A kind of MFI structure molecular sieve containing phosphorus and loaded metal and preparation method thereof

A technology of loading metals and molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, molecular sieves and alkali exchange compounds, etc., can solve the problems of poor hydrothermal stability in production costs, popularization and application, etc., and achieve the suppression of non-selective side reactions on the surface, strengthening Strong effect of aromatization performance, isomerization ability and aromatization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

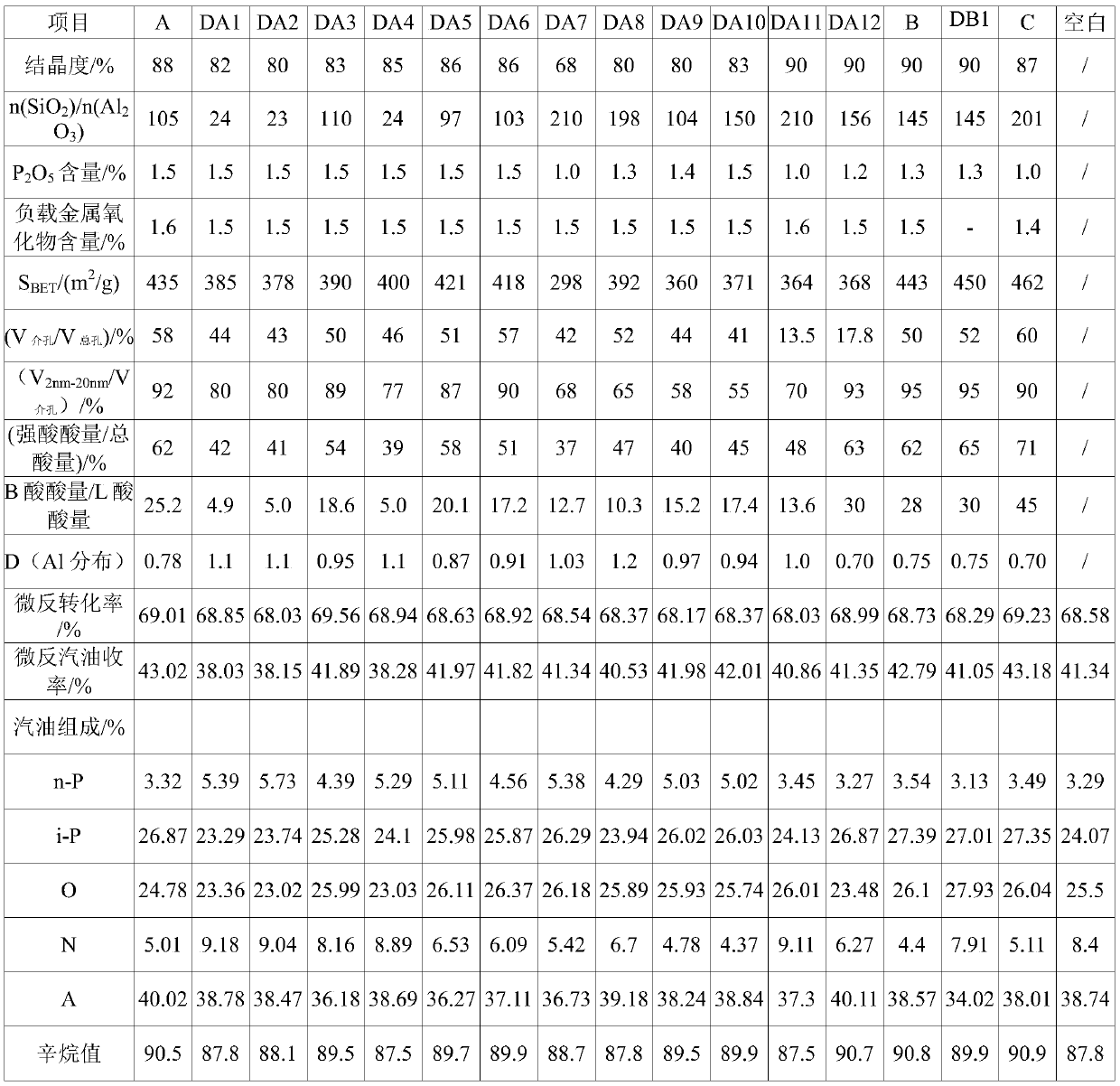

Examples

preparation example Construction

[0047] The present disclosure also provides a method for preparing the phosphorus-containing and metal-loaded MFI molecular sieve provided in the present disclosure, the preparation method comprising: a. After filtering and washing the MFI molecular sieve slurry obtained by crystallization, to obtain a water-washed molecular sieve; Wherein, based on sodium oxide and the total dry weight of the washed molecular sieve, the sodium content of the washed molecular sieve is less than 3% by weight; b, the water-washed molecular sieve obtained in step a is desiliconized in an alkaline solution, and carried out After filtering and washing, desiliconized molecular sieves are obtained; c, the desiliconized molecular sieves obtained in step b are subjected to ammonium exchange treatment to obtain ammonium exchanged molecular sieves; wherein, in terms of sodium oxide and based on the total dry basis weight of ammonium exchanged molecular sieves, the obtained The sodium content of the ammoni...

Embodiment 1

[0075] Crystallized ZSM-5 molecular sieve (produced by Catalyst Qilu Branch Company, synthesized without amine method, n(SiO 2 ) / n(Al 2 o 3 )=27) filter out mother liquor, wash with water to Na 2 O content is lower than 3.0% by weight, filter to obtain filter cake; Take above-mentioned molecular sieve 100g (dry basis) and add in 1000g 2.0% NaOH solution, heat up to 65 ℃, after reacting for 30min, after rapidly cooling to room temperature, filter, wash to filtrate neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, and obtains molecular sieve filter cake; Get above-mentioned molecular sieve 50g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add oxalic acid 11g in stirring, then 110g hydrochloric acid (mass fraction 10%) and 92g of fluosilicic acid (mass fraction 3%) were added in parallel,...

Embodiment 2

[0101] Crystallized ZSM-5 molecular sieve (produced by Catalyst Qilu Branch Company, synthesized without amine method, n(SiO 2 ) / n(Al 2 o 3 )=27) filter out mother liquor, wash with water to Na 2 O content is lower than 3.0% by weight, filter to obtain filter cake; Get above-mentioned molecular sieve 100g (dry basis) and add in 1500g 2.4% NaOH solution, heat up to 60 ℃, after reacting for 45min, after rapidly cooling to room temperature, filter, wash to filtrate neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, obtains molecular sieve filter cake; Get above-mentioned molecular sieve 50g (dry basis) and add water and be mixed with the molecular sieve slurry of solid content 10% by weight, add citric acid 22g in stirring, then 55g sulfuric acid (mass Fraction 10%) and 280g fluosilicic acid (mass fraction 3%) were added in parallel, and the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com