Reforming pre-hydrogenation catalyst with aromatization property and preparation method thereof

A pre-hydrogenation and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reducing olefin content in oil products, losing gasoline octane number, etc. Structuring and aromatization properties, and the effect of increasing the latent content of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

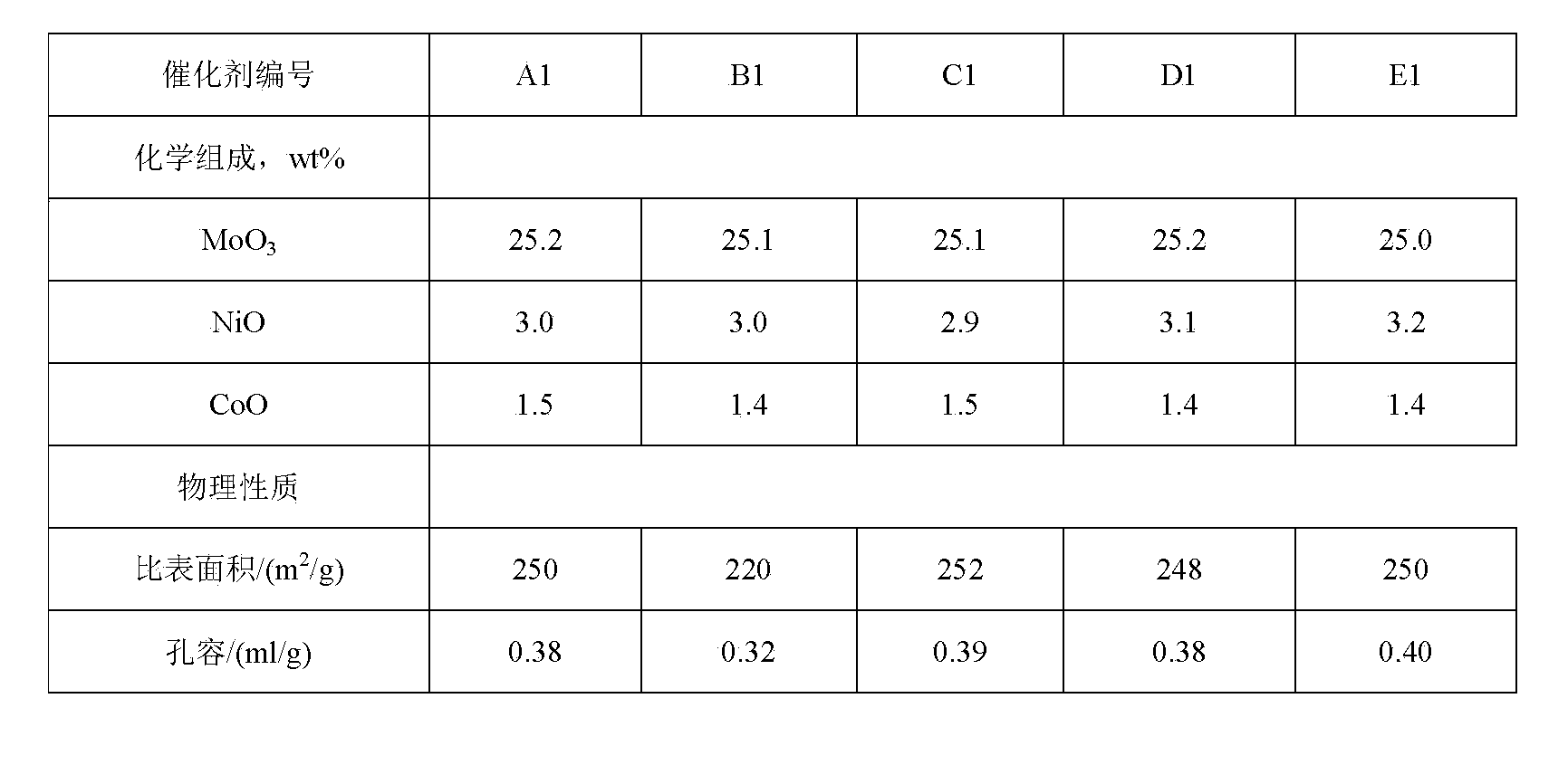

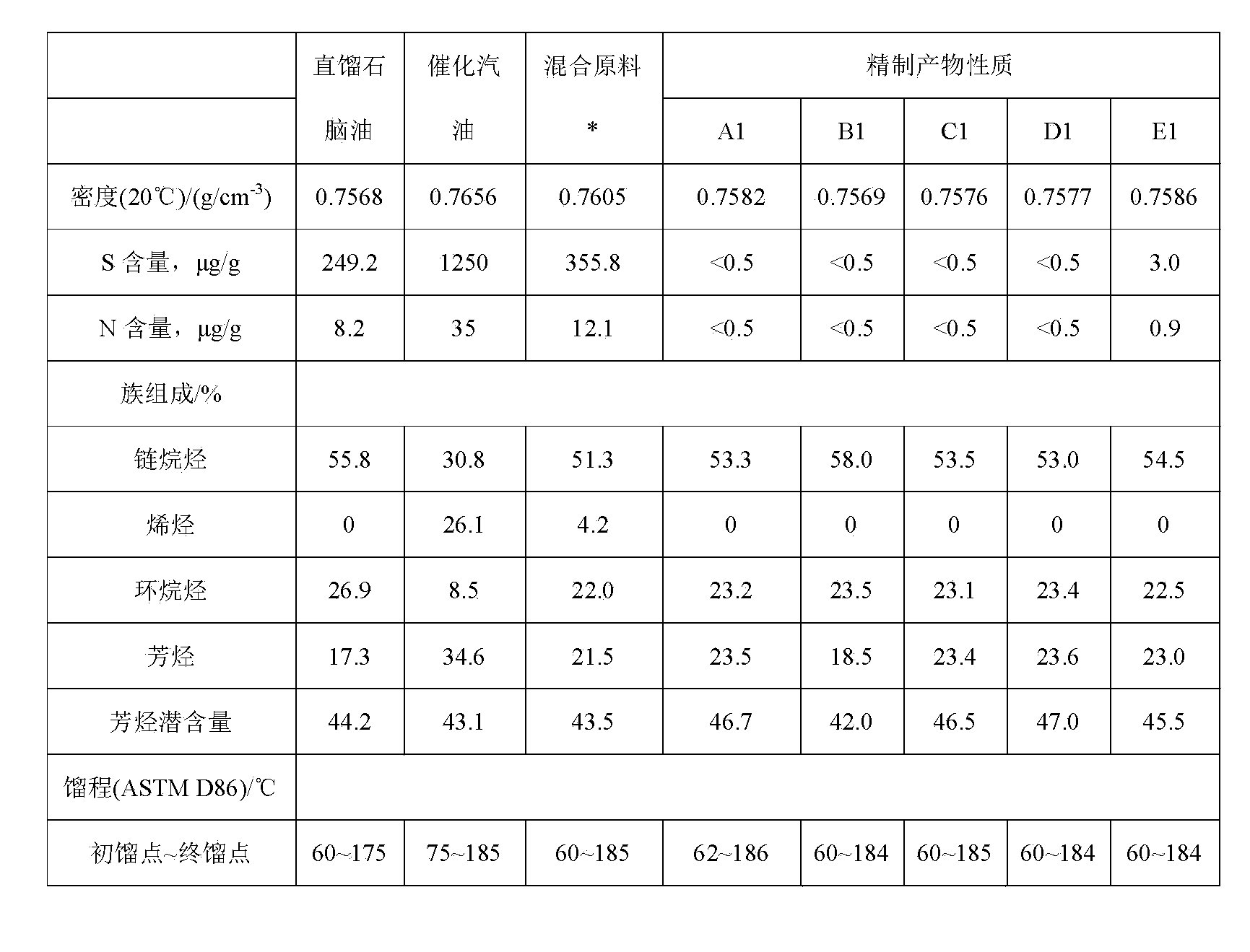

Embodiment 1

[0025] (1) Preparation of molded carrier

[0026] Weigh 300g of pseudoboehmite powder produced by Wenzhou Jingjing Alumina Co., Ltd., 50g of HZSM-5 molecular sieve produced by Nankai University Catalyst Factory, 10g of turnip powder, 10g of nitric acid (65%) and 250ml of deionized water, mix well , Knead into a plastic shape and then extrude wet strips of clover strips (Φ1.5mm). The wet strip was dried at 110° C. for 4 hours and calcined at 550° C. for 4 hours to obtain a molded carrier.

[0027] (2) Catalyst preparation

[0028] At room temperature, weigh 31.2 g of ammonium molybdate, 12.0 g of nickel nitrate, and 6.0 g of cobalt nitrate into 50 ml of deionized water to make an impregnation solution, and then add ammonia water to adjust the pH value of the impregnation solution to 5.0. Take 70g of the above shaped carrier and put it into a 500ml beaker, add the above impregnation solution for saturated impregnation, then dry the wet strip at 120°C for 4h, and then bake it a...

Embodiment 2

[0030] (1) Carrier preparation

[0031] Same as Example 1 (1), except that HZSM-5 molecular sieve is not added during the carrier preparation process.

[0032] (2) Catalyst preparation

[0033] Same as in Example 1 (2), the finished catalyst B1 was finally obtained.

Embodiment 3

[0035] (1) Carrier preparation

[0036] Same as Example 1(1).

[0037] (2) Catalyst preparation

[0038] Same as Example 1 (2), except that ammonia water was used to adjust the pH of the impregnation solution to 8.0, and finally the finished catalyst C1 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com