A method for cleaning full fraction FCC gasoline

A technology for catalytically cracked gasoline and full distillate, which is applied in the field of cleaning of full distillate catalytic cracked gasoline, can solve the problems of inability to reduce olefin content, loss of octane number, etc., so as to reduce energy consumption, improve carbon deposition resistance and shorten process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw material is FCC gasoline, and its composition is shown in Table 1.

[0041] The FCC gasoline composition in the embodiment 1 of table 1

[0042]

[0043] FCC gasoline is firstly processed through a pre-hydrogenation reactor to remove diolefins, the reaction temperature is 100°C, the reaction pressure is 1.5MPa, and the liquid volume space velocity is 6h -1 , the volume ratio of hydrogen to oil is 4:1. The catalyst composition is MoO 3 6%, NiO 13% and γ-Al 2 o 3 81%.

[0044] The obtained product undergoes deep desulfurization through the adsorption desulfurization unit, the operating temperature is 400°C, the operating pressure is 2MPa, and the weight hourly space velocity is 4h -1 , the adsorbent is a composite oxide catalyst (by mass, containing 80% zinc oxide, 15% nickel oxide and 5% aluminum oxide).

[0045] Finally, the desulfurized product is subjected to olefin isomerization, the reaction temperature is 300°C, the reaction pressure is 2.0MPa, a...

Embodiment 2

[0052] Raw material is identical with the raw material in embodiment 1.

[0053] FCC gasoline is firstly processed through a pre-hydrogenation reactor, the reaction temperature is 120°C, the reaction pressure is 2MPa, and the liquid volume space velocity is 4h -1 , the volume ratio of hydrogen to oil is 5:1, and the catalyst composition is MoO 3 8%, NiO 15%, K 2 O 1%, La 2 o 3 1% and γ-Al 2 o 3 75%.

[0054] The obtained product undergoes deep desulfurization through the adsorption desulfurization unit, the operating temperature is 450°C, the operating pressure is 3MPa, and the weight hourly space velocity is 6h -1 The adsorbent is an activated carbon-based adsorbent (by weight, containing 88% of activated carbon and 12% of zinc oxide).

[0055] Finally, the desulfurized product is subjected to olefin isomerization, the reaction temperature is 350°C, the reaction pressure is 3.0MPa, and the weight hourly space velocity is 6h -1 , The volume ratio of hydrogen to oil i...

Embodiment 3

[0062] Raw material is identical with the raw material in embodiment 1.

[0063] FCC gasoline is first processed through a pre-hydrogenation reactor, the reaction temperature is 150°C, the reaction pressure is 2.5MPa, and the liquid volume space velocity is 4h -1 , the volume ratio of hydrogen to oil is 6:1, and the catalyst composition is MoO 3 9%, NiO13%, K 2 O 4%, La 2 o 3 1% and γ-Al 2 o 3 73%.

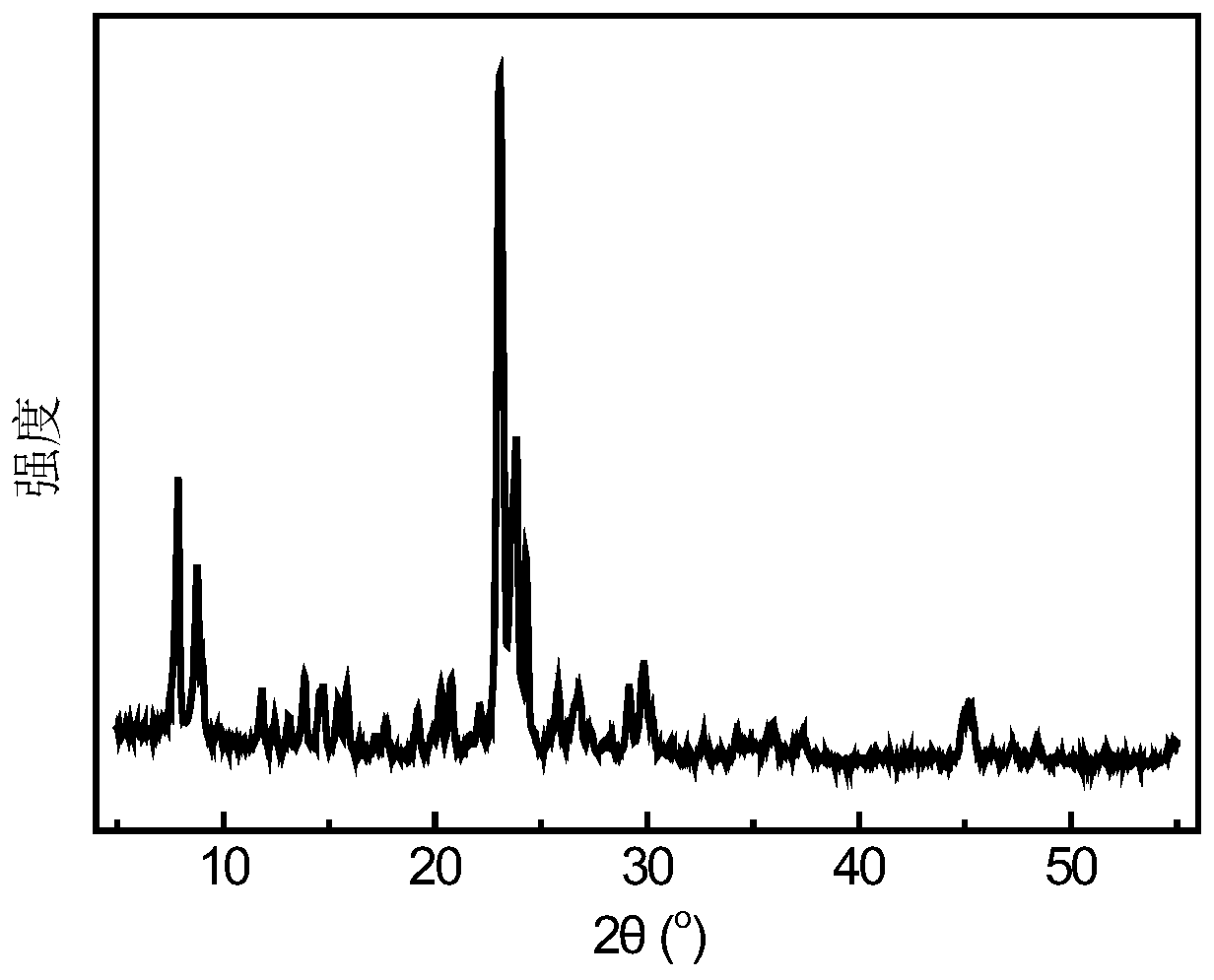

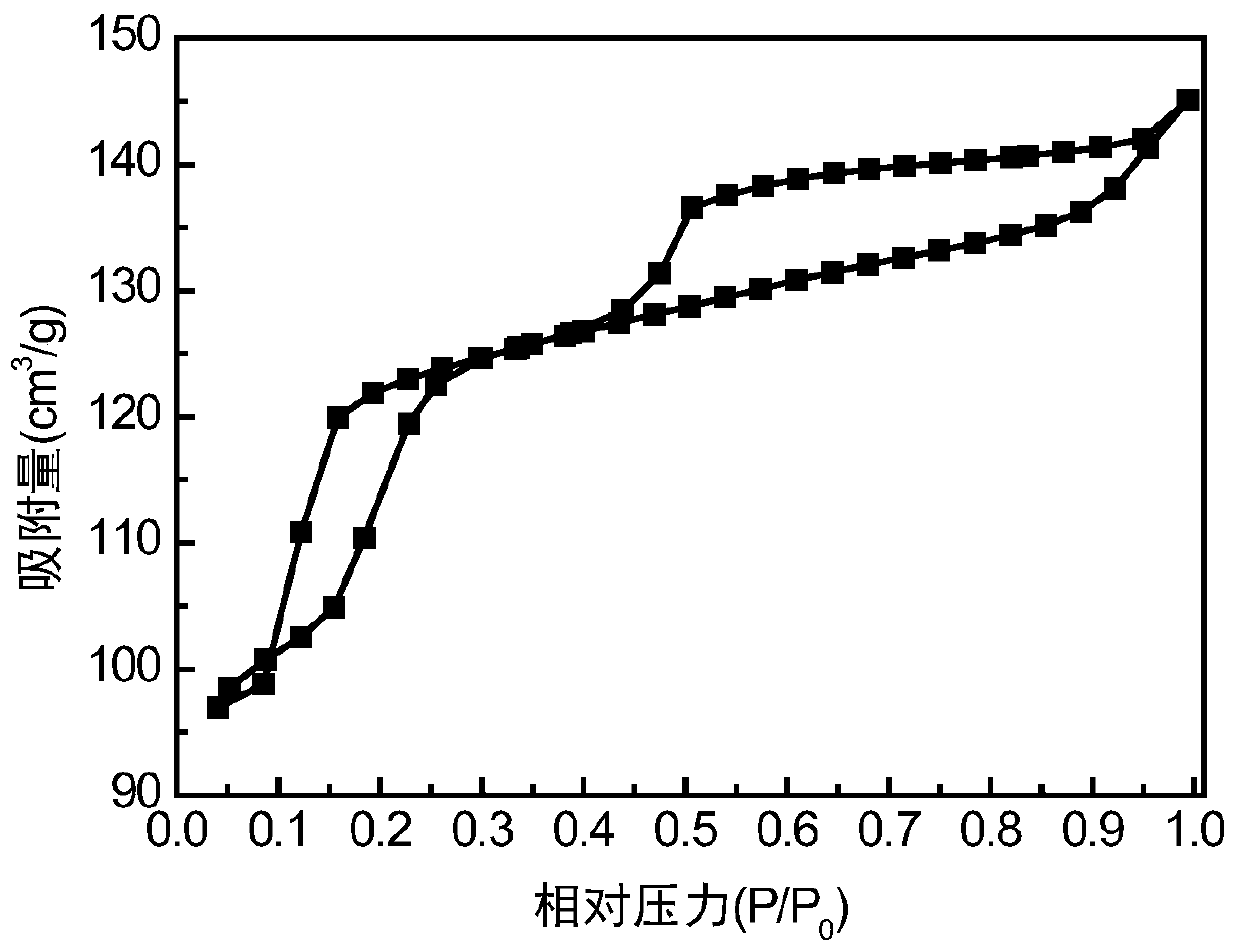

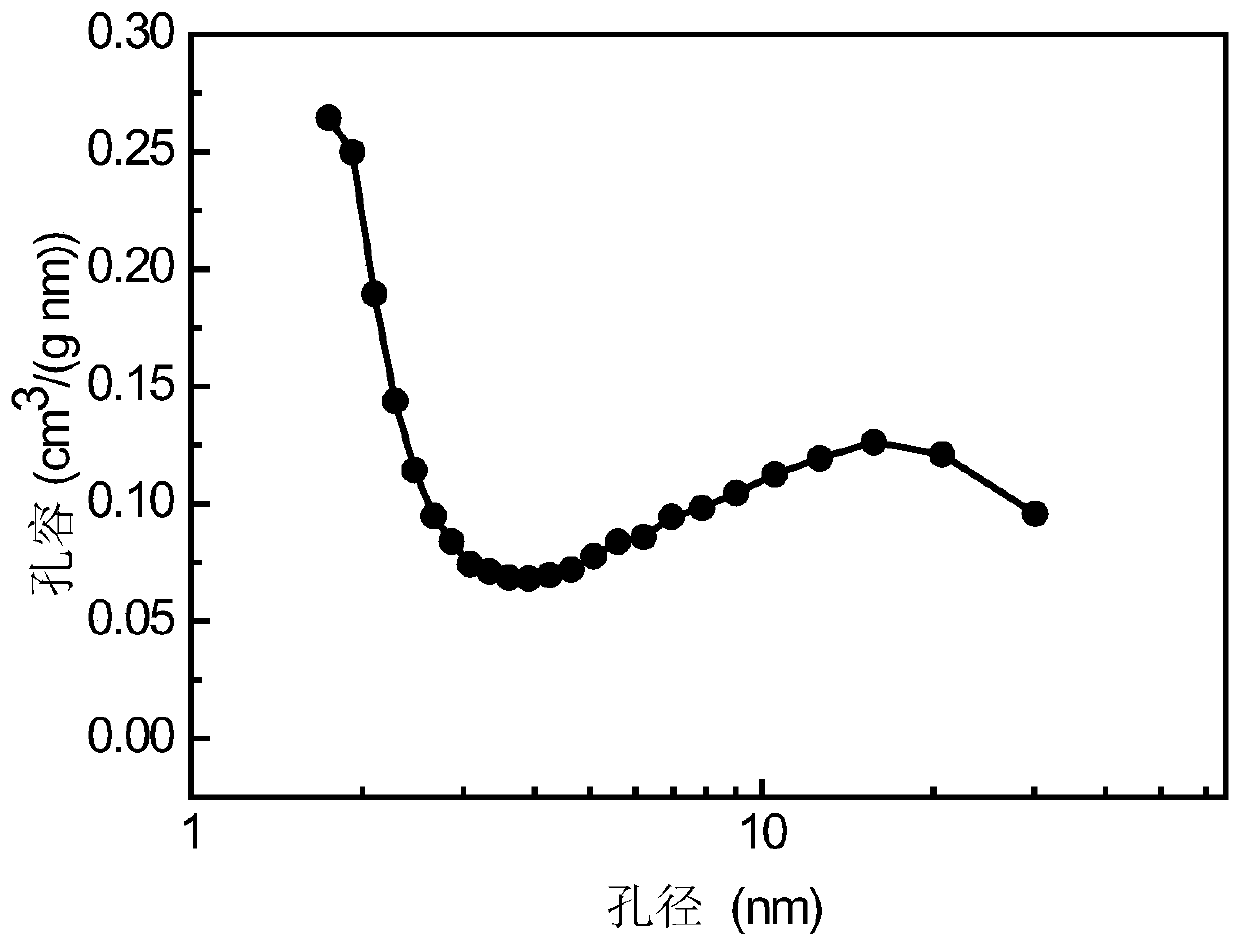

[0064] The above products undergo deep desulfurization through the adsorption desulfurization unit, the operating temperature is 380°C, the operating pressure is 3.5MPa, and the weight hourly space velocity is 3h -1 The adsorbent is a molecular sieve-based adsorbent (by weight, containing 75% of Y-type molecular sieve and 25% of mordenite).

[0065] Finally, the desulfurized product is subjected to olefin isomerization, the reaction temperature is 200°C, the reaction pressure is 4.5MPa, and the weight hourly space velocity is 2h -1 , the volume ratio of hydrogen to oil i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com