A kind of methanol aromatization catalyst and its preparation method and application

A catalyst and aromatization technology, applied in the field of methanol aromatization catalyst and its preparation, to achieve the effect of improving yield and stability, and improving aromatization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

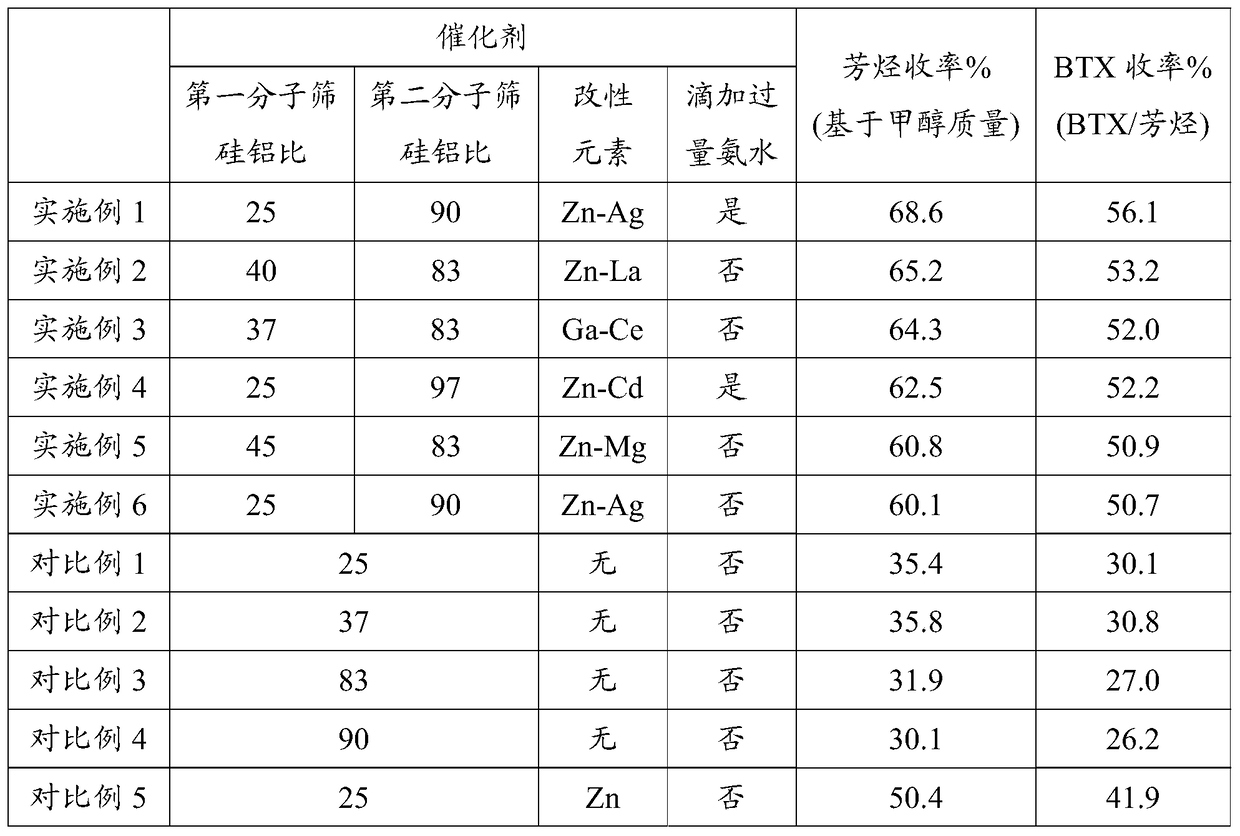

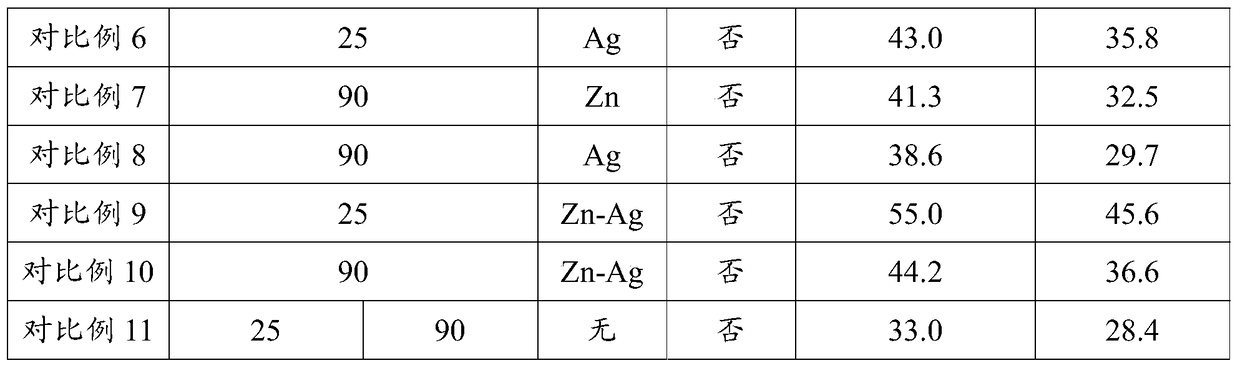

Examples

Embodiment 1

[0039] This example is used to illustrate the methanol aromatization catalyst and its preparation method. Specifically, the preparation method of methanol aromatization catalyst comprises the following steps:

[0040] (1) Weigh 25 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 25 and 5 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 90, place them in a reaction kettle, and mix them evenly.

[0041] (2) The first metal modification element precursor Zn(NO 3 ) 2 ·6H 2 O and the second metal modifying element precursor AgNO 3 Dissolve in 150ml of deionized water, then dropwise add 4.6ml of 15% ammonia water, and stir at room temperature for 0.5h to obtain a mixed solution of the metal modifying element precursor and ammonia water; wherein, the sum of the mass of Zn and Ag elements accounts for 1% of the molecular sieve 2wt%, and Zn(NO 3 ) 2 and AgNO 3 The molar ratio of the substances is 1:0.5.

[0042] (3) Add the mixture of metal modifying e...

Embodiment 2

[0046] This example is used to illustrate the methanol aromatization catalyst and its preparation method. Specifically, the preparation method of methanol aromatization catalyst comprises the following steps:

[0047] (1) Weigh 26 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 37 and 4 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 80, place them in a reaction kettle, and mix them evenly.

[0048] (2) The first metal modification element precursor Zn(NO 3 ) 2 ·6H 2 O and the second metal modifying element precursor La(NO 3 ) 3 ·6H 2 O was dissolved in 150ml deionized water, and stirred at room temperature for 0.5h to obtain a metal modification element precursor mixed solution; wherein, the sum of the mass of Zn and La elements accounted for 3.0wt% of the molecular sieve, and Zn(NO 3 ) 2 and La(NO 3 ) 3 The amount ratio of the substances is 1:0.3.

[0049] (3) Add the metal modifying element precursor solution obtained in step (2) into t...

Embodiment 3

[0053] This example is used to illustrate the methanol aromatization catalyst and its preparation method. Specifically, the preparation method of methanol aromatization catalyst comprises the following steps:

[0054] (1) Weigh 20 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 37 and 10 g of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 80, place them in a reaction kettle, and mix them evenly.

[0055] (2) The first metal modification element precursor Ga 2 (SO 4 ) 3 16H 2 O and the second metal modifying element precursor Ce(NO 3 ) 3 ·6H 2 O was dissolved in 150ml of deionized water and stirred at room temperature for 0.5h to obtain a mixed solution of metal modifying element precursors; wherein, the sum of the mass of Ga and Ce elements accounted for 2.5wt% of the molecular sieve, and Ga 2 (SO 4 ) 3 and Ce(NO 3 ) 3 The material ratio of the material is 1:0.4 (that is, the material ratio of the Ga element to the Ce element is 1:0.2).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com