Method and system for desulfurization and aromatization of gasoline

An aromatization and gasoline technology, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problem of gasoline product octane number reduction, achieve no reduction in octane number, improve reaction efficiency, and reduce investment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] A specific embodiment, based on the dry weight of the adsorption desulfurization catalyst and based on the weight of oxides, the zinc oxide in the adsorption desulfurization catalyst accounts for 10-90% by weight, and the silicon dioxide accounts for 5-85% by weight. %, aluminum oxide accounts for 5-30% by weight; based on the dry basis weight of the adsorption desulfurization catalyst and calculated by element weight, the content of the desulfurization active metal in the adsorption desulfurization catalyst is 5-30% by weight.

[0056] According to the present invention, the olefin aromatization catalyst refers to a catalyst capable of converting hydrocarbons such as olefins in gasoline raw materials into aromatics, generally including molecular sieves, preferably including molecular sieves, supports and metals, for example, on a dry basis and in terms of the olefins Based on the total weight of the aromatization catalyst, the olefin aromatization catalyst may contain 1...

specific Embodiment approach

[0057] A specific embodiment, the preparation process of the molecular sieve with MFI structure can include ammonia exchange, phosphorus modification, metal component modification and roasting treatment steps, more specifically, the molecular sieve with MFI structure obtained by conventional crystallization The sodium type molecular sieve according to the molecular sieve: ammonia salt: H 2 The weight ratio of O=1:(0.1-1):(5-10) is exchanged at room temperature to 100°C for 0.3-1 hour and then filtered to introduce phosphorus-containing compounds and selected from Fe, Co, Ni, Zn, Mn, Ga and one or more of Sn to modify the molecular sieve, and then calcined at 400-800° C. for 0.5-8 hours, wherein the calcining process can also be carried out under a water vapor atmosphere. Furthermore, for the molecular sieve with MFI structure provided by the present invention, the molecular sieve can be modified by impregnation or ion exchange during the preparation process. Further, the phos...

Embodiment 1

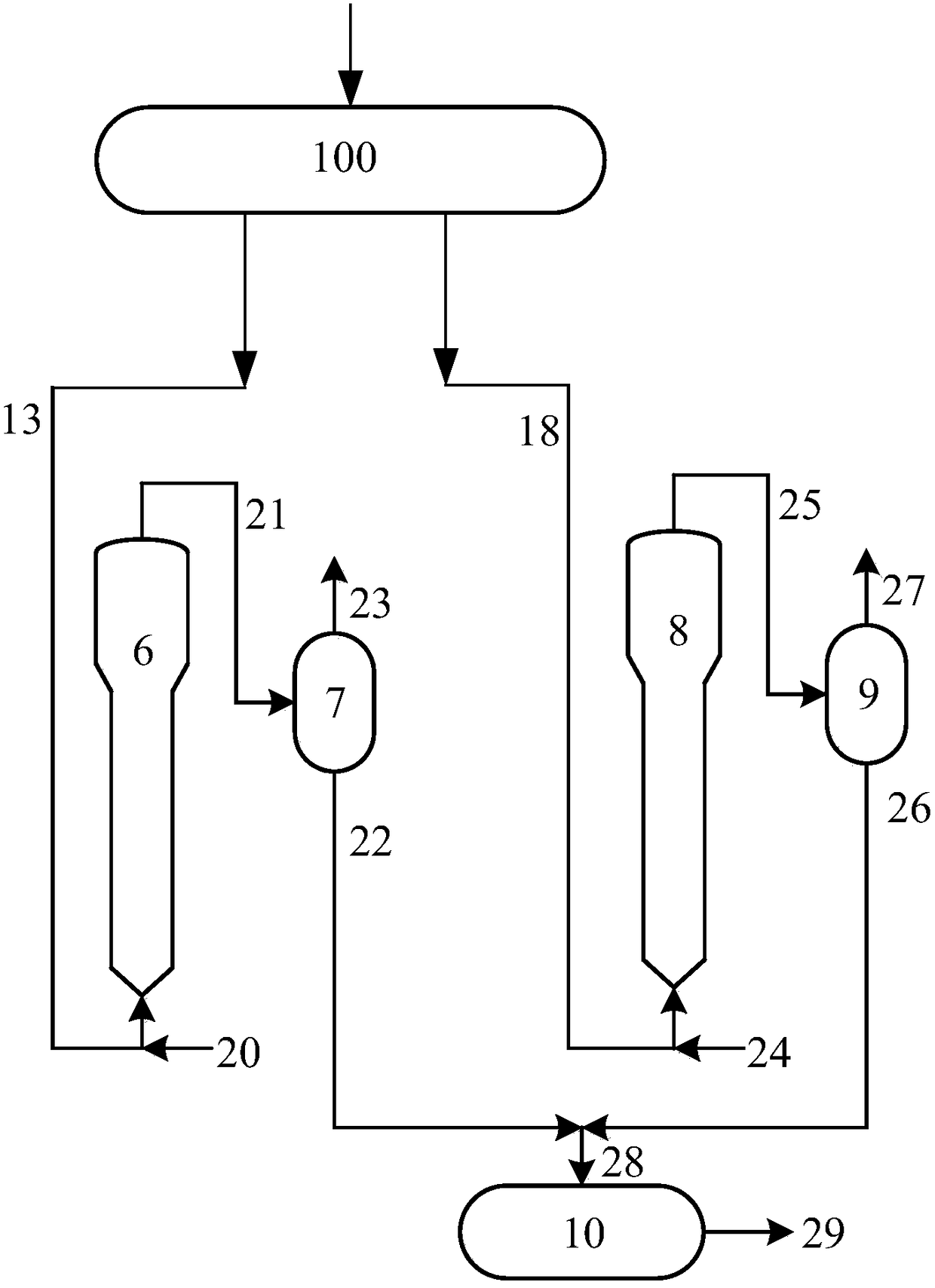

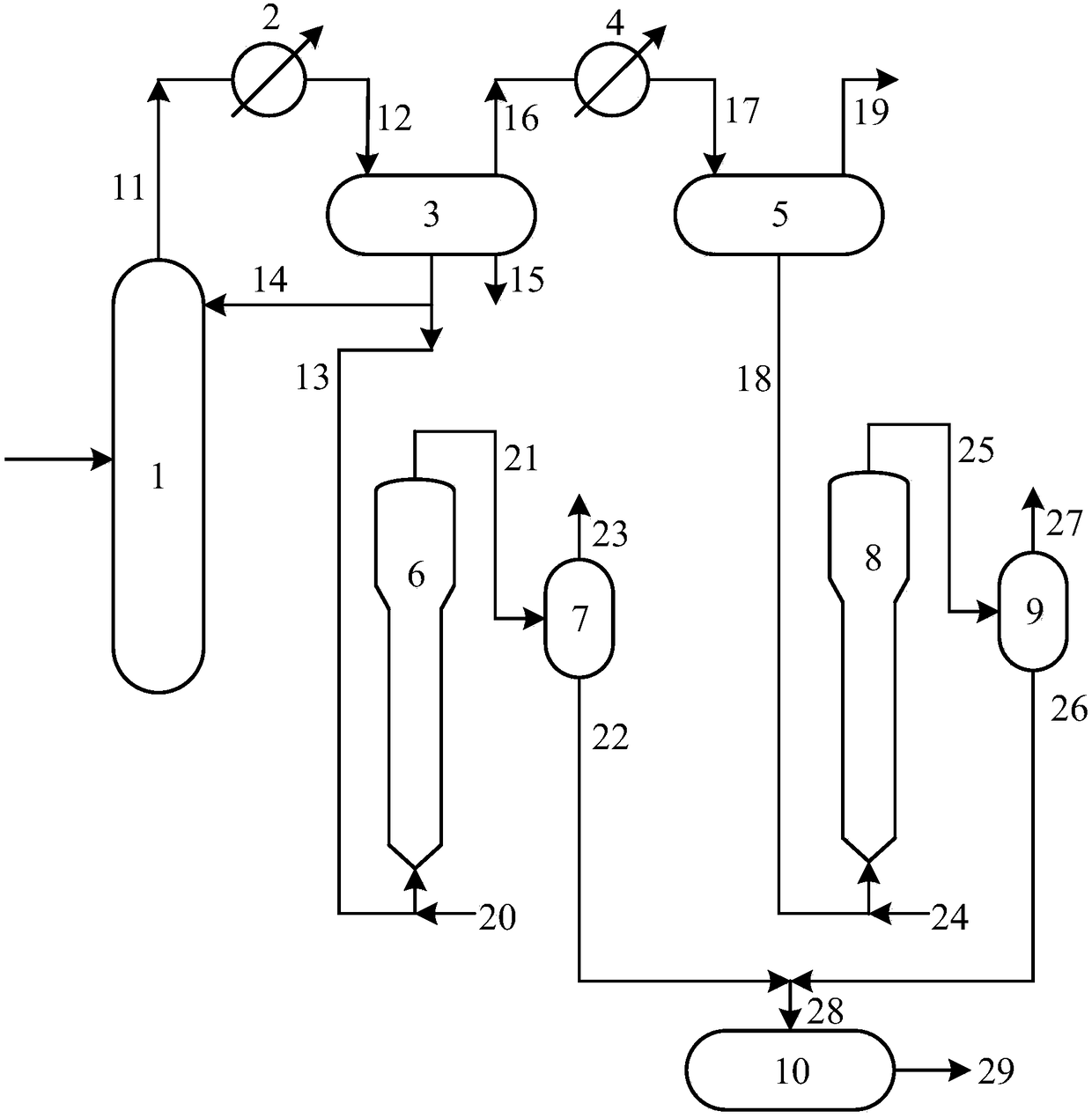

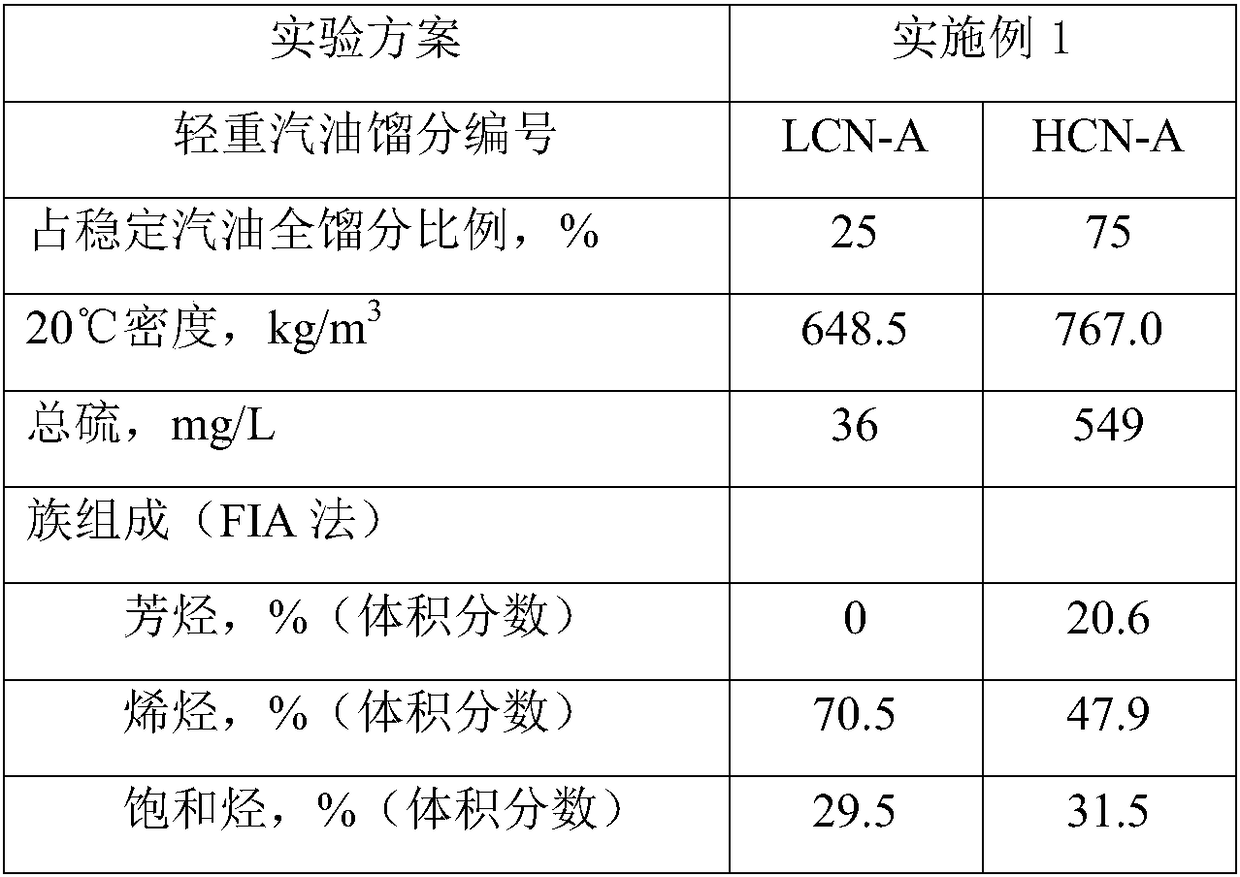

[0092] Such as figure 2 As shown, the top of catalytic cracking main fractionation tower 1 adopts a two-stage condensation cooling process, the operating temperature of the first-stage condenser 2 is about 65°C, and the heavy gasoline fraction HCN-A is separated, and the uncondensed gas phase flows through the second-stage condenser 4 After cooling to about 40°C, the light gasoline fraction LCN-A was obtained by separation. The properties of HCN-A and LCN-A are listed in Table 2. The heavy gasoline fraction HCN-A is sent to the first set of fluidized reactor 6 mixed with adsorption desulfurization catalyst FCAS and fresh aromatization catalyst OTAZ-C-3 (fresh aromatization catalyst OTAZ-C-3 is mixed with 7% by weight of the total weight of the catalyst) to contact and perform desulfurization and aromatization reactions in a hydrogen-facing state, and the reaction conditions are listed in Table 5. The reaction product obtained from the top of the reactor is cooled and separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com