Gasoline hydrogenation device

A hydrogenation unit and gasoline hydrogenation technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, and can solve the problems of large octane loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

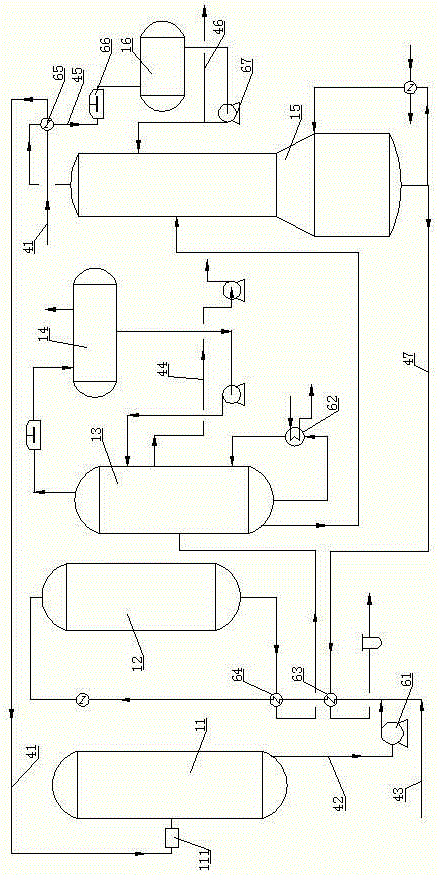

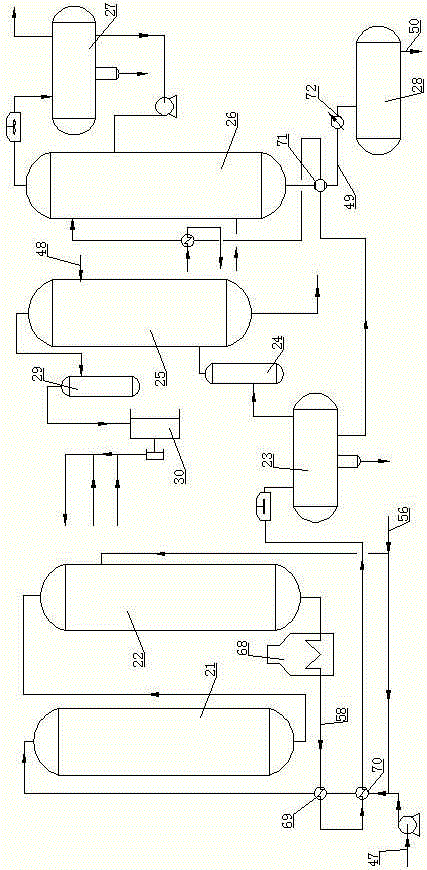

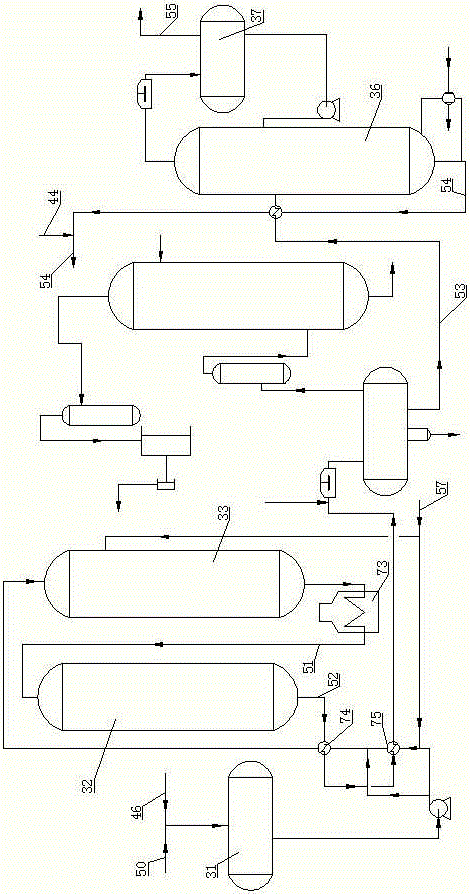

[0015] Such as Figure 1 to Figure 3 As shown, the gasoline hydrogenation unit includes a whole-fraction hydrogenation unit, a pre-fractionator, a first-stage hydrogenation unit, a first-stage desulfurization unit, a stripper, a heavy gasoline buffer tank, a second-stage hydrogenation unit, a second-stage desulfurization unit, and a product stabilization tower . For the body structure of each reactor, tower, and tank in the present invention, those skilled in the art can correctly select existing equipment on the market according to their respective purposes of use, and their specific structures will not be described in detail here.

[0016] The full-fraction hydrogenation unit includes a full-fraction hydrogenation feed buffer tank 11, a full-fraction hydrogenation reactor 12, a full-fraction hydrogenation stabilization tower 13, and a full-fraction hydrogenation feed buffer tank 11 that are sequentially connected through pipelines. The mouth is connected with the gasoline r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com