Phosphorus and loading metal containing MFI structure molecular sieve and preparation method thereof

A technology of loading metals and molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the petroleum industry. Effect of Aromatics Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the phosphorus-containing and metal-loaded MFI molecular sieve, the method comprising: a. performing ammonium exchange on a sodium-type MFI molecular sieve to obtain an ammonium exchange molecular sieve; Based on the total dry basis weight of the ammonium-exchanged molecular sieve, the sodium content of the ammonium-exchanged molecular sieve is less than 0.2% by weight; Dealuminated molecular sieves are obtained in the dealuminated agent solution, filtered and washed; c, the dealuminated molecular sieves obtained in step b are subjected to phosphorus modification treatment, metal loading treatment and roasting treatment to obtain The phosphorus-containing and metal-loaded MFI molecular sieves.

[0042] According to the method of the present invention, the sodium-type MFI molecular sieve is well known to those skilled in the art, and can be obtained by amine-free crystallization, or obtained by roasting a molecul...

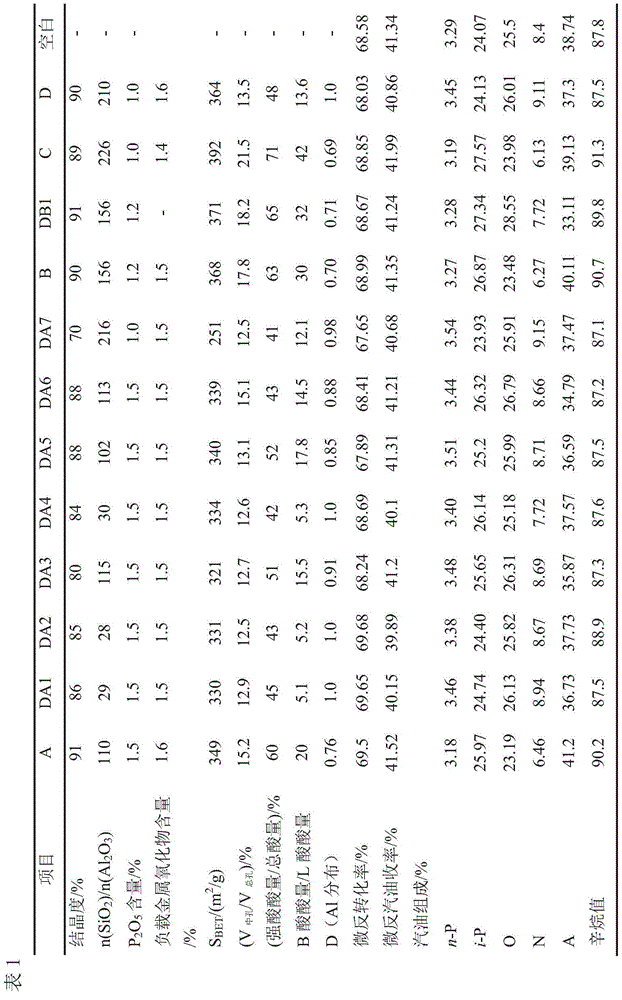

Embodiment 1

[0065] With ZSM-5 molecular sieve (catalyst Qilu branch production, no amine synthesis, n(SiO 2 ) / n(Al 2 o 3 )=27) with NH 4 Cl solution exchange wash to Na 2 O content is lower than 0.2% by weight, filters to obtain filter cake; Get above-mentioned molecular sieve 100g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add oxalic acid 20g in stirring, then 200g hydrochloric acid (mass fraction 10%) and 167g of fluosilicic acid (mass fraction 3%) was added in parallel, and the addition time was 30 minutes; the temperature was raised to 65°C and stirred for 1 hour, filtered and washed until the filtrate was neutral; the filter cake was beaten with water to obtain a molecular sieve slurry with a solid content of 40% by weight, and added 2.4gH 3 PO 4 (Concentration 85% by weight) and 6.6gZn(NO 3 ) 2 ·6H 2 O, homogeneously mixed dipping, drying, 550 ℃ roasting treatment for 2 hours. Molecular sieve A was obtained, and th...

Embodiment 2

[0081] With ZSM-5 molecular sieve (catalyst Qilu branch production, no amine synthesis, n(SiO 2 ) / n(Al 2 o 3 )=27) with NH 4 Cl solution exchange wash to Na 2 O content is lower than 0.2% by weight, filters to obtain filter cake; Get above-mentioned molecular sieve 100g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add citric acid 40g in stirring, then add 100g sulfuric acid (mass fraction 10%) and 500g of fluosilicic acid (3% by mass) were added in parallel, and the addition time was 30min; the temperature was raised to 45°C and stirred for 1h, filtered and washed until the filtrate was neutral; the filter cake was beaten with water to obtain a molecular sieve slurry with a solid content of 40% by weight, Add 2.0gH 3 PO 4 (concentration 85% by weight) and 3.6 grams of Ga 2 (SO 4 ) 3 ·16H 2 O, homogeneously mixed dipping, drying, 550 ℃ roasting treatment for 2 hours. Molecular sieve B was obtained, and the phys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com