Preparation method of catalytic cracking gasoline octane number additive

A technology for catalytic cracking of gasoline and octane number, applied in catalytic cracking, molecular sieve catalysts, chemical instruments and methods, etc. The performance of texture and aromatization, the effect of increasing liquefied gas and increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

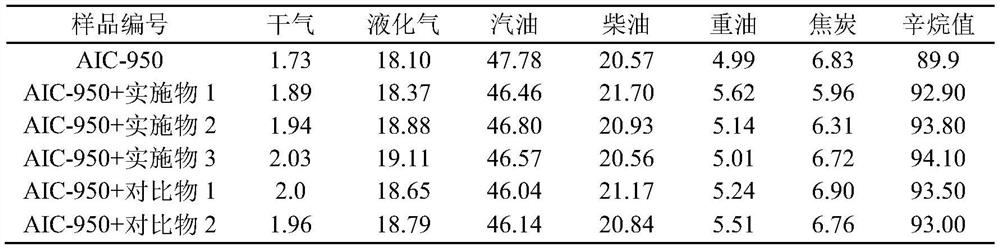

Embodiment 1

[0031] (1) Beat ZSM-5-① with water, add magnesium citrate, Mg 2+ / ZSM-5-①The mass ratio is 0.02, 650 ℃ hydrothermal roasting for 1 hour;

[0032] (2) According to the ratio: ZSM-5-①: silica fume: silica sol=35:45:20, mix and beat, and spray-dry to obtain the title compound 1.

Embodiment 2

[0034] (1) Beat ZSM-5-② with water, add magnesium lactate, Mg 2+ The mass ratio of / ZSM-5-② is 0.04, and the hydrothermal roasting is performed at 600℃ for 1.5 hours;

[0035] (2) Mix and beat according to the ratio: ZSM-5-②: silica fume: silica sol=35:48:17, spray-dry to obtain the title compound 2.

Embodiment 3

[0037] (1) Add water to make ZSM-5-③, add magnesium lactate, Mg 2+ The mass ratio of / ZSM-5-③ is 0.03, and the hydrothermal roasting is performed at 600℃ for 1.5 hours;

[0038] (2) According to the ratio: ZSM-5-③: silica fume: silica sol=35:50:15, mix and beat, and spray-dry to obtain title compound 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com