A kind of upgrading method of catalytic cracking gasoline

A technology for catalytic cracking and upgrading of gasoline, which is applied in the treatment of hydrocarbon oil, petroleum industry, and hydrocarbon oil treatment products. The effect of improving the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is further described in detail by examples below, but these examples should not be considered as limiting the present invention. The raw material reagents used in the present invention are all commercially available products.

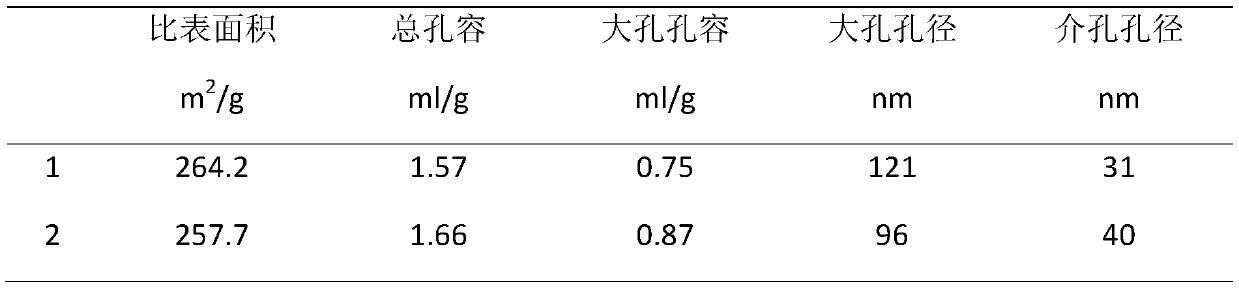

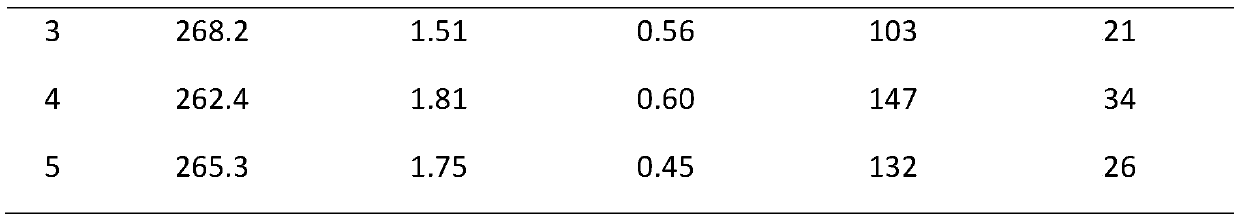

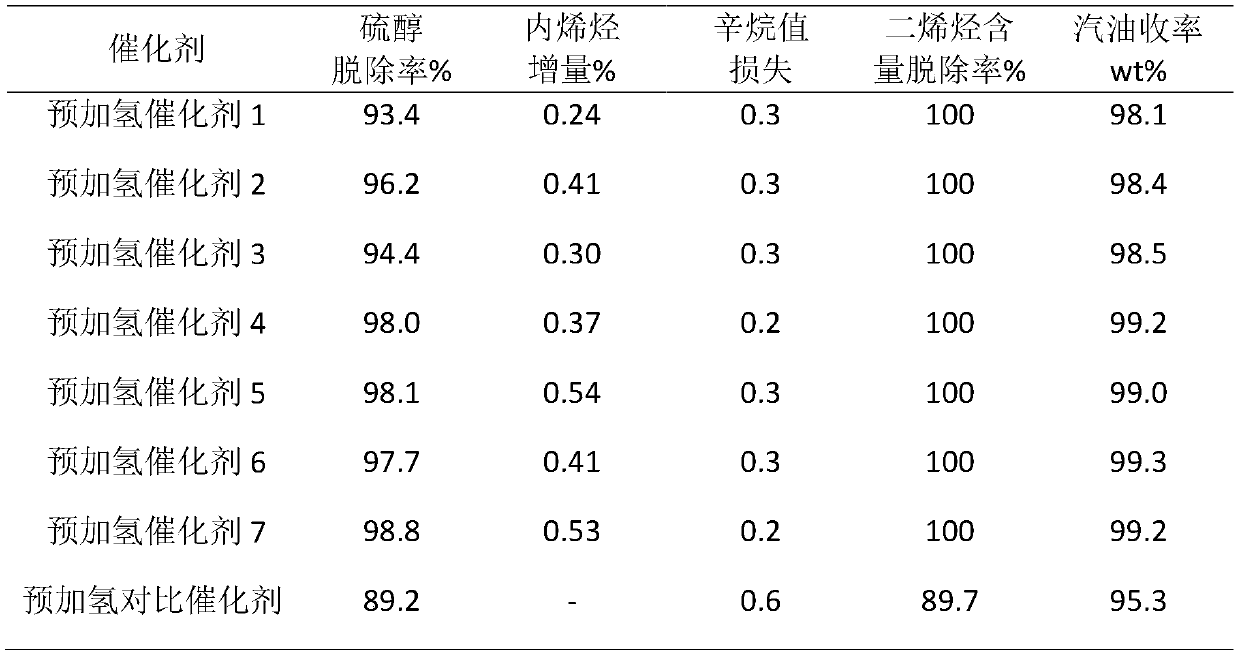

[0053] 1. Preparation of prehydrogenation catalyst

[0054] (1) Preparation of prehydrogenation catalyst 1

[0055] 1. Preparation of tungsten-doped lanthanum ferrite with micro-mesoporous

[0056] Under stirring conditions, 2.2mol La(NO 3 ) 3 Dissolve in 100mL water, add citric acid and stir to dissolve; then add 4.2mol Fe(NO 3 ) 3 , and then add 160g of sodium polyacrylate, then add an aqueous solution containing 10g of ammonium metatungstate, continue stirring for 30min, and obtain micro-mesoporous tungsten-doped lanthanum ferrite through drying, roasting and grinding.

[0057] 2. Preparation of alumina carrier

[0058] Add citric acid to 2.2g of micro-mesoporous tungsten-doped lanthanum ferrite for later use, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com