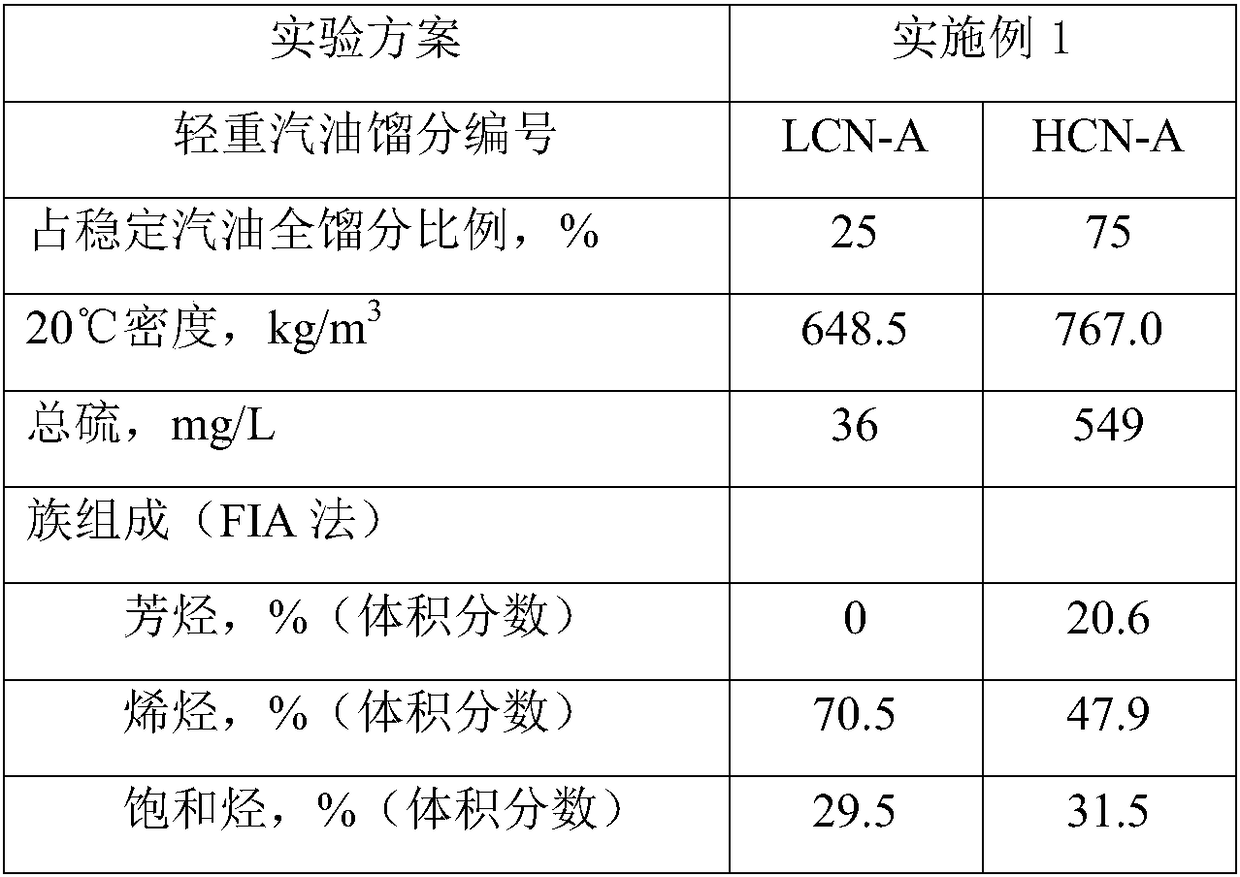

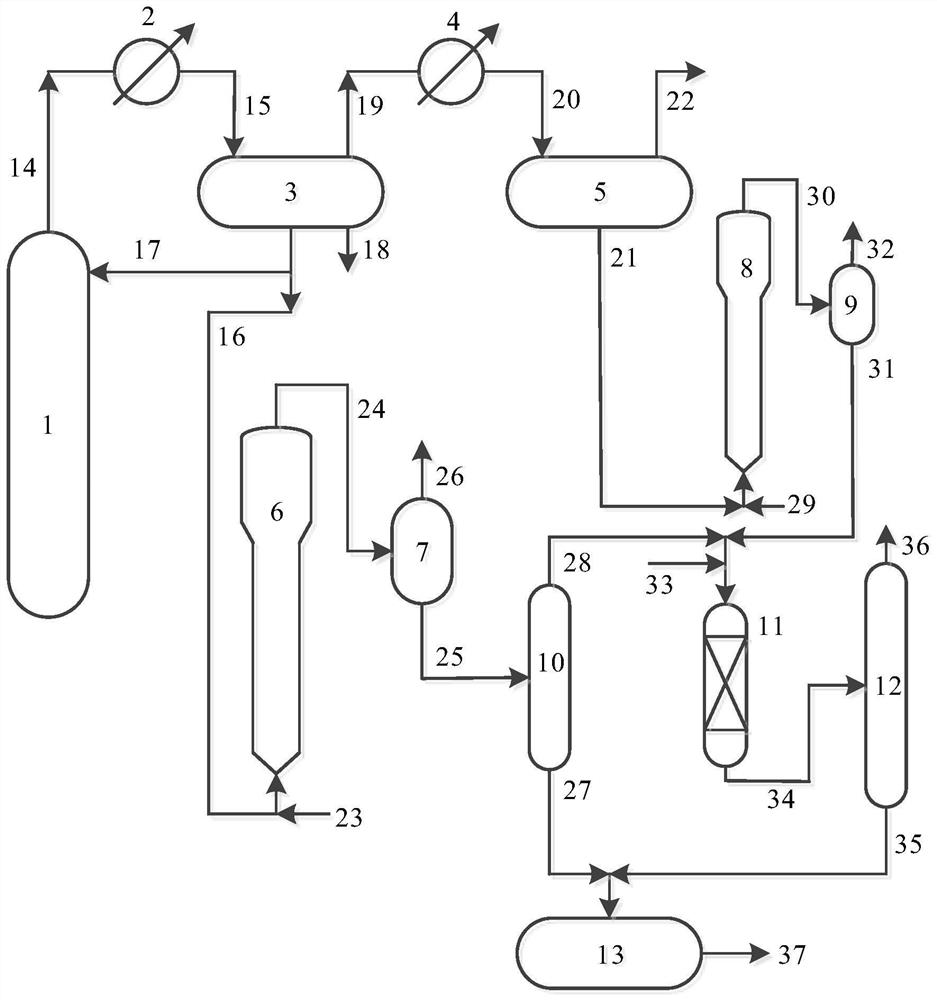

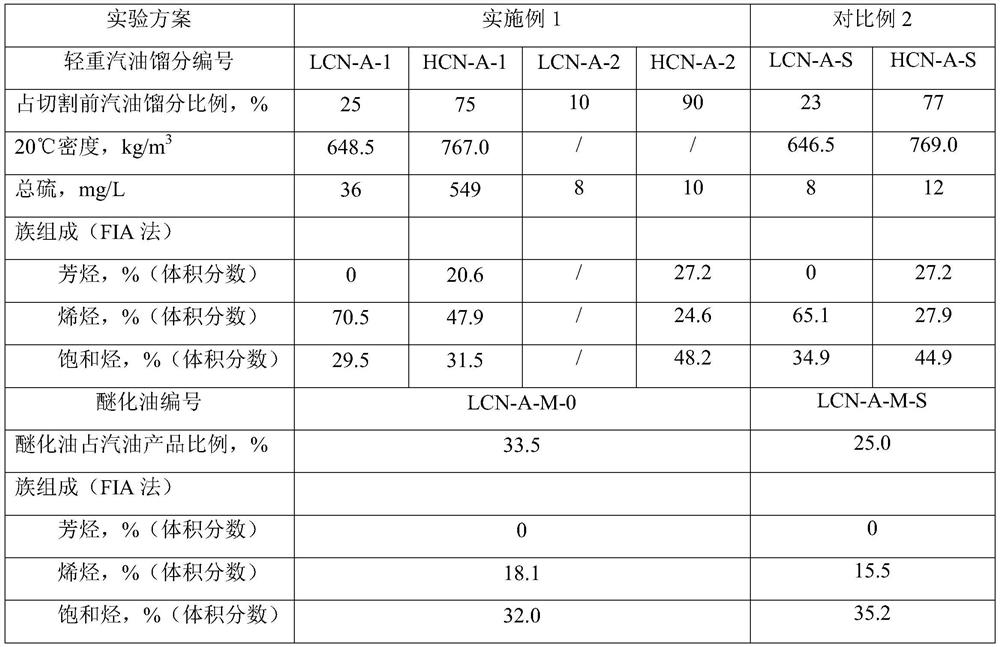

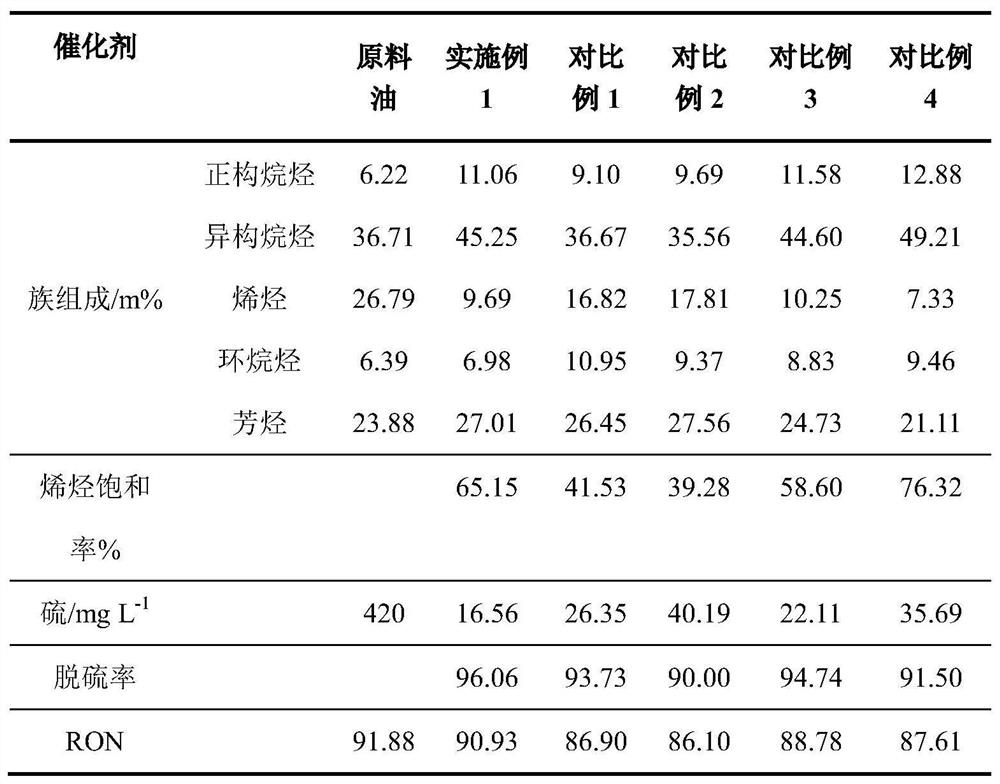

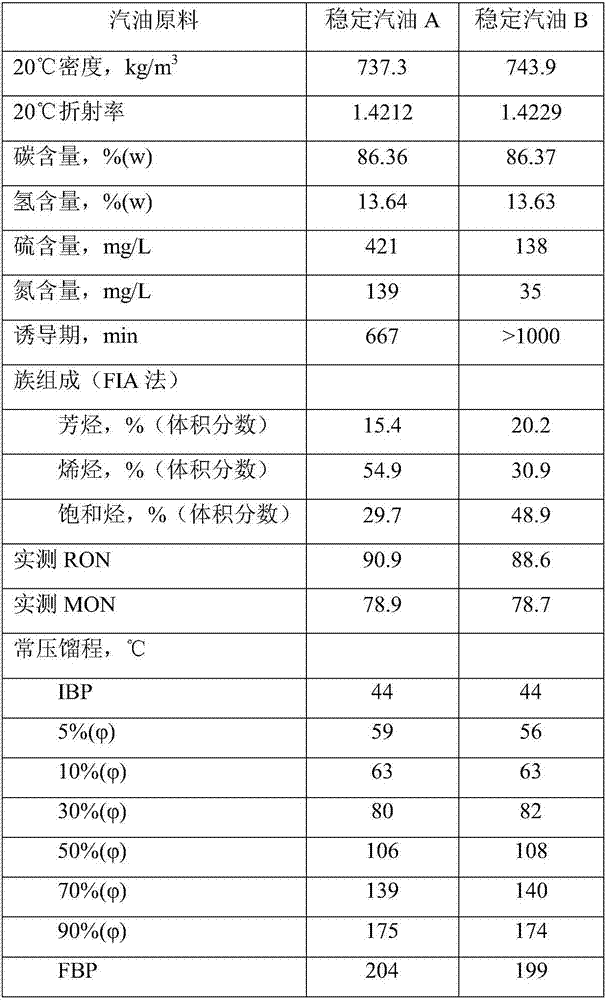

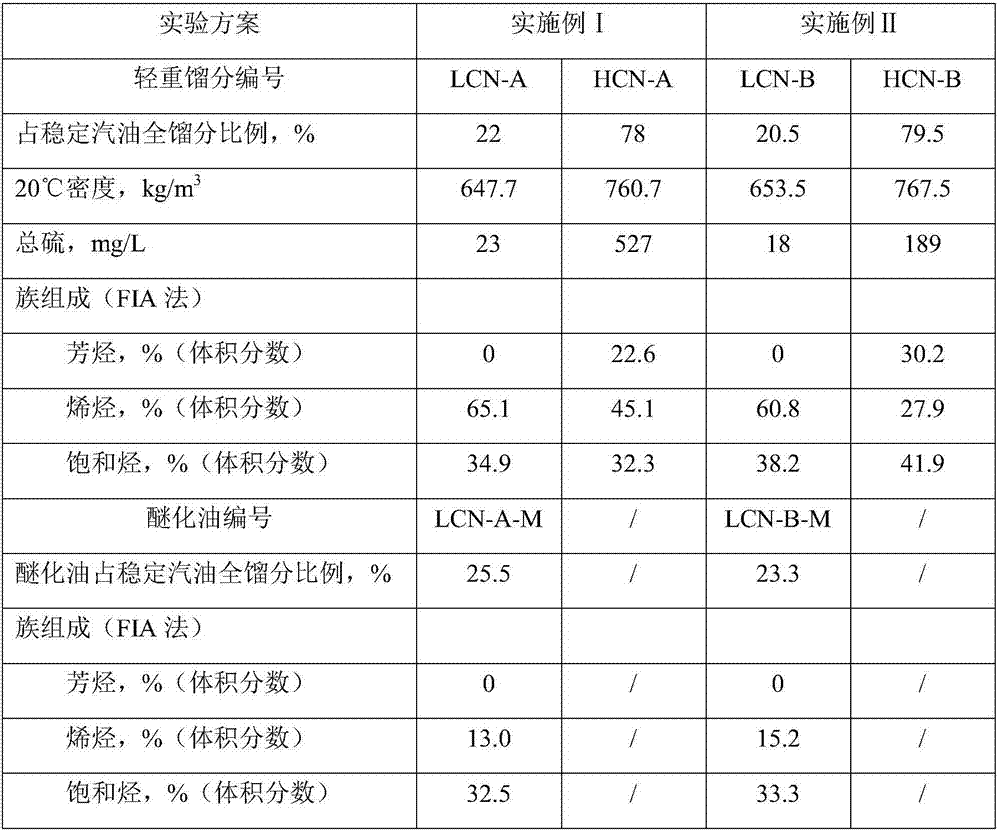

The invention relates to a cleaning method of full-range FCC (Fluid Catalytic Cracking) gasoline. The cleaning method comprises the following process: firstly, removing alkadiene in the full-range FCC(Fluid Catalytic Cracking) gasoline through a prehydrogenation reactor; then, carrying out hydro-adsorption desulfurization on a prehydrogenation product, thus removing sulfide; then carrying out isomerization on reaction effluent under the action of an olefin isomerization catalyst by using a weakly acidic mesoporous H-shaped Zn-ZSM-5 molecular sieve or an improved weakly acidic mesoporous H-shaped Zn-ZSM-5 molecular sieve as a carrier, thus converting olefin into isohydrocarbons, wherein an isomerization reaction product is clean gasoline meeting national standard VI.

Owner:FUZHOU UNIV

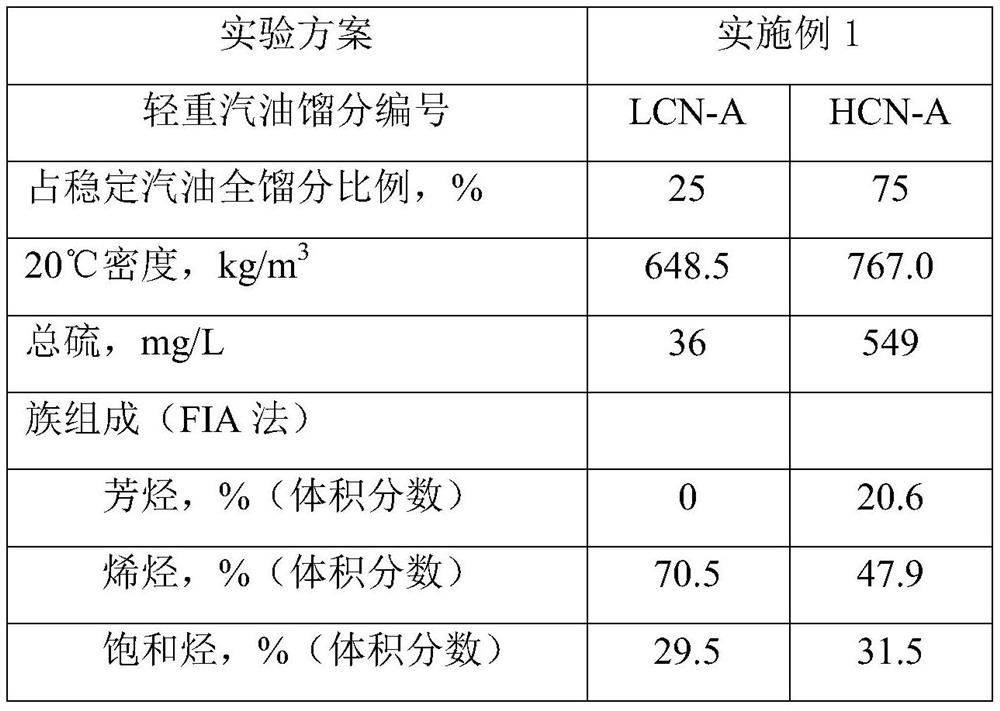

FCC gasoline cleaning method

ActiveCN109082303AHigh yieldImprove pore structureMolecular sieve catalystsTreatment with hydrotreatment processesChemistryDouble bond

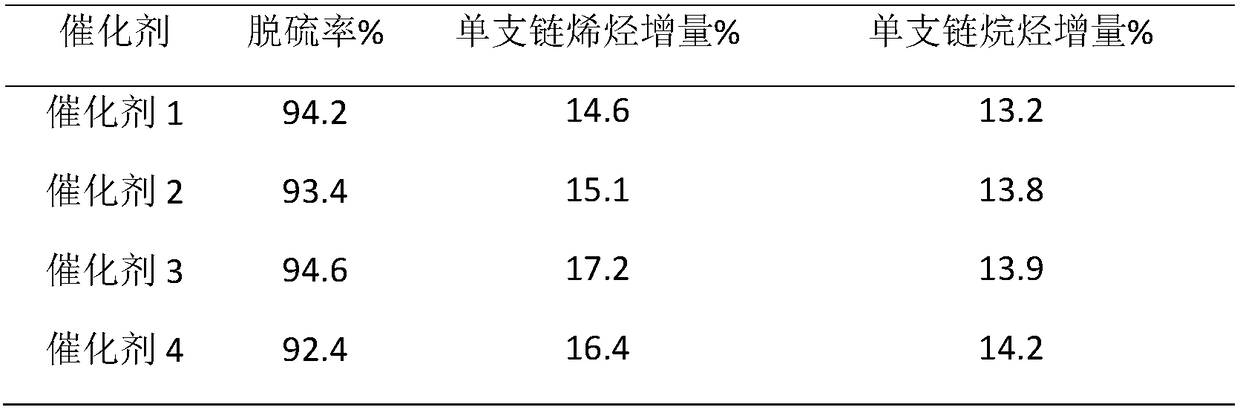

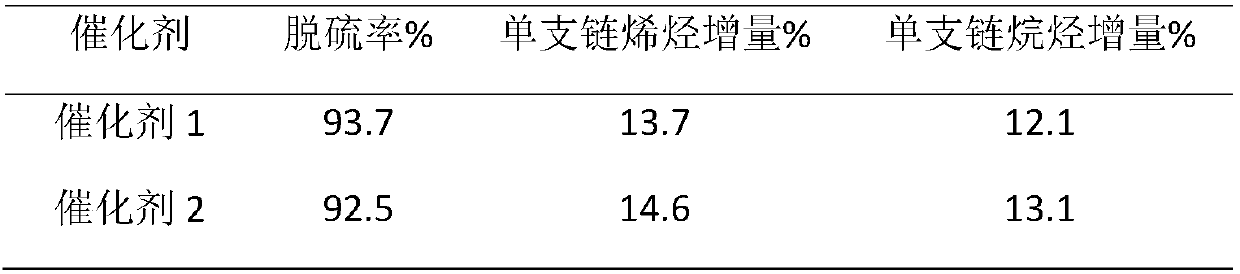

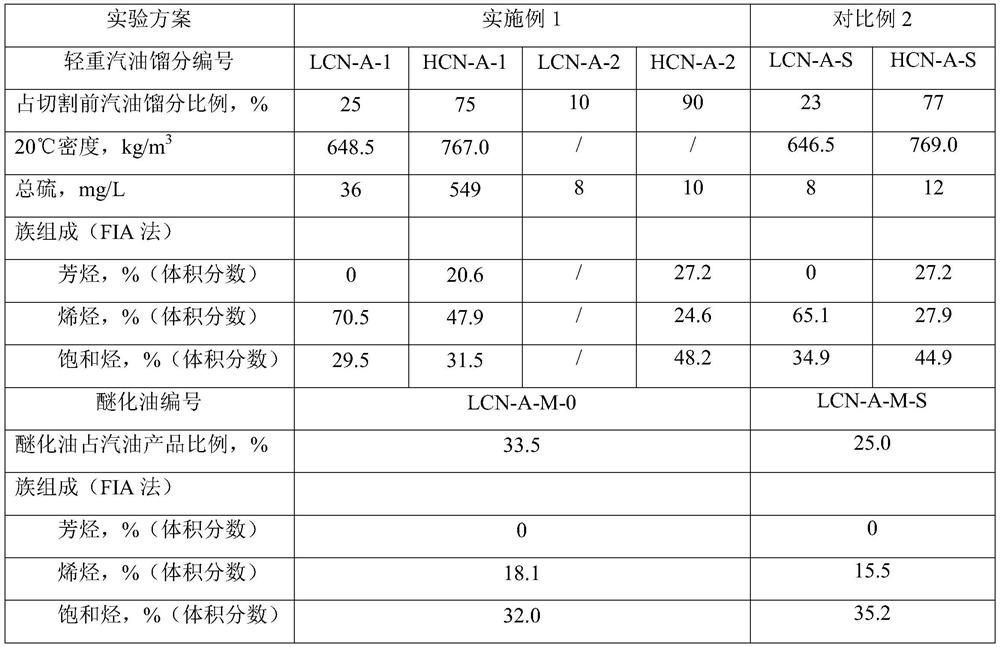

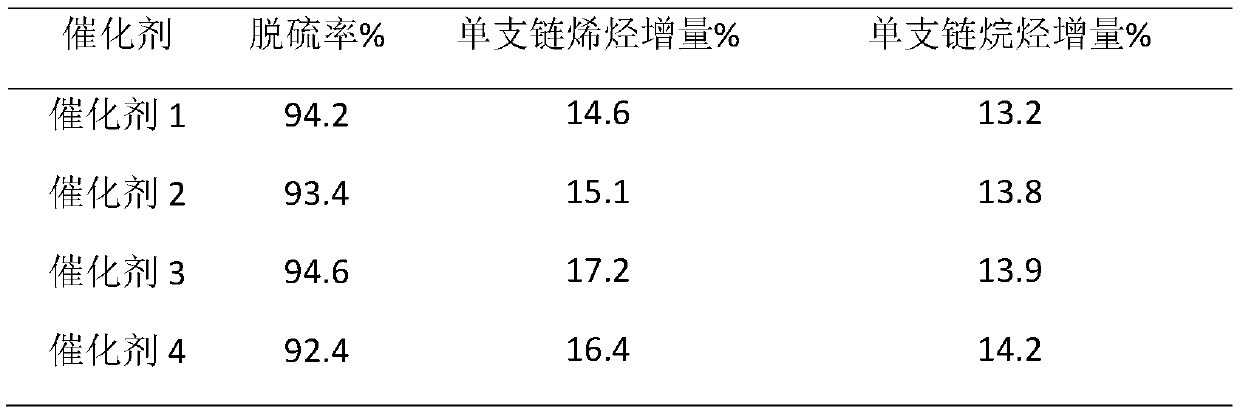

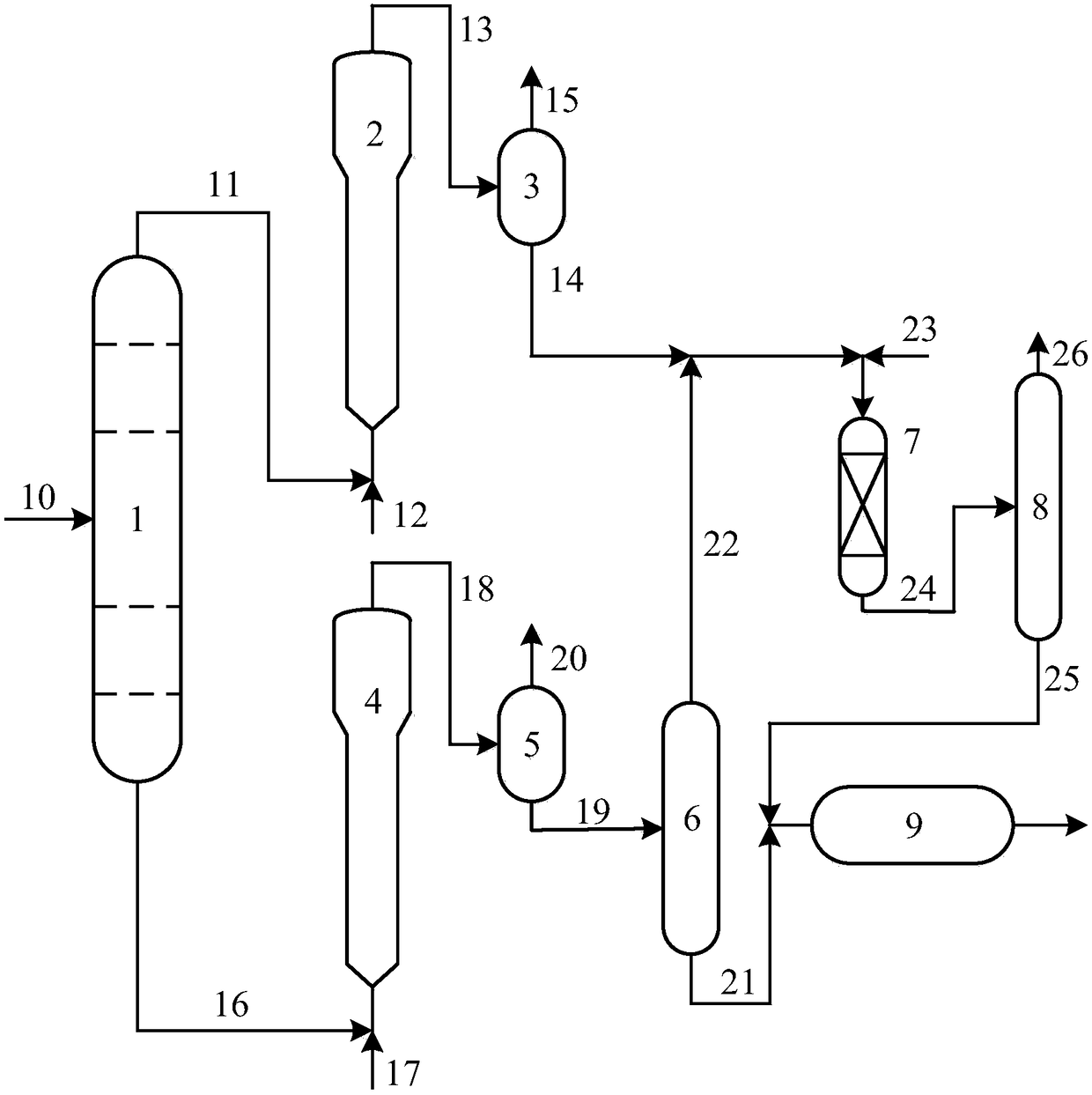

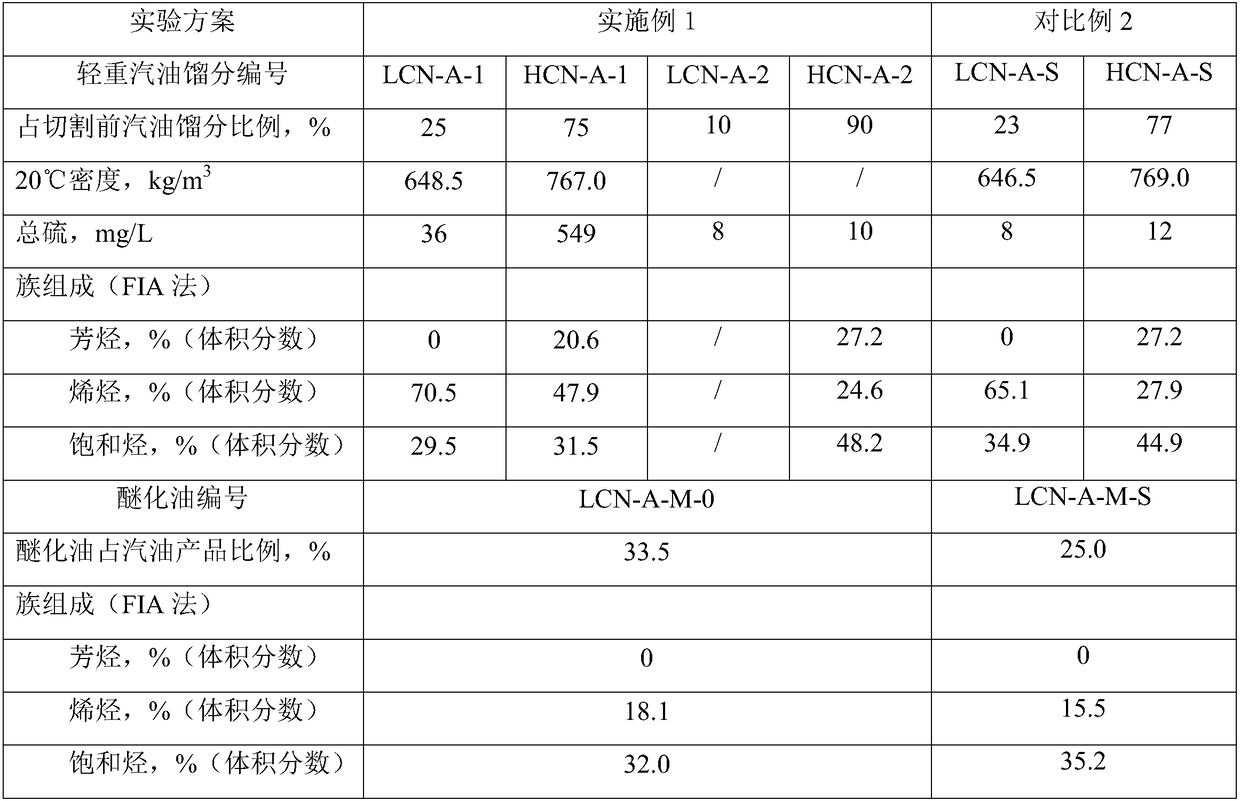

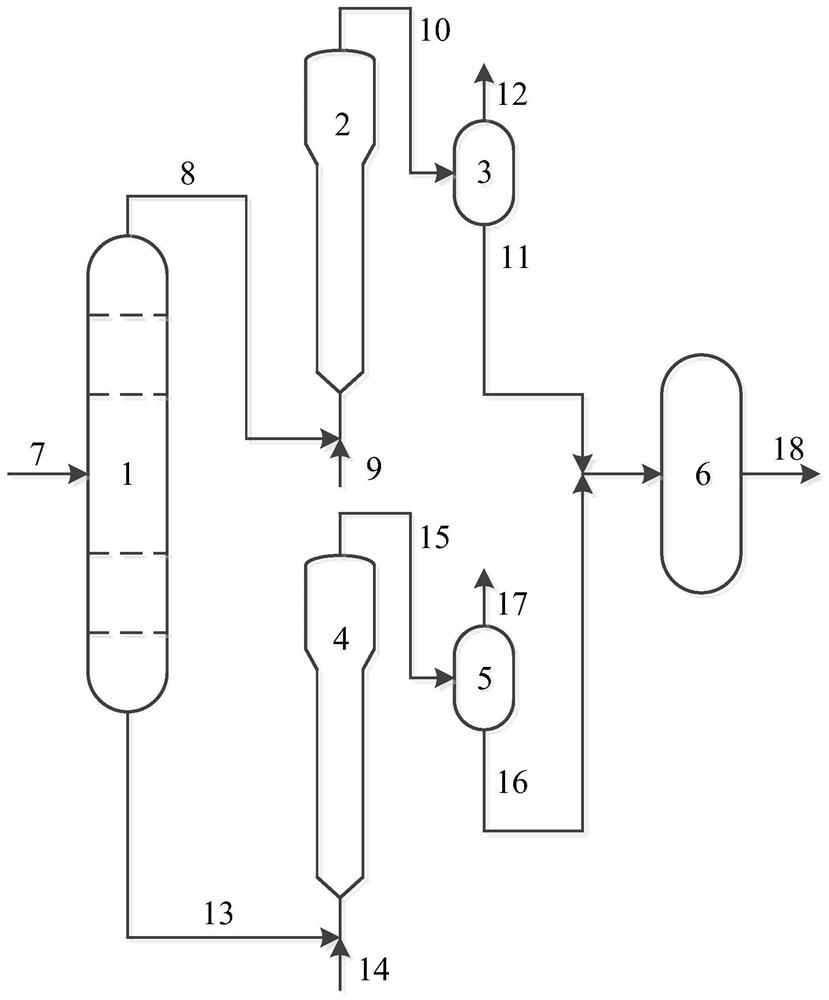

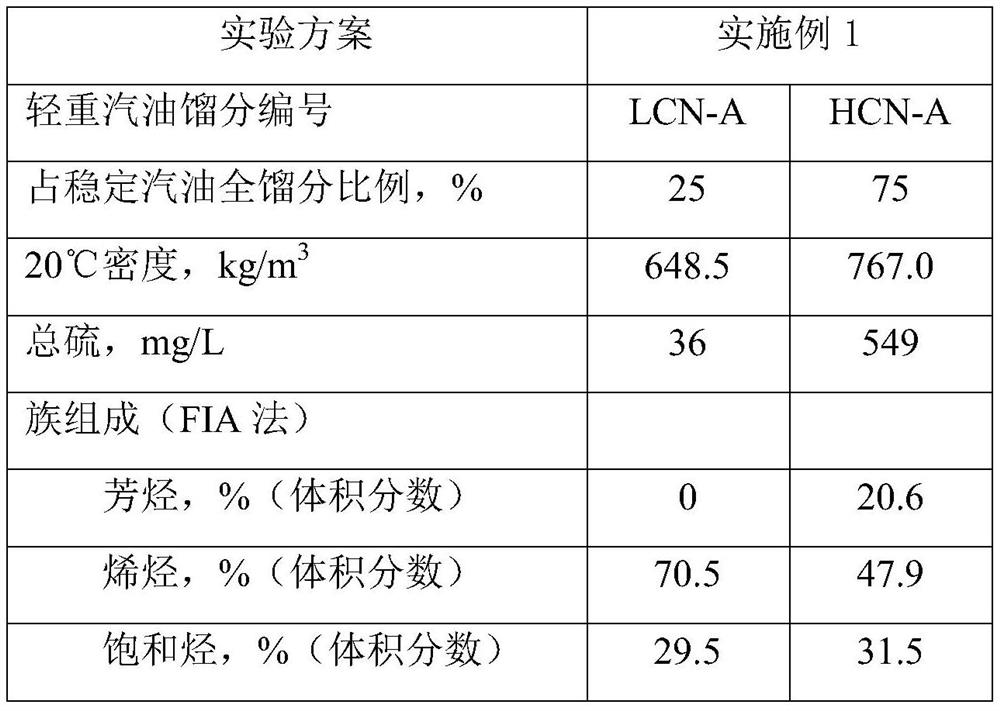

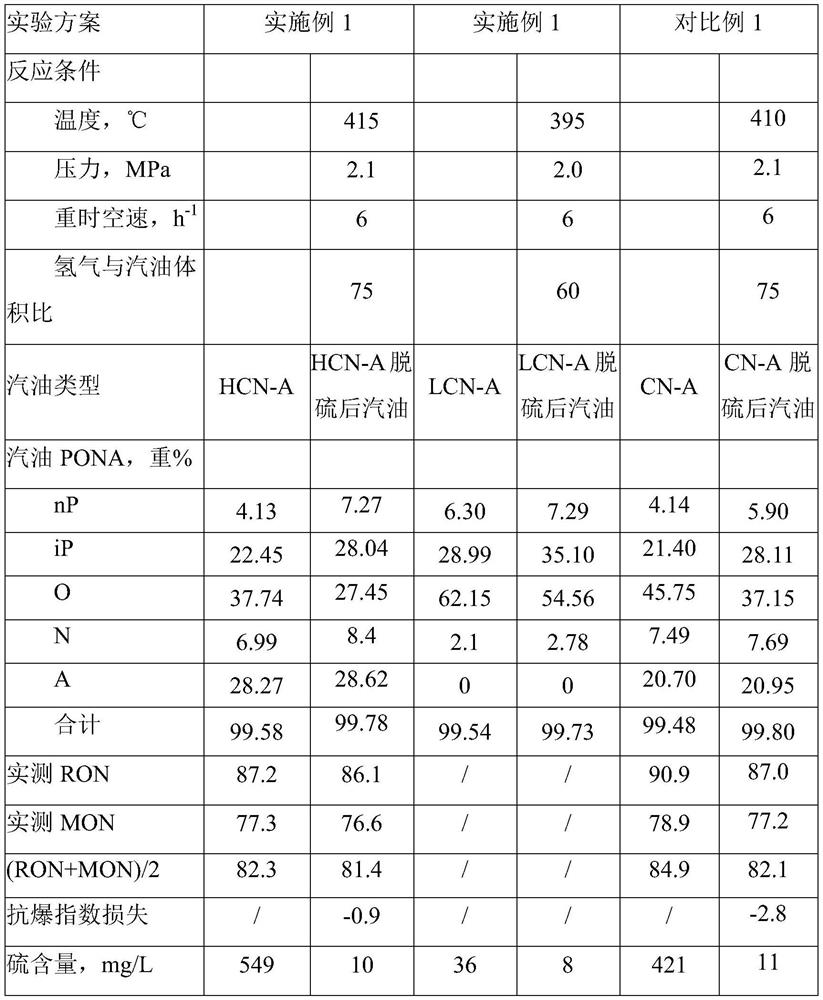

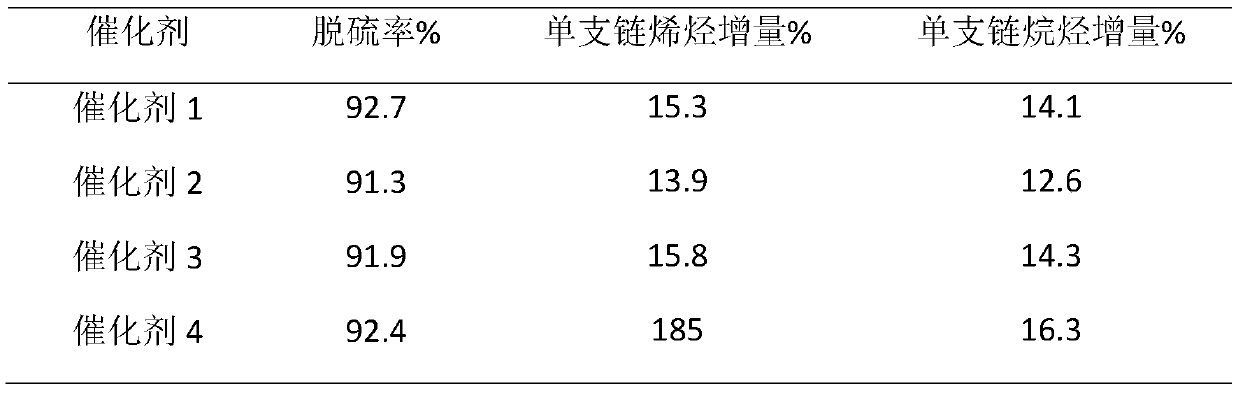

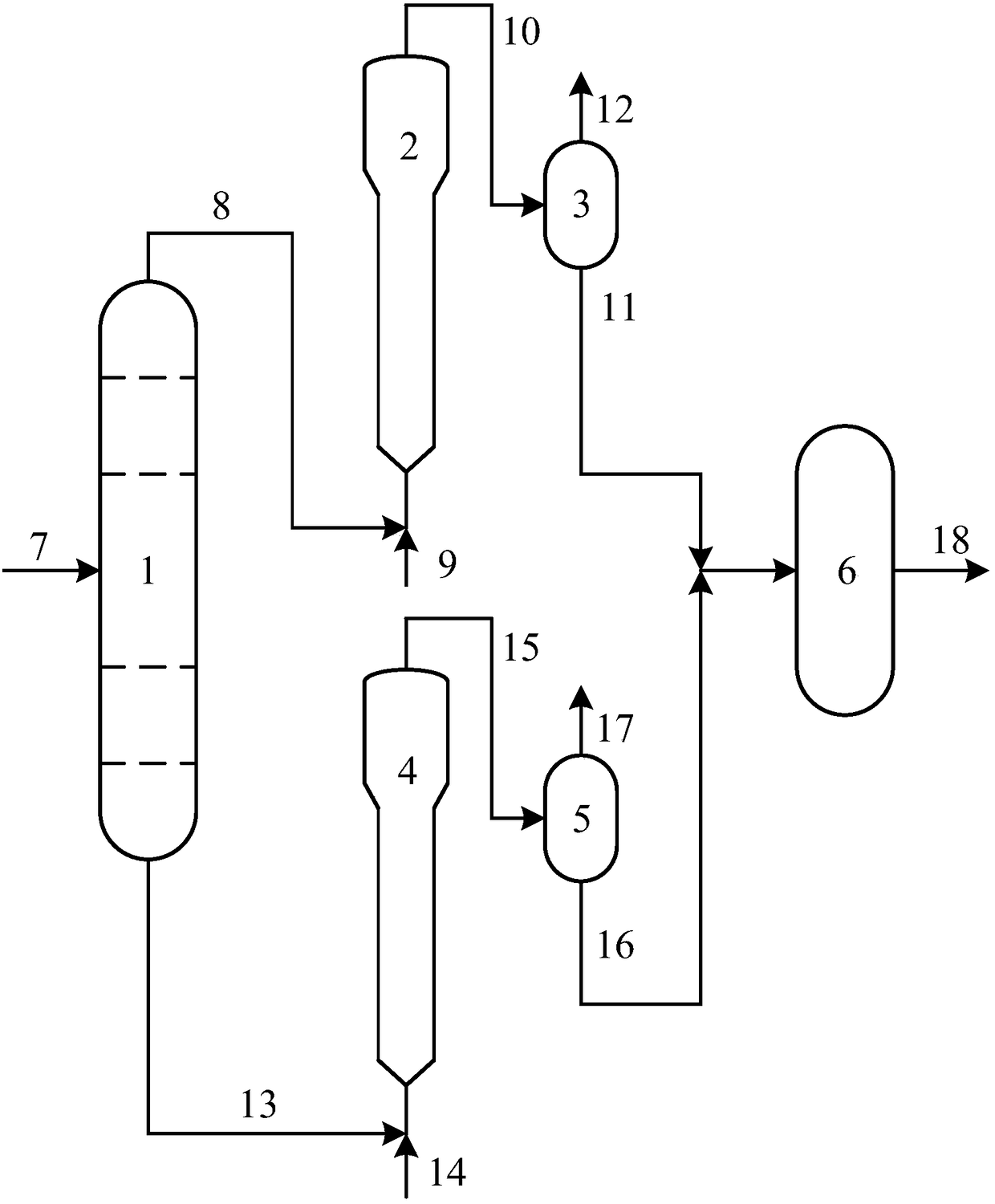

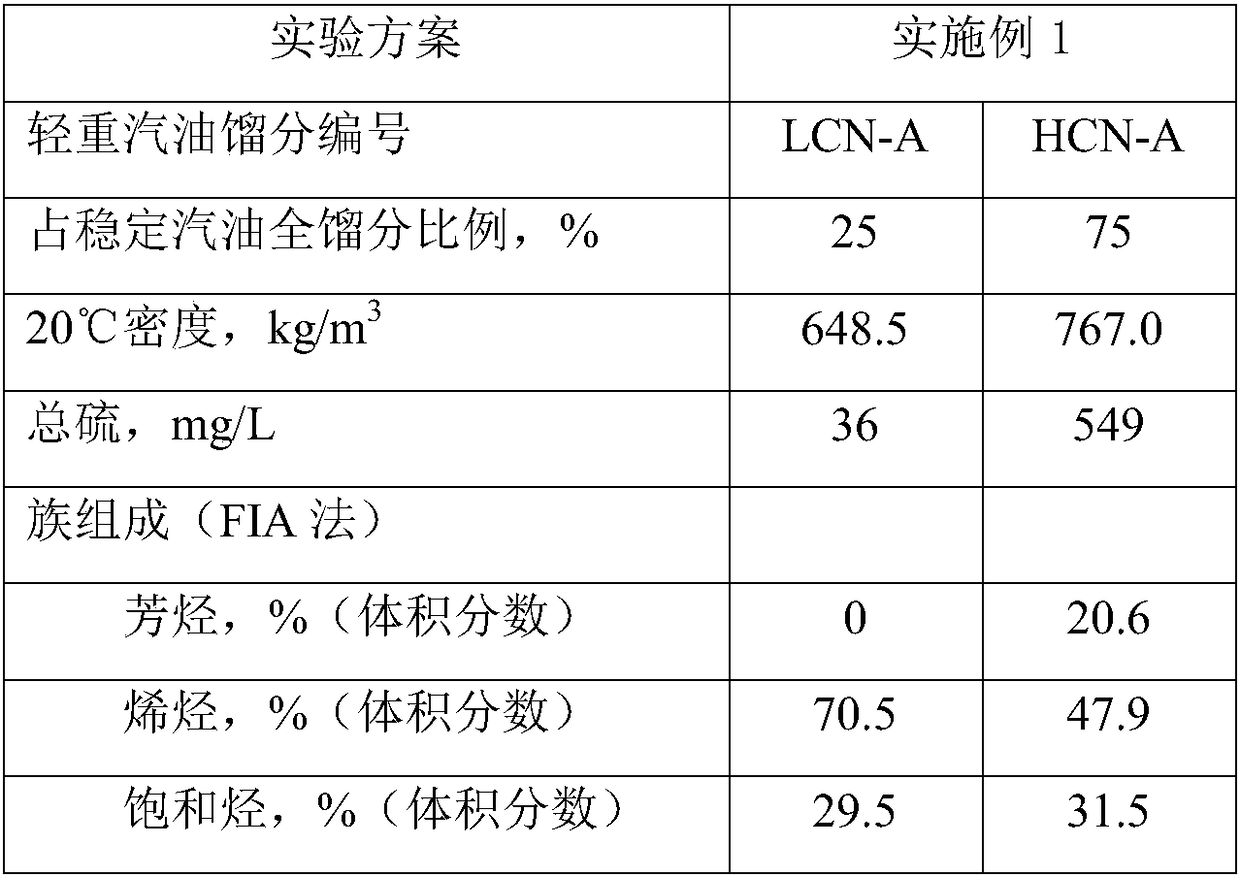

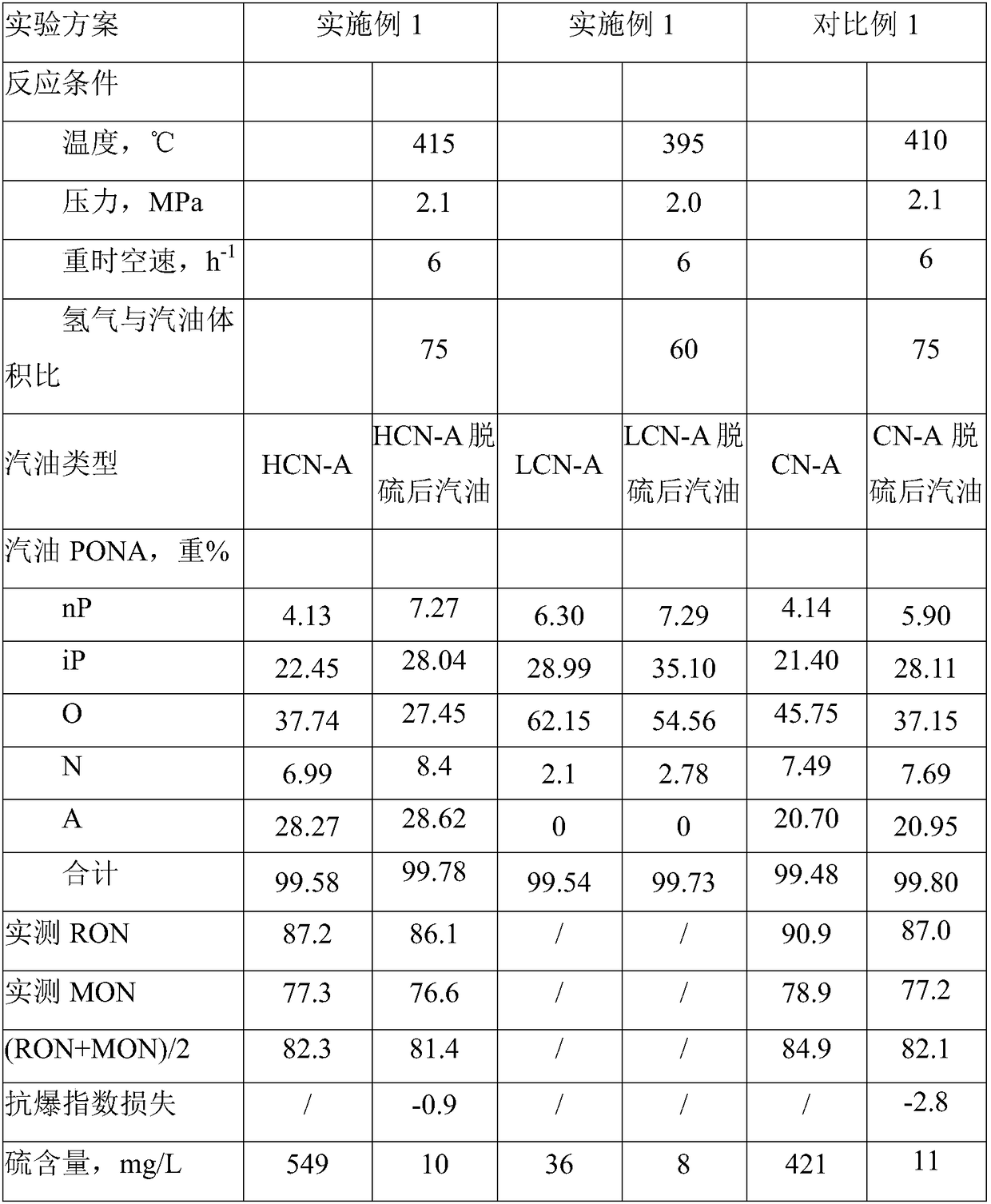

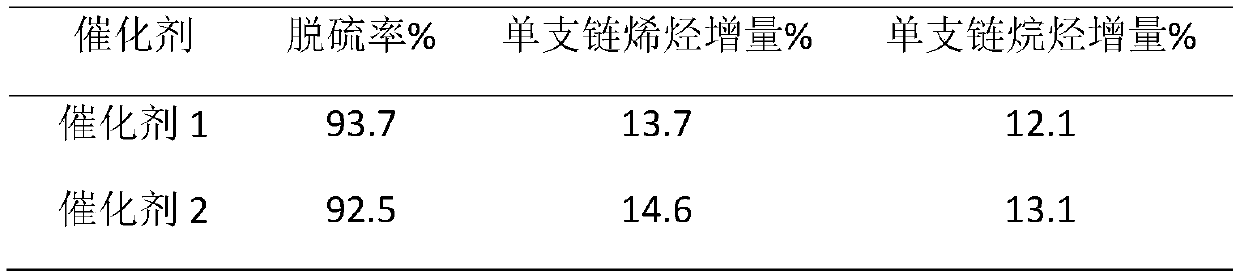

The invention relates to a FCC gasoline cleaning method. The method includes that under action of a prehydrogenation catalyst, catalytic cracking gasoline is in mercaptan etherification and double-bond isomerization reaction through a prehydrogenation reactor, prehydrogenation reaction efflux is cut and fractionated into light and heavy gasoline fraction, the light gasoline fraction is in superimposition reaction under action of a superimposition catalyst, the heavy gasoline fraction is subjected to selective hydrodesulfurization under action of a hydrodesulfurization-isomerization catalyst, and linear-chain olefin is isomerized to be single-branch-chain olefin or single-branch-chain paraffin; the heavy gasoline fraction after reaction enters an octane value restoration unit for double-branche-chain isomerization reaction under action of an isomerization catalyst; blending the light and heavy gasoline fraction to obtain a clean gasoline product with low olefin, ultralow sulfur contentand high octane value.

Owner:FUZHOU UNIV

Hydro-upgrading method for ungraded gasoline

ActiveCN102167985AGood activity at low temperatureKeep octaneTreatment with hydrotreatment processesLiquid productHydrodesulfurization

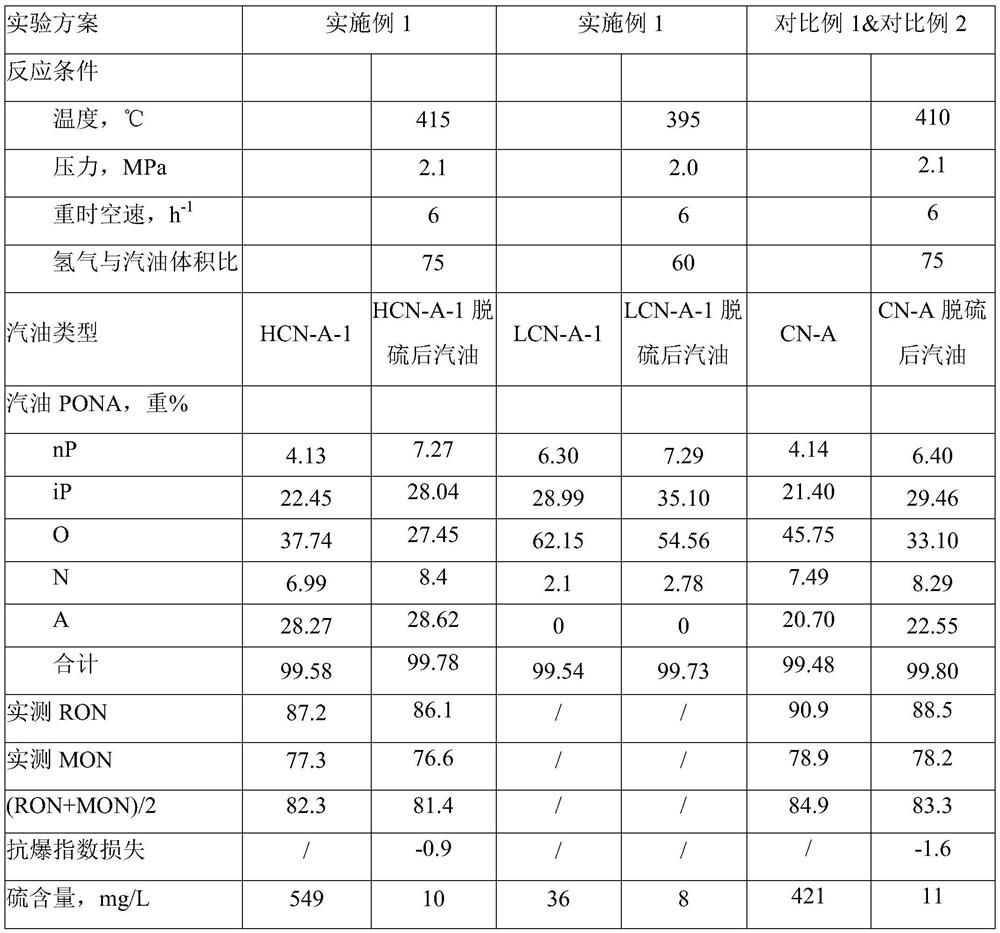

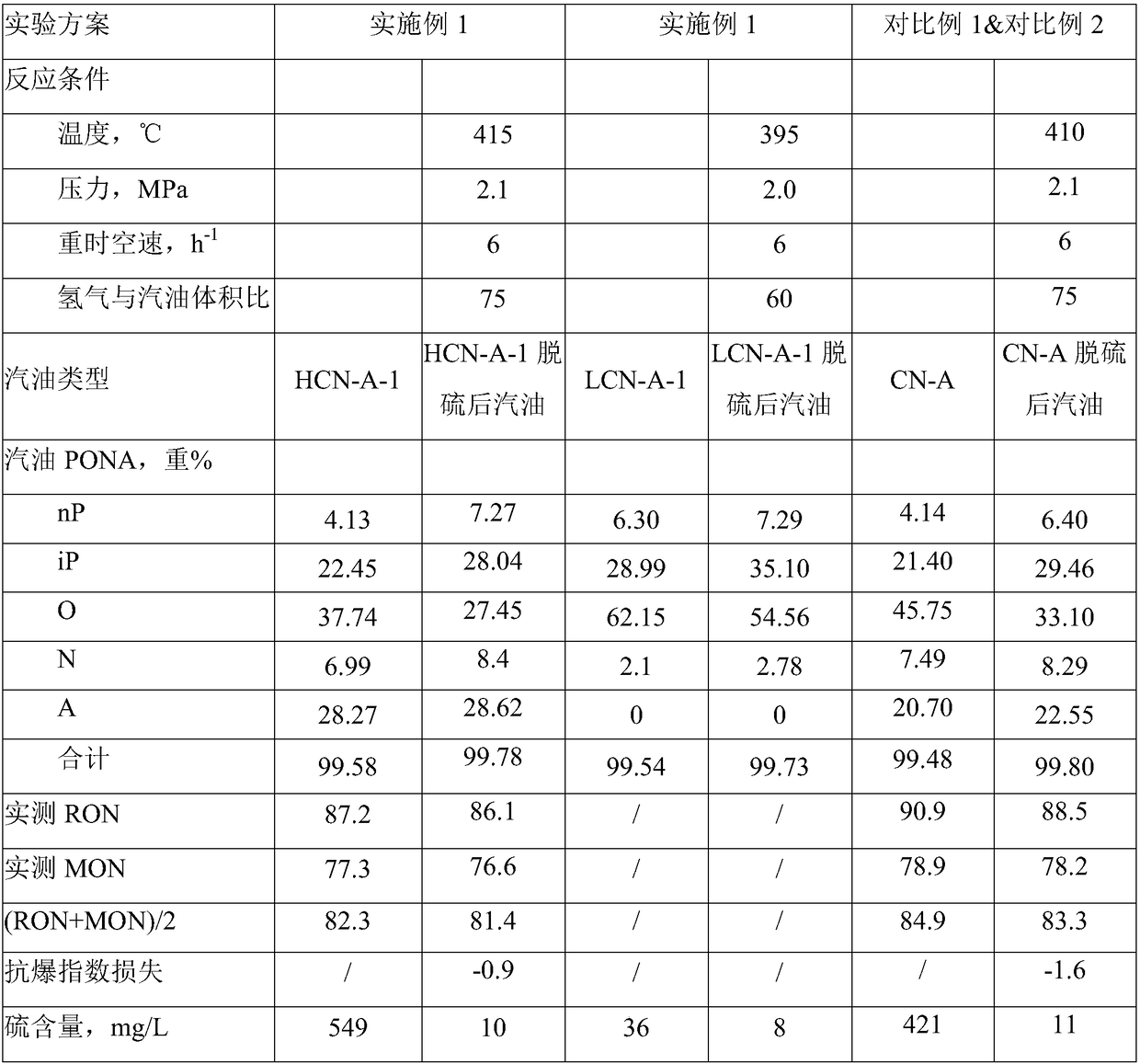

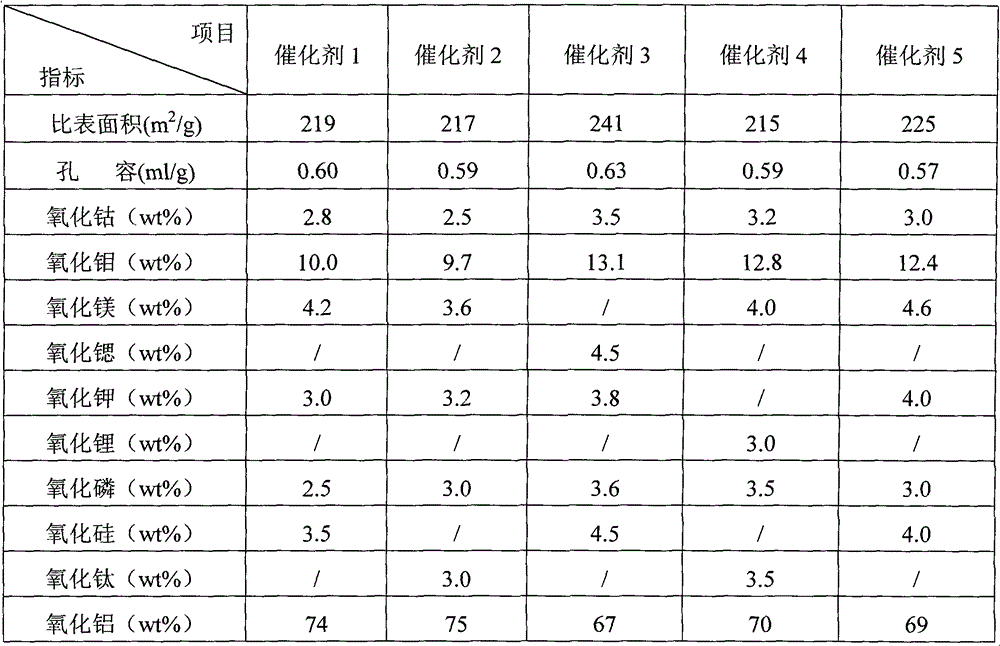

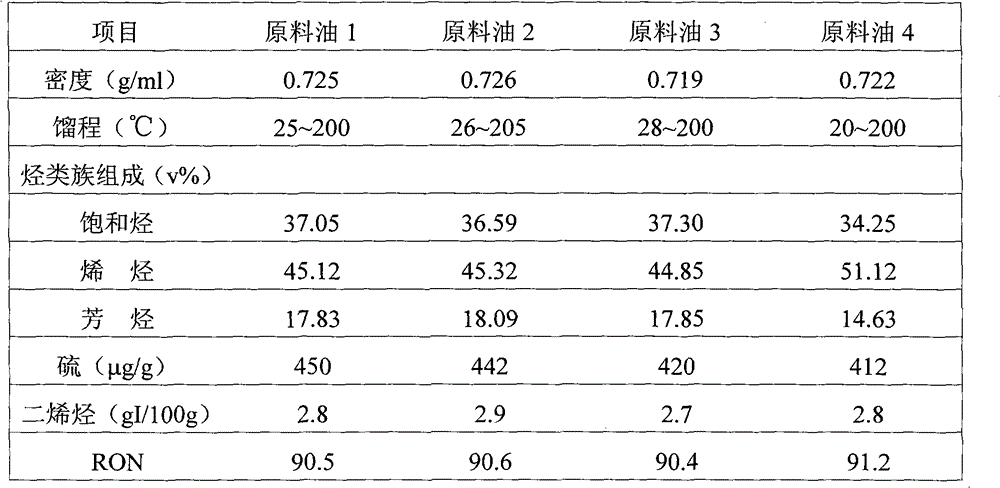

The invention provides an upgrading method for implementing the desulfuration, alkene reduction and octane number recovery of ungraded gasoline by selective hydrogenation. In the method, a two-catalyst and two-reactor serial process flow is used, wherein a first-section reactor is loaded with a selective hydrodesulfurization catalyst; and a second-section reactor is loaded with an octane number recovery catalyst. Ungraded gasoline can be directly subjected to hydro-upgrading without being pre-fractionated into light and heavy fractions. The gasoline product upgraded by the two reactors can have a sulfur content less than 30mu g / g; compared with the raw material, the alkene is reduced by 17-20%; and the method can achieve an optimal effect that the octane number is hardly lost and the total liquid yield is more than 98.5wt%. The invention has better hydro-upgrading effect on the full-fraction catalytically cracked gasoline with high sulfur and alkene content, and can greatly reduce the alkene and sulfur content, ensure that the octane number is hardly lost and maintain a high liquid product yield.

Owner:PETROCHINA CO LTD

Hydro-upgrading method for ungraded gasoline

ActiveCN102167985BGood activity at low temperatureKeep octaneTreatment with hydrotreatment processesLiquid productHydrodesulfurization

The invention provides an upgrading method for implementing the desulfuration, alkene reduction and octane number recovery of ungraded gasoline by selective hydrogenation. In the method, a two-catalyst and two-reactor serial process flow is used, wherein a first-section reactor is loaded with a selective hydrodesulfurization catalyst; and a second-section reactor is loaded with an octane number recovery catalyst. Ungraded gasoline can be directly subjected to hydro-upgrading without being pre-fractionated into light and heavy fractions. The gasoline product upgraded by the two reactors can have a sulfur content less than 30mu g / g; compared with the raw material, the alkene is reduced by 17-20%; and the method can achieve an optimal effect that the octane number is hardly lost and the total liquid yield is more than 98.5wt%. The invention has better hydro-upgrading effect on the full-fraction catalytically cracked gasoline with high sulfur and alkene content, and can greatly reduce the alkene and sulfur content, ensure that the octane number is hardly lost and maintain a high liquid product yield.

Owner:PETROCHINA CO LTD

Method for producing clean gasoline from catalytic gasoline

ActiveCN109097103AHigh yieldReduction of re-cracking reactionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneHydrodesulfurization

The invention relates to a method for producing clean gasoline from catalytic gasoline. The method comprises the following steps: under the action of a pre-hydrogenation catalyst, carrying out a thioletherification reaction and a double-bond isomerism reaction on catalytic gasoline in a pre-hydrogenation reactor; under the action of a hydrogenation desulfuration-isomerism catalyst, carrying out selective hydrodesulfurization on a pre-hydrogenation reaction effluent, wherein straight-chain olefin isomerism is single branched-chain olefin or single branched-chain alkane; further carrying out adouble-branched-chain isomerism reaction on a reaction effluent, thereby obtaining clean gasoline which is low in olefin content, super lo win sulfur content and high in octane rate.

Owner:FUZHOU UNIV

Technology for producing naphtha or motor gasoline through flexible hydrogenation of Fischer-Tropsch synthesis oil

InactiveCN104342207ALarge amount of processingReduce processingTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

A technology for producing motor diesel oil and steam cracking naphtha through hydrofining / cracking of Fischer-Tropsch synthesis oil is ripe and industrialized. According to a technology disclosed by the invention, oil-washing naphtha coming from a Fischer-Tropsch synthesis oil apparatus is singly subjected to mild hydrogenation, a complete hydrogenation refining and cracking technology for heavy distillate oil and wax is reserved, when high-quality diesel oil is produced, easily-blendable vehicle gasoline is produced, on-site sale is facilitated, and various difficulties when naphtha is transported and sold to steam cracking apparatuses are avoided. By adjusting the mild hydrogenation operation conditions, complete hydrogenation on naphtha can be realized, thereby satisfying material requirements for steam cracking.

Owner:王生友

FCC gasoline upgrading method

ActiveCN109097104AHigh yieldHigh activityTreatment with hydrotreatment processesChemical recyclingAlkaneIsomerization

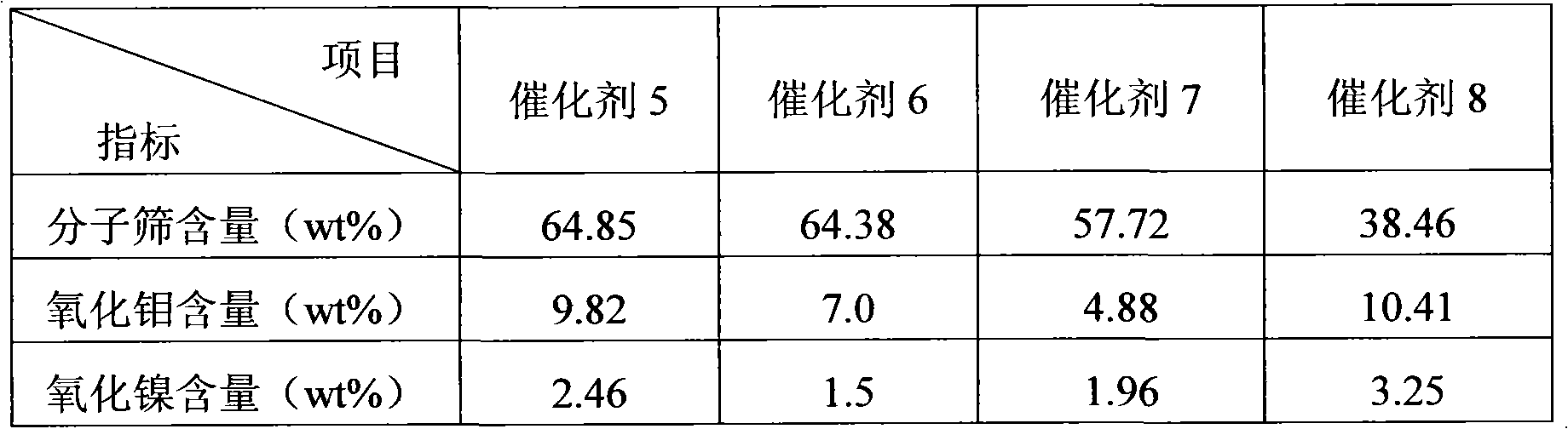

The invention relates to a FCC gasoline upgrading method. FCC gasoline is subjected to a mercaptan etherification and double-bond isomerism reaction under the action of a prehydrogenation catalyst bya prehydrogenation reactor, a prehydrogenation reaction effluent is cut into light and heavy gasoline fractions, the light gasoline fraction is subjected to isomerization reaction under the action ofan isomerization catalyst, the heavy gasoline fraction is subjected to selective hydrodesulfurization under the action of a hydrodesulfurization-isomerization catalyst, and simultaneously, linear olefin is isomerized into single branched olefin or single branched paraffin; then, the heavy gasoline fraction after the reaction enters an octane number recovery unit and is in contact with an octane number recovery catalyst to be subjected to a double branched isomerization reaction; finally, the light and heavy gasoline fractions are blended to obtain a clean gasoline product with low olefin content, ultra low sulfur content and a high octane number.

Owner:FUZHOU UNIV

A kind of upgrading method of catalytic cracking gasoline

ActiveCN109097102BUltra-low sulfur content reductionKeep octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationHydrogenation reaction

The invention relates to a modification method of catalytic gasoline. Under the effect of a pre-hydrogenation catalyst, sulfur alcohol etherification and double bond isomerism reactions are carried out on gasoline through a pre-hydrogenation reactor, an effluent of a pre-hydrogenation reaction is cut and fractionated into light and weight components, an isomerism reaction is carried out on the light component under the effect of an isomerism catalyst, the heavy component enters a desulfuration-octane value recovery reactor, a hydrogen desulfurization-isomerism catalyst and an octane value recovery catalyst are loaded inside the reactor, the heavy component is firstly in contact with the hydrogen desulfurization-isomerism catalyst, a selective hydrogen desulfurization-isomerism reaction iscarried out under the effect of the hydrogen desulfurization-isomerism catalyst, and simultaneously, straight chain olefin is isomerized into single branched chain olefin or single branched chain paraffin; the heavy component after the reaction is then in contact with the octane value recovery catalyst to carry out a double branched chain isomerism reaction; and finally the light and heavy fractions are blended to obtain a gasoline product with low olefin, ultra-low sulfur content and high octane value. The hydrogen desulfurization-isomerism catalyst and the octane value recovery catalyst arearranged inside the same reaction device, and the technology is simplified.

Owner:FUZHOU UNIV

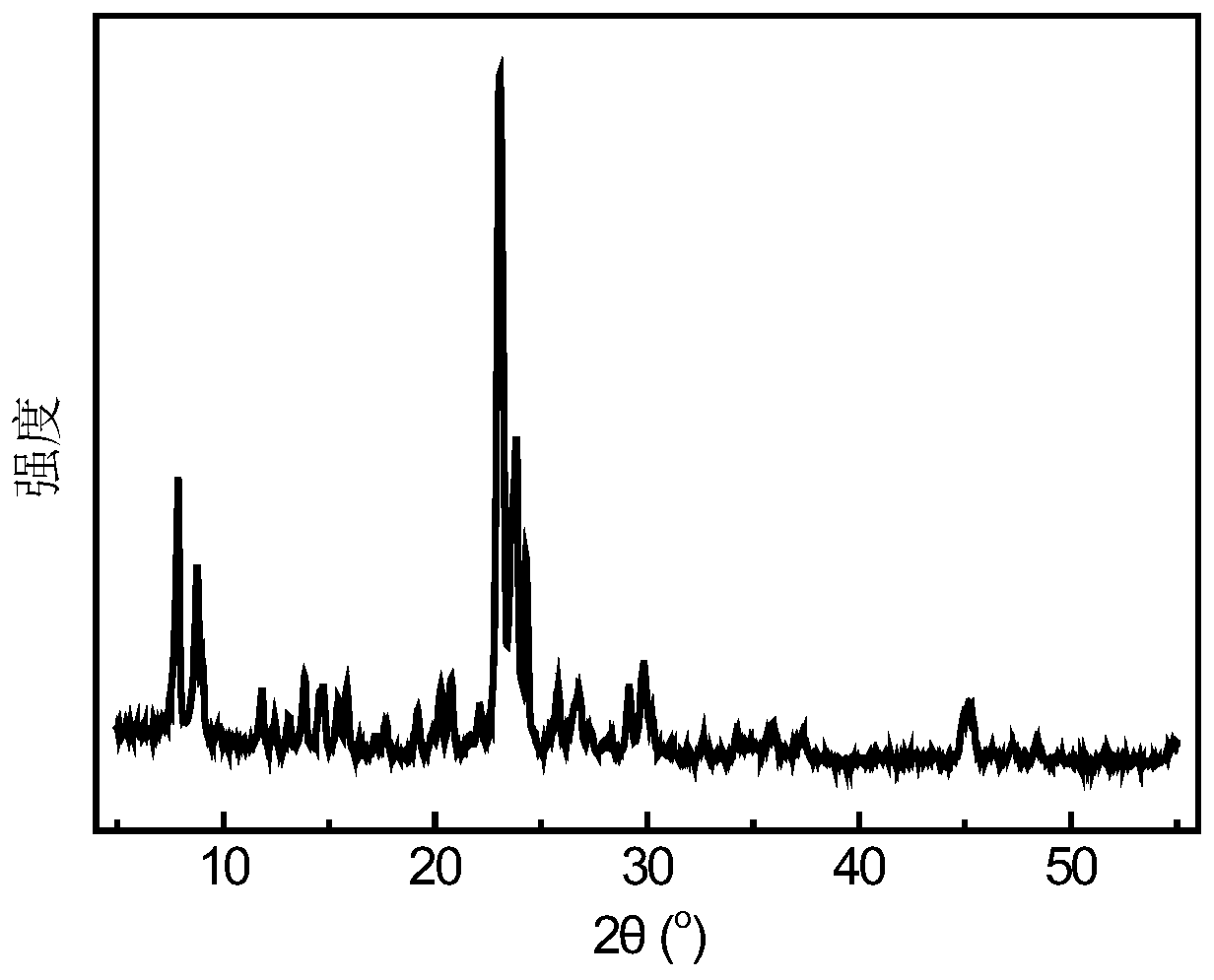

Phosphorus and loading metal containing MFI structure molecular sieve and preparation method thereof

ActiveCN106140270AEnhanced aromatization performanceReduce olefin contentCatalytic crackingMolecular sieve catalystsStrong acidsPetroleum

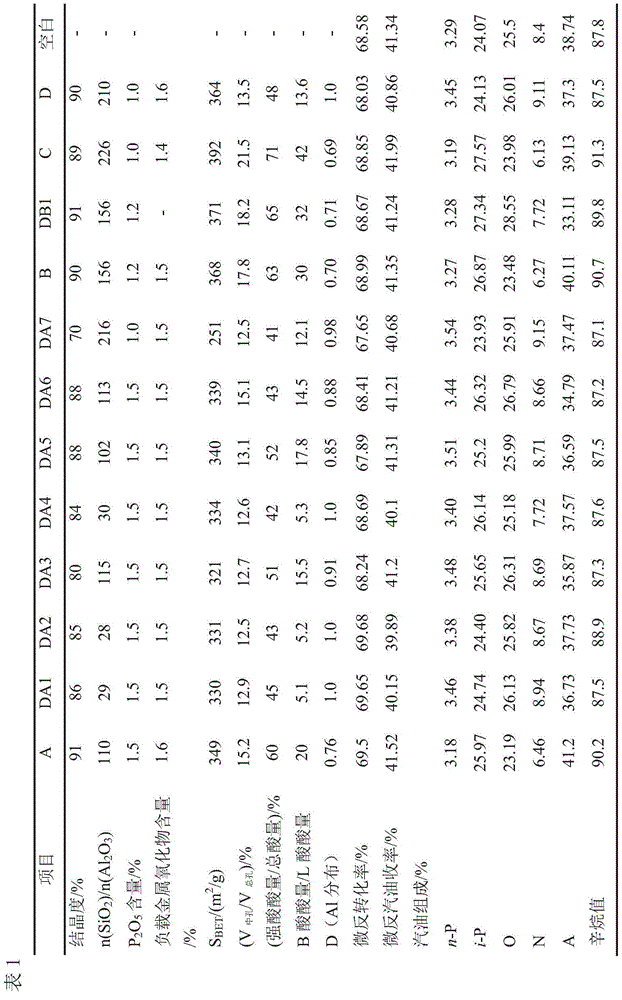

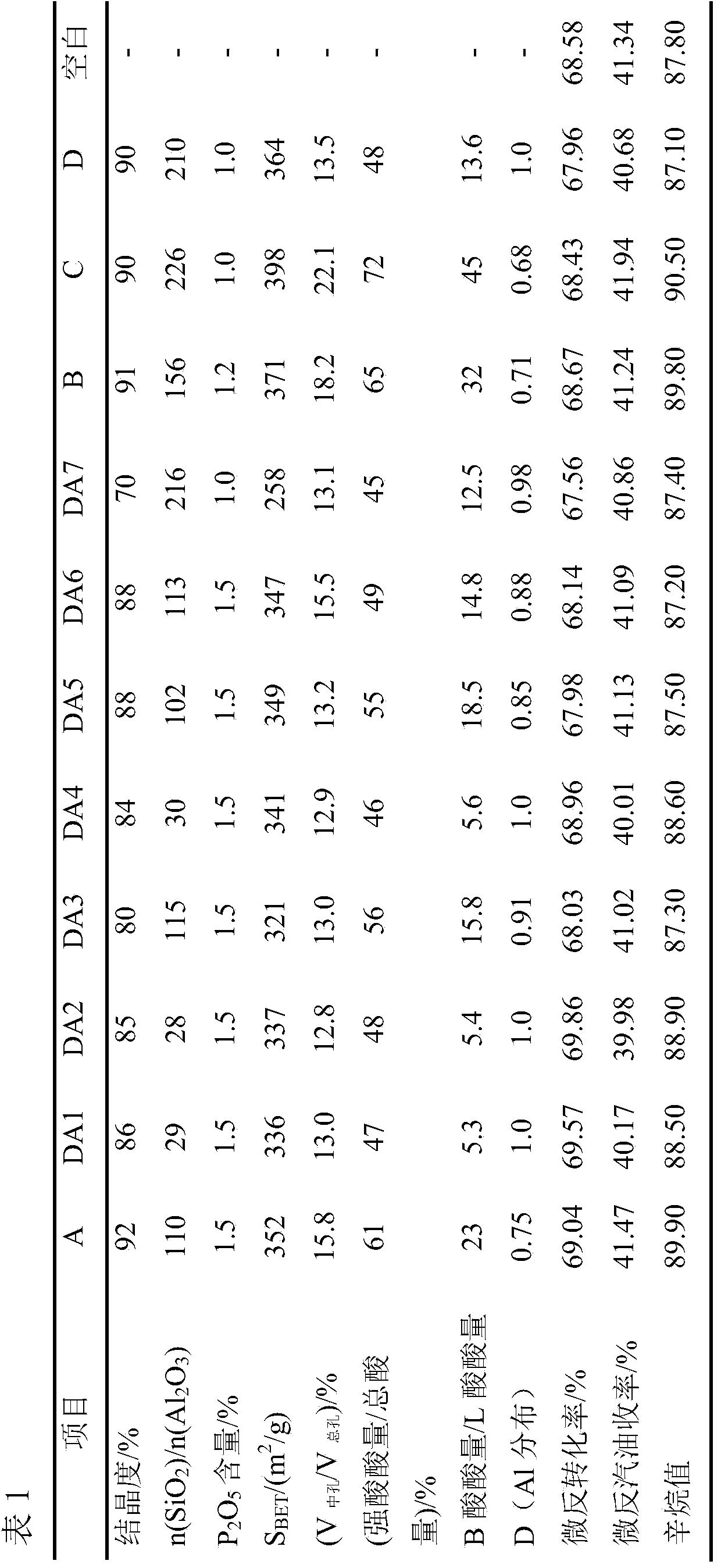

The invention discloses a phosphorus and loading metal containing MFI structure molecular sieve. According to the phosphorus and loading metal containing MFI structure molecular sieve, n(SiO2) / n(Al2O3) is larger than 100; with P2O5 for calculation and the dry basis weight of the molecular sieve being a reference, the phosphorus content of the molecular sieve is 0.1-5wt%; with loading metal oxides for calculation and the dry basis weight of the molecular sieve being a reference, the loading metal content of the molecular sieve is 0.5-5wt%; the Al distribution parameter D of the molecular sieve meets the equation of 0.5<=D<=0.8; the proportion of the medium pore volume to the total pore volume of the molecular sieve is 15-30vt%; the proportion of the strong acid amount to the total acid amount of the molecular sieve is 60-80%, and the ratio of the amount of acid B to the amount of acid L is 20-100. The phosphorus and loading metal containing MFI structure molecular sieve serves as an active component for preparing catalysts or auxiliaries, and in a petroleum hydrocarbon catalytic cracking reaction, the gasoline octane value can be effectively increased while the gasoline yield is kept, or the gasoline yield is increased while the gasoline octane value is kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

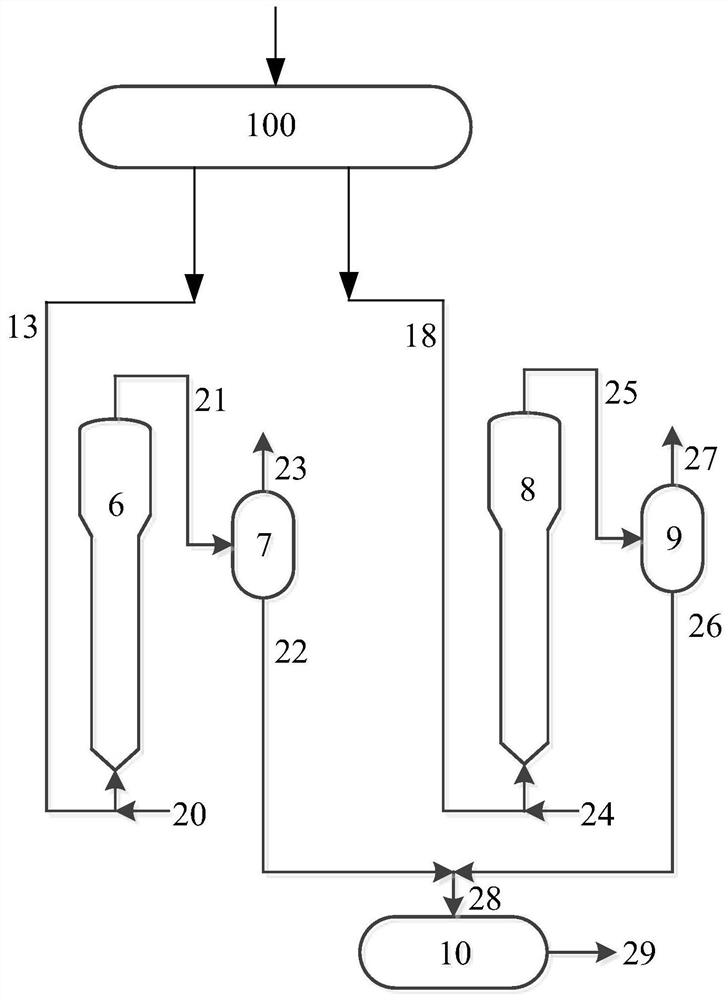

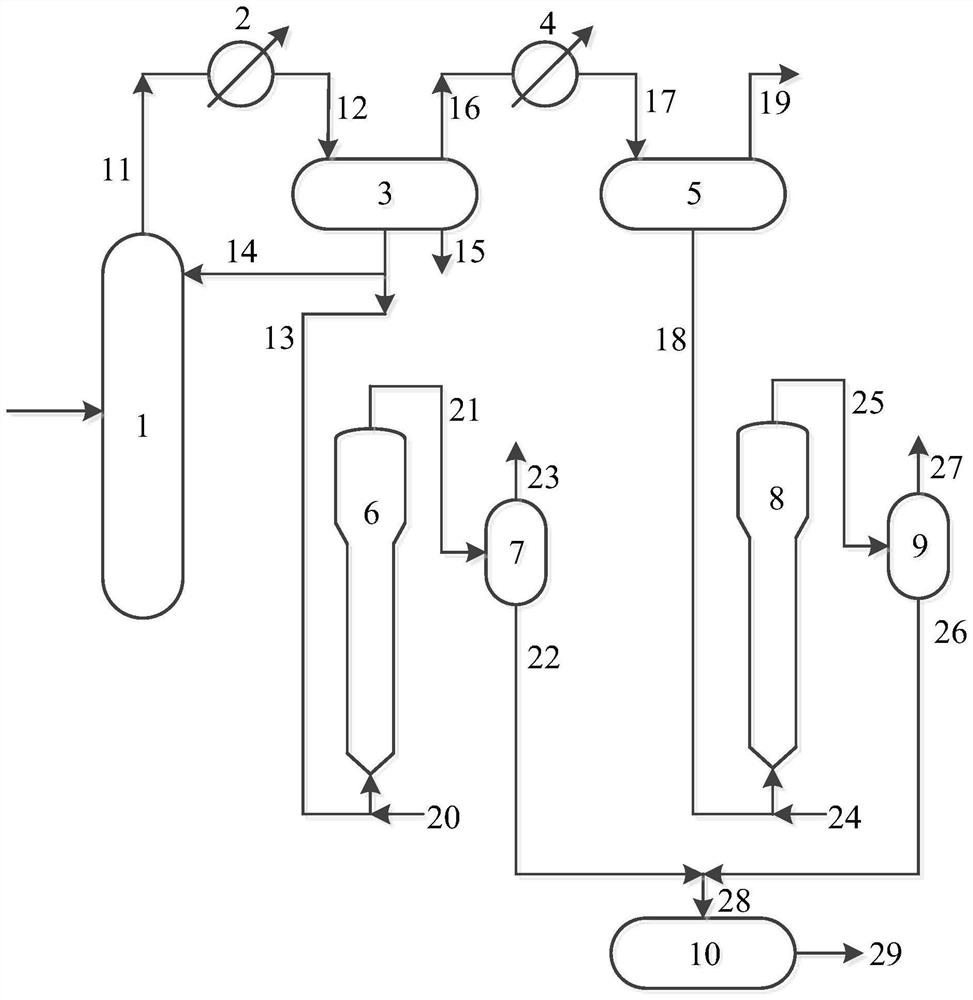

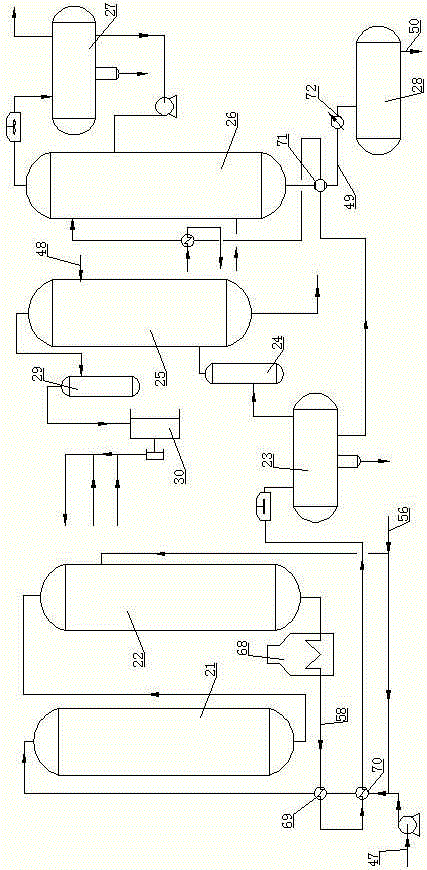

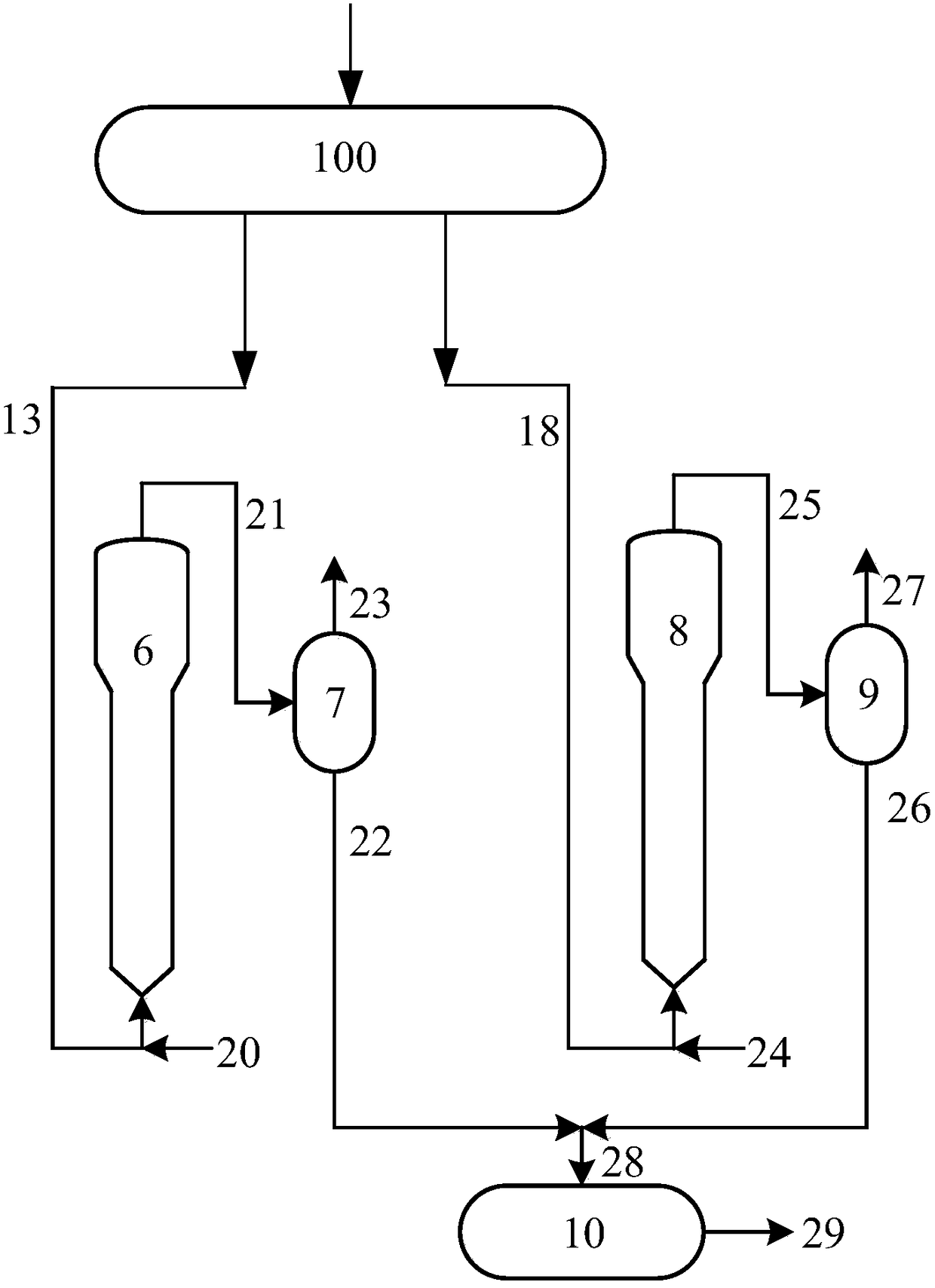

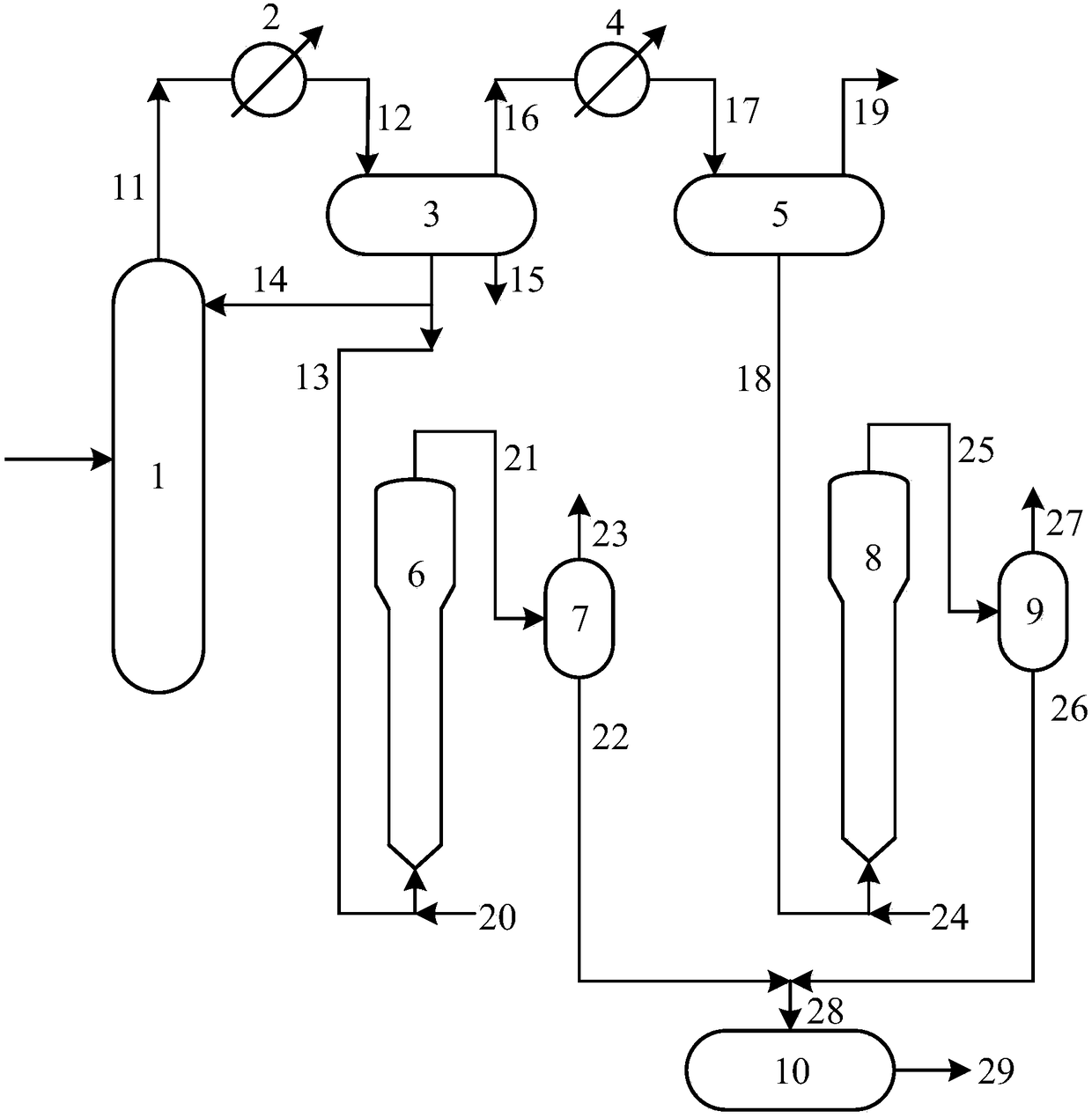

Method and system for gasoline desulfurization and aromatization

ActiveCN108659880BKeep octaneReduce sulfur contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystAromatization

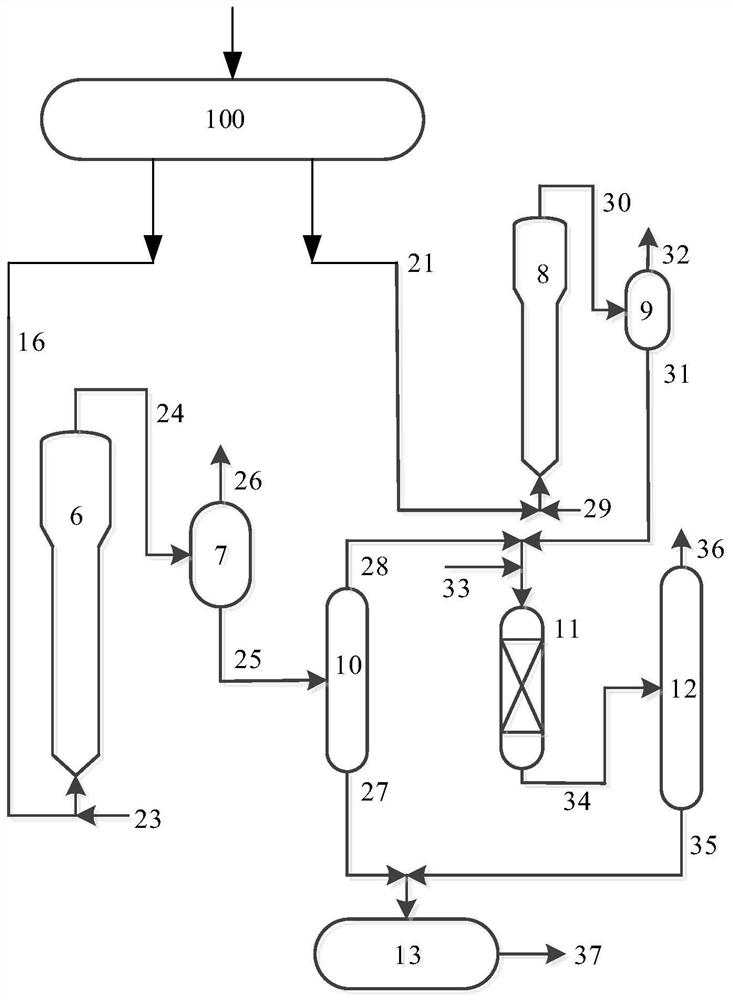

The invention relates to a method and system for desulfurization and aromatization of gasoline. The method comprises the following steps: subjecting a raw gasoline material to cutting so as to obtaina light gasoline fraction and a heavy gasoline fraction; conveying the heavy gasoline fraction into a first set of fluidization reactor for contacting with a mixed catalyst and carrying out desulfurization and aromatization in the presence of hydrogen so as to obtain a desulfurization and aromatization product, wherein the mixed catalyst comprises an adsorption desulfurization catalyst and an olefin aromatization catalyst; and conveying the light gasoline fraction into a second set of fluidization reactor for contacting with the adsorption desulfurization catalyst and carrying out a desulfurization reaction so as to obtain a second desulfurization product. The method and system provided by the invention can reduce the contents of sulfur and olefins in gasoline, decrease the octane number loss of the gasoline and maintain high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline desulfurization method

ActiveCN108659884BKeep octaneHigh yieldTreatment with hydrotreatment processesPtru catalystProcess engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of fcc gasoline cleaning method

ActiveCN109082303BKeep octaneRealize ultra-deep desulfurizationMolecular sieve catalystsTreatment with hydrotreatment processesPtru catalystIsomerization

Owner:FUZHOU UNIV

Gasoline desulfurization method

ActiveCN108659884APreprocessing unitReduce olefinsTreatment with hydrotreatment processesGasolineSulfur

The invention relates to a gasoline desulfurization method. The gasoline desulfurization method comprises the following steps: subjecting a raw gasoline material to primary cutting so as to obtain a first light gasoline fraction and a first heavy gasoline fraction; conveying the first heavy gasoline fraction into a first set of fluidization reactor for contacting with an adsorption desulfurizationcatalyst and carrying out a first desulfurization reaction in the presence of hydrogen so as to obtain a first desulfurization product; conveying the first light gasoline fraction into a second set of fluidization reactor for contacting with the adsorption desulfurization catalyst and carrying out a second desulfurization reaction so as to obtain a second desulfurization product; subjecting the first desulfurization product to secondary cutting so as to obtain a second light gasoline fraction and a second heavy gasoline fraction; and subjecting the second desulfurization product and the second light gasoline fraction to etherification together so as to obtain etherified oil. The method provided by the invention can reduce the contents of sulfur and olefins in gasoline, decrease the octanenumber loss of the gasoline and maintain high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of ultra-deep gasoline and diesel hydrodesulfurization catalyst

PendingCN112473718AExcellent electron donating propertiesGood lookingPhysical/chemical process catalystsHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention relates to the field of gasoline and diesel oil hydrodesulfurization catalysts, and provides a preparation method of an ultra-deep gasoline and diesel oil hydrodesulfurization catalyst,which comprises the following steps: by using a nitrogen-doped carbon material as a carrier, attaching an active component to the carrier by an impregnation method, performing drying and roasting to obtain the ultra-deep gasoline and diesel oil hydrodesulfurization catalyst, wherein the active component comprises a metal salt and an auxiliary metal salt. According to the invention, a nitrogen-doped carbon material is used as a carrier, and a traditional Co (Ni)-Mo (W) metal active phase is loaded to prepare the novel catalyst; compared with a Co (Ni)-Mo (W) hydrogenation catalyst commonly usedin the industry, the catalyst has the advantages that a nitrogen-doped carbon material formed by introducing N atoms with high charges and spin density into a carbon material has excellent electron donating characteristics, and the electron and morphology structures of a metal active phase can be effectively regulated and controlled through the anchoring effect and the electron donating effect, therefore, the catalyst has higher gasoline and diesel hydrogenation activity and desulfurization effect, and better reserves the octane number of gasoline.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

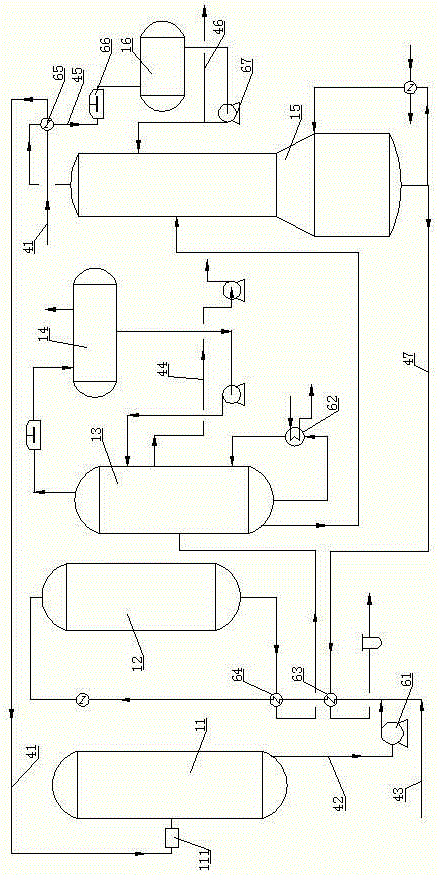

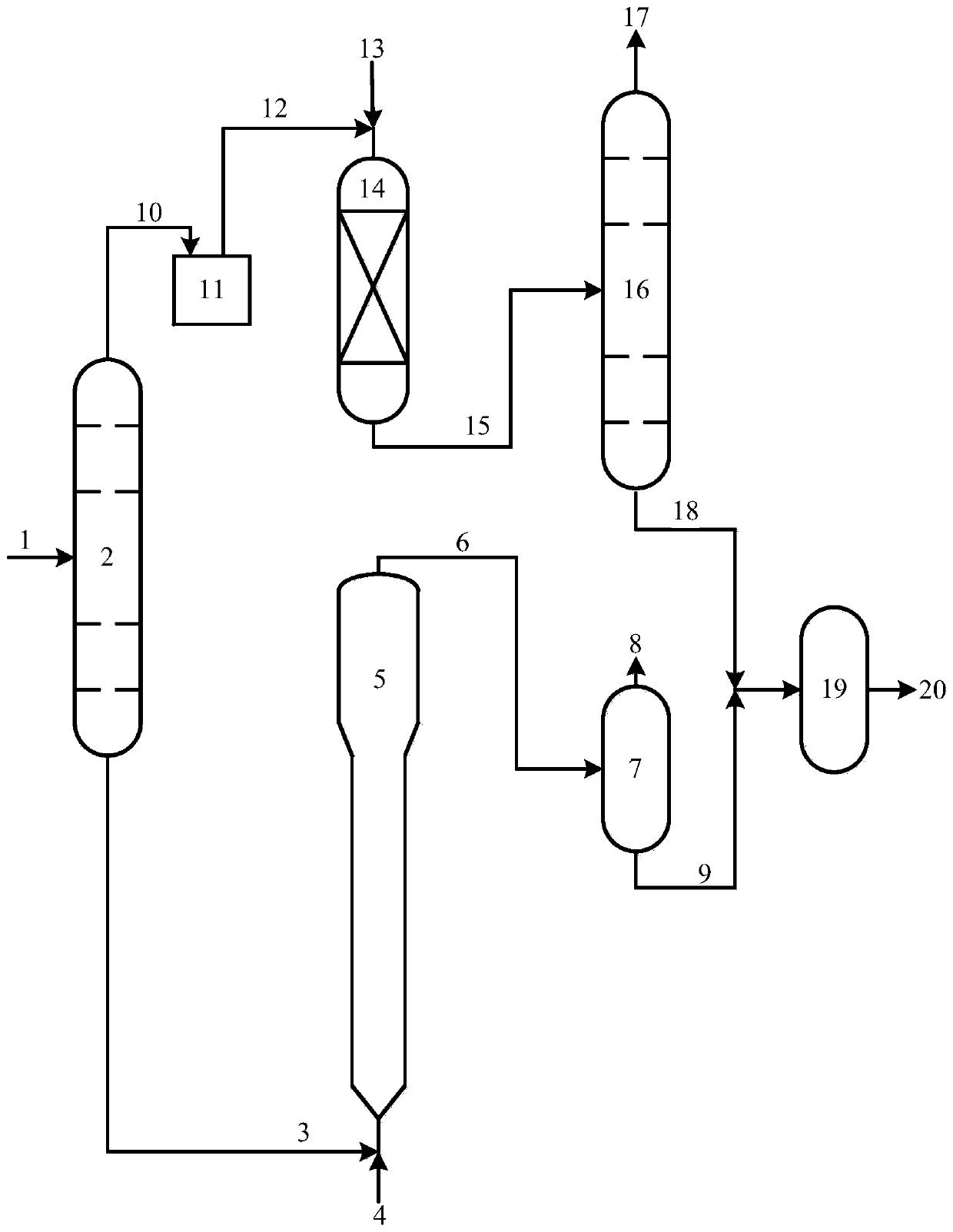

Gasoline hydrogenation device

InactiveCN106398763AIncrease saturation rateReduce sulfur contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineTower

The invention discloses a gasoline hydrogenation device. A full-fraction hydrogenation stabilizing tower is provided with a light petrol separation pipe; a product outlet in the bottom of the full-fraction hydrogenation stabilizing tower communicates with a material inlet of a prefractionator through a pipeline; a moderate petrol branching pipe is arranged at the top of the prefractionator, and the bottom of the prefractionator is connected with a heavy petrol separation pipe; the heavy petrol separation pipe is connected with a material inlet of a first-section hydrogenation device; a first-section hydrogenation product outlet of the first-section hydrogenation device communicates with a material inlet of a first-section desulphurization device; a liquid desulphurization product of the first-section desulphurization device communicates with a material inlet of a second-section hydrogenation device through a pipeline; the moderate petrol branching pipe communicates with a material inlet of the second-section hydrogenation device; a second-section hydrogenation product outlet of the second-section hydrogenation device communicates with a material inlet of a second-section desulphurization device; a liquid desulphurization product of the second-section desulphurization device communicates with a material inlet of a product stabilizing tower through a pipeline; a finished product outlet of the product stabilizing tower is connected with a refined petrol discharging pipe; the refined petrol discharging pipe communicates with the light petrol separation pipe.

Owner:SHANDONG CHANGYI PETROCHEM

A method for cleaning full fraction FCC gasoline

ActiveCN108219841BKeep octaneRealize ultra-deep desulfurizationMolecular sieve catalystsTreatment with hydrotreatment processesAlkadieneIsomerization

Owner:FUZHOU UNIV

Method and system for desulfurization and aromatization of gasoline

ActiveCN108659880AKeep octaneReduce sulfur contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenSulfur

The invention relates to a method and system for desulfurization and aromatization of gasoline. The method comprises the following steps: subjecting a raw gasoline material to cutting so as to obtaina light gasoline fraction and a heavy gasoline fraction; conveying the heavy gasoline fraction into a first set of fluidization reactor for contacting with a mixed catalyst and carrying out desulfurization and aromatization in the presence of hydrogen so as to obtain a desulfurization and aromatization product, wherein the mixed catalyst comprises an adsorption desulfurization catalyst and an olefin aromatization catalyst; and conveying the light gasoline fraction into a second set of fluidization reactor for contacting with the adsorption desulfurization catalyst and carrying out a desulfurization reaction so as to obtain a second desulfurization product. The method and system provided by the invention can reduce the contents of sulfur and olefins in gasoline, decrease the octane number loss of the gasoline and maintain high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-upgrading method of inferior gasoline

ActiveCN102295955BHigh desulfurization rateLess octane lossTreatment with hydrotreatment processesGramAlkene

The invention provides a hydro-upgrading method of inferior gasoline through selectively hydrodesulfurizing, greatly reducing olefin and recovering octane value. The method adopts a process flow of two agents and two series devices. The first stage reactor is filled with a selective hydrodesulfurizing catalyst, and the second stage reactor is filled with a octane value recovering catalyst. The inferior gasoline can be directly hydro-upgraded without being pre-fractionated into light and heavy fractions. After upgrading through the two stages, the sulfur content of the product gasoline is less than 30 micrograms per gram, compared with the raw material, the olefin content is reduced by 20%, and the best effect is that the octane value can be basically not lost and the total liquid yield is more than 99 wt%. In the invention, particularly a better hydro-upgrading effect on fully fractionated catalytic cracking gasoline with high contents of sulfur and olefin can be obtained, thus, a higher product liquid yield can be kept at the same time of greatly reducing the olefin and sulfur contents and basically not losing the octane value.

Owner:PETROCHINA CO LTD

A method for gasoline desulfurization

ActiveCN108659879BKeep octaneReduce sulfur contentHydrocarbon oils treatment productsRefining to eliminate hetero atomsPtru catalystReaction temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

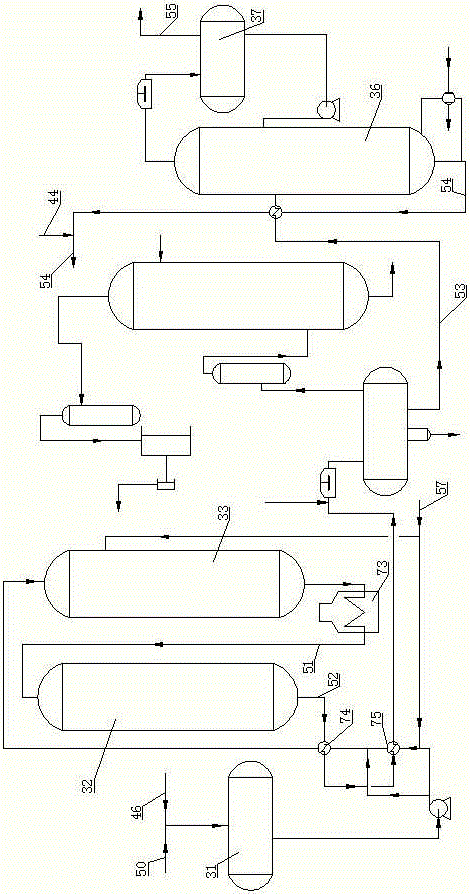

Method and system for gasoline desulfurization and aromatization

ActiveCN108659883BKeep octaneHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystAromatization

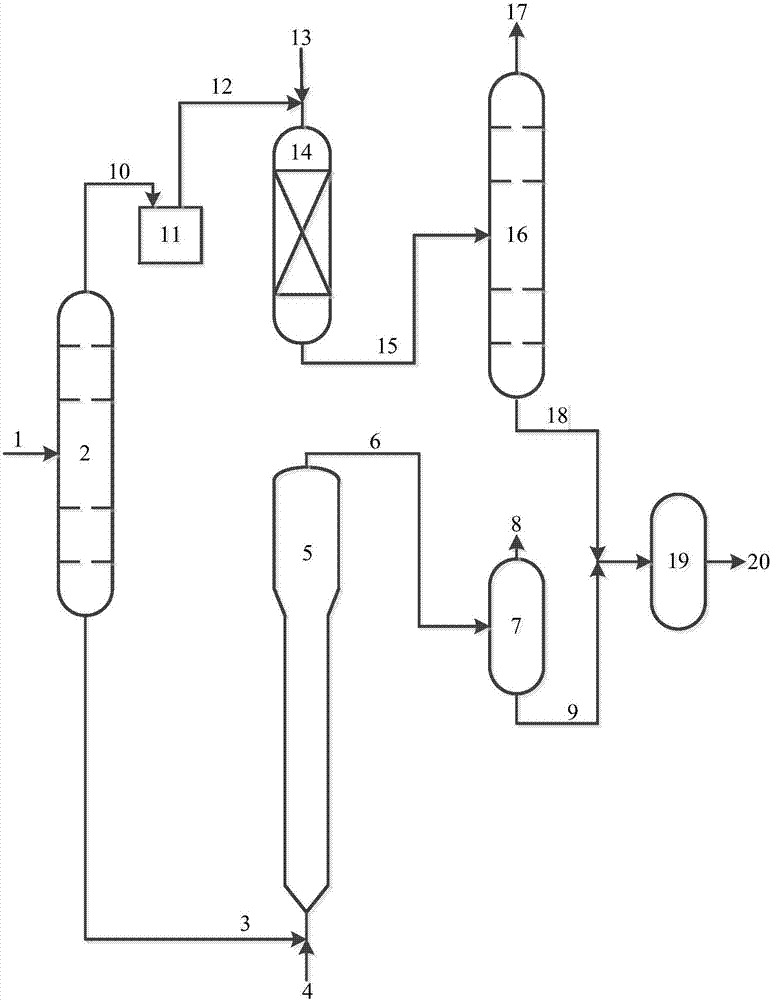

The invention relates to a method and system for desulphurization and aromatization of gasoline. The method comprises the following steps: subjecting a raw gasoline material to primary cutting so as to obtain a first light gasoline fraction and a first heavy gasoline fraction; conveying the first heavy gasoline fraction into a first set of fluidization reactor for contacting with a mixed catalystand carrying out desulphurization and aromatization in the presence of hydrogen so as to obtain a desulphurization and aromatization product; conveying the first light gasoline fraction into a secondset of fluidization reactor for contacting with an adsorption desulfurization catalyst and carrying out a desulphurization reaction so as to obtain a second desulphurization product; subjecting the desulphurization and aromatization product to secondary cutting so as to obtain a second light gasoline fraction and a second heavy gasoline fraction; and subjecting the second light gasoline fraction and the desulphurization product to etherification together so as to obtain etherified oil. The method and system provided by the invention can reduce the contents of sulfur and olefins in gasoline, decrease the octane number loss of the gasoline and maintain high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing clean gasoline from catalytic cracking gasoline

ActiveCN109097103BKeep octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystHydrodesulfurization

The invention relates to a method for producing clean gasoline from catalytic gasoline. The method comprises the following steps: under the action of a pre-hydrogenation catalyst, carrying out a thioletherification reaction and a double-bond isomerism reaction on catalytic gasoline in a pre-hydrogenation reactor; under the action of a hydrogenation desulfuration-isomerism catalyst, carrying out selective hydrodesulfurization on a pre-hydrogenation reaction effluent, wherein straight-chain olefin isomerism is single branched-chain olefin or single branched-chain alkane; further carrying out adouble-branched-chain isomerism reaction on a reaction effluent, thereby obtaining clean gasoline which is low in olefin content, super lo win sulfur content and high in octane rate.

Owner:FUZHOU UNIV

A kind of fcc gasoline desulfurization hydrogenation upgrading method

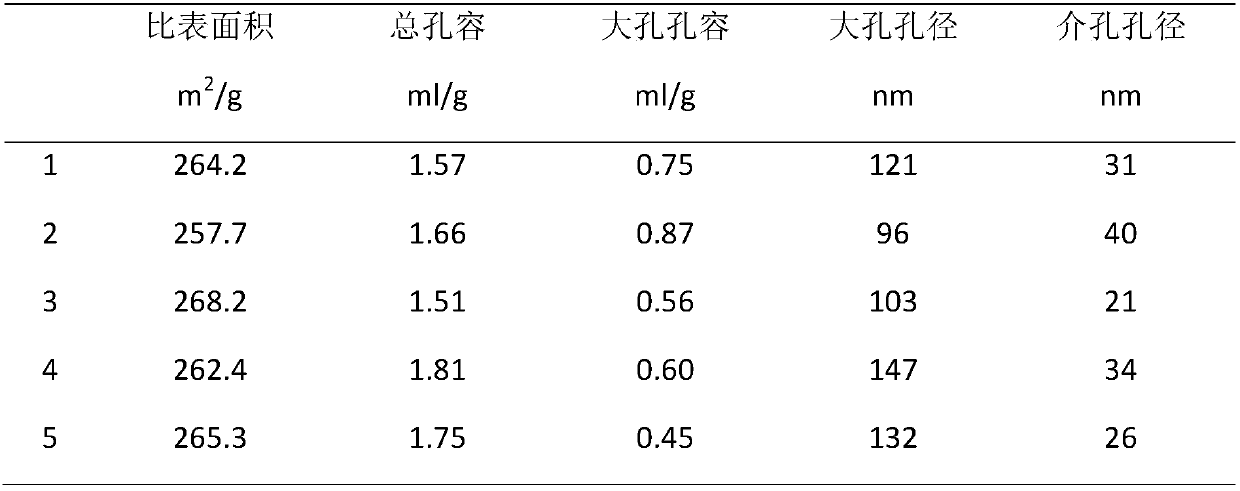

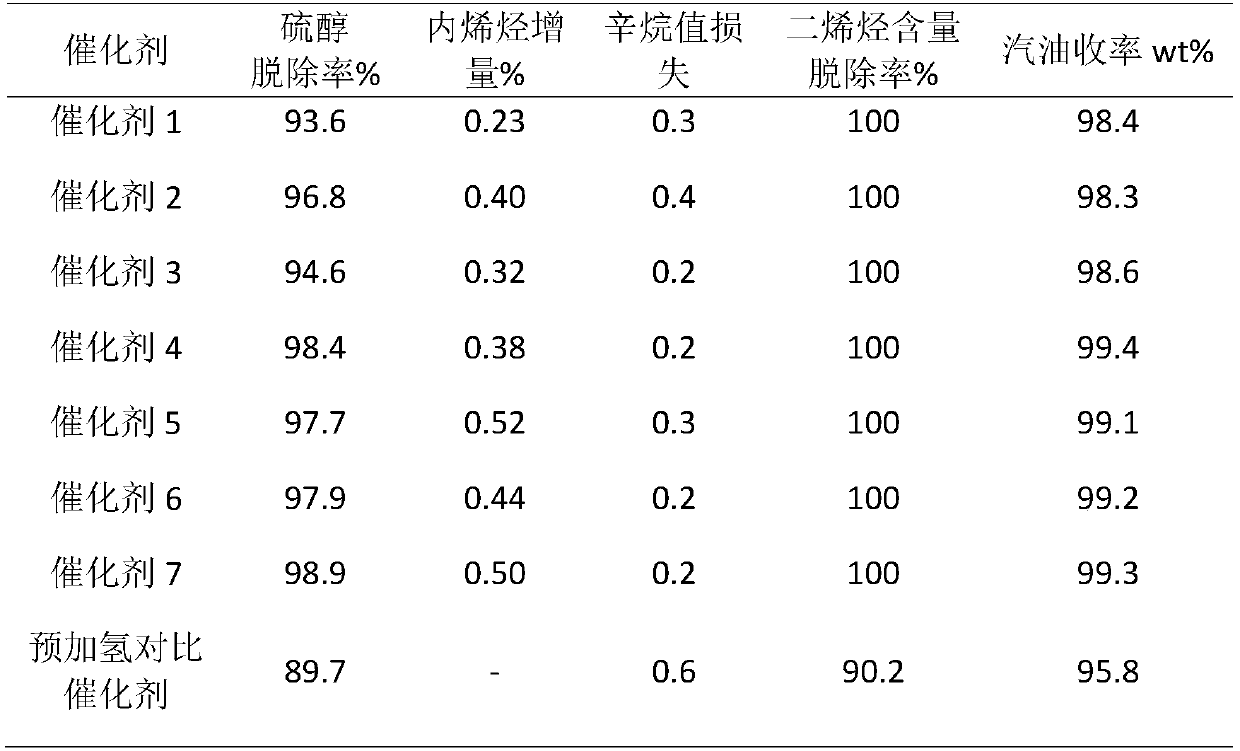

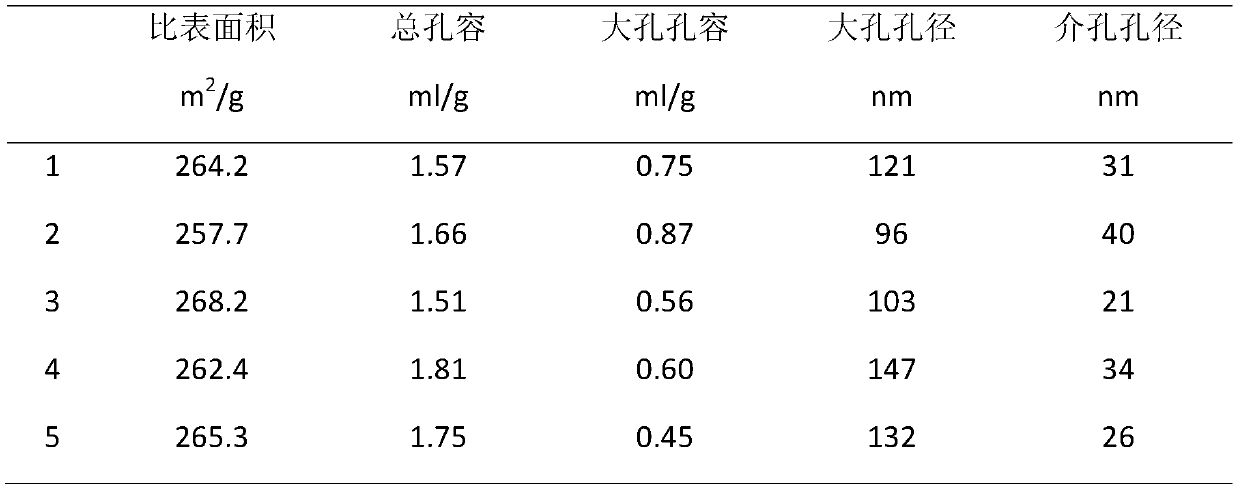

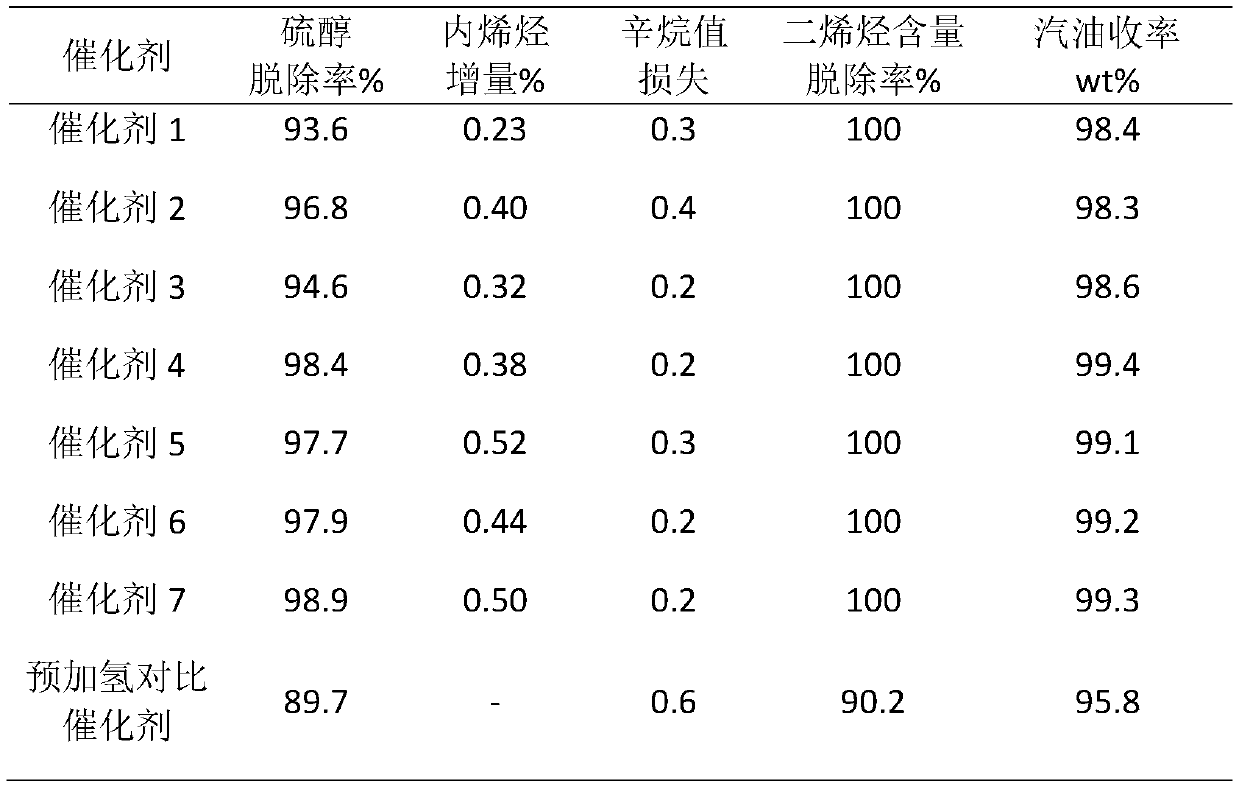

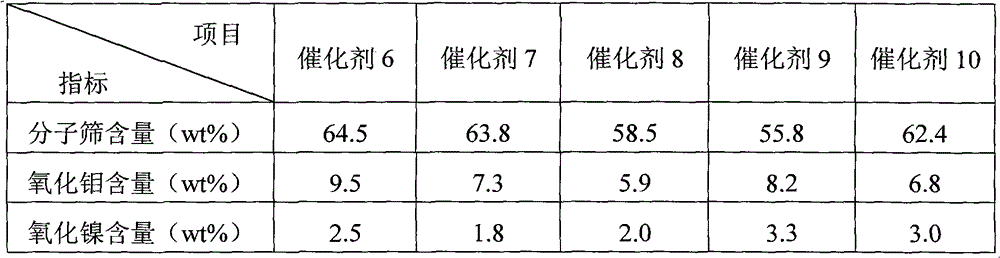

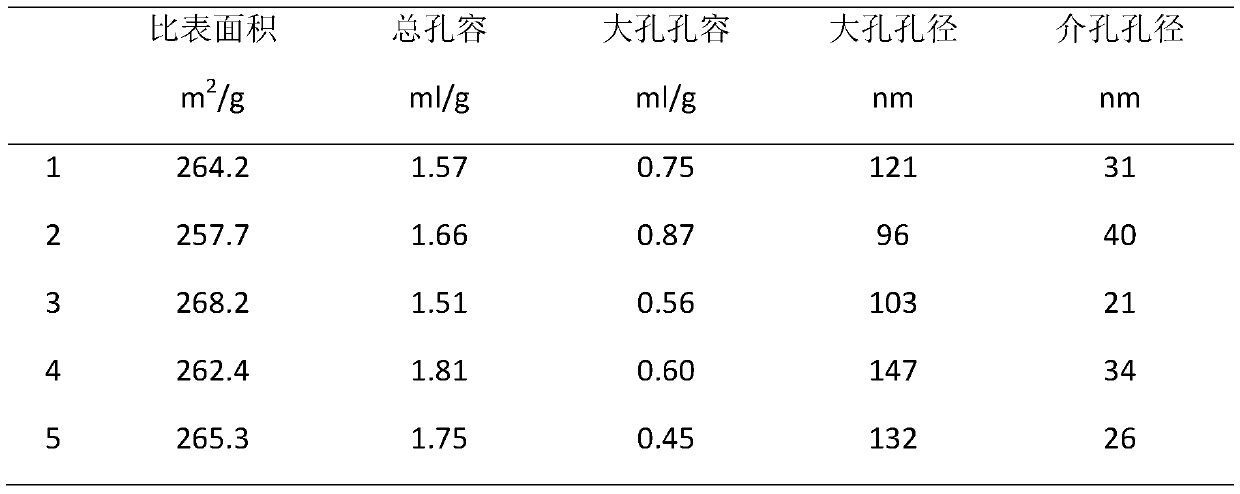

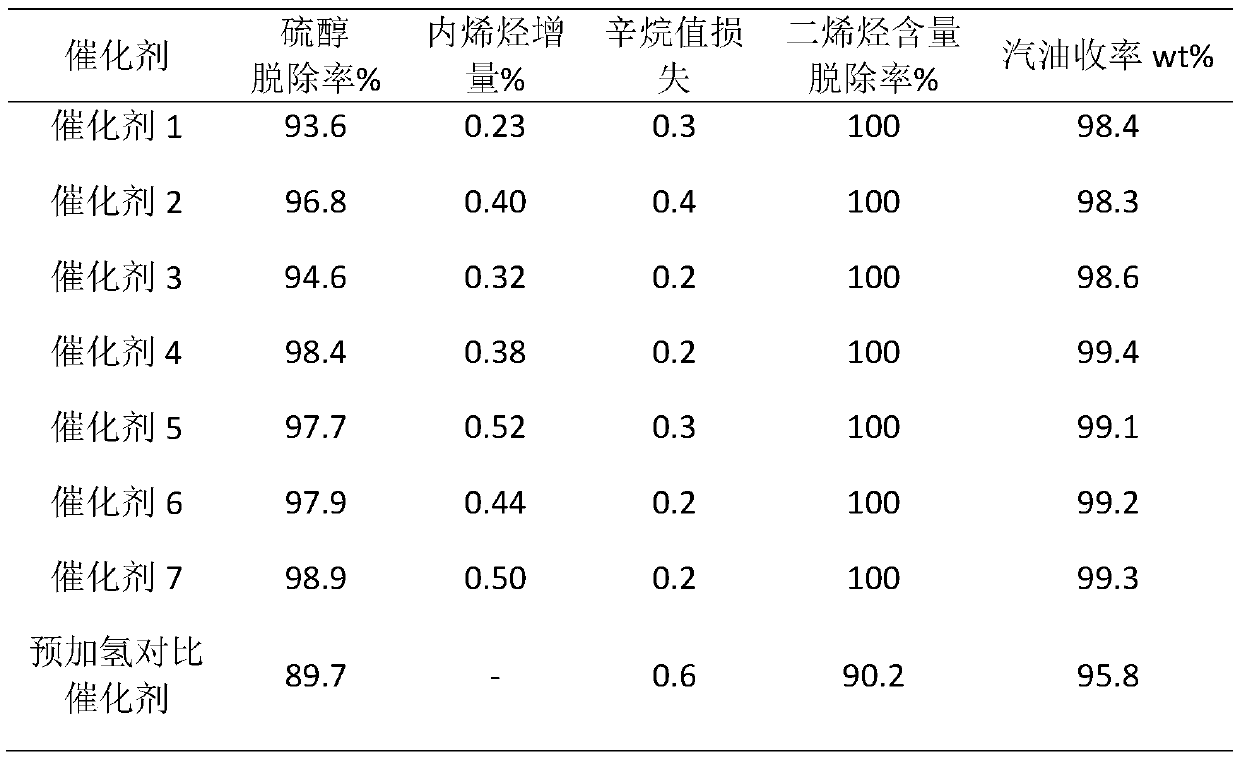

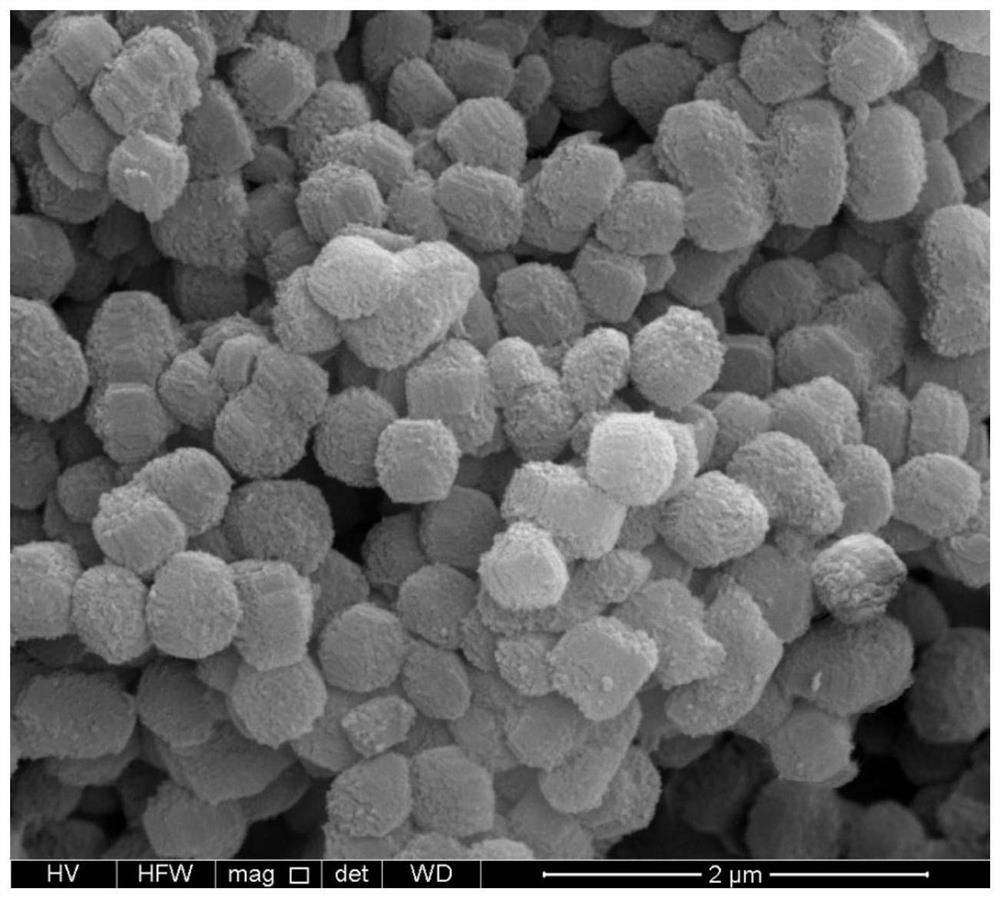

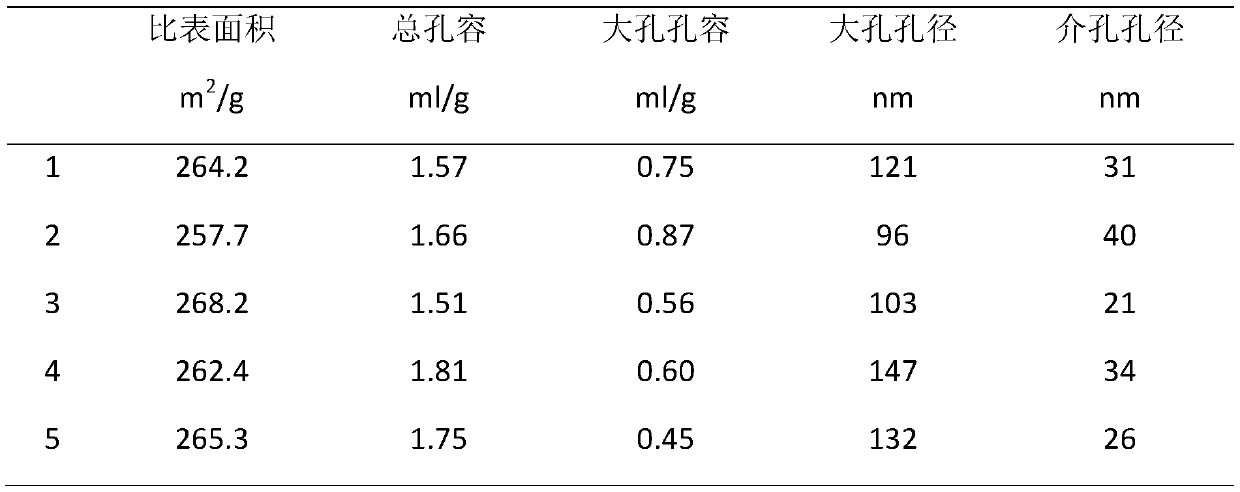

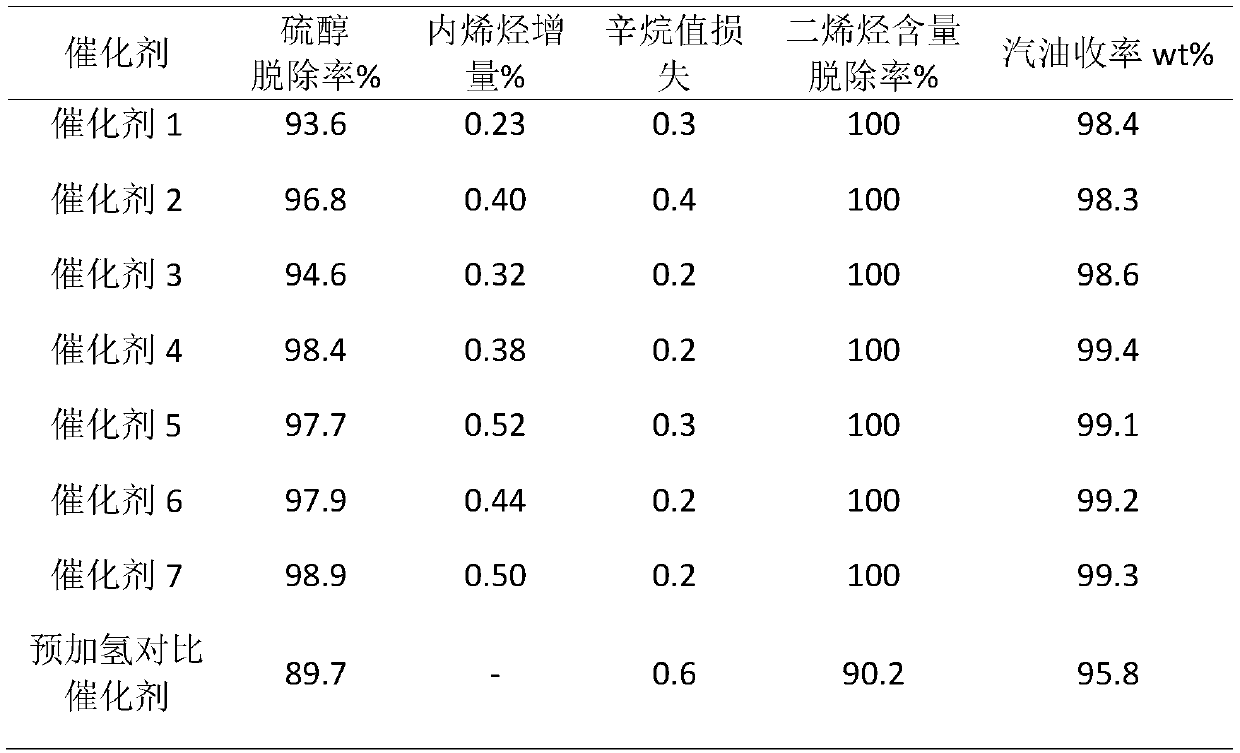

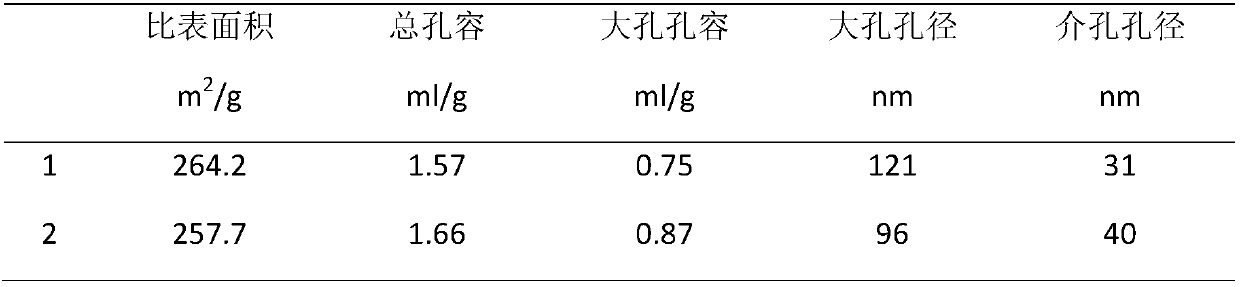

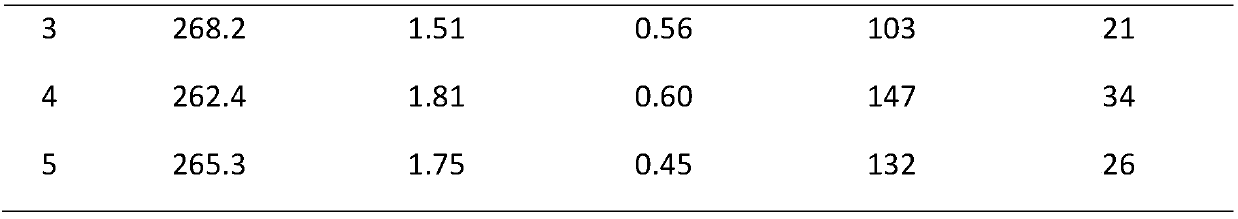

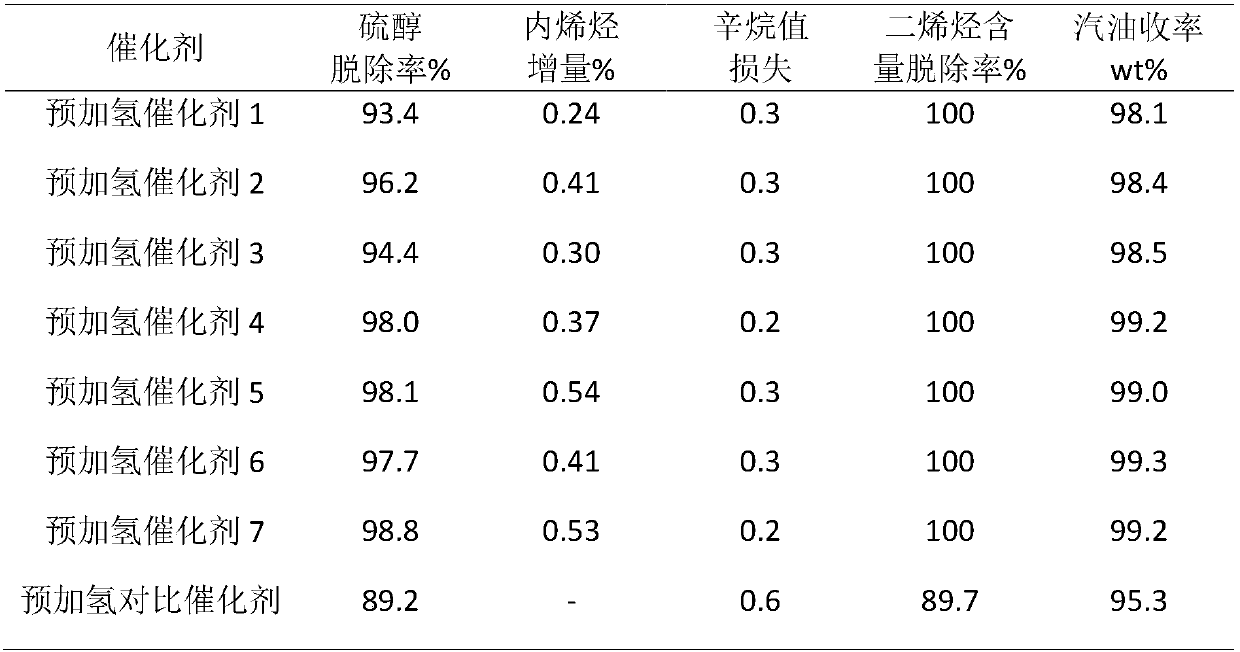

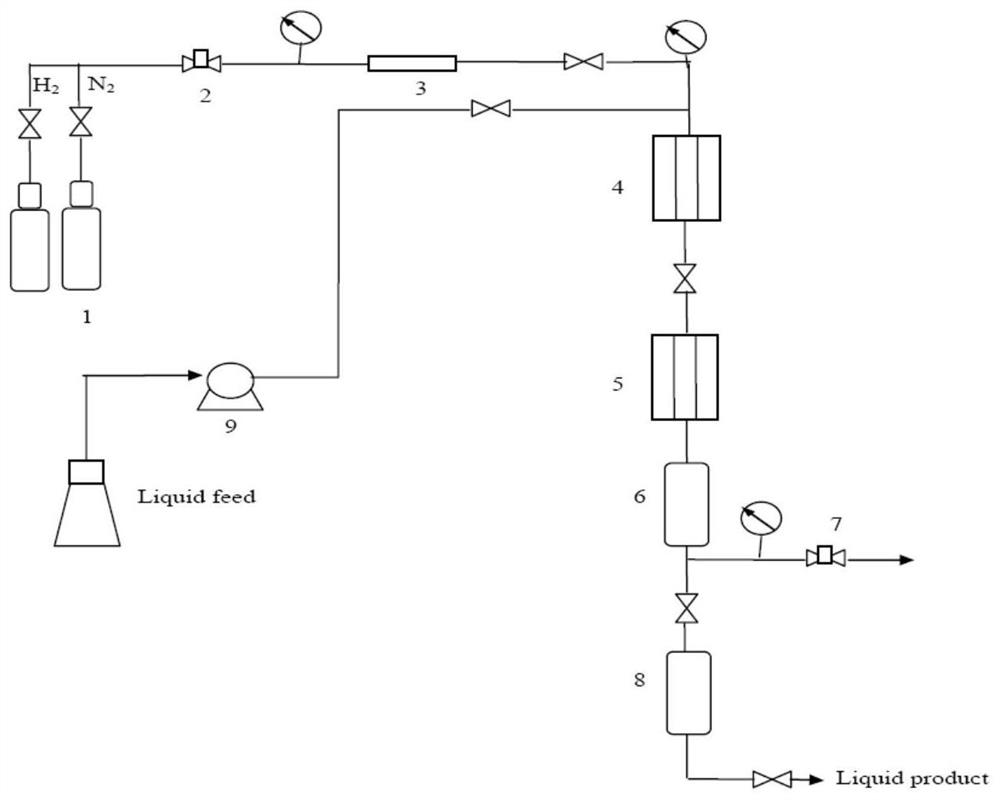

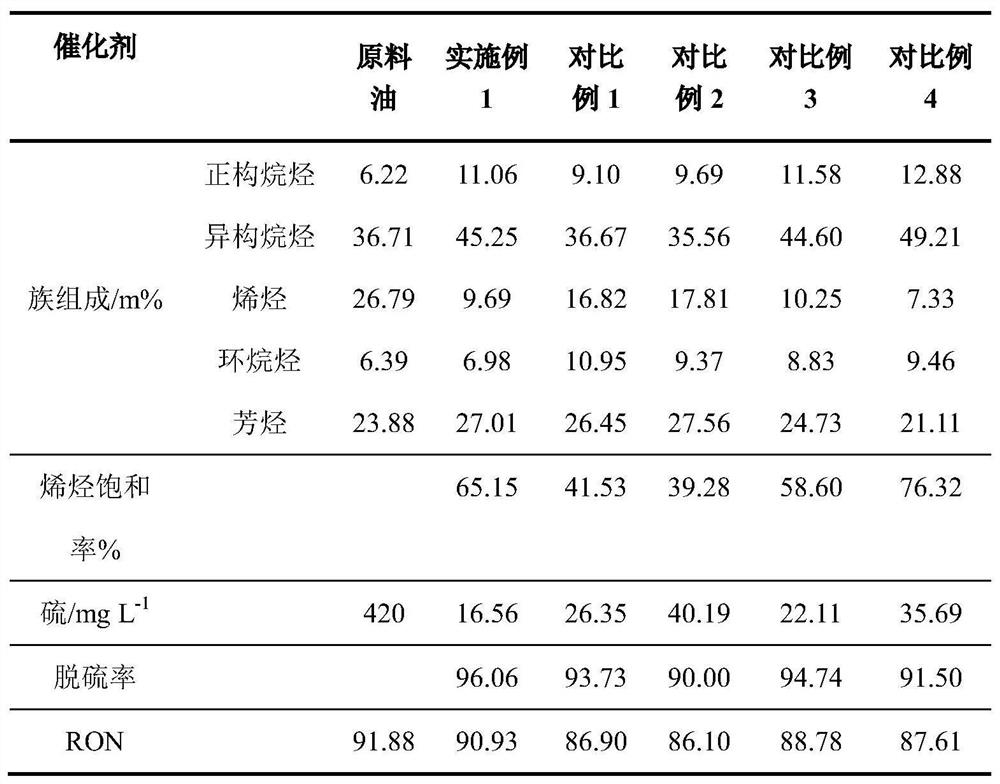

ActiveCN108404976BHighly reactive site densityFacilitated DiffusionMolecular sieve catalystsHydrocarbon oils refiningPtru catalystHydrodesulfurization

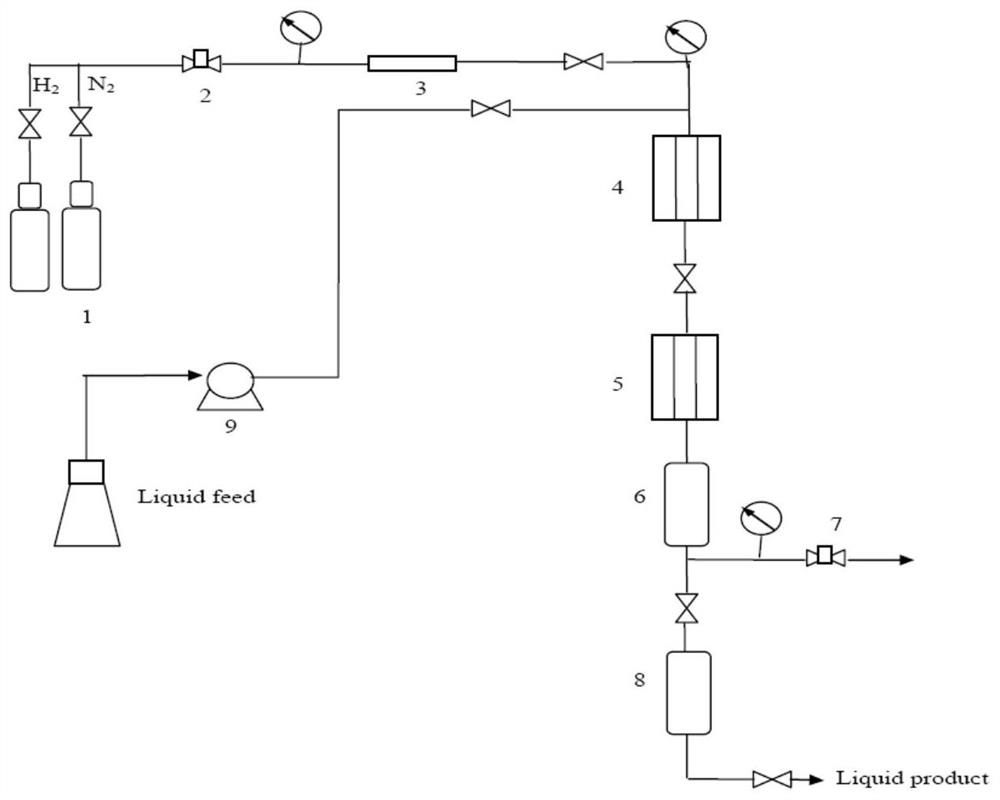

The invention relates to a method for improving the performance of gasoline hydrogenation modification. Catalyst HDS activity evaluation uses FCC gasoline as raw material. The vulcanizing agent used in HDS evaluation is cyclohexane solution containing 2m% CS2. The evaluation process of catalyst HDS activity is as follows: first, presulfurization is carried out, the loading amount of catalyst is 2g, the pressure is adjusted to 2.5MPa, and the gas flow rate is 25ml·min ‑1 , turn on the load switch of the reactor, adjust the temperature controller of the reactor to raise the temperature, and when the temperature measuring display of the reactor shows 150°C, open the pre-vulcanization valve on the panel of the device to start the pre-vulcanization. h 2 / Oil volume ratio is 300, WHSV is 1.82h ‑1 , pre-sulfurized for 4 hours, and then switched the raw oil for reaction. HDS evaluation conditions are: temperature 260°C, H 2 / Oil volume ratio 200, pressure 2.0MPa, WHSV 2.0h ‑1 , the use of multi-stage molecular sieve composite catalysts for FCC gasoline hydro-upgrading process shows a high hydrodesulfurization rate, and maintains the octane number of FCC gasoline to the greatest extent, showing excellent hydro-upgrading performance.

Owner:UNIV OF JINAN

Gasoline desulfurization method

ActiveCN108659879AKeep octaneReduce sulfur contentHydrocarbon oils treatment productsRefining to eliminate hetero atomsHydrogenSulfur

The invention relates to a gasoline desulfurization method. The gasoline desulfurization method comprises the following steps: subjecting a raw gasoline material to cutting so as to obtain a light gasoline fraction and a heavy gasoline fraction; conveying the first heavy gasoline fraction into a first set of fluidization reactor for contacting with an adsorption desulfurization catalyst and carrying out a first desulfurization reaction in the presence of hydrogen so as to obtain a first desulfurization product; and conveying the obtained light gasoline fraction into a second set of fluidization reactor for contacting with the adsorption desulfurization catalyst and carrying out a second desulfurization reaction so as to obtain a second desulfurization product, wherein a first reaction temperature and a first reaction pressure in the first desulfurization reaction are 380 to 470 DEG C and 2.0 to 3.5 MPa, respectively, and a second reaction temperature and a second reaction pressure in the second desulfurization reaction are 360 to 450 DEG C and 1.5 to 3.0 MPa, respectively. The method provided by the invention can reduce the contents of sulfur and olefins in gasoline, decrease the octane number loss of the gasoline and maintain high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treating method for gasoline

ActiveCN107974295AHigh yieldReduce contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenSulfur

The invention relates to a treating method for gasoline. The treating method comprises the following steps: cutting a raw gasoline material so as to obtain a light gasoline fraction and a heavy gasoline fraction; subjecting the light gasoline fraction to etherification so as to obtain etherified oil; and conveying the heavy gasoline fraction to a fluidization reactor for contacting with a mixed catalyst and carrying out desulphurization and aromatization in the presence of hydrogen so as to obtain a heavy gasoline product, wherein the mixed catalyst comprises an adsorption desulphurization catalyst and an olefin aromatization catalyst. The method provided by the invention can reduce the contents of sulfur and olefins in gasoline and maintain the octane number of the gasoline and high gasoline yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of fcc gasoline upgrading method

ActiveCN109097104BKeep octaneUltra-low sulfur content reductionTreatment with hydrotreatment processesChemical recyclingAlkaneIsomerization

The invention relates to a method for upgrading FCC gasoline. Under the action of a prehydrogenation catalyst, FCC gasoline is subjected to mercaptan etherification and double bond isomerization reaction through a prehydrogenation reactor, and the prehydrogenation reaction effluent is cut into light, Heavy gasoline fractions and light gasoline fractions undergo isomerization reactions under the action of isomerization catalysts, heavy gasoline fractions undergo selective hydrodesulfurization under the action of hydrodesulfurization-isomerization catalysts, and linear olefins are isomerized into single branched olefins at the same time Or single-branched alkanes; the reacted heavy gasoline fraction enters the octane number recovery unit, contacts with the octane number recovery catalyst, and undergoes a double-branched isomerization reaction; finally, the light and heavy gasoline fractions are reconciled to obtain low olefins, ultra-low sulfur content, clean gasoline products with high octane number.

Owner:FUZHOU UNIV

A kind of phosphorus-containing MFI structure molecular sieve and preparation method thereof

ActiveCN106140271BHigh acid center ratioRaise the ratioCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

Modification method of catalytic gasoline

ActiveCN109097102AHigh yieldHigh activityTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationHydrogenation reaction

The invention relates to a modification method of catalytic gasoline. Under the effect of a pre-hydrogenation catalyst, sulfur alcohol etherification and double bond isomerism reactions are carried out on gasoline through a pre-hydrogenation reactor, an effluent of a pre-hydrogenation reaction is cut and fractionated into light and weight components, an isomerism reaction is carried out on the light component under the effect of an isomerism catalyst, the heavy component enters a desulfuration-octane value recovery reactor, a hydrogen desulfurization-isomerism catalyst and an octane value recovery catalyst are loaded inside the reactor, the heavy component is firstly in contact with the hydrogen desulfurization-isomerism catalyst, a selective hydrogen desulfurization-isomerism reaction iscarried out under the effect of the hydrogen desulfurization-isomerism catalyst, and simultaneously, straight chain olefin is isomerized into single branched chain olefin or single branched chain paraffin; the heavy component after the reaction is then in contact with the octane value recovery catalyst to carry out a double branched chain isomerism reaction; and finally the light and heavy fractions are blended to obtain a gasoline product with low olefin, ultra-low sulfur content and high octane value. The hydrogen desulfurization-isomerism catalyst and the octane value recovery catalyst arearranged inside the same reaction device, and the technology is simplified.

Owner:FUZHOU UNIV

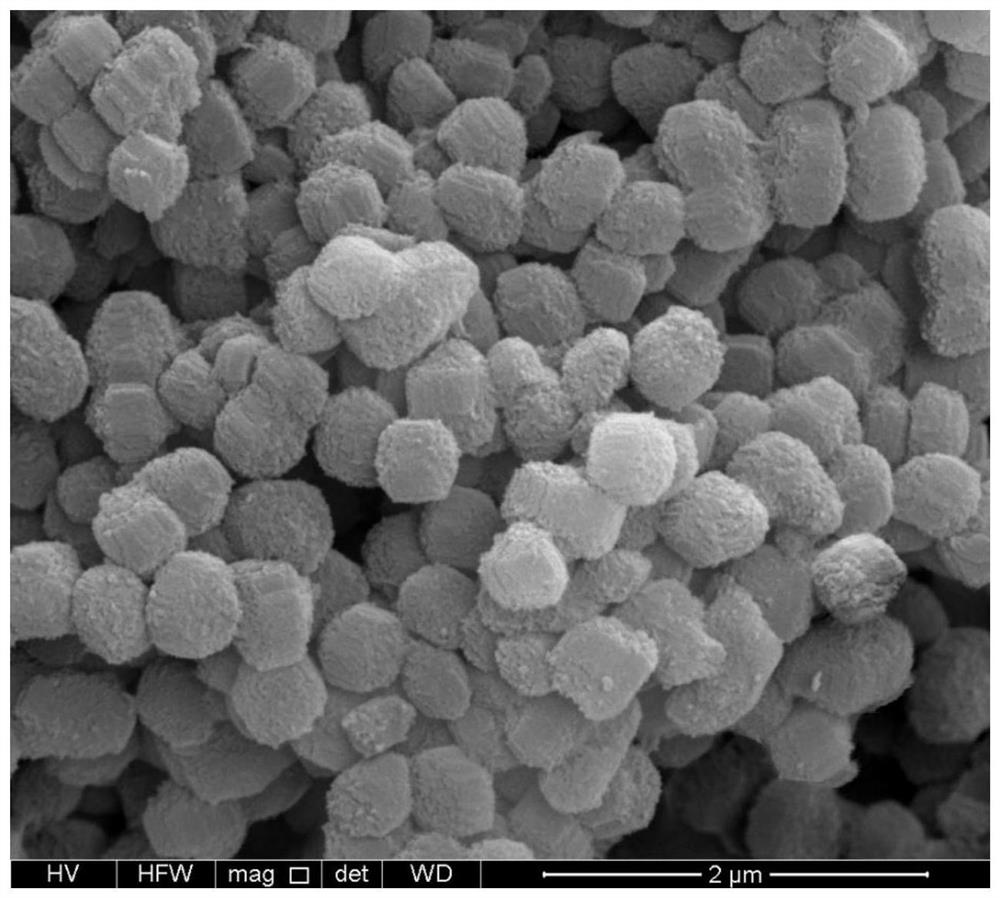

A kind of preparation method of FCC gasoline desulfurization hydrogenation upgrading catalyst

ActiveCN108465484BHighly reactive site densityFacilitated DiffusionMolecular sieve catalystsHydrocarbon oils refiningPtru catalystHydrodesulfurization

The invention relates to a preparation method of a catalyst for improving the performance of gasoline hydrogenation modification. The MoCoNi / EMT-FAU / SBA-15 catalyst prepared by the present invention not only has a higher reactive site density, a stable alloy nanoparticle active component, but also has an open pore structure, which is beneficial to the sulfur-containing FCC gasoline in the catalyst On the other hand, the dispersion of active metals in the catalyst can be ensured by the method of equal-volume fractional metal impregnation and citric acid modification. The particle length is beneficial to the improvement of hydrodesulfurization performance. The obtained hierarchical porous molecular sieve composite catalyst has a high hydrodesulfurization rate, and maintains the octane number of FCC gasoline to the greatest extent, showing excellent hydromodification performance.

Owner:UNIV OF JINAN

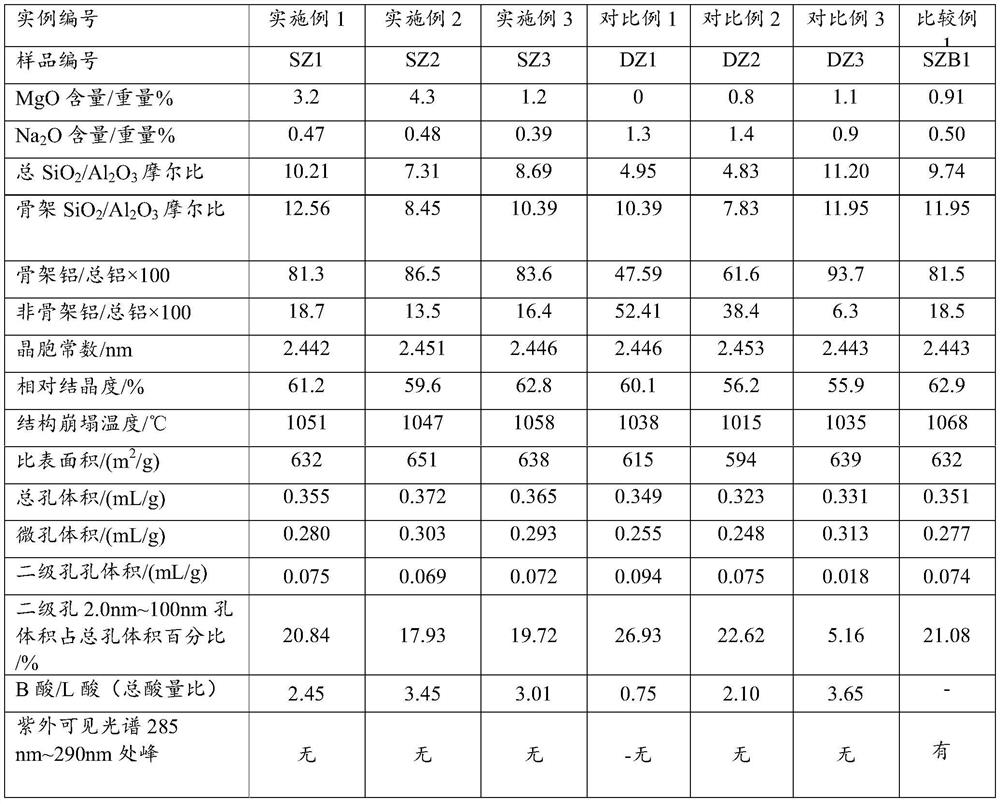

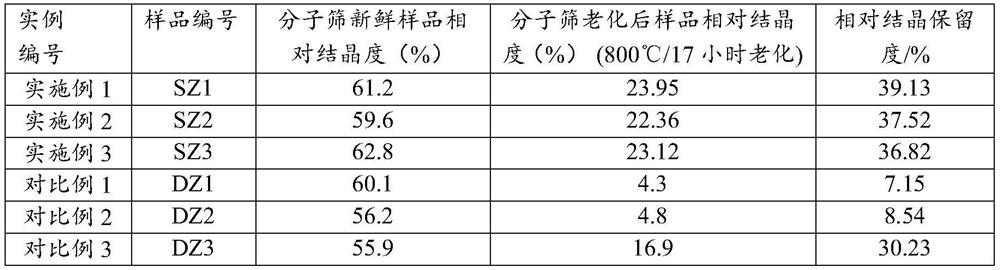

A kind of highly stable modified Y-type molecular sieve producing more isomeric hydrocarbons and its preparation method

ActiveCN110652998BHigh cracking activityEvenly distributedCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

A highly stable modified Y-type molecular sieve that is prolific in producing isomeric hydrocarbons and a preparation method thereof. The MgO content of the modified Y-type molecular sieve is 0.5 to 4.5% by weight, and Na 2 The O content is 0.1~0.5% by weight, the total pore volume is 0.33~0.39mL / g, the pore volume of the secondary pores of 2~100nm accounts for 10~25% of the total pore volume, and the unit cell constant is 2.440~2.455nm. The skeleton aluminum content accounts for no more than 20% of the total aluminum content, the lattice collapse temperature is no less than 1040°C, and the ratio of the B acid amount to the L acid amount measured at 200°C using the pyridine adsorption infrared method is not less than 2.30; There is no absorption peak in the UV-visible absorption spectrum of molecular sieves between 285nm and 295nm. The preparation method of the molecular sieve includes the steps of ion exchange, modification treatment under certain temperature and water vapor conditions, and reaction with silicon tetrachloride. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, higher gasoline yield, liquefied gas yield, and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of processing method of gasoline

ActiveCN107974295BHigh yieldReduce contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystAromatization

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com