Gasoline selective hydrodesulfurization catalyst, preparation method and application thereof, and gasoline selective hydrodesulfurization method

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as loss of octane number and increase in hydrogen consumption, achieve low olefin saturation rate, reduce Sulfur content, effect of improving hydrodesulfurization activity and hydrodesulfurization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

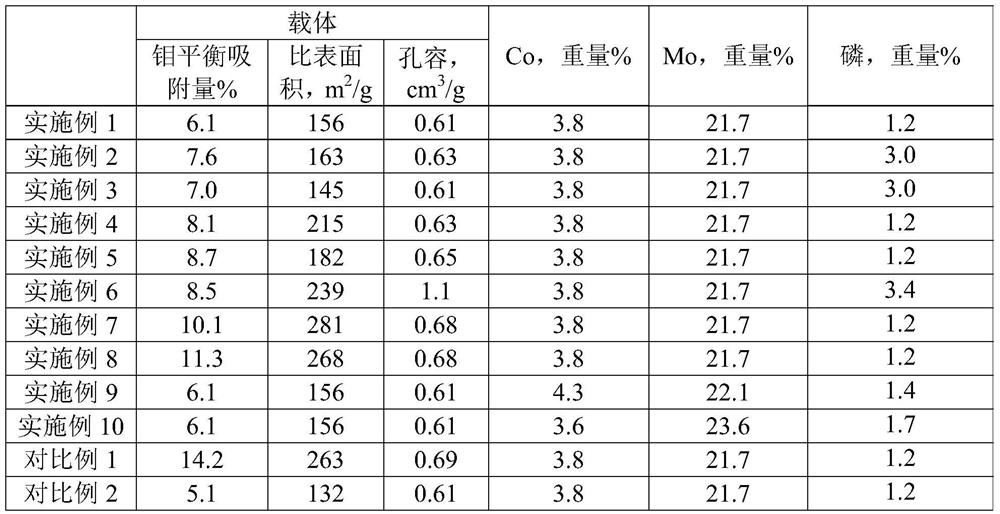

Examples

preparation example Construction

[0022] Preferably, the preparation method of the carrier comprises:

[0023] (1) mixing pseudo-boehmite with or without additives with a solution containing an inorganic aluminum-containing compound to obtain a first slurry;

[0024] (2) adjusting the pH of the slurry to 7-10 to obtain a second slurry;

[0025] (3) aging the second slurry;

[0026] (4) The solid aging product obtained in step (3) is sequentially subjected to roasting and hydrothermal treatment.

[0027] The inventors of the present invention found that the carrier prepared by this specific method can achieve better hydrodesulfurization effect when combined with the above-mentioned active components.

[0028] In the present invention, the types of the inorganic aluminum-containing compound can be selected widely. Preferably, the inorganic aluminum-containing compound is selected from at least one of aluminum sulfate, sodium metaaluminate, aluminum nitrate and aluminum trichloride.

[0029] The present invent...

specific Embodiment approach

[0039] According to a specific embodiment of the present invention, the preparation method of the carrier further includes filtering, washing, and drying the aged product obtained in step (3) to obtain the solid aged product. In the present invention, the specific operations of filtering, washing and drying are not particularly limited, and can be performed according to conventional technical means in the art. The drying conditions include but are not limited to: the temperature is 60-180°C, preferably 80-150°C; the time is 0.5-24h, preferably 3-12h.

[0040] According to a preferred embodiment of the present invention, the calcination conditions include: a temperature of 300-1200° C., preferably 400-950° C.; a time of 0.5-15 hours, preferably 2-10 hours.

[0041] According to the present invention, specifically, the hydrothermal treatment is carried out under closed conditions, such as in a closed reactor. The closed reactor can be any reactor that can realize the hydrotherm...

Embodiment approach

[0042] According to a preferred embodiment of the present invention, the conditions of the hydrothermal treatment include: the mass ratio of water to the solid product obtained by roasting is 1-20:1, preferably 5-10:1; the temperature is 100-250°C, Preferably it is 140-220°C; the time is 0.5-48 hours, preferably 1-24 hours.

[0043] Unless otherwise specified, the dry basis in the present invention refers to: Alumina hydrate is raised to 600°C at a rate of 4°C / min in a muffle furnace under an air atmosphere, and then kept at a constant temperature of 600°C for 4 hours, and the product after roasting The percentage of the ratio of the weight of the alumina hydrate to the weight of the alumina hydrate before roasting, dry basis=the weight of the product after roasting÷the weight of the alumina hydrate before roasting×100%.

[0044] The pseudo-boehmite in the present invention may or may not contain additives, which is not particularly limited in the present invention. The auxil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com